Pedal-type shaft transmission mechanism which adopts a non-circular bevel gear

A non-conical gear and non-conical technology, applied in the direction of wheel transmission, rotary transmission, vehicle gearbox, etc., can solve the problems of unconformity with ergonomic mechanical characteristics, chain shedding and slack, poor transmission stability, etc., and achieve improvement The effect of cycling experience, reducing discomfort, and smooth transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

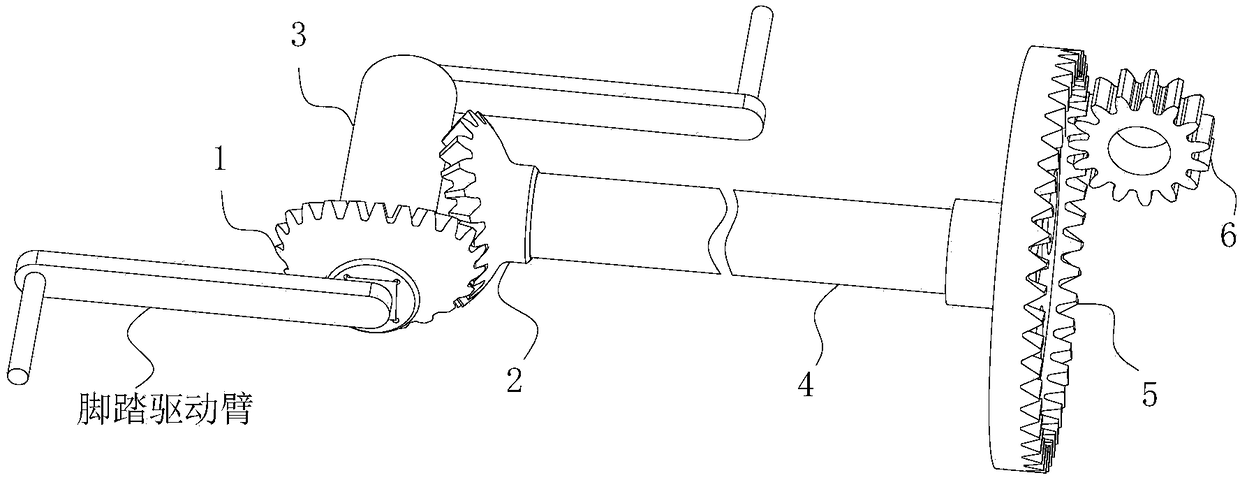

[0038] see figure 1 , a pedal-type shaft transmission mechanism using non-conical gears includes a non-conical gear pair, a pedal shaft 3, a power transmission shaft 4 and a face gear pair.

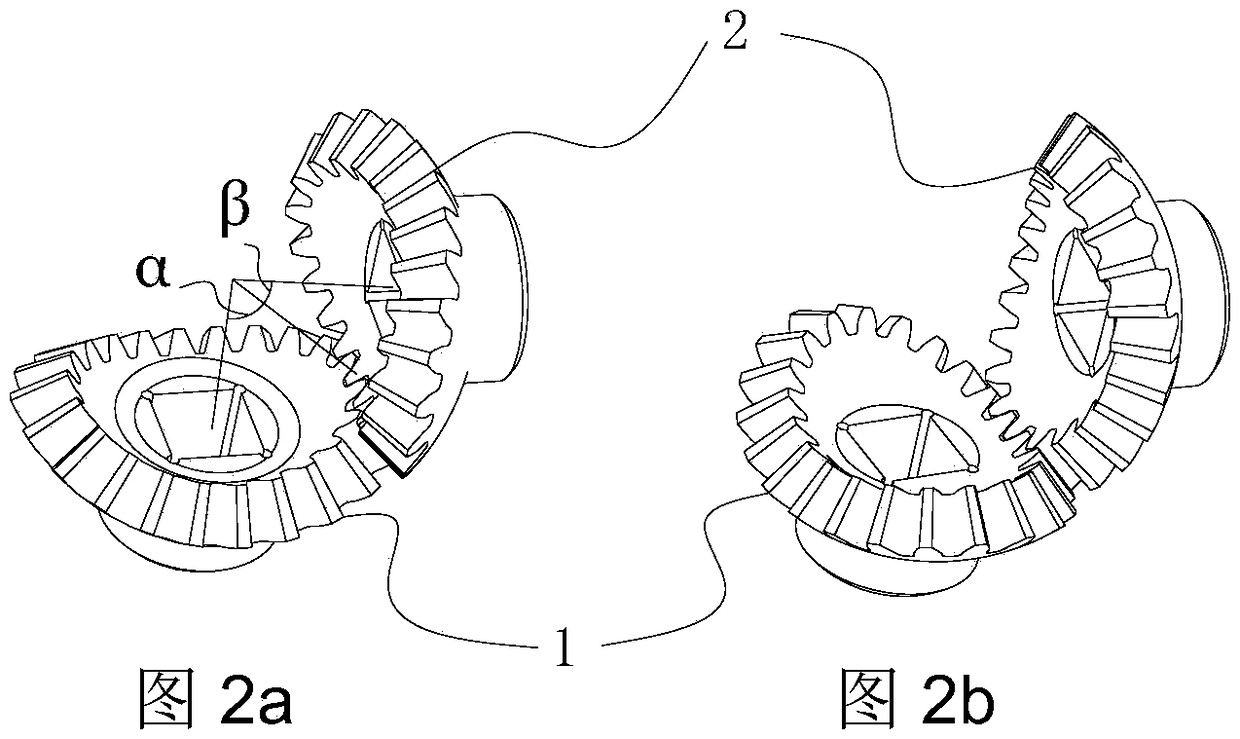

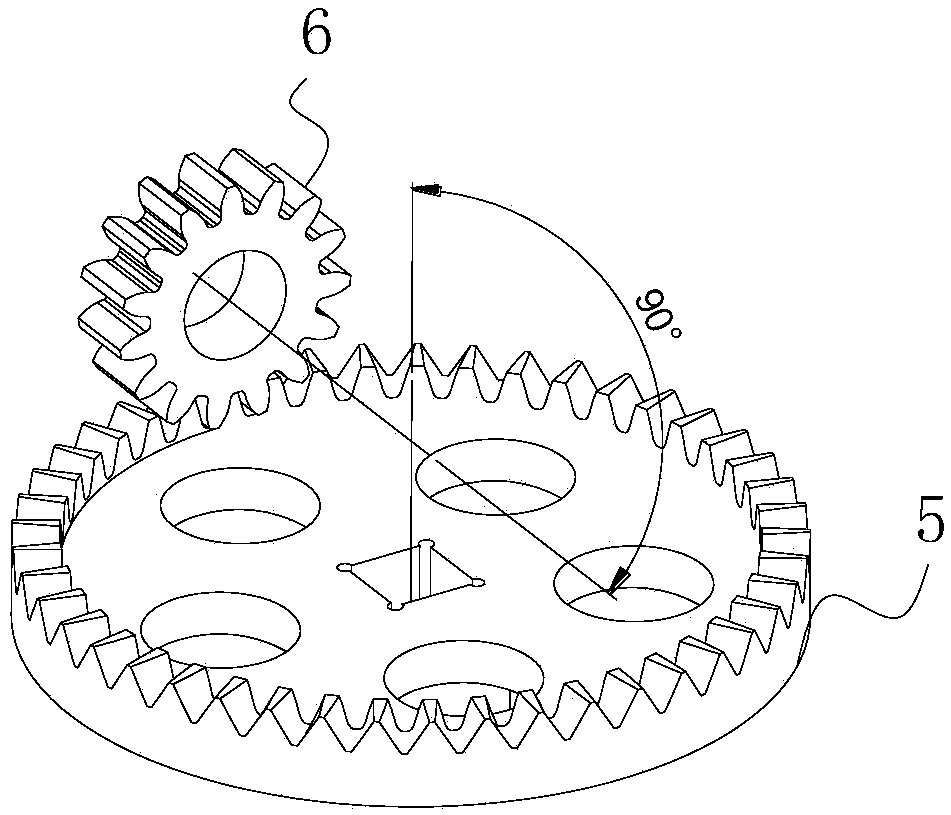

[0039] see figure 2 a and figure 2 b. The non-conical gear pair includes non-conical driving gear 1 and non-conical driven gear 2. The non-conical driving gear and non-conical driven gear have the same structure, which is an oval bevel gear pair with a long diameter part and a short diameter part. The pitch cone surface of the oval bevel gear pair is non-conical, the sum of the maximum pitch cone angle α of the long diameter part and the minimum pitch cone angle β of the short diameter part is 90°, the maximum pitch cone angle α of the long diameter part and the short diameter part The minimum pitch angle β ratio of the diameter part is 1.35. see image 3 , the shaft angle of the non-conical gear pair is 90 degrees.

[0040] The non-conical driving gear 1 is fixedly mounted on one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com