Organic waste treatment system

a waste plastic treatment and organic technology, applied in the field of organic waste treatment system, can solve the problems that the treatment apparatus for waste plastics cannot be used for rubber or garbage treatment, the treatment apparatus for making feed and fertilizer cannot be used for waste plastic treatment, and it is near impossible for local small municipalities to have so many treatment apparatuses. to achieve the effect of reducing the treatment cost and facilitating the treatment of was

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

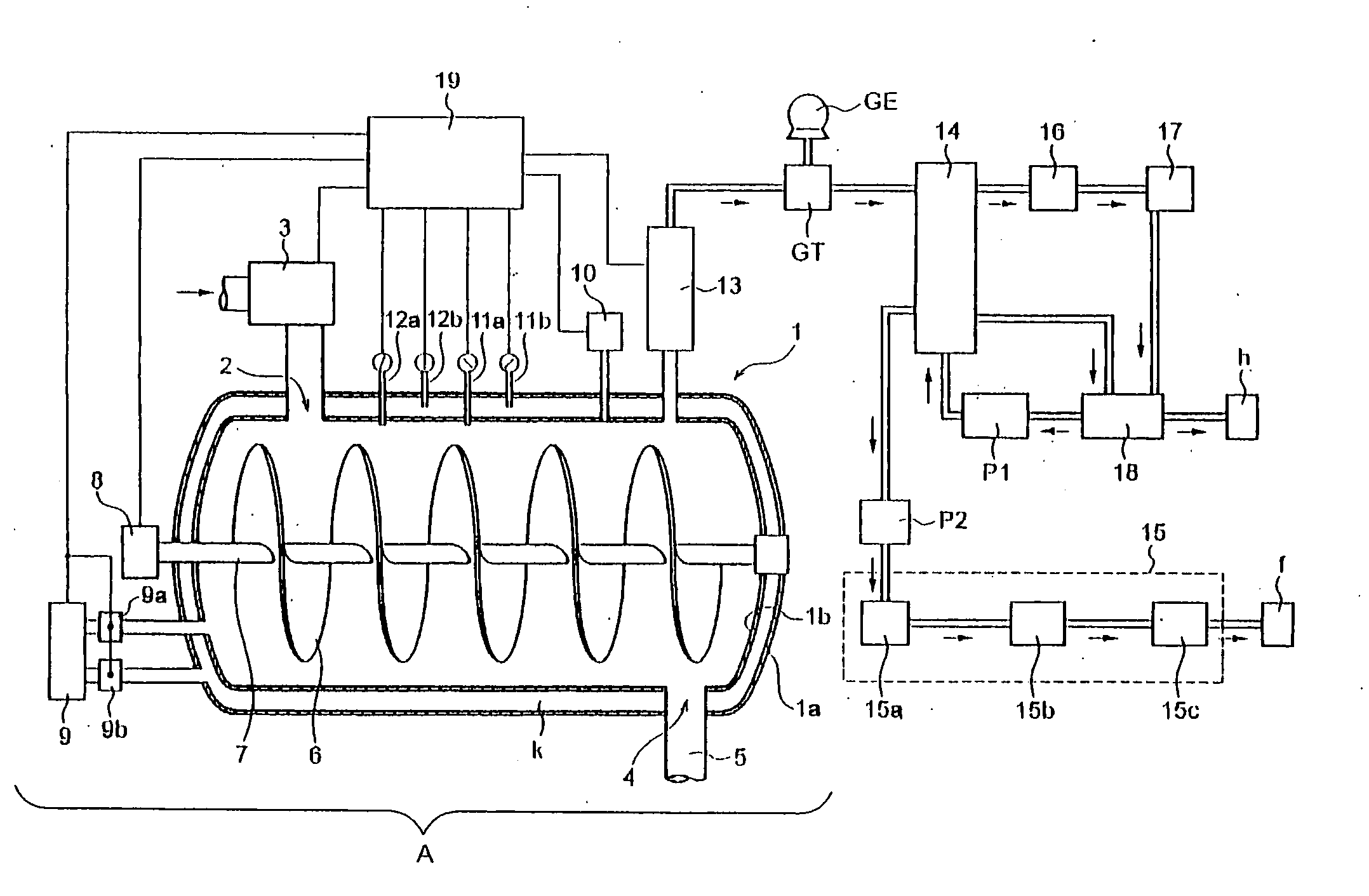

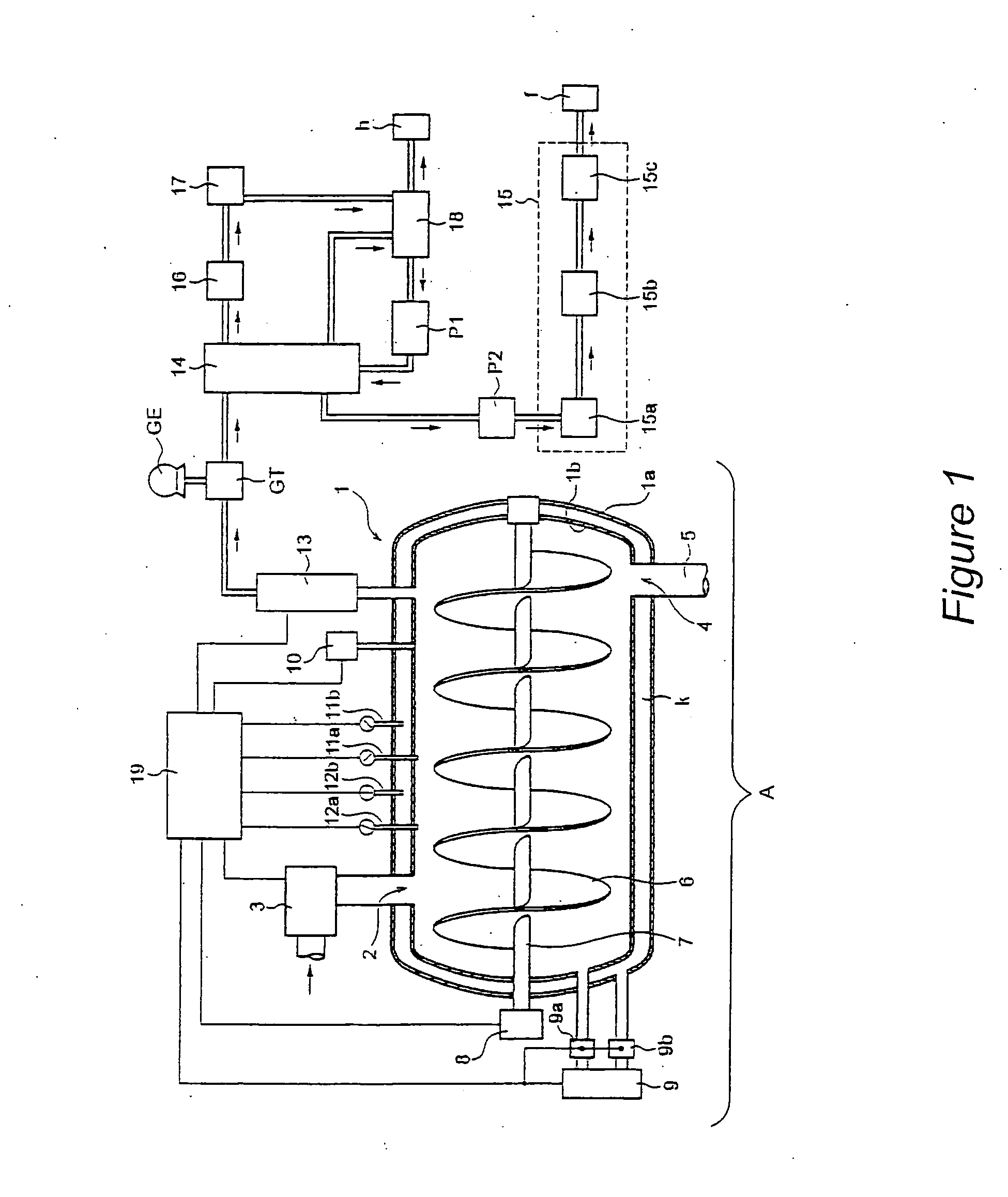

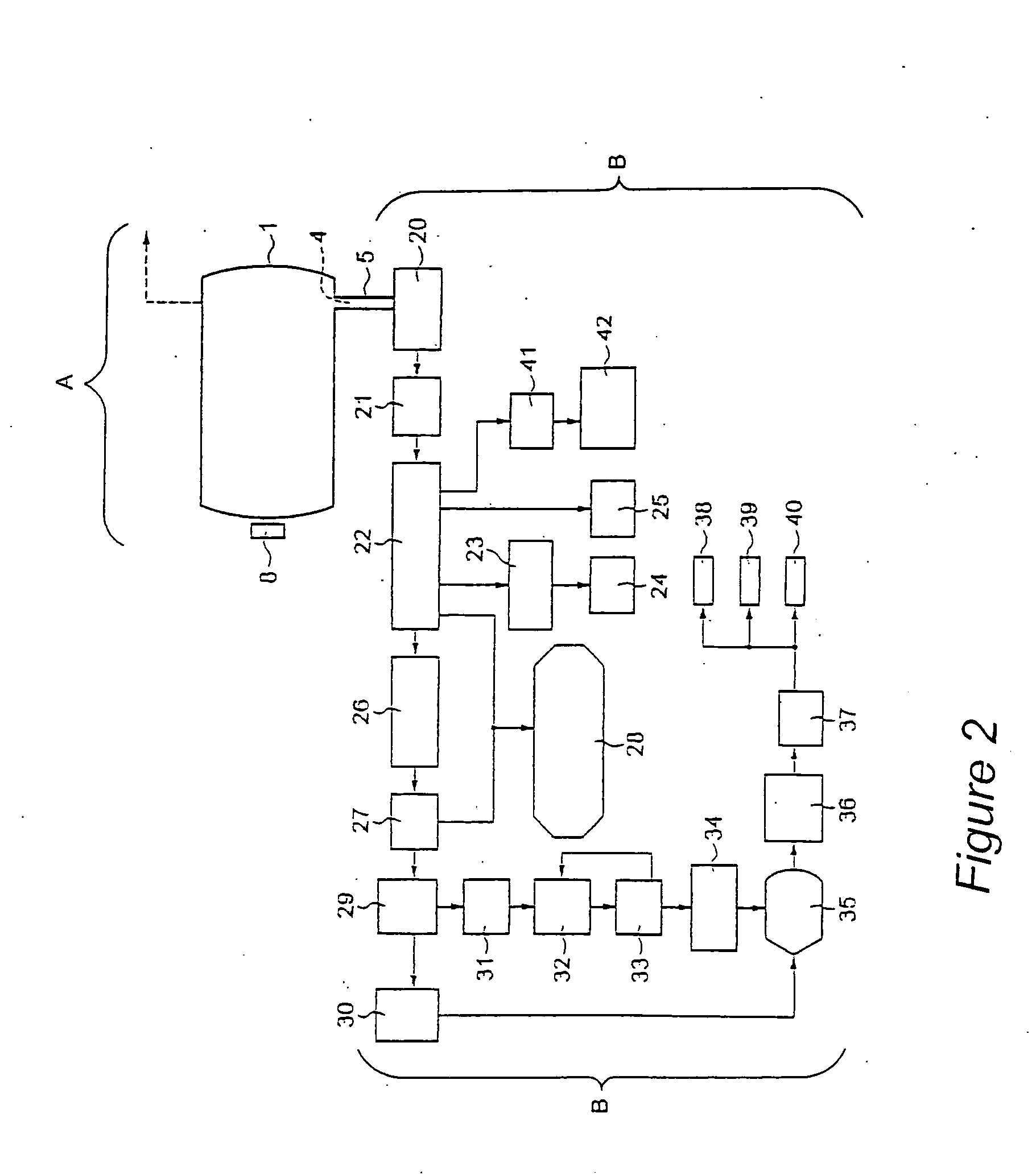

[0032]Next, an embodiment of the present invention will be described based on the drawings. FIG. 1 is a sectional view of an example of an organic waste treatment apparatus A of a waste treatment system of the present invention. FIG. 2 is a block diagram of an example of the waste treatment system of the invention into which the treatment apparatus A of FIG. 1 is integrated.

[0033]In FIG. 1, a reference numeral A designates an organic waste treatment apparatus which is a main portion of a waste treatment system of the invention, 1 designates a double-walled heat-resistant and pressure-resistant container forming the organic waste treatment apparatus A, 1a designates an outer wall of the heat-resistant and pressure-resistant container 1, and 1b is an inner wall of the same. A proper clearance k is provided between the outer wall 1a and the inner wall 1b. In the clearance k high-temperature vapor is supplied and circulates as will be described later. As the heat-resistant and pressure-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com