Injectable expansion type bone cement and preparation method thereof

A bone cement and expansion technology, which is applied in the field of medical biomaterial preparation, can solve the problems of water absorption and swelling, easy to fall off, weak bonding, high elastic modulus, etc., and achieve the effects of avoiding friction and wear, considerable volume expansion ratio, and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

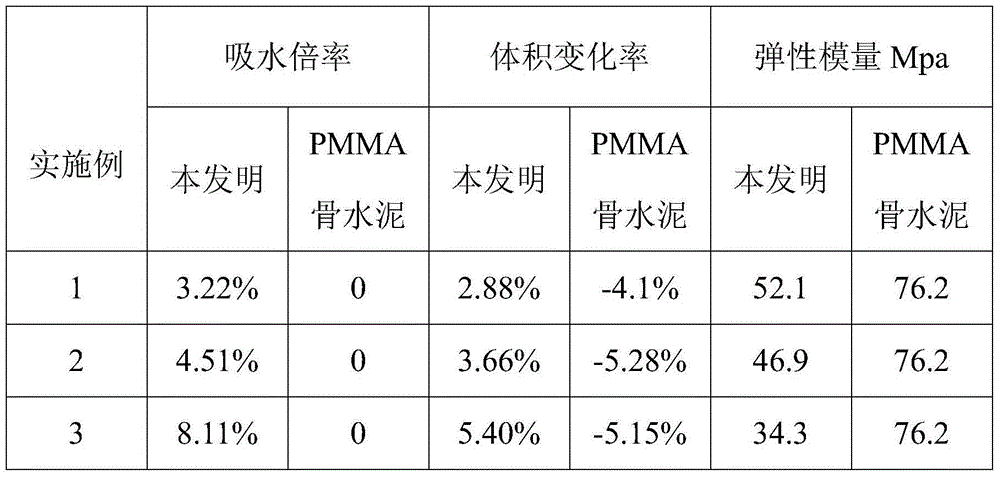

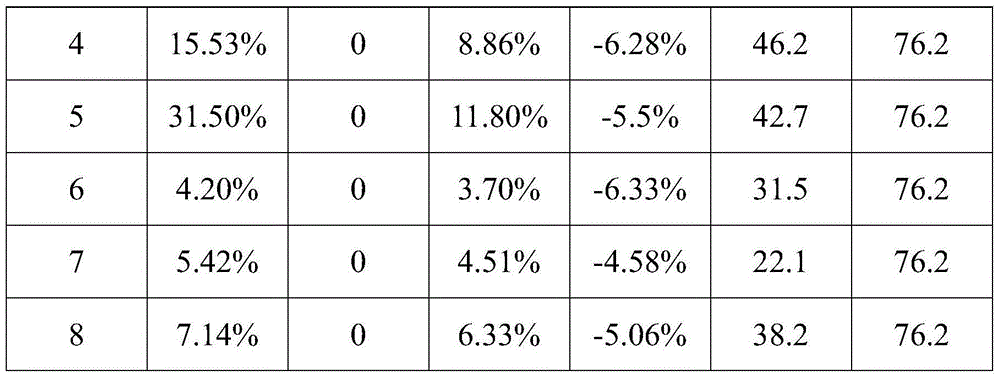

Examples

preparation example Construction

[0034] The present invention also provides a preparation method for the above-mentioned injectable expansive bone cement, comprising the following steps:

[0035] Step 1, preparation of solid phase components

[0036] Methyl methacrylate (MMA) and acrylic acid (AA) are used as reactive monomers, and under the action of an initiator and a crosslinking agent, a polymerization reaction occurs to form a methyl methacrylate-acrylic acid copolymer.

[0037] Step 2, Preparation of Liquid Phase Components

[0038] Mix methyl methacrylate, N,N-dimethyl-p-toluidine and hydroquinone evenly, to liquid phase components.

[0039] Step 3, Preparation of Injectable Expandable Bone Cement

[0040] Mix the solid phase components prepared in step 1 with the liquid phase components prepared in step 2 at a mass ratio of 1.5:1 to 3:1, and stir uniformly for 1 min to 3 min to obtain bone cement fluid. Quickly inject into a syringe and self-cure for 10 minutes to 30 minutes in an environment with ...

Embodiment 1

[0050] A kind of injectable expansible bone cement, its preparation method comprises the following steps:

[0051] Step 1, preparation of solid phase components

[0052] Methyl methacrylate-acrylic acid copolymer was prepared by dispersion polymerization. The MMA and AA monomers were distilled under reduced pressure before use respectively to remove the polymerization inhibitor therein. Dissolve 0.2g of dispersant PVP in 50ml of water, put it into a three-necked flask equipped with a condenser, a mechanical stirrer and a nitrogen conduit, raise the temperature to 60°C, blow nitrogen for 0.5h, slowly add the dissolved initiator potassium persulfate, crosslinking MMA and AA monomers of N-N methylene bisacrylamide, wherein, 0.04 g of initiator potassium persulfate, 0.07 g of cross-linking agent N-N methylene bis acrylamide, 18 g of monomer MMA, and 1.44 g of AA. A constant temperature reaction was carried out at 60° C. for 6 hours to obtain an emulsion sample. Centrifuge the e...

Embodiment 2

[0058] A kind of injectable expansible bone cement, its preparation method comprises the following steps:

[0059] Step 1, preparation of solid phase components

[0060] Methyl methacrylate-acrylic acid copolymer was prepared by dispersion polymerization. The MMA and AA monomers were distilled under reduced pressure before use respectively to remove the polymerization inhibitor therein. Dissolve 0.18g of dispersant PVP in 60ml of water, put it into a three-necked flask equipped with a condenser, a mechanical stirrer and a nitrogen conduit, raise the temperature to 60°C, blow nitrogen for 0.5h, slowly add the dissolved initiator potassium persulfate, cross-linking Agent N-N methylenebisacrylamide MMA, AA monomer. Among them, the initiator potassium persulfate is 0.03g, the crosslinking agent N-N methylenebisacrylamide is 0.056g, the monomer MMA is 16g, and the AA is 2.88g. A constant temperature reaction was carried out at 80° C. for 12 hours to obtain an emulsion sample. C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com