Nickel plating method for stainless steel strips

A technology of stainless steel and strips, which is applied in the field of nuclear power fuel elements and its manufacturing, to achieve the effect of good bonding force, good assembly performance, and meeting the requirements of technical indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

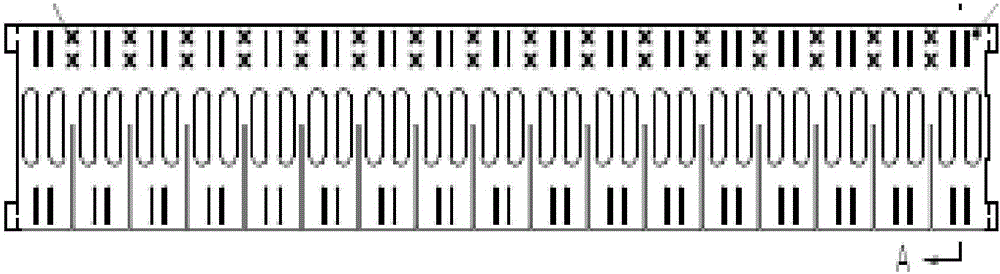

[0021] A kind of nickel plating method of stainless steel strip according to the present invention, strip is as figure 1 As shown, it includes the following steps:

[0022] (1) Degreasing: the strip is placed in a degreasing solution to remove the oil on the surface of the strip; the degreasing solution uses an alkaline cleaning agent; the degreasing time is 3 minutes, and the temperature is 70 ° C;

[0023] The alkaline cleaning agent is a mixture solution of sodium hydroxide, sodium phosphate and sodium carbonate, with a concentration of 15g / L;

[0024] (2) Pre-etching: the strip pre-etching after step (1) degreasing removes the Cr on the strip surface 2 o 3 Passivation film; the pre-etching solution is a mixed solution of nitric acid and hydrofluoric acid;

[0025] The pre-etching solution is a mixed solution of 50wt% hydrofluoric acid solution, 68wt% nitric acid solution and deionized water. The volume percentage of 50wt% hydrofluoric acid solution in the mixed solution...

Embodiment 2

[0035] A kind of nickel-plating method of stainless steel strip of the present invention, it comprises the steps:

[0036] (1) degreasing: the strip is placed in a degreasing solution to remove the oil on the surface of the strip;

[0037] The degreasing solution uses an alkaline cleaning agent; the degreasing time is 2 minutes, and the temperature is 80° C.; the alkaline cleaning agent is sodium hydroxide solution, and the concentration is 10 g / L;

[0038] (2) Pre-etching: the strip pre-etching after step (1) degreasing removes the Cr on the strip surface 2 o 3 Passivation film; the pre-etching solution is a mixed solution of nitric acid and hydrofluoric acid;

[0039]The pre-etching solution is a mixed solution of 45wt% hydrofluoric acid solution, 67wt% nitric acid solution, and deionized water. The volume percentage of the 45wt% hydrofluoric acid solution in the mixed solution is 10vol%, and the volume percentage of the 67wt% nitric acid solution is 60vol. %, the rest is...

Embodiment 3

[0049] A kind of nickel-plating method of stainless steel strip of the present invention, it comprises the steps:

[0050] (1) Degreasing: the strip is placed in a degreasing solution to remove the oil on the surface of the strip; the degreasing solution uses an alkaline cleaning agent; the degreasing time is 5 minutes, and the temperature is 60 ° C;

[0051] (2) Pre-etching: the strip pre-etching after step (1) degreasing removes the Cr on the strip surface 2 o 3 Passivation film; the pre-etching solution is a mixed solution of nitric acid and hydrofluoric acid;

[0052] The pre-etching solution is a mixed solution of 55wt% hydrofluoric acid solution, 70wt% nitric acid solution, and deionized water. The volume percentage of the 55wt% hydrofluoric acid solution in the mixed solution is 6vol%, and the volume percentage of the 70wt% nitric acid solution is 40vol. %, the rest is deionized water; the pre-etching temperature is 35 degrees, and the time is 2 minutes.

[0053] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com