Method and device for recovering gas containing water-soluble organic compounds

An organic compound and water-soluble technology, which is used in the field of recycling waste gas containing water-soluble organic compounds, can solve the problems of inability to perform rectification, low column top temperature, and large thermal energy consumption, so as to ensure continuous normal operation and reduce energy consumption. , the effect of reducing heat consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

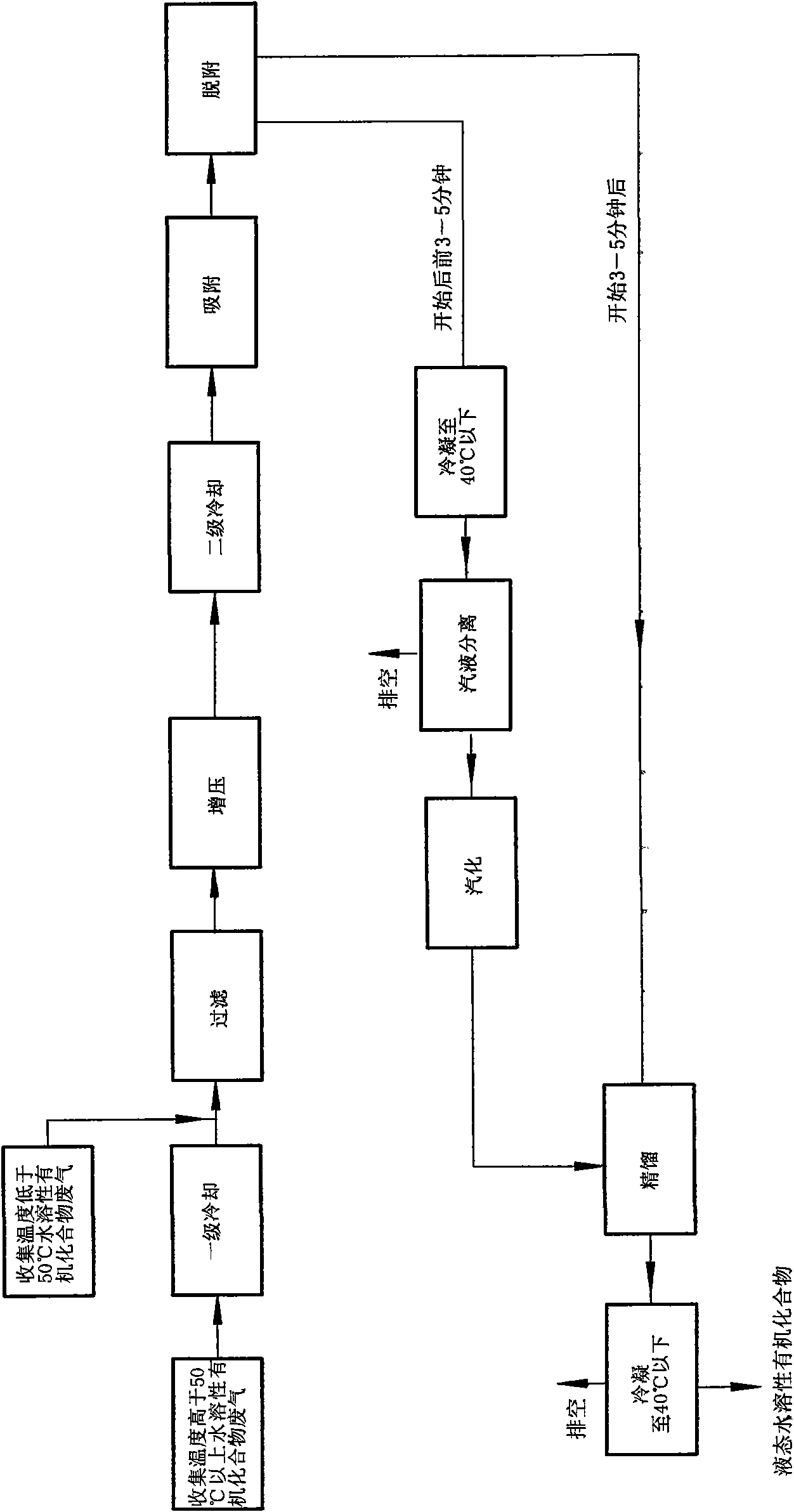

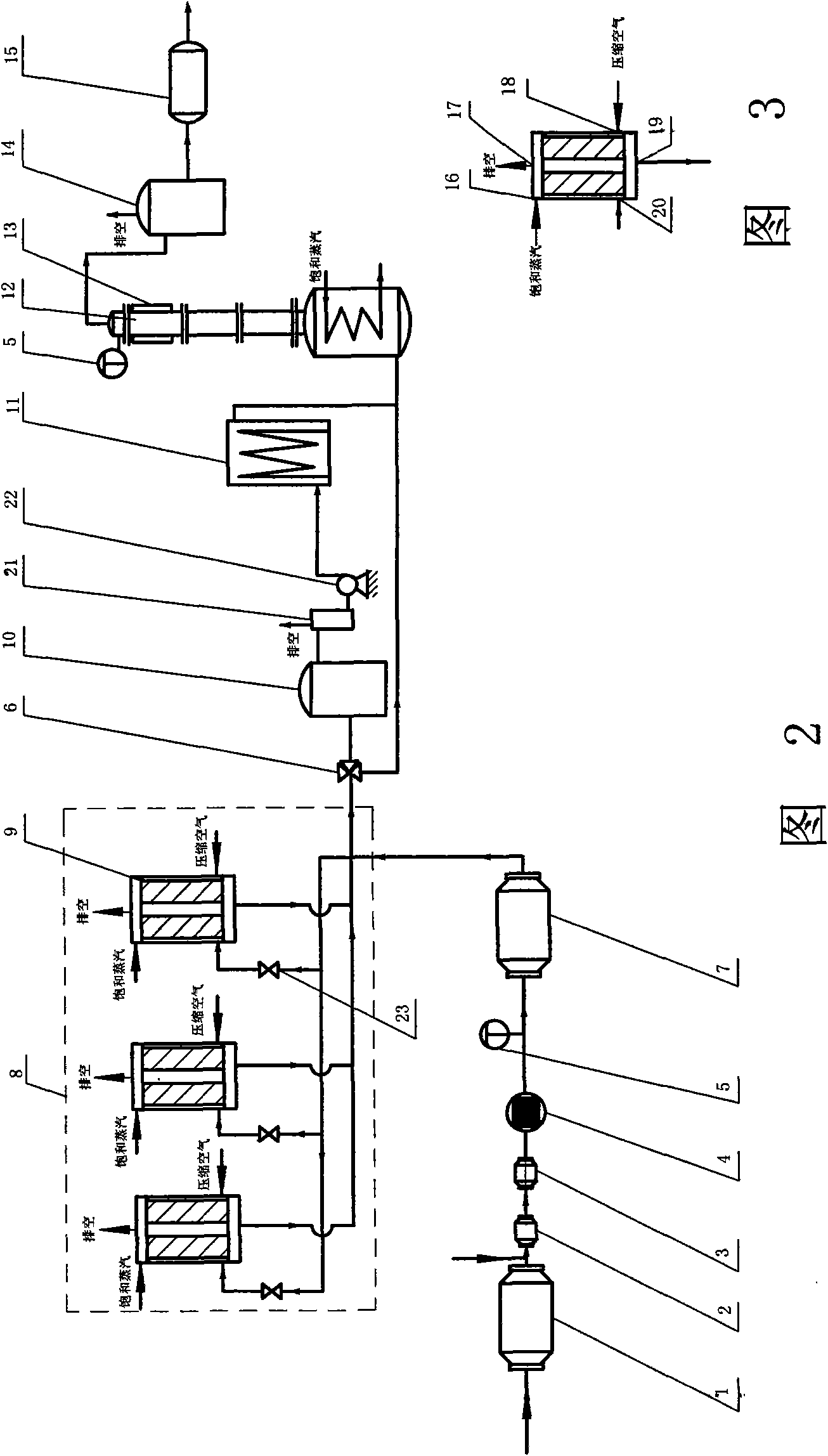

[0025] Such as figure 1 with figure 2 As shown, in general, if the water-soluble mixture contains organic compounds with multiple components, the rectification temperature is usually higher than the boiling point of the component with the highest boiling point among all the components. The above operating data are based on specific process requirements. Selection, these selections are easy to do for those of ordinary skill in the art.

[0026] A method of recovering waste gas containing water-soluble organic compounds of the present invention comprises:

[0027] (1) Collect waste gas of water-soluble organic compounds whose temperature is higher than 50°C; send the above-mentioned waste gas into the first-level surface cooler 1 to cool to 35-40°C;

[0028] (2) Collect the waste gas of water-soluble organic compounds at a temperature lower than 50°C; combine the waste gas with the cooled waste gas in step (1), and then send it to the bag filter 2 for filtration, and then sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com