Chilling device and process for dry coal powder pressure gasifying

A technology for pressurized gasification and dry coal powder, which is used in the gasification of granular/powdered fuels, the petroleum industry, and the manufacture of combustible gases. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

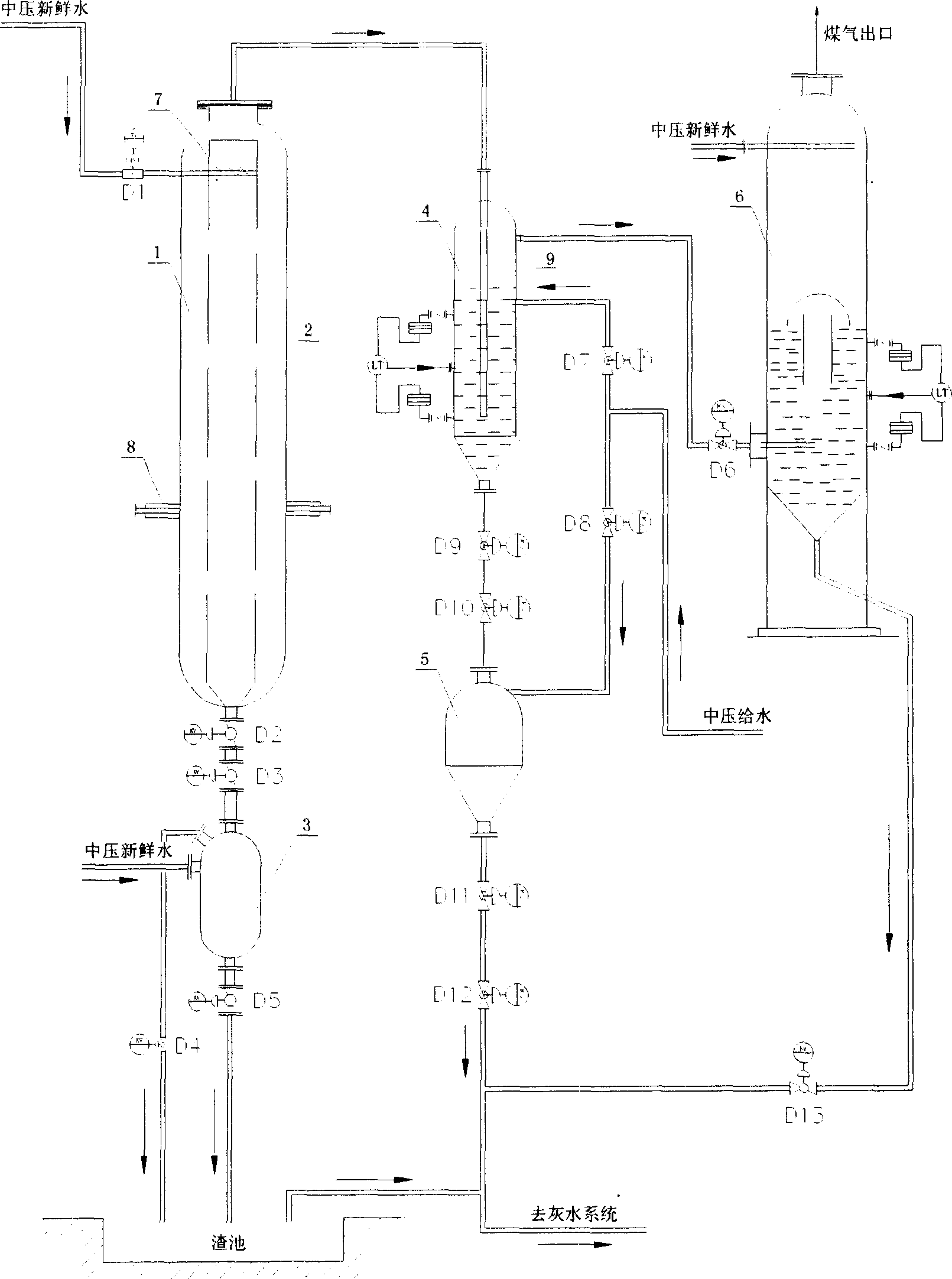

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0021] Referring to accompanying drawing 1, the present invention comprises gasification furnace 1 and the slag lock pot 3 that is communicated with gasification furnace 1 through pipeline, is provided with one group or more than one group of nozzles 8 symmetrically at the bottom of gasification furnace 1, gasification The interior of the furnace 1 is provided with a water-cooled wall 2, and a shower 7 connected with the medium-pressure feed water is provided at the upper end of the gasification furnace. The gas outlet of the gasification furnace 1 is connected with the quenching chamber 4 through a pipeline. The gas outlet of the quenching chamber 4 communicates with the washing tower 6 through a pipeline, and the lower end outlet of the quenching chamber 4 communicates with the gray water tank 5 through a pipeline. The water inlet 9 connected with the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com