Gear pump with phase dislocation gear compensation structures

A compensation structure and gear pump technology, applied to rotary piston type/oscillating piston type pump components, pumps, pump elements, etc., can solve the problem of large output flow pulsation, reduce output pulsation amplitude, improve stability, and improve flow rate The effect of output improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

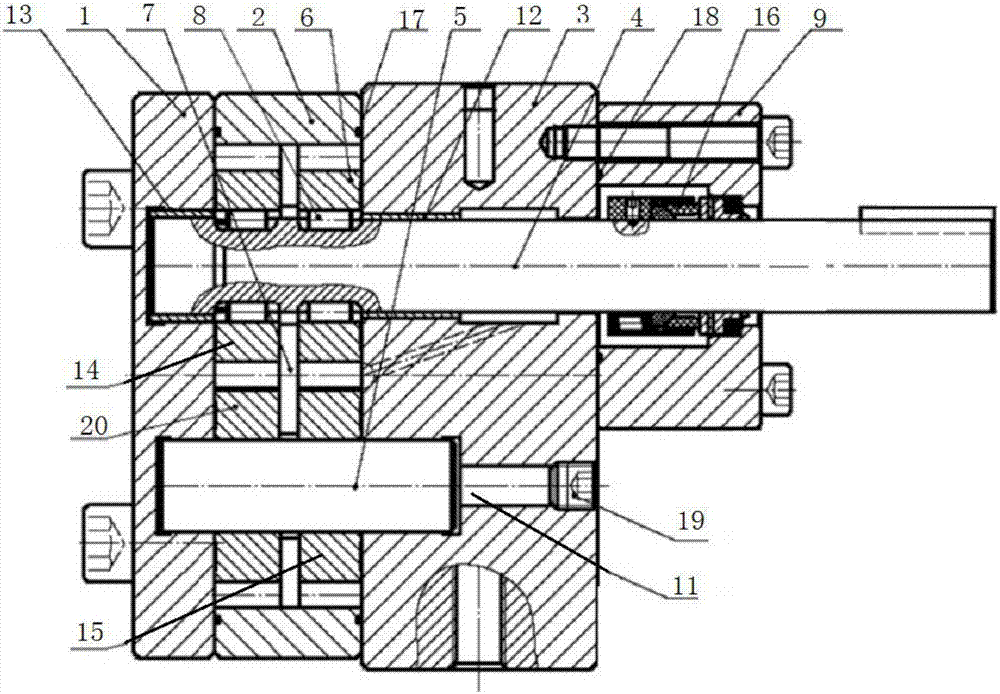

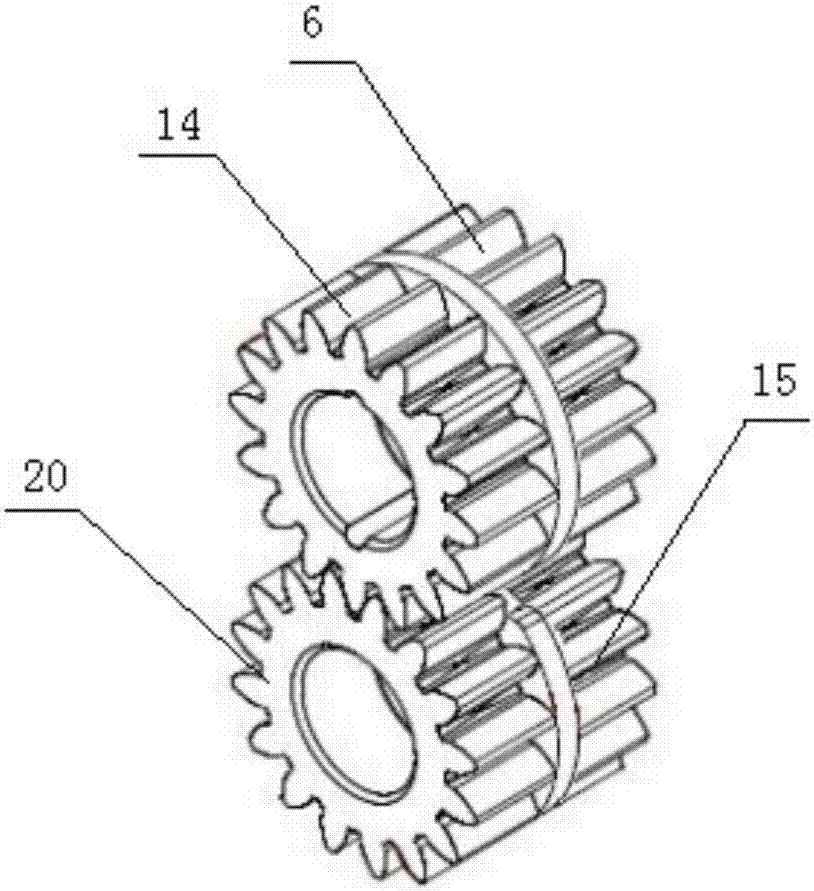

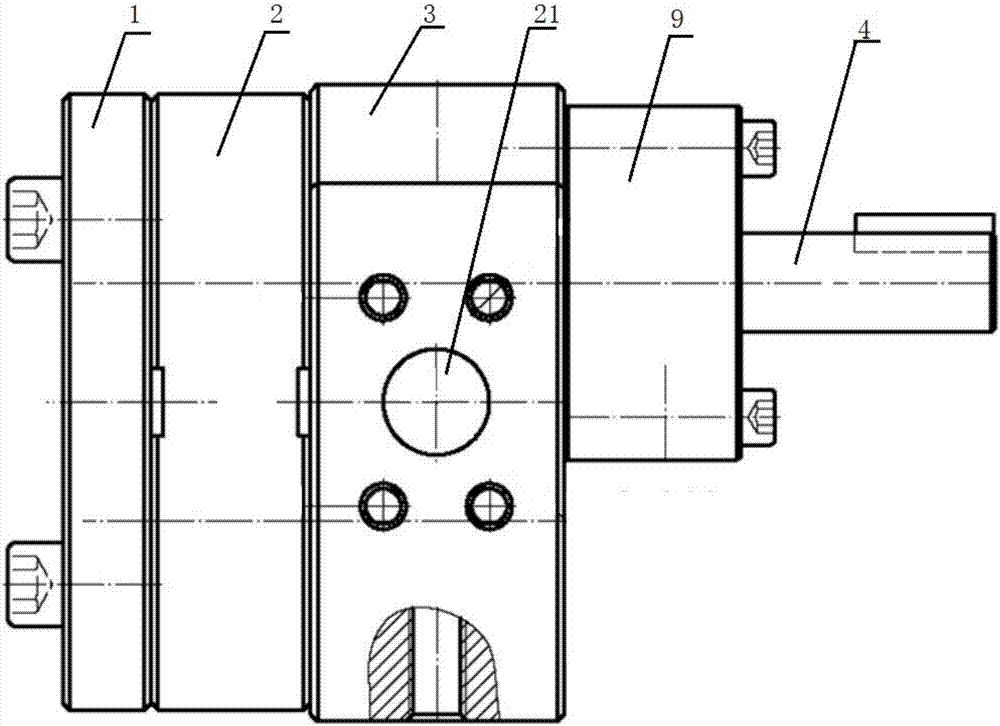

[0033] combine Figure 1~3 , the gear pump with the out-of-phase gear compensation structure mainly includes a pump body and two sets of meshing gear sets arranged in the pump body, the driving gear of the meshing gear set is fixed on the main shaft 4, and the driven gear of the meshing gear set is installed on the pin shaft 5 One end of the pin shaft 5 is fixed inside the front pump plate 3 of the pump body, and the other end is assembled with the rear pump plate 1 of the pump body. A partition 7 is arranged between adjacent meshing gear groups, and the partition 7 makes each meshing gear The two sets of gears form an independent working chamber to ensure the normal operation of each meshing gear set. The positions of the teeth of each driving gear are staggered to form a phase difference, thereby forming a complementarity. In this way, when the materials are discharged from the two pairs of gears, the pulsation waves formed by each are just opposite. , and compensate each ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com