Partial emission pump with low specific speed

A technology of low specific speed and throat, applied in the direction of pumps, pump components, non-variable pumps, etc., can solve the problems of shortening the axial size, reducing the radial size of the impeller, and high efficiency, so as to suppress the axial vortex, Effect of reducing axial size and suppressing secondary flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

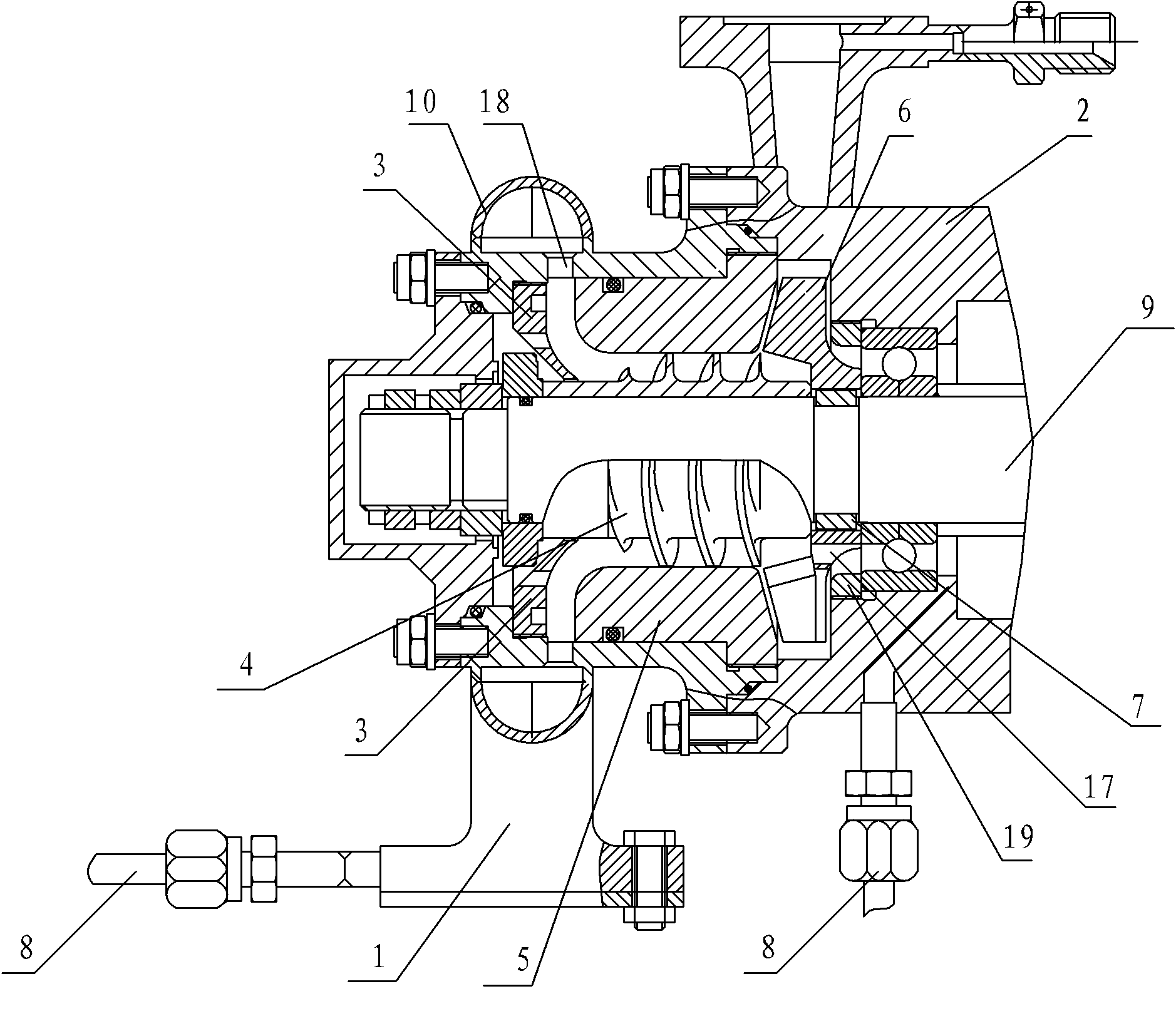

[0027] The low specific speed partial flow pump of the present invention, as figure 2 As shown, it includes an inlet assembly 1 and a housing assembly 2 .

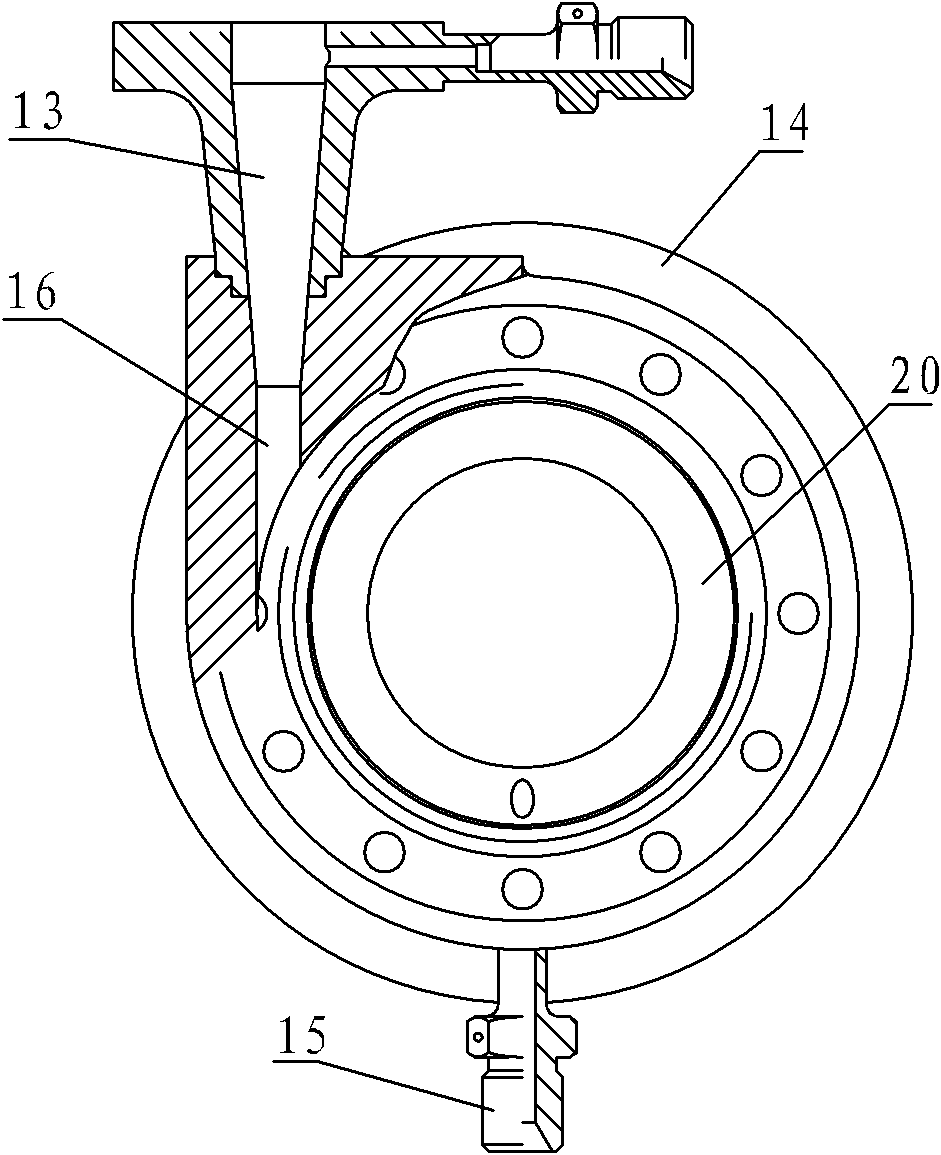

[0028] Such as Figure 5 As shown, the inlet assembly 1 is composed of an inlet pipe 12 , a liquid collecting ring 10 and an inlet housing 11 . Due to the limitation of the overall structure of the turbine bias, the pump adopts a radial inlet, the liquid collecting ring 10 and the inlet pipe 12 are welded on the inlet casing, and a certain number of small radial holes 18 are designed on the inlet casing to ensure the collection The propellant in the liquid ring enters the pump evenly.

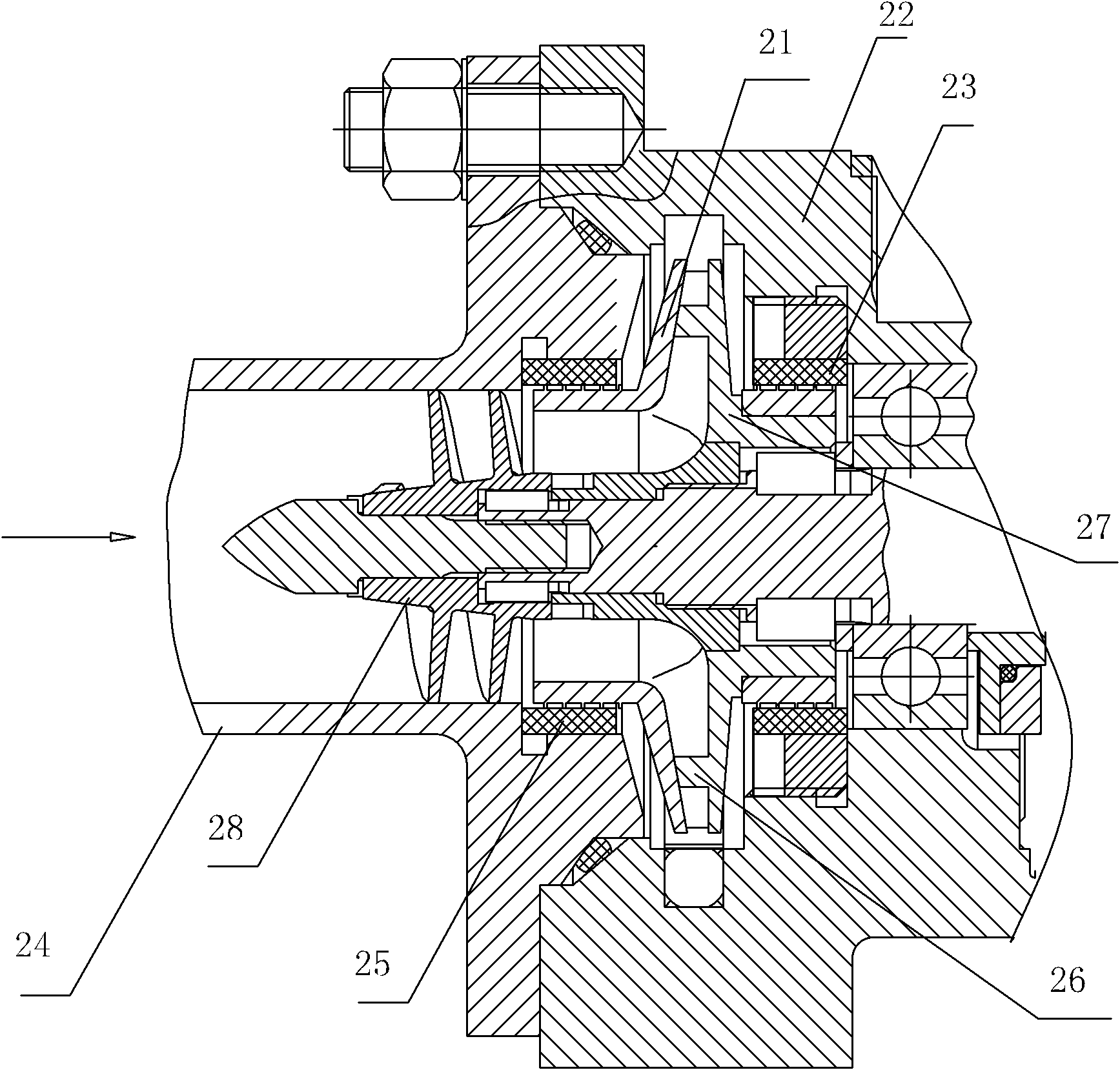

[0029] Such as figure 2 and image 3 As shown, the housing assembly includes a housing 14, a throat 16, a welding nozzle 15 and a diffuser pipe 13; the welding nozzle 15 is welded to the housing 14; the impeller 6, the induction wheel 4, the transmission shaft 9 and the guide sleeve 5 are set Inside the housing 14; the throat 16 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com