Injection molding process of thin wall plastic products

An injection molding process and a technology of plastic products, which are applied to household components, household appliances, and other household appliances to achieve the effects of reducing internal stress and residual stress, ensuring accuracy and stability, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

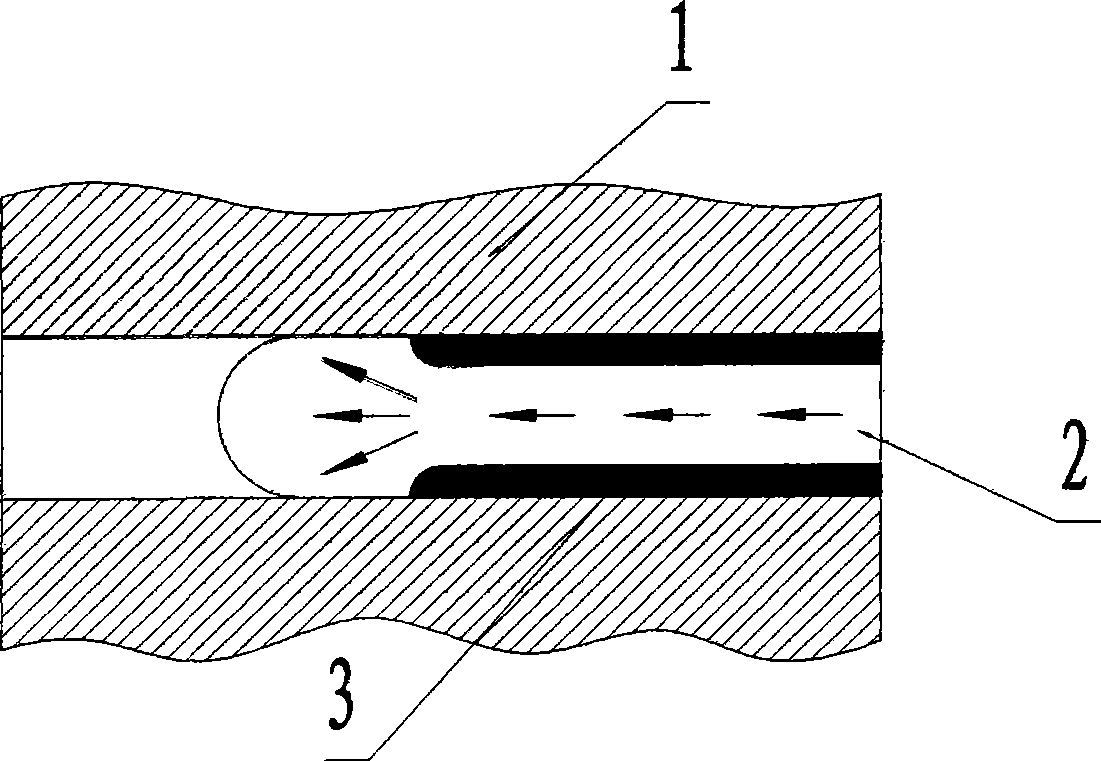

Image

Examples

Embodiment 1

[0023] Example 1: Digital camera battery case, the product is 40.35mm long, 35.40mm wide, the thinnest wall thickness is 0.25mm, and the thinnest wall area is 1400mm 2 , the material is polycarbonate, and its injection molding process is as follows:

[0024] (A) Put the polycarbonate material into the hopper of the injection molding machine, and set the temperature of the barrel: the nozzle is 300°C, the front part is 295°C, the middle part is 290°C, and the rear part is 280°C;

[0025] (B) Mold temperature setting: 60°C;

[0026] (C) Entering the injection stage, the injection pressure is 2700kg / cm 2 , the injection time is 0.1s; the injection speed is 600mm / s, the mold is closed, and the injection starts;

[0027] (D) Switch to the pressure-holding state, using 3 stages of pressure-holding,

[0028] The first stage of holding pressure: pressure 500kg / cm 2 , time 0.05s,

[0029] The second stage of holding pressure: pressure 1300kg / cm 2 , time 0.8s,

[0030] The third ...

Embodiment 2

[0038] Example 2: Mobile phone battery case, the product is a frame structure, length 55.30mm, width 35.40mm, the thinnest wall thickness is 0.20mm, the material is polycarbonate, and its injection molding process is as follows:

[0039] (A) Put the polycarbonate material into the hopper of the injection molding machine, and set the barrel temperature: 305°C for the nozzle, 300°C for the front, 290°C for the middle, and 280°C for the rear;

[0040] (B) Mold temperature setting: 75°C;

[0041] (C) Entering the injection stage, the injection pressure is 2800kg / cm 2 , the injection time is 0.2s; the injection speed is 700mm / s, the mold is closed, and the injection starts;

[0042] (D) Switch to the pressure-holding state, using three-stage pressure-holding,

[0043] The first stage of holding pressure: pressure 800kg / cm 2 , time 0.08s,

[0044]The second stage of holding pressure: pressure 1800kg / cm 2 , time 1s,

[0045] The third holding pressure: pressure 800kg / cm 2 , ti...

Embodiment 3

[0053] Embodiment 3: mobile phone front cover, length 98.10mm, width 49.40mm, thinnest wall thickness 0.40mm, the blend of polycarbonate and acrylonitrile-butadiene-styrene copolymer for material, its injection molding process is as follows:

[0054] (A) Put the blend of polycarbonate and acrylonitrile-butadiene-styrene copolymer into the hopper of the injection molding machine, and set the temperature of the barrel: 270°C for the nozzle, 265°C for the front, 265°C for the middle, and 265°C for the rear Part 255°C;

[0055] (B) Mold temperature setting: 85°C

[0056] (C) Entering the injection stage, the injection pressure is 2000kg / cm 2 , the injection time is 0.6s; the injection speed is 500mm / s, the mold is closed, and the injection starts;

[0057] (D) Switch to the pressure-holding state, using two-stage pressure-holding,

[0058] The first stage of holding pressure: pressure 500kg / cm 2 , time 0.3s,

[0059] The second stage of holding pressure: pressure 1200kg / cm 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com