Fuel cell system

a fuel cell and system technology, applied in the direction of fuel cells, solid electrolyte fuel cells, electrical equipment, etc., can solve the problems of water vapor in the catalytic burner not working properly, moisture may condense on the catalyst surface, and the water vapor in the catalytic burner may saturate, so as to achieve simple composition and reduce water vapor in the catalytic burner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

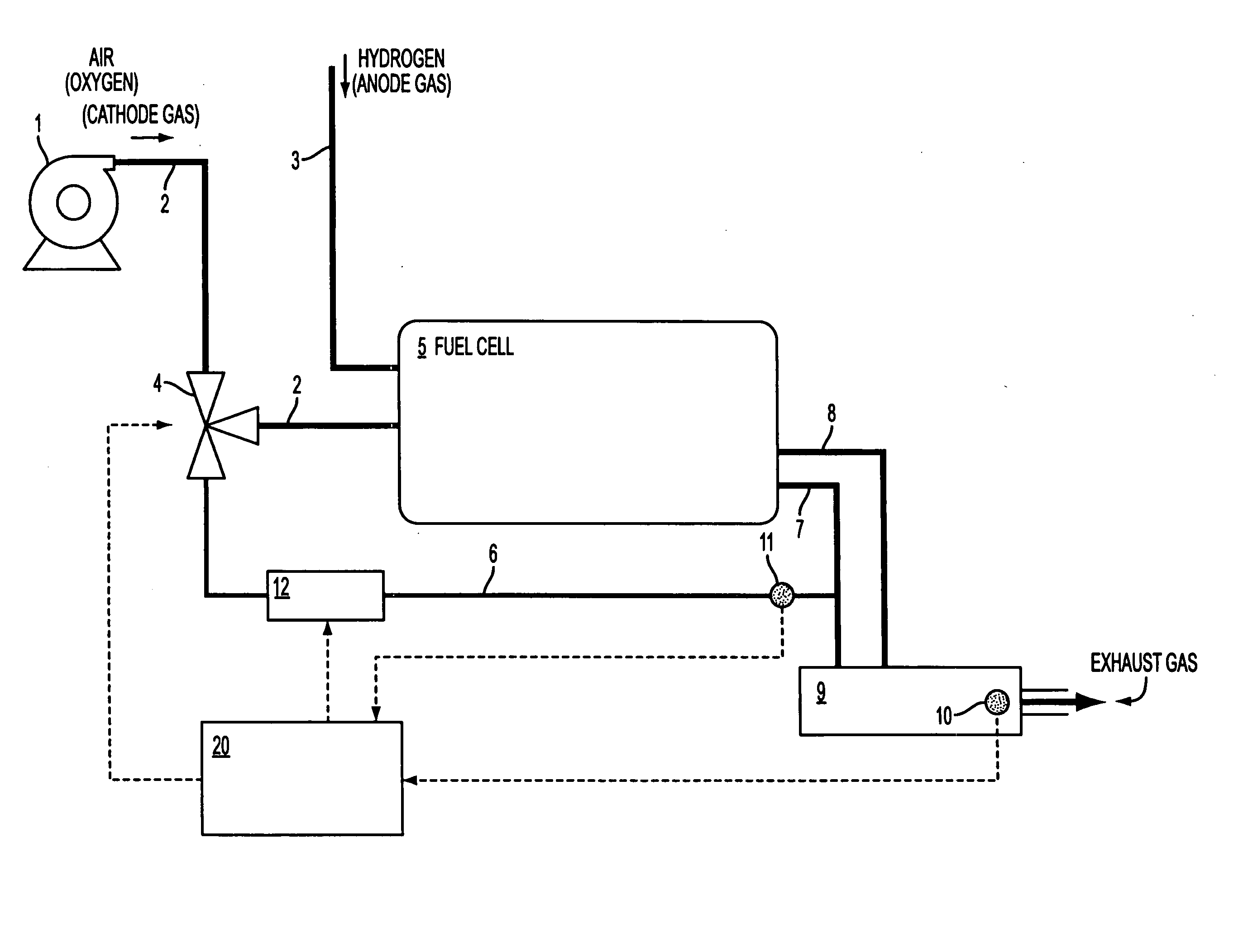

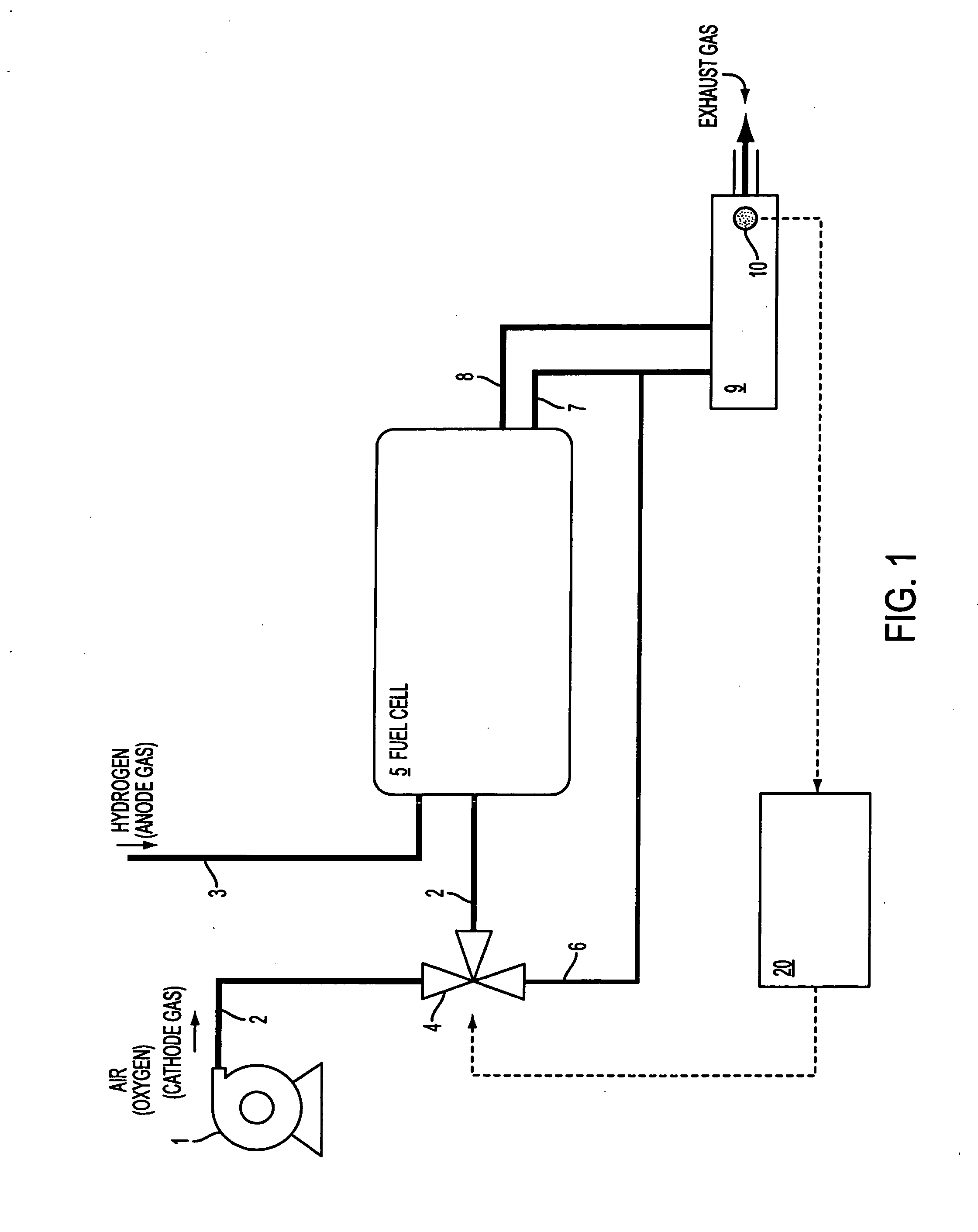

[0013]FIG. 1 shows the composition of the operation of the fuel cell system of this invention.

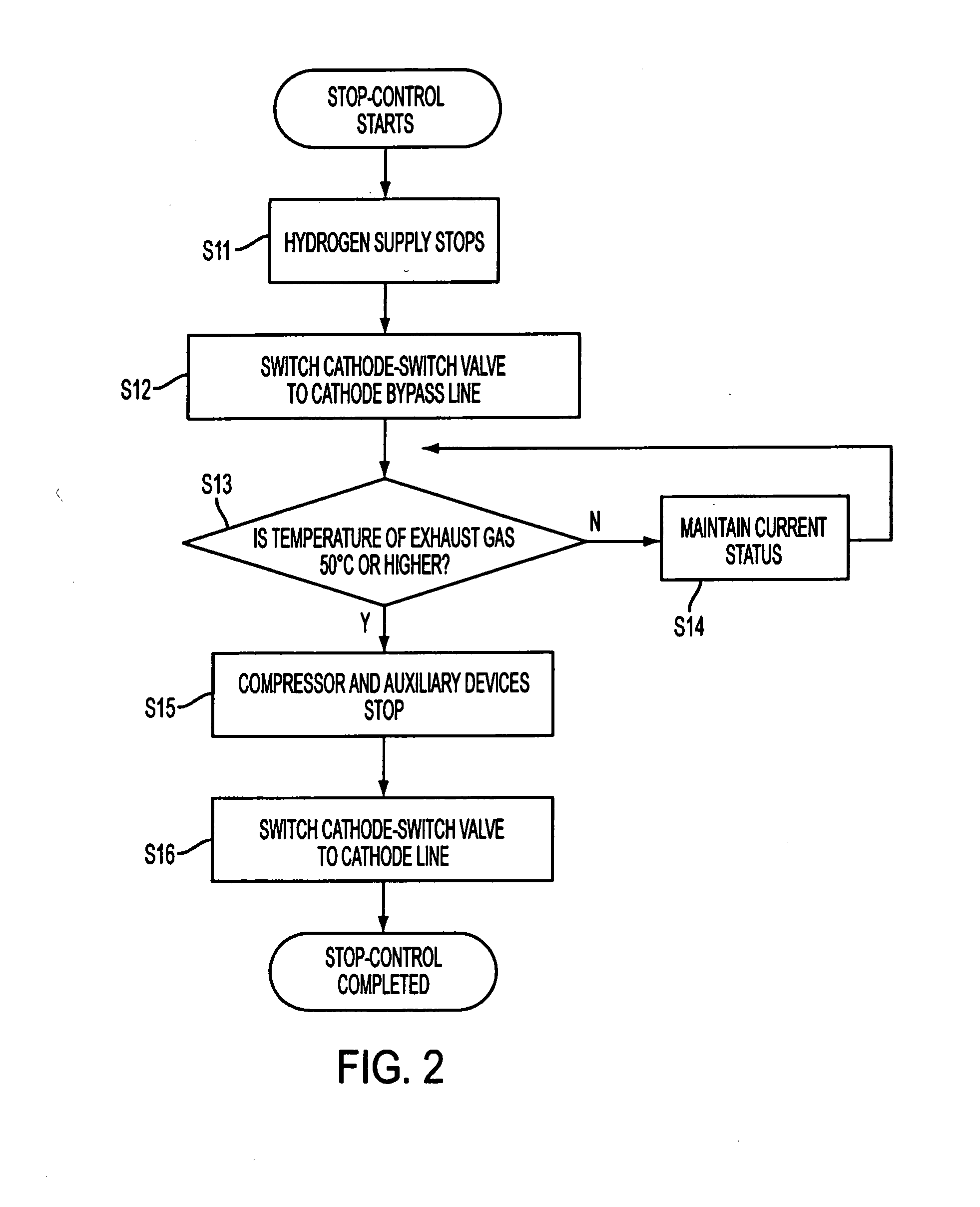

[0014] As shown in FIG. 1, a fuel cell system is comprised of a compressor 1 which supplies air (cathode gas) including oxygen gas, and a cathode line 2 which supplies air compressed by the compressor 1 to a fuel cell 5, and an anode line 3 which supplies hydrogen (anode gas) to the fuel cell 5, and a catalytic burner 9 which burns discharge hydrogen from the fuel cell 5, and a cathode exhaust gas line 7 which discharges the oxygen after a reaction from the fuel cell 5 to the catalytic burner 9, and an anode exhaust gas line 8 which discharges the hydrogen after a reaction from the fuel cell 5 to the catalytic burner 9, and an exhaust temperature sensor 10 which measures the temperature of the exhaust gas discharged from the catalytic burner 9.

[0015] A cathode switch valve 4 is provided in the middle of the cathode line 2. The cathode switch valve 4 switches the flow of oxygen to the catho...

third embodiment

[0027]FIG. 5 shows the composition of the operation of the fuel cell system of this invention. In this embodiment, the fuel cell system has an anode switch valve 13. The anode switch valve 13 switches the flow of hydrogen to the anode line 3 or an anode bypass line 14. The anode bypass line 14 is connected to the anode exhaust gas line 8.

[0028] Below, the concrete control logic of a controller 20 is explained along with the flow chart shown in FIG. 6.

[0029] Stop control of the fuel cell system is performed as follows. First, in step S31, the cathode switch valve 4 is switched to the cathode bypass line 6. The air does not go through the fuel cell 5 but instead, the non-saturated air is supplied to the catalytic burner 9.

[0030] In step S32, the anode switch valve 13 is switched to the anode bypass line 14. The hydrogen that does not go through the fuel cell 5, i.e., the unreacted hydrogen, is supplied to the catalytic burner 9. In step S33, the catalytic burner 9 operates so that t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| electrical power | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com