Surface precipitation-free flame-retardant polypropylene compound and preparation method thereof

A technology for flame-retardant polypropylene and composites, which is applied in the field of non-surface-precipitated flame-retardant polypropylene composites and its preparation, and can solve problems such as difficulty in guaranteeing market supply, affecting mechanical properties of materials, and general flame-retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

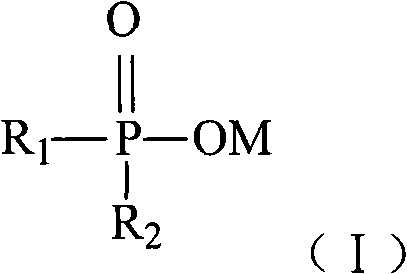

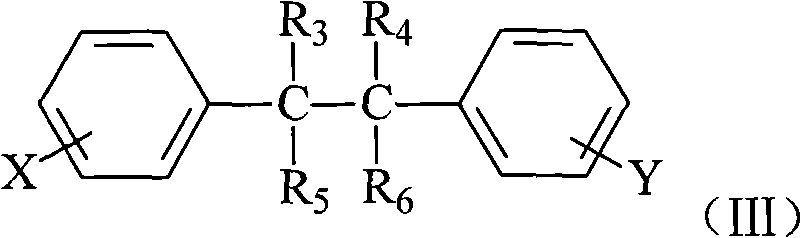

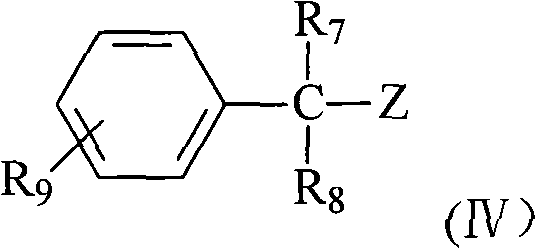

Method used

Image

Examples

Embodiment 1

[0081]Weigh 98KG of homopolymerized PP resin (melt index 20g / 10min), 0.5KG of aluminum 2-carboxyethylphenyl phosphinate, 1KG of melamine hydrobromide, 2-methyl-3-ethyl-2,3-bis Put 0.3KG of phenyl octane, 0.1KG of antioxidant-168, and 0.1KG of magnesium stearate into the mixer and mix them thoroughly, then put them into a twin-screw extruder, melt and extrude at 180-200°C, granulate and dry to obtain The flame retardant polypropylene precipitated on the surface, the flame retardant grade of the obtained flame retardant polypropylene is UL94 V-2 (1.6mm), after 1000 hours in the natural air environment at 80 ℃, no flame retardant precipitated on the surface.

Embodiment 2-26

[0083] Weigh each substance according to the amount shown in Table 1, then put it into a mixer for full mixing, put it into a twin-screw extruder for melt extrusion, granulate and dry to obtain a flame-retardant polypropylene without surface precipitation, and then test its flame-retardant And precipitation resistance, the results are shown in Table 1.

[0084] Table 1

[0085]

[0086]

[0087]

[0088]

[0089]

[0090]

[0091]

[0092]

Embodiment 27

[0094] Weigh 95KG of homopolymer PP resin (melt index 30g / 10min), 1KG of melamine phosphinate, 1KG of sodium 2-carboxyethylphenyl phosphinate, 2KG of melamine hydrobromide, 2,3-diethyl- Put 0.5KG of 2,3-diphenylbutane and 0.5KG of antimony trioxide into the mixer and mix them thoroughly, put them into a twin-screw extruder, melt and extrude them at 180-200°C, granulate and dry to obtain a product without surface precipitation Flame-retardant polypropylene, the resulting flame-retardant polypropylene has a flame-retardant rating of UL94V-2 (1.6mm), and after 1000 hours in a natural air environment at 80°C, no flame retardant is precipitated on the surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com