Radial-force-balanced manual control air valve

A balanced, radial force technology, applied to valve details, multi-way valves, valve devices, etc., can solve problems such as inflexible operation, unsafe hidden dangers, and wear of contact surfaces, achieving light and flexible operation, long service life, reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] specific implementation plan

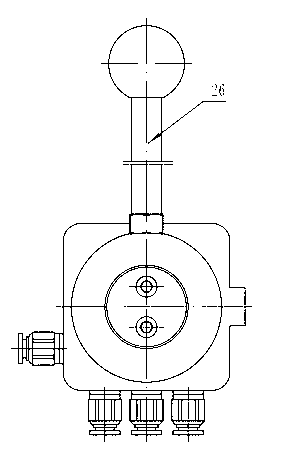

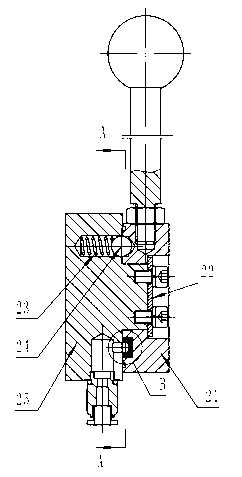

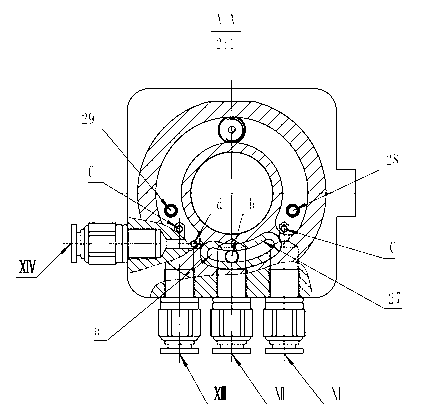

[0015] Refer to attached Figure 5 , 6 , 7, 8, radial force balance manual control air valve, including valve body 1, rotating valve core 2, handle 6, sealing gasket 5, positioning spring 4, steel ball 3 and the first, Ⅱ, Ⅲ, Ⅳ air port joints, which are characterized in that the rotating valve core 2 is placed in the inner hole of the valve body 1 and connected with the handle 6, and the valve body 1 is provided with a groove for the range of rotation of the handle 6, and the handle 6 is connected with the inner hole of the valve body 1. The rotating spool 2 is constrained axially and radially. Turning the handle 6 can make the rotating spool 2 rotate in the inner hole of the valve body 1 according to the stroke range. The steel balls 3 can fall into the positioning grooves C of the valve body 1 respectively. Two sealing pads 5 are symmetrically placed in the outer circular sealing groove of the rotating valve core 2, and the sealing pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com