Combined biological trickling filter of denitrification and dephosphorization

A biological trickling filter, denitrification and phosphorus removal technology, applied in sustainable biological treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. The problem of uneven distribution of water, etc., can achieve the effect of eliminating filter blockage, improving water flow effect, and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

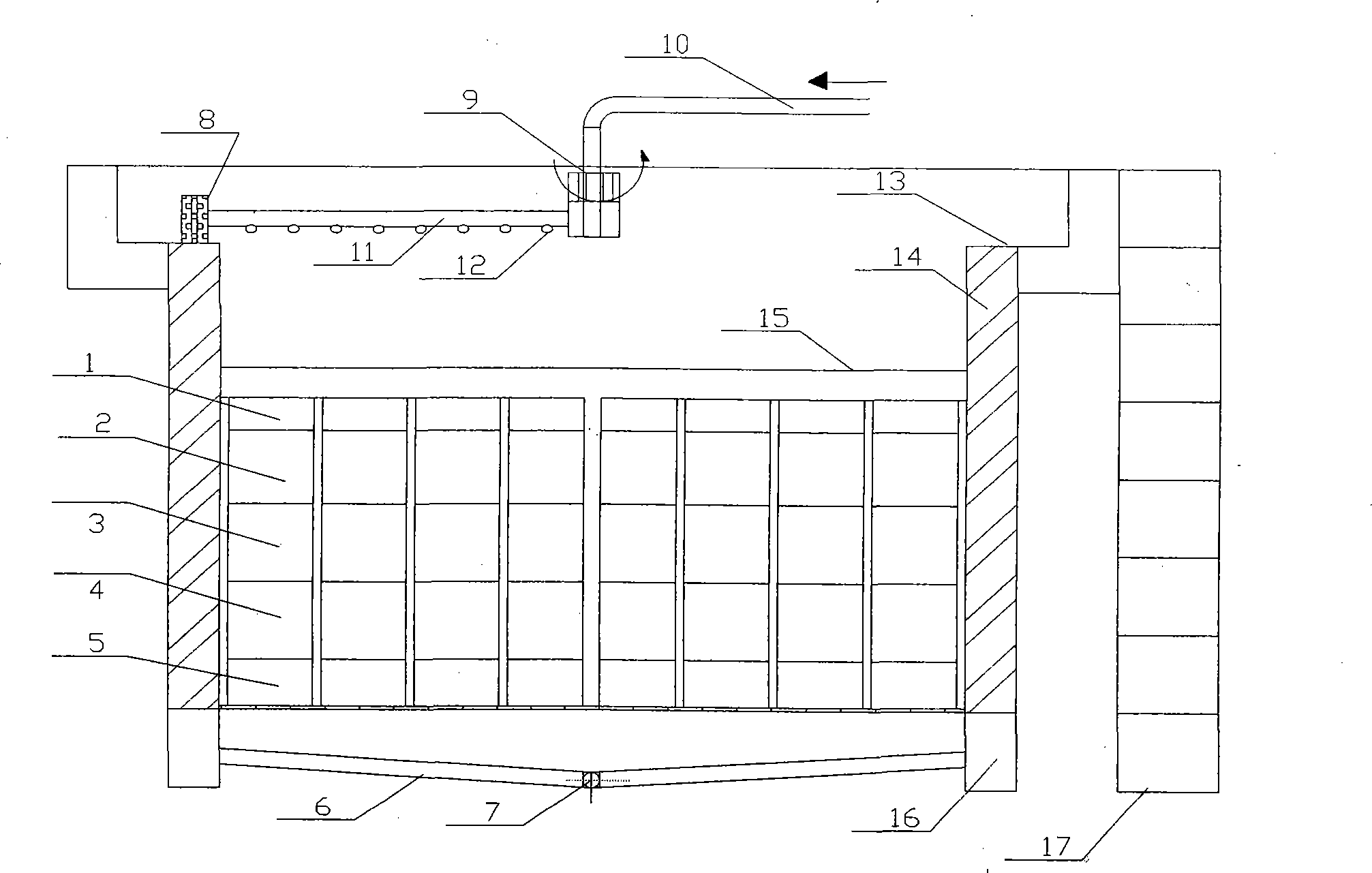

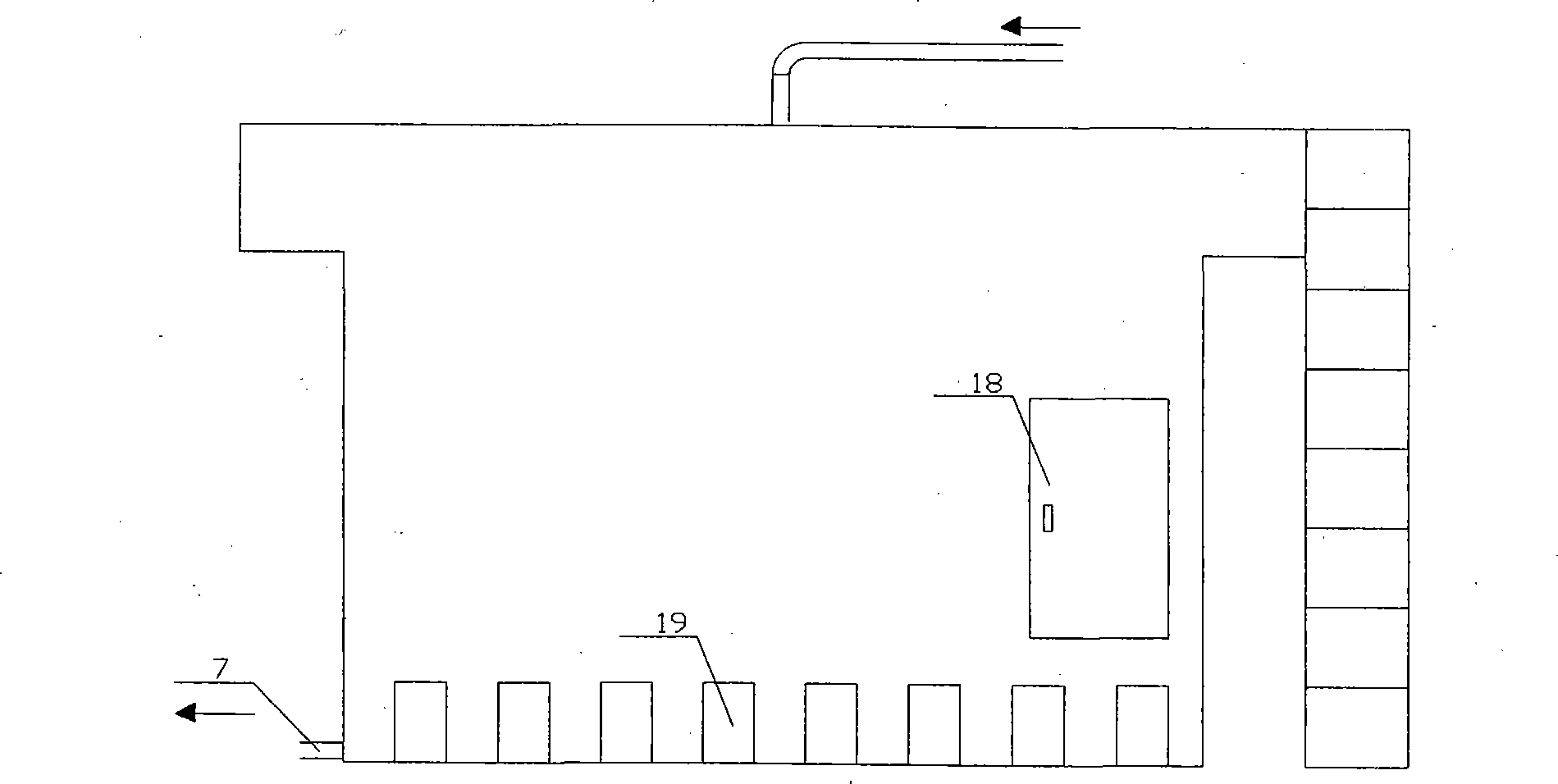

[0032] The biological trickling filter is designed as a cylinder, surrounded by the trickling filter wall 14, the top of the biological trickling filter is open, the bottom of the trickling filter wall 14 is fully open, and the inside of the biological trickling filter is a separate Layer multi-module structure; for ease of use, a ladder 17 is provided on one side of the trickling filter pool wall 14 .

[0033] The top of the biological trickling filter is the sewage water intake area, and the rotary water distributor 9 is used for water distribution. Rotary water distributor 9 begins to rotate water distribution when starting according to the water inlet pump, stops rotating after the water inlet pump stops.

[0034] The lower part of the rotary water distributor 9 is a packing layer, and the packing layer is sequentially provided with a sandstone layer 5, a steel slag composite packing layer 4, a gypsum packing layer 3, a sawdust packing layer 2, and a coke layer 1 from bott...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com