Punch forming method of thin-wall end socket

A stamping forming and sealing head technology, which is applied to other household appliances, household appliances, applications, etc., can solve the problems of difficult forming of thin-walled heads, large size of lining heads, and difficulty in forming, and achieves novel technology, The effect of high product quality and short molding cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

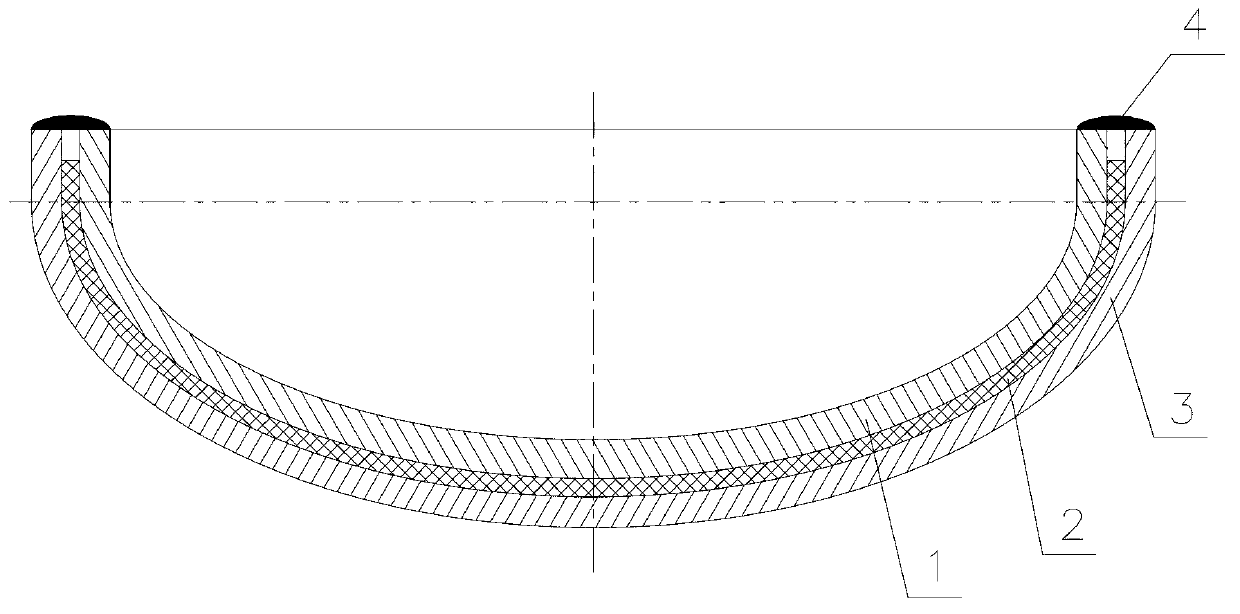

[0042] The material of the thin-walled head in this embodiment is pure titanium, the cross-sectional shape is oval, the nominal diameter is DN800mm, and the wall thickness is 1mm.

[0043] The stamping method of the thin-walled head of the present embodiment includes the following steps:

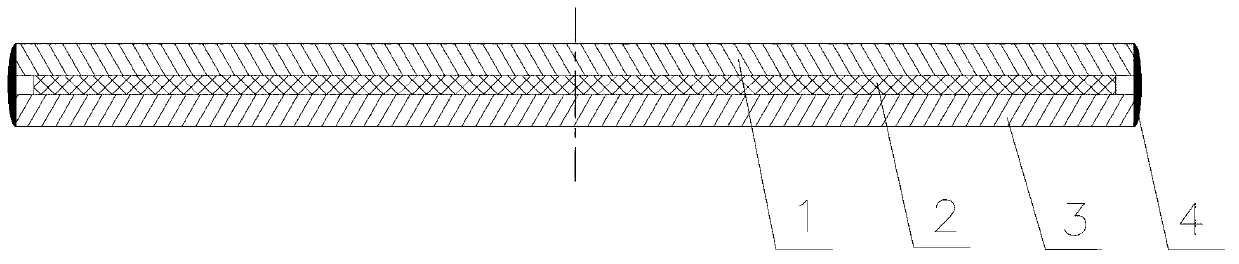

[0044] Step 1. According to the material and size of the thin-walled head to be stamped and formed, select the TA2 pure titanium whole plate and cut it to obtain the whole head plate 2 without welds, and then according to the size of the head plate 2 Q345R The steel plate is cut to obtain an upper steel plate 1 and a lower steel plate 3; the head plate 2, the upper steel plate 1 and the lower steel plate 3 are all circular plates, and the diameters of the upper steel plate 1 and the lower steel plate 3 are all larger than the diameter of the head plate 2. The diameter is 10mm larger; the thickness of the upper steel plate 1 and the lower steel plate 3 are both 6mm;

[0045] Step 2. Stack th...

Embodiment 2

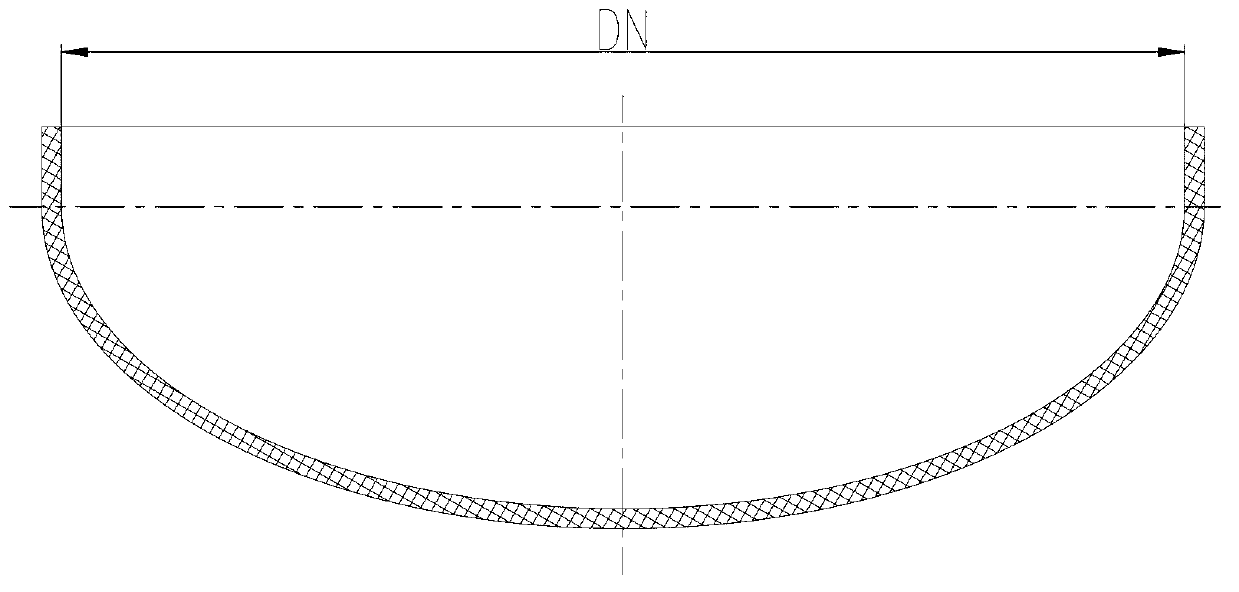

[0051] The material of the thin-walled head in this embodiment is pure tantalum, the section shape is hemispherical, the nominal diameter is DN600mm, and the wall thickness is 0.5mm.

[0052] The stamping forming method of the thin-walled head of the present embodiment includes the following steps:

[0053] Step 1. According to the material and size of the thin-walled head to be stamped and formed, select a Ta1 pure tantalum tailor welded blank and cut it to obtain a head plate 2 with a tailor welded seam, and then according to the size of the head plate 2 The steel plate is cut to obtain the upper steel plate 1 and the lower steel plate 3; the head plate 2, the upper steel plate 1 and the lower steel plate 3 are all circular plates, and the diameters of the upper steel plate 1 and the lower steel plate 3 are all larger than the head plate 2 The diameter of the steel plate is 30mm larger; the thickness of the upper steel plate 1 is 6mm, and the thickness of the lower steel pla...

Embodiment 3

[0060] The material of the thin-walled head in this embodiment is pure zirconium, the cross-sectional shape is a spherical crown, the nominal diameter is DN300mm, and the wall thickness is 2mm.

[0061] The stamping forming method of the thin-walled head of the present embodiment includes the following steps:

[0062] Step 1. According to the material and size of the thin-walled head to be stamped and formed, select the R60702 pure zirconium whole plate and cut it to obtain the whole head plate 2 without welds, and then align the steel plate according to the size of the head plate 2 Carry out cutting, obtain upper layer steel plate 1 and lower layer steel plate 3; Described head plate 2, upper layer steel plate 1 and lower layer steel plate 3 are all circular plates, and the diameters of upper layer steel plate 1 and lower layer steel plate 3 are all larger than the diameter of head plate 2 15mm larger; the thickness of the upper steel plate 1 and the lower steel plate 3 are b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com