Halogen-free anti-flaming silicon rubber and its preparing method and use

A silicone rubber, rubber technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) 20 parts by weight of high vinyl content methyl vinyl silicone rubber with molecular weight 600000, vinyl molar content 0.23% and molecular weight 580000, 30 weight parts of low vinyl content methyl vinyl silicone rubber with vinyl molar content 0.08% The parts are mixed on the double-roller mill for 3 to 5 minutes, and the mixing is uniform;

[0042] (2) Add 0.4 parts by weight hydrogen-containing silicone oil, 4 parts by weight hydroxyl silicone oil and 25 parts by weight to the mixture of (1) successively. 2 / g of fumed silica, mixed evenly, to make rubber compound A;

[0043] (3) Mix 100 parts by weight of low vinyl content methylvinyl silicone rubber with a molecular weight of 580000 and a vinyl molar content of 0.08% on a double-roll mill for 3 to 5 minutes. Base silicone oil, 0.8 parts by weight of hydrogen-containing silicone oil, mixed evenly;

[0044] (4) Add 55 parts by weight of aluminum hydroxide and 5 parts by weight of zinc borate to the mixture of ...

Embodiment 2

[0047] Steps (1)-(4) are all the same as in Example 1.

[0048](5) Mix the mixed rubbers A and B prepared in (2) and (4), add solvent petroleum ether, mix the mixture with the solvent at a weight ratio of 1:2, add 1 part by weight of vulcanizing agent 2,5- Dimethyl-2,5-di-tert-butyl peroxide hexane, dispersed evenly on the glass fiber cloth by high-speed stirring, vulcanized on a flat vulcanizer at 180°C for 5 minutes, and then placed in an oven at 200°C for the second time Vulcanized for 2 hours, cooled and parked to obtain a halogen-free silicone rubber glass fiber cloth.

Embodiment 3

[0050] Other steps are the same as in Example 1 with uniform dosage, except that 55 parts by weight of aluminum hydroxide is changed to 55 parts by weight of melamine cyanurate, and vulcanized silicone rubber D is obtained through vulcanization.

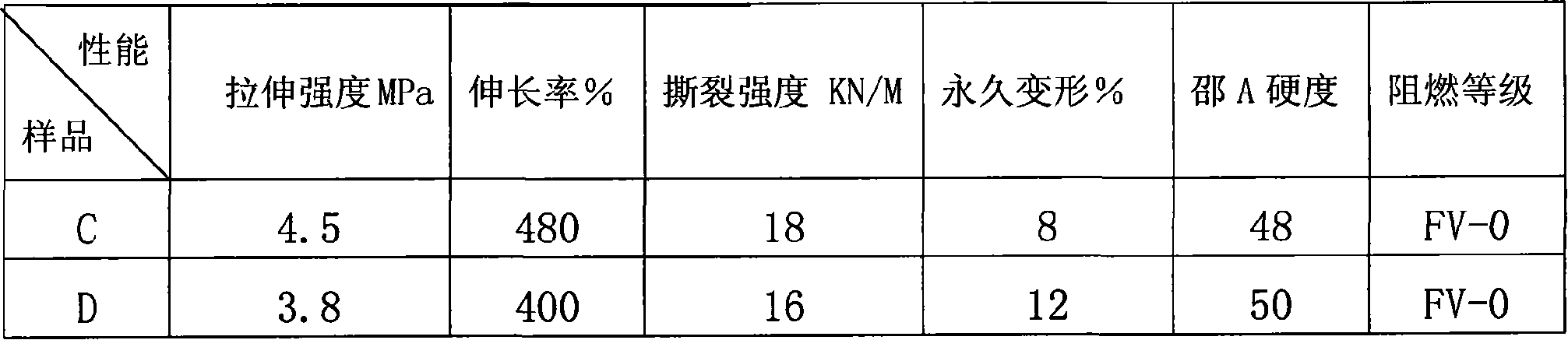

[0051] Performance tests were performed on vulcanized silicone rubbers C and D (the flame retardant grade was tested according to GB / T13488-92), and the results are shown in Table 1.

[0052] Table 1

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com