Building sandwich composite wallboard

A composite wallboard and sandwich technology, which is applied to buildings, building components, building structures, etc., can solve problems such as easy cracks in the wall and shedding of the outer layer of the wall, and achieve easy standardized production, simple wall construction, and heat preservation. Effect of heat insulation effect improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described with reference to the accompanying drawings.

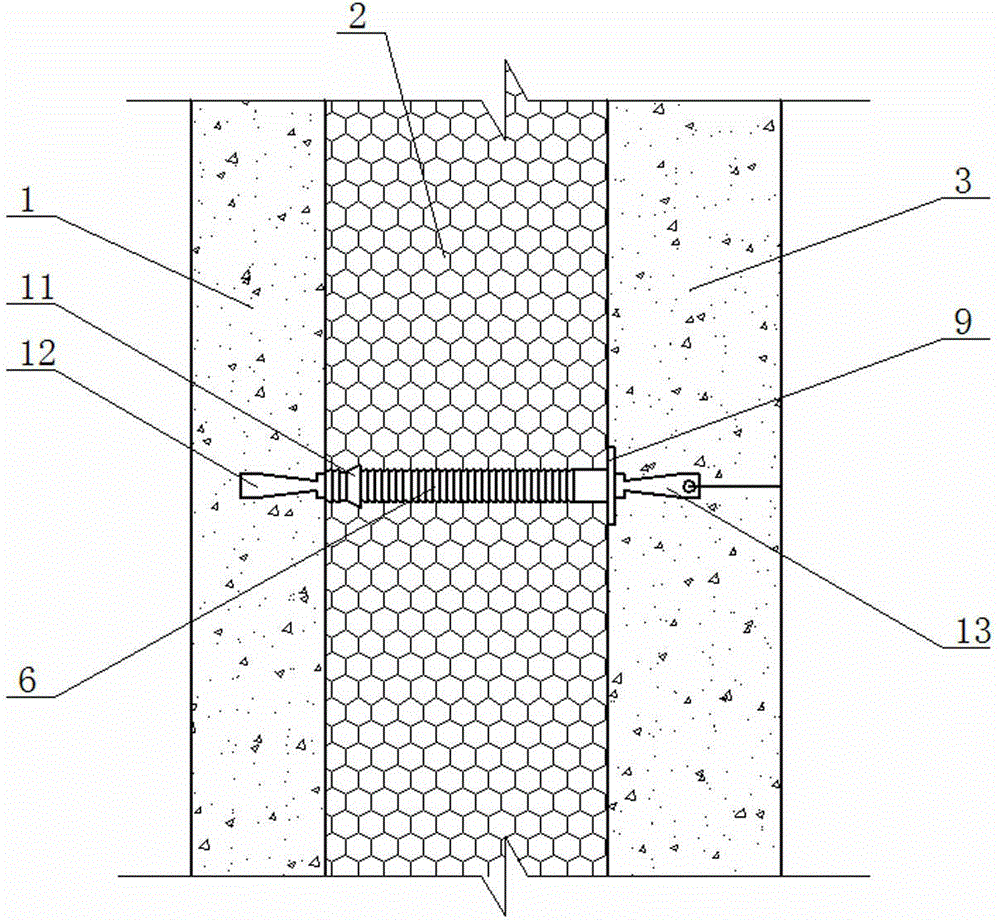

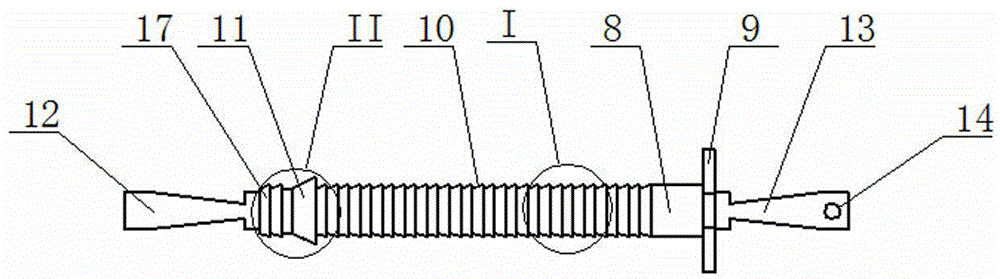

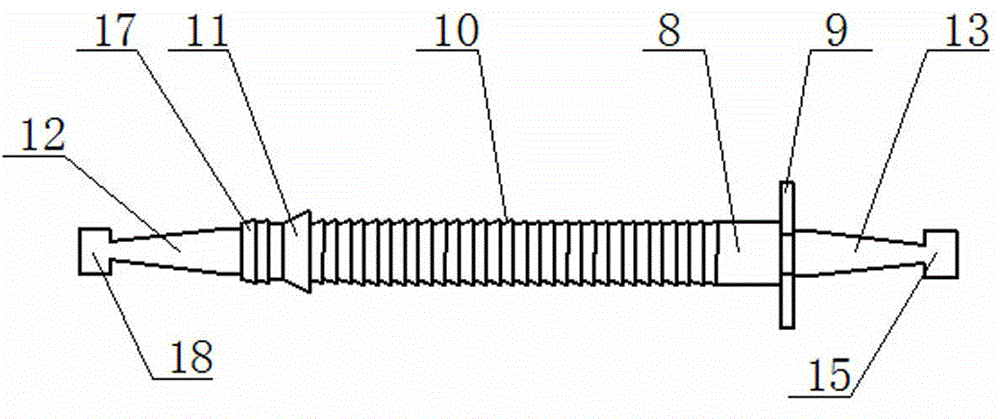

[0008] In the figure, 1 is an exterior wall panel, 3 is a concrete interior wall panel, and an insulation layer 2 is arranged between the exterior wall panel 1 and the interior wall panel 3, and non-metallic panels are pre-embedded in the exterior wall panel 1, the insulation layer panel 2 and the interior wall panel. The connecting rod 6, the middle part of the non-metallic connecting rod 6 is set as a rod body 8, the rod body 8 is provided with annular teeth 10, one side of the rod body 8 is provided with an annular baffle plate 9, and the other side of the rod body 8 is provided with an annular sealing platform 11 , the first anchor 12 is in contact with the sealing convex ring 11, the second anchor 13 is in contact with the annular baffle 9, and the annular baffle 9 is located at the junction of the insulation layer 2 and the inner wall panel 3, and the annular seal The pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com