Wedgethread pipe connection

A threaded pipe and threaded technology, which is applied in the field of wedge-shaped threaded pipe connection, can solve problems such as the inability to close the tooth crest gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

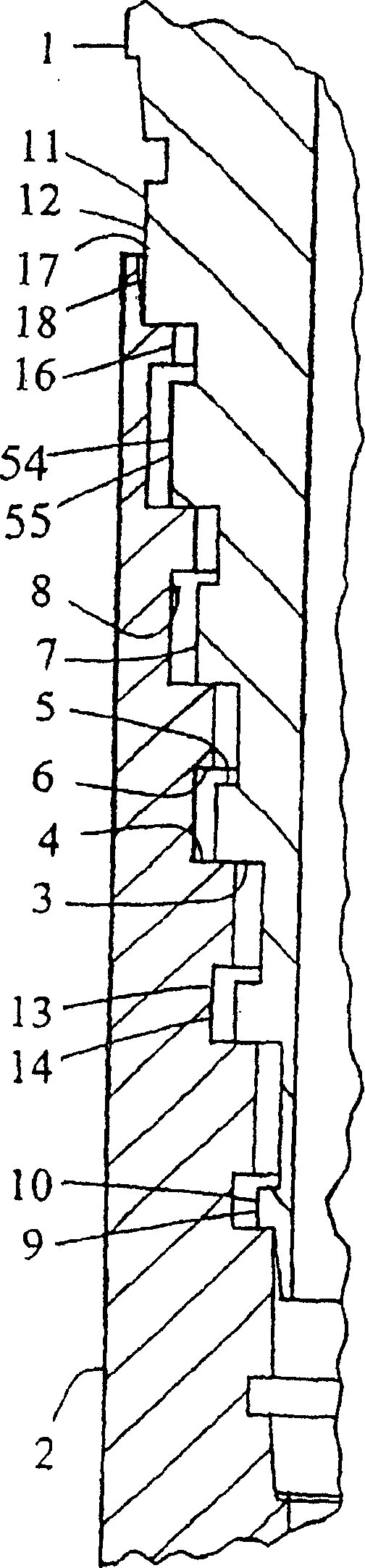

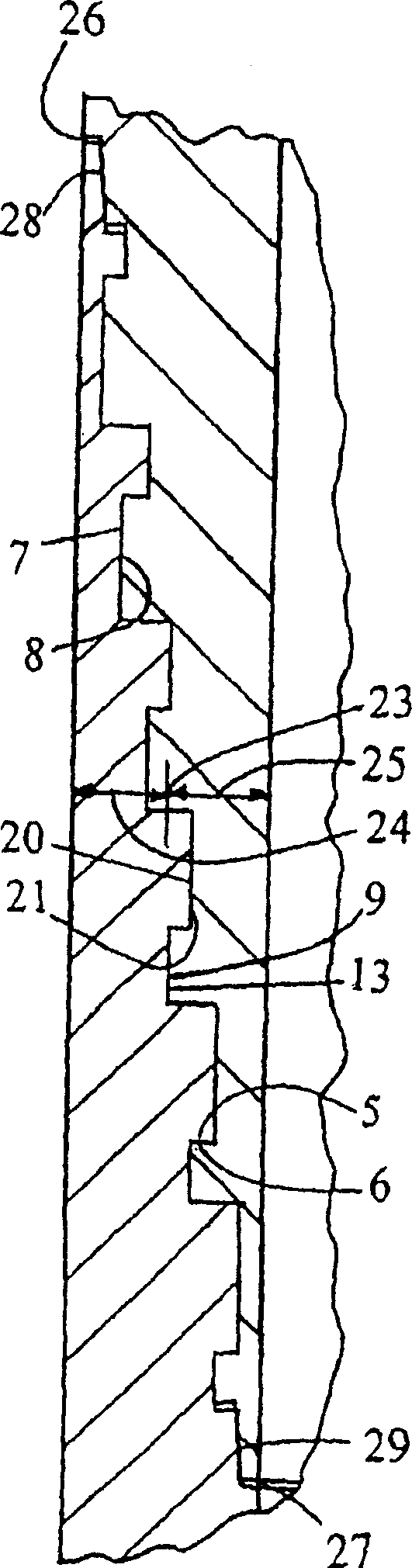

[0092] figure 1 Indicates the male thread (1) at the embedded position in the female thread (2), so that the helically formed male thread embeds the thread flank (3) and the weight of the pipe joint on which it is formed, by the helically formed The female thread is embedded in the thread side (4) for support. The male thread load thread flank (5) and the female thread load thread flank (6) do not touch each other. The embedded position is maintained by lowering the male thread into the female thread without rotation, wherein the male thread turns pass down through the female thread turns until the male thread recess flank of each turn is diametrically equal to the female thread. The thread insert flank contact is too small for it to pass through, so that the pin insert flank presses against the box insert flank and the pin crest (7) is aligned horizontally within the box root (8) . The roots and crests are preferably formed parallel to the connection axis in order to preve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com