Pipeline connecting pipe fitting

A technology for connecting pipe fittings and connecting pipes, which is applied in the direction of pipe/pipe joint/pipe fitting, sealing surface connection, passing element, etc., can solve the problems of anti-vibration, low anti-loosening performance, poor reliability of sealing performance, low connection sealing pressure, etc. Achieve the effect of reliable connection loosening ability, high disassembly torque, and high connection sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

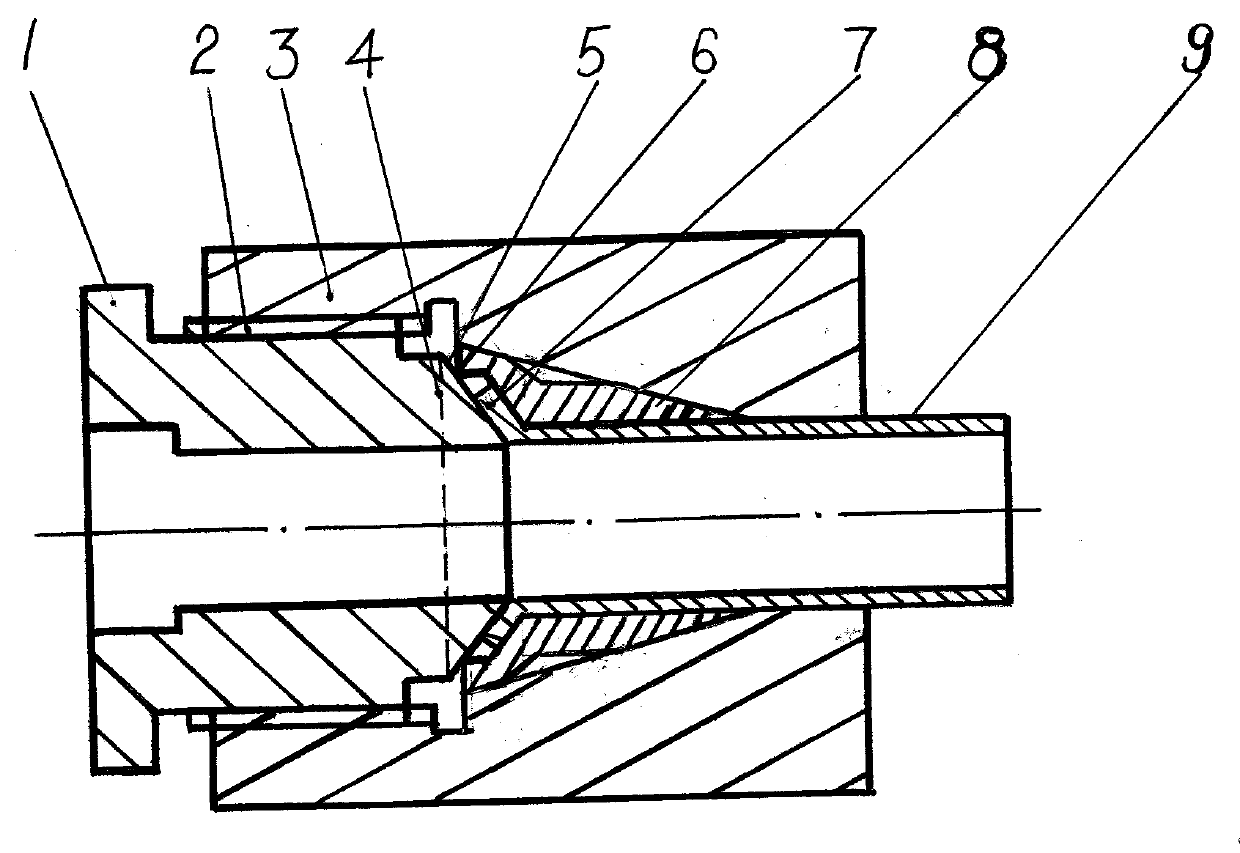

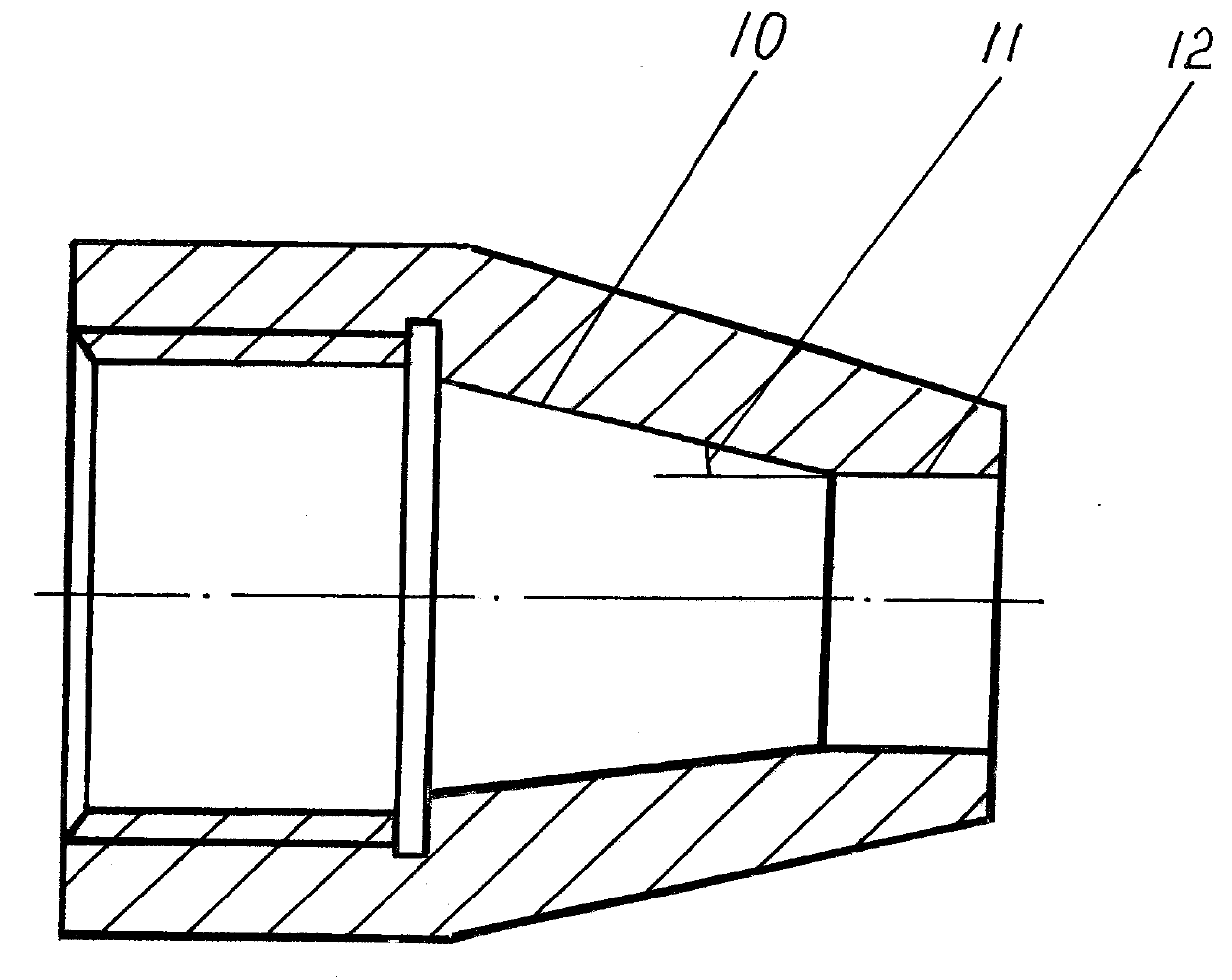

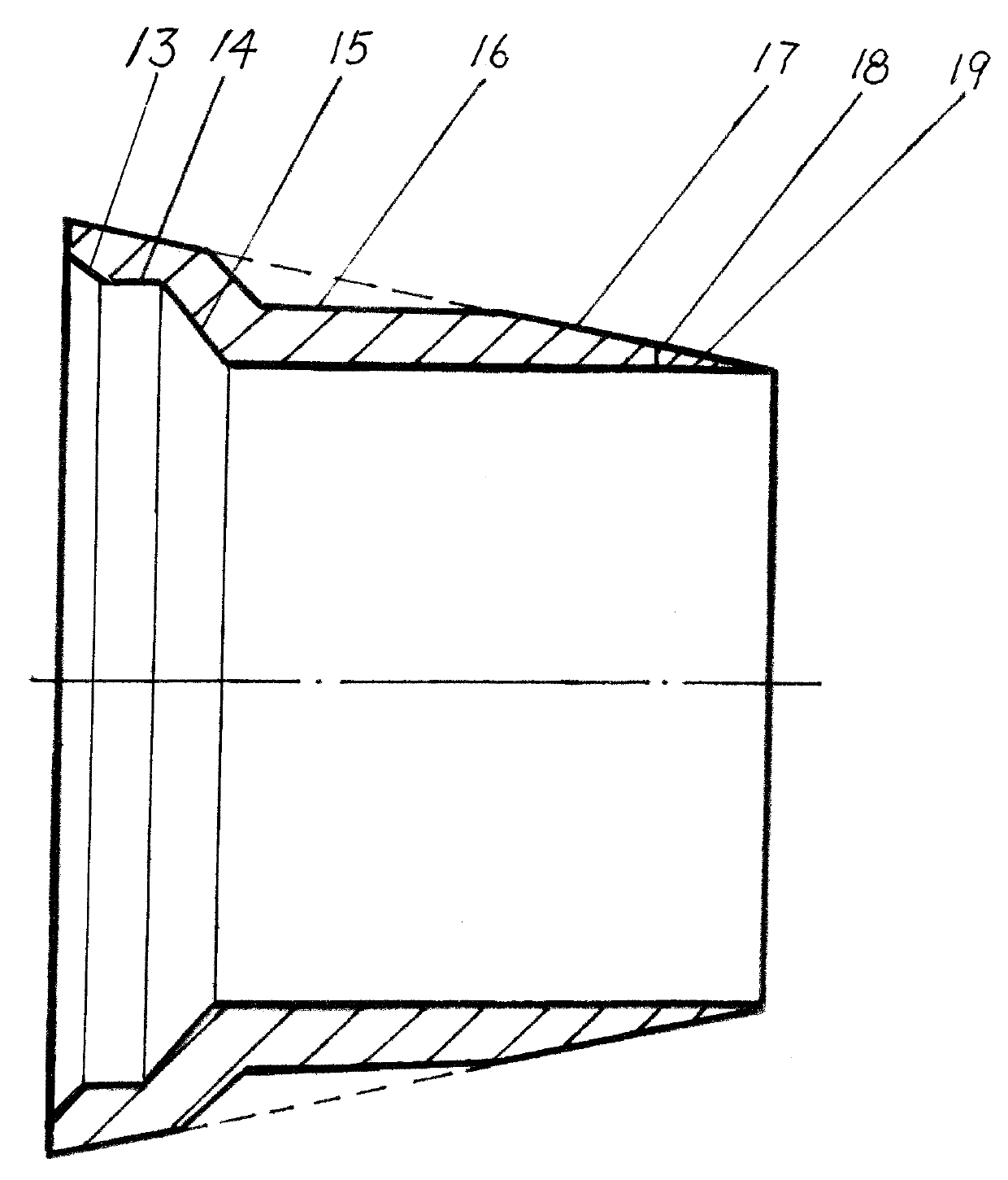

[0039] Example: figure 1 It is a schematic diagram of the connection structure of the present invention. The connecting pipe fittings of the present invention include a nut 3 and a ferrule 8. When connecting, the nut 3 and the ferrule 8 are sequentially set on the connecting pipe 9, the bevel angle 18 of the ferrule is directed toward the inner taper hole of the nut, the bevel angle 11, and the connecting pipe 9 Expand the bell mouth 7 of the connecting pipe at the end of the pipe, pull the connecting pipe 9 lightly, pull the ferrule 8 into the inner taper hole 10 of the nut through the bell mouth 7 of the connecting pipe, and rotate the nut 3 several times left and right until the hand feels that it cannot be pulled, so that the connection The tube bell mouth 7 and the ferrule inner tapered hole horn groove 15, the ferrule sleeve hole wall 19 and the outer wall of the connecting pipe 9, the ferrule outer cone slope 17 and the nut inner cone hole 10 are mutually fitted togeth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com