Roller positioning structure of rolling mill

A configuration structure and roll technology, which is applied to the driving device, rolls, and metal rolling stands of metal rolling mills, can solve the problems of complex claw manufacturing, expensive rolls, and difficult disassembly, and achieve convenient roll replacement and roll Low risk of cracking, effect of simple contour

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

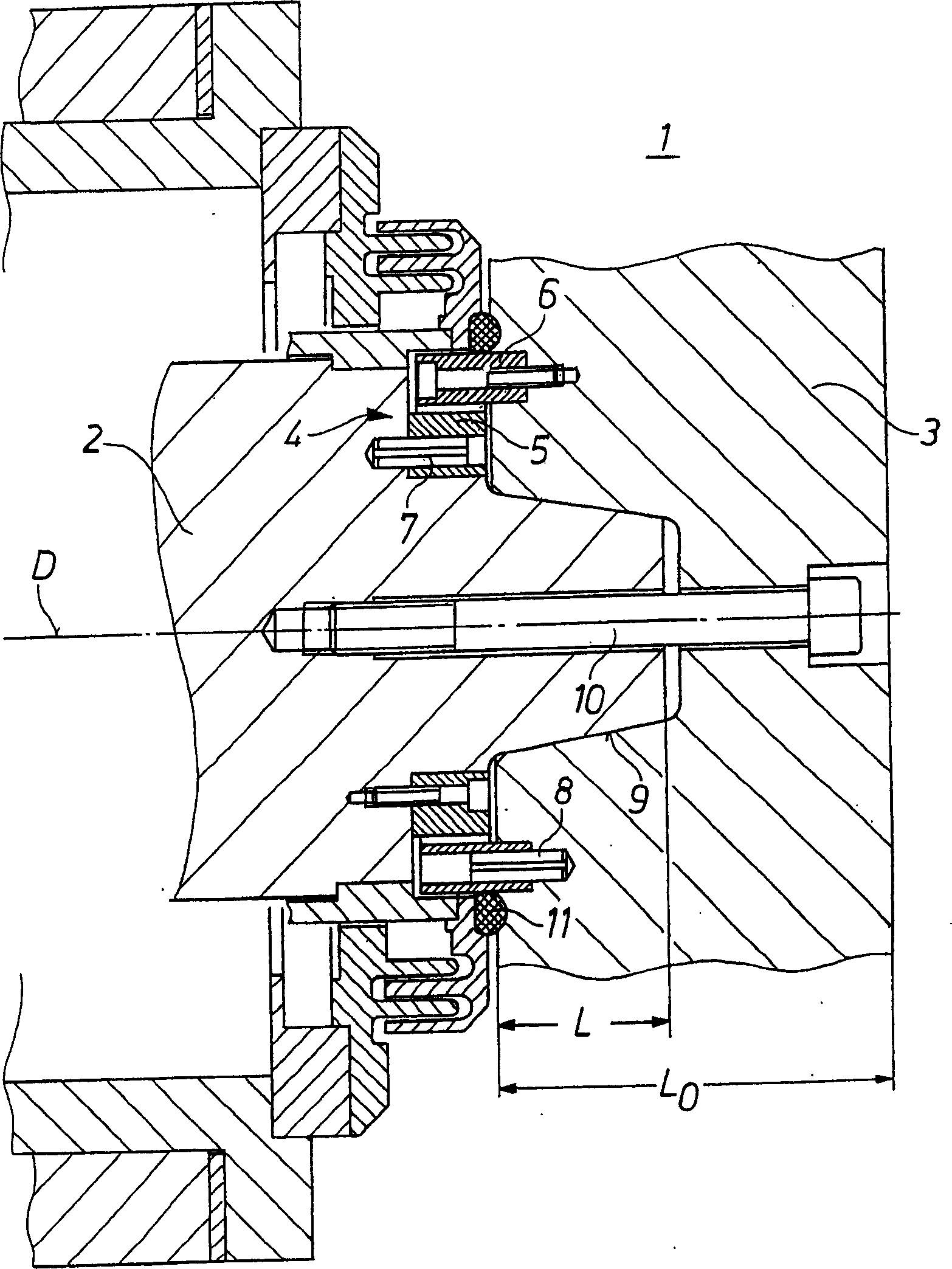

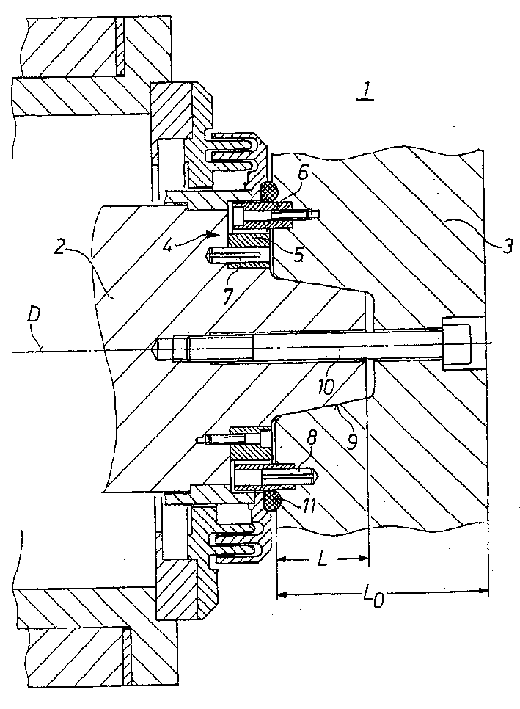

[0023] The roll arrangement 1 has a roll shaft 2 , which is rotatable about an axis D of rotation. On one axial end of the roll shaft 2 (the right end in the figure), a roll 3 is fixed. The centering of the roll 3 relative to the roll shaft 2 is effected via a conical centering mechanism 9, ie via a conical seat, which connects the two aforementioned parts to one another. The fastening of the roll 3 on the roll shaft 2 is effected by a threaded connection 10 , which here is a single screw whose axis is identical to the axis of rotation.

[0024] To ensure good centering of the roll 3 relative to the roll shaft 2 and to ensure good concentric rotation, the length L of the conical centering means 9 covers a substantial part of the entire axial extension Lo of the roll 3 . In this case, the length L of the conical centering means 9 should amount to at least 30% of the axial extent Lo of the roll 3 . This has just ensured that the bending force of roll 3 is borne by the relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com