Method for treating titanium-silicon molecular sieve

A titanium-silicon molecular sieve, the said technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of poor activity stability, not easy to TS-1 molecular sieve, low effective titanium content, etc., to achieve volume utilization and improve environmental protection efficiency , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

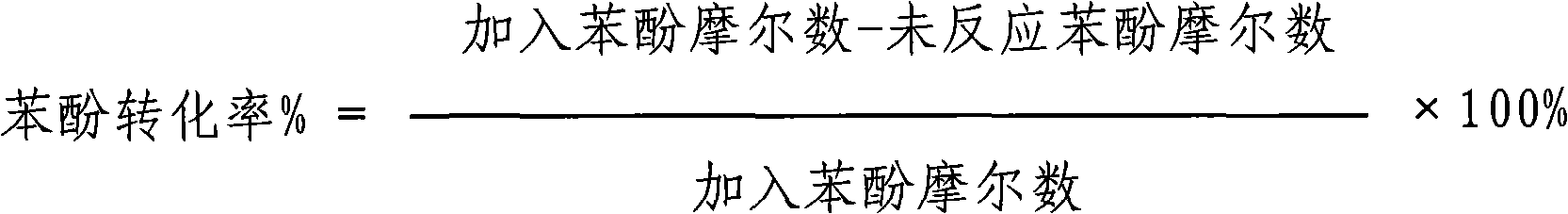

Method used

Image

Examples

Embodiment 1

[0031] Mix measured tetraethyl orthosilicate and tetraethylammonium hydroxide, add distilled water, mix well, stir at room temperature for 1.0 hour, and then stir at 75°C for 3 hours to obtain a modified solution, which consists of silicon (mol ): titanium (mol): organic base (mol): water (mol) = 1: 0: 0.85: 20 (where silicon and titanium are SiO 2 and TiO 2 count)). Take 12 grams of the TS-1 molecular sieve obtained above and mix with 10 grams of the modifying liquid evenly. The above mixture was charged into a 50 ml polytetrafluoroethylene liner and placed in a 100 ml polytetrafluoroethylene liner, and then reacted in a sealed autoclave at 175° C. for 12 hours.

[0032] The obtained product was dried at 150° C. for 120 minutes, and then calcined at 580° C. for 5 hours to obtain modified TS-1 molecular sieve A.

Embodiment 2

[0034] Mix measured amount of amorphous silica gel with tetrapropylammonium hydroxide, add distilled water, mix well, stir at room temperature for 1.5 hours, then add n-butyl titanate and stir for 0.5 hours, then stir at 70°C for 3 hours to obtain modified Liquid, its composition is silicon (mol): titanium (mol): organic base (mol): water (mol) = 1: 0.02: 0.75: 25 (where silicon and titanium are SiO 2 and TiO 2 count)). Take 10 grams of the TS-1 molecular sieve obtained above and mix with 8.5 grams of the modified liquid evenly. The mixture was charged into a 50 ml polytetrafluoroethylene liner, then placed in a 100 ml polytetrafluoroethylene liner, and then reacted at 180° C. for 24 hours in a sealed autoclave.

[0035] The obtained product was dried at 150° C. for 120 minutes, and then calcined at 650° C. for 2 hours to obtain modified TS-1 molecular sieve B.

Embodiment 3

[0037] Mix measured tetraethyl orthosilicate, tetraethyl titanate and tetrapropylammonium hydroxide, add distilled water, mix well, stir at room temperature for 1.0 hour, and then stir at 80°C for 3 hours to obtain a modified solution. Its composition is silicon (mol): titanium (mol): organic base (mol): water (mol) = 1: 0.02: 0.75: 35 (where silicon and titanium are SiO 2 and TiO 2 count)). Take 15 grams of the above-obtained TS-1 molecular sieve and mix with 13 grams of modifying liquid evenly. The mixture was charged into a 50 ml polytetrafluoroethylene liner and placed in a 100 ml polytetrafluoroethylene liner, and then reacted at 160° C. for 62 hours in a sealed autoclave.

[0038] The obtained product was dried at 135° C. for 240 minutes, and then calcined at 560° C. for 3 hours to obtain modified TS-1 molecular sieve C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com