Method for cleaning immersed ultrafiltration membrane in wastewater reuse

An ultrafiltration membrane, immersion technology, applied in the field of filter membrane cleaning and reuse, can solve the problems of decreased membrane flux, decreased water production rate, increased transmembrane pressure difference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Embodiment 1: Adopt single alkaline washing method to clean submerged ultrafiltration membrane

[0066]When cleaning, the hot water pool is filled with water, the temperature is heated to 35°C, and the backwash pump of the ultrafiltration unit is started. After backwashing, the water in the membrane pool is discharged to 1.1~1.2 meters, and the hot water pump is started to inject hot water and cleaning agents into the ultrafiltration unit. In the membrane pool, after the water level reaches 2.2~2.3 meters, the hot water pump stops, and the ultrafiltration permeate pump starts to perform self-circulation.

[0067] Specifically include the following steps:

[0068] (1) Backwash

[0069] ①Close the water inlet valve of the ultrafiltration device, and continue to filter until the liquid level in the membrane pool reaches 1.2 meters;

[0070] ②The inlet pressure of the ultrafiltration device is 1.5bar<p<2.5bar, air and water enter the membrane pool at the same time, th...

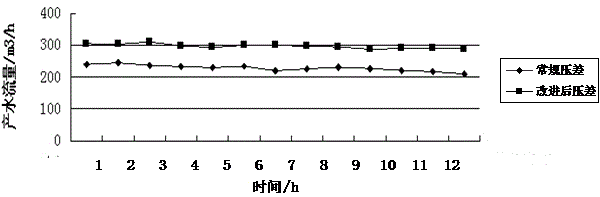

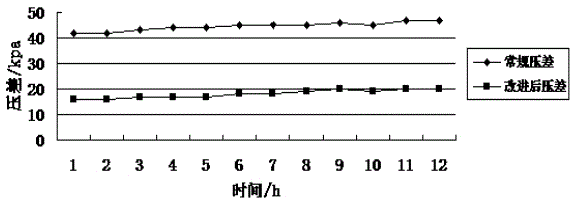

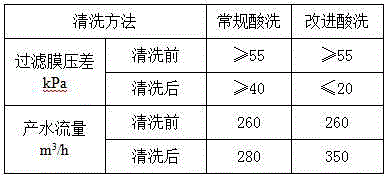

Embodiment 2

[0087] Embodiment 2: Adopt single pickling method to clean submerged ultrafiltration membrane

[0088] Specifically include the following steps:

[0089] (1) Backwash

[0090] ①Close the water inlet valve of the ultrafiltration device, and continue to filter until the liquid level in the membrane pool reaches 1.1 meters;

[0091] ②The inlet pressure of the ultrafiltration device is 1.5bar<p<2.5bar, air and water enter the membrane pool at the same time, the air scrubbing time is 35 seconds, and the water level is increased to 2.2 meters. After the air scrubbing is completed, the sewage inside the ultrafiltration device is drained ;

[0092] (2) Acid chemical cleaning and medicine soaking

[0093] ① The membrane tank is fed with water by the hot water pump. During this process, the hydrochloric acid and citric acid metering pumps are started, and the pH is flexibly adjusted to 2 according to the online pH meter;

[0094] ② After the dosing is completed, soak for 30 minutes....

Embodiment 3

[0105] Embodiment 3: adopt alkali cleaning and pickling method to clean submerged ultrafiltration membrane

[0106] (1) Backwash

[0107] ①Close the water inlet valve of the ultrafiltration device, and continue to filter until the liquid level in the membrane pool reaches 1.2 meters;

[0108] ②The inlet pressure of the ultrafiltration device is 1.5bar<p<2.5bar, the air and water enter the membrane pool at the same time, the air scrubbing time is 30 seconds, and the water level is increased to 2.3 meters. After the air scrubbing is completed, the sewage inside the ultrafiltration device is drained ;

[0109] (2) Chemical cleaning and medicine soaking

[0110] ① The membrane tank is fed with water by the hot water pump. During this process, the sodium hypochlorite metering pump is started, and the pH is flexibly adjusted to 12 according to the online pH meter;

[0111] ② After the dosing is completed, soak for 45 minutes.

[0112] (3) Ultrafiltration cleaning cycle

[0113]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com