Fixed bed biofilm inclusive type microelectrolysis deep nitrogen and phosphorus removal cabin

A deep denitrification and biofilm technology, applied in the field of water treatment, can solve problems such as high construction costs, loss of electrode plates, and complex sewage components, and achieve the effects of saving manpower and maintenance costs, improving water output indicators, and excellent slow-release effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

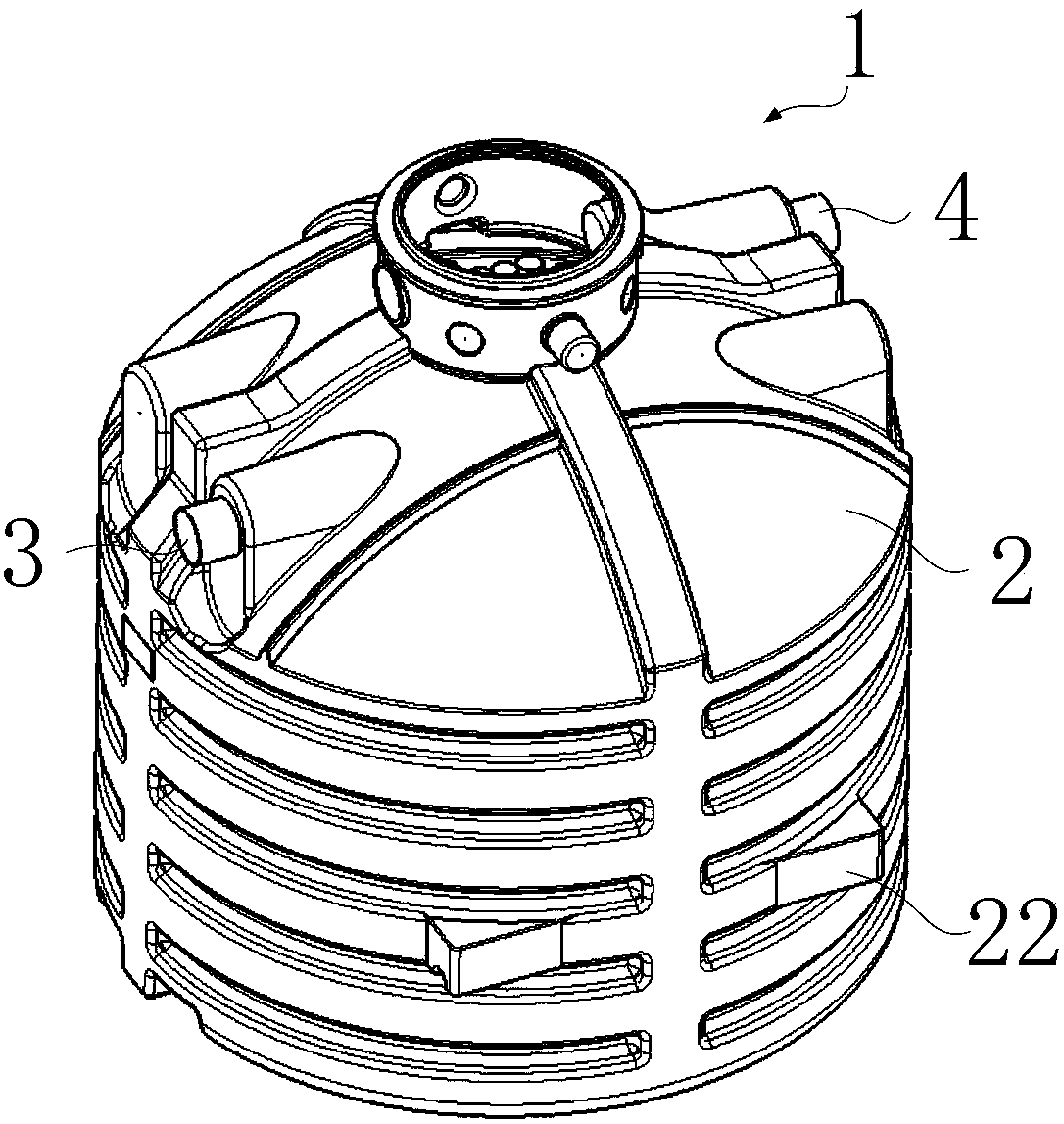

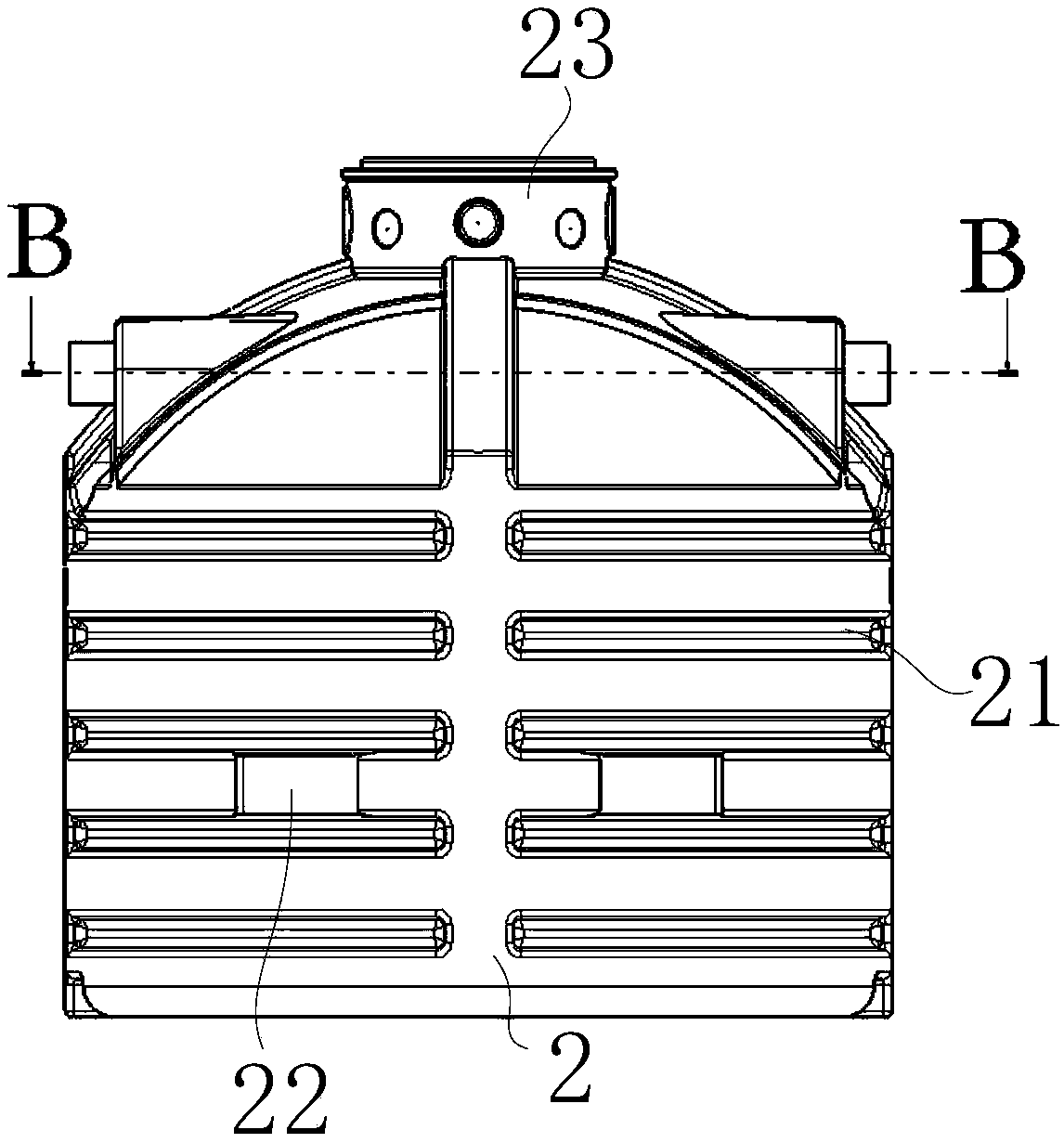

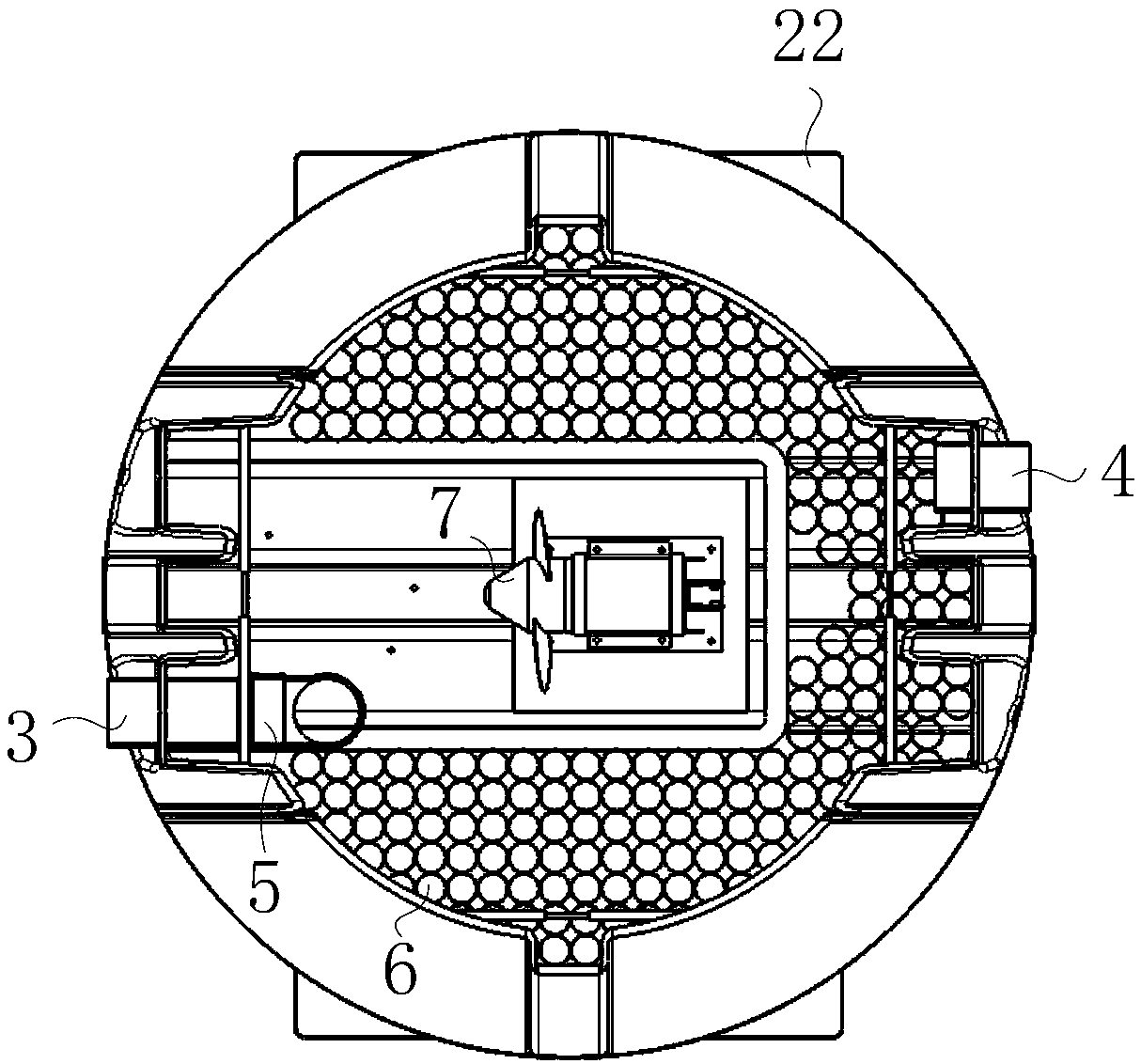

[0030] A fixed-bed biofilm contained micro-electrolysis deep nitrogen and phosphorus removal cabin, such as Figure 1-Figure 4 As shown, it includes a cabin body 1; the cabin body 1 is a hollow cylindrical wall structure with an open top; the top side of the cabin body 1 is respectively provided with a water inlet 3 and a water outlet 4; the water inlet guides the fixed bed organism through the water inlet pipe 5 Membrane tube 6, a number of fixed bed biofilm tubes 6 are vertically and closely arranged inside the cabin body 1; the fixed bed biofilm tube 6 is a hollow tubular structure; the wall of the fixed bed biofilm tube 6 is provided with a number ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com