Halogen-free flame retardant, high-temperature resisting and rapidly solidified deacetone silicon rubber and preparation method thereof

A fast-curing, flame-retardant technology, used in adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of high price and untimely supply, and achieve fast curing speed, mechanical properties and mechanical properties. The effect of improved performance and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

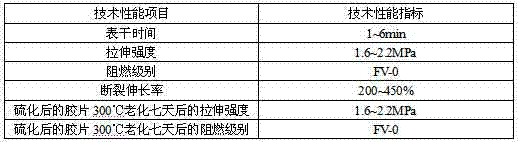

[0045] 100 parts by weight of hydroxyl-terminated polydimethylsiloxane (viscosity of 6000 mPa·s at 25°C), 100 parts by weight of surface-treated magnesium hydroxide, 20 parts by weight of surface-treated zinc borate, 8 parts by weight of white carbon black Parts by weight, 10 parts by weight of iron oxide red was added to a kneader at a temperature of 120°C, kneaded and dehydrated for 240 minutes, and the base material was cooled for later use; the base material was added to a double planetary mixer, and methyl tris(isopropenyloxy ) silane 2 weight parts, phenyl tris (isopropenyloxy) silane 6 weight parts, vacuumize and stir for 20~30min (vacuum degree is above -0.095MPa), add γ-aminopropyltriethoxysilane 1 weight Parts, 0.6 parts by weight of 1,1,3,3-tetramethylguanidinopropyltrimethoxysilane, vacuumized and stirred for 20 to 30 minutes, then discharged and sealed for storage.

Embodiment 2

[0047] 100 parts by weight of hydroxyl-terminated polydimethylsiloxane (viscosity of 8000 mPa·s at 25°C), 120 parts by weight of surface-treated magnesium hydroxide, 20 parts by weight of surface-treated zinc borate, 8 parts by weight of white carbon black Parts by weight, 10 parts by weight of iron oxide red was added to a kneader at a temperature of 120°C, kneaded and dehydrated for 240 minutes, and the base material was cooled for later use; the base material was added to a double planetary mixer, and chloromethyl tris(isopropylene oxide base) silane 4 parts by weight, phenyl tris (isopropenyloxy) silane 4 parts by weight, after vacuum stirring for 20~30min (vacuum degree is above -0.095MPa), add N-(β-aminoethyl)-γ - 1 part by weight of aminopropyltrimethoxysilane, 0.7 part by weight of 1,1,3,3-tetramethylguanidinopropyltrimethoxysilane, vacuumize and stir for 20 to 30 minutes, then discharge and seal for storage.

Embodiment 3

[0049] 100 parts by weight of hydroxyl-terminated polydimethylsiloxane (viscosity of 10,000 mPa·s at 25°C), 120 parts by weight of surface-treated magnesium hydroxide, 20 parts by weight of surface-treated zinc borate, and 10 parts by weight of white carbon black Parts by weight, 8 parts by weight of nano-cerium oxide were added to a kneader at a temperature of 120°C, kneaded and dehydrated for 240 minutes, and the base material was cooled for later use; the base material was added to a double planetary mixer, and chloromethyl tris(isopropylene oxide Base) silane 4 weight parts, phenyl tris (isopropenyloxy) silane 4 weight parts, vacuumize and stir for 20~30min (vacuum degree is above -0.095MPa), add γ-[(2,3)-epoxy 1 part by weight of propyl]propyltrimethoxysilane, 0.8 part by weight of 1,1,3,3-tetramethylguanidinopropyltriethoxysilane, vacuumize and stir for 20 to 30 minutes, then discharge and seal for storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com