Intelligent waterproof moisture-permeable film and preparation method thereof

A waterproof and moisture-permeable membrane and waterproof and moisture-permeable technology are applied in the field of preparation and modification of functional polymer materials, which can solve the problems of limited application fields, poor mechanical properties of membranes, damage to mechanical properties of polyurethane materials, etc. Improve performance, excellent waterproof and moisture permeability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

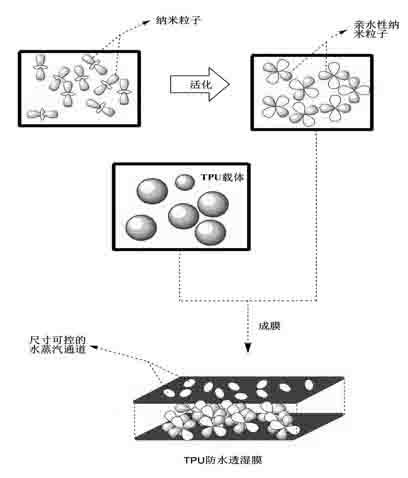

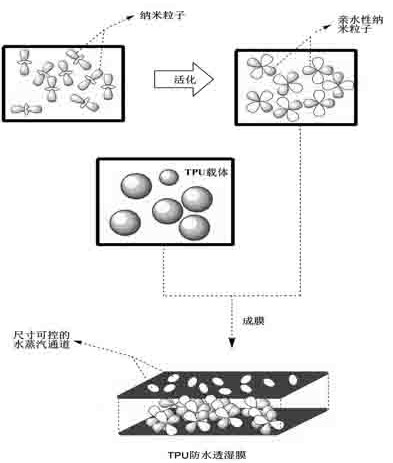

[0038] The present invention also provides a method for preparing an intelligent waterproof and moisture-permeable membrane, which includes the following steps:

[0039] a. Clean and dry the base material for later use;

[0040] b. Add the thermoplastic carrier material, inorganic nanoparticles with two-dimensional microporous or three-dimensional microporous structure, and processing aids to a high-speed mixer at room temperature in a ratio of 100:5-100:0.5-1 by mass. Stirring to obtain functional mixed materials;

[0041] c. The above-mentioned functional mixed material is extruded and granulated using an extruder at an extrusion temperature of 120°C-250°C by a melt blending method to obtain a waterproof and moisture-permeable functional material;

[0042] d. After the above-mentioned spare base material and the above-prepared waterproof and moisture-permeable functional material are uniformly mixed in a mass ratio of 100:5-200, use a single-screw extruder at an extrusion temperatur...

Embodiment 1

[0046] First, the polyamide 1010 of the base material is washed and dried for use.

[0047] Secondly, under normal temperature conditions, add 100g of polyether polyurethane, 50g of molecular sieve, 0.2g of polyethylene wax, 0.1g of calcium stearate, 0.05g of antioxidant 1010 and 0.05g of diphenyl phosphite in a high-speed mixer. After mixing uniformly with the mixer at 1000r / min to obtain the functional mixed material, the parallel twin-screw extruder is used to extrude and granulate the obtained functional mixed material at the extrusion temperature of 180°C to obtain the waterproof and moisture-permeable function. material.

[0048] Then, according to the mass ratio of 100:30, the above-mentioned dried polyamide 1010 and the prepared waterproof and moisture-permeable functional material are put into the barrel of the up-blowing single-screw extruder, and the polyamide 1010 is formed at 230°C. Ether polyurethane is a polyamide-based waterproof and moisture-permeable membrane mad...

Embodiment 2

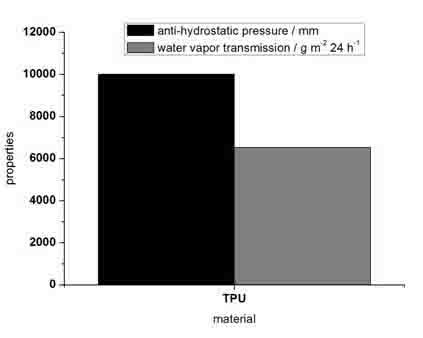

[0052] First, the polyether polyurethane matrix material is selected for use after cleaning and drying.

[0053] Secondly, under normal temperature, add 100g polyether glycol terephthalate, 10g nano-SiO2, 90g nano-Al2O3, 0.3g polyethylene wax, 0.3g calcium stearate, and 0.1g antioxidant in a high-speed mixer. 1010 and 0.05g of diphenyl phosphite, mixed uniformly under the condition of 1000r / min in a mixer to obtain the functional mixed material, and then use the parallel twin-screw extruder to extrude the obtained functional mixed material at 210℃. , Prepared waterproof and moisture-permeable functional materials.

[0054] Then put the above-mentioned dried polyether polyurethane base material and the above-prepared waterproof and moisture-permeable functional material into the barrel of the up-blowing single-screw extruder according to the mass ratio of 100:100, and shape it at 220°C It is a polyurethane-based waterproof and moisture-permeable membrane using polyether glycol tere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com