Method for eliminating broaching elastic deformation of high-temperature alloy turbine disk

A high-temperature alloy and elastic deformation technology, which is applied in the field of mechanical processing, can solve the problems of affecting product quality, increasing the elastic deformation of the turbine wheel groove, and poor overall rigidity, so as to improve product quality, eliminate elastic deformation, and eliminate the effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0018] Specific implementation mode one: combine Figure 4 Explain, the superalloy turbine disc broaching elastic deformation elimination method of the present embodiment, said method is realized in this way:

[0019] Step 1: Segmented fine broaching: first divide the profile of the wheel groove of the superalloy turbine disc to be broached into several broaching segments, and then carry out fine broaching on each broaching segment (reduce the The tooth cutting edge is wide, which reduces the broaching force and reduces the springback by 50%. The principle of division can be determined according to the elastic deformation of the finishing broach after broaching. The segmented finishing broaching has changed the previous method of full-tooth broaching , divide the profile line into several broaching parts for broaching, and reduce the cutting length);

[0020] Step 2: The broaching tool teeth use two teeth as a group to complete a tooth lift for anti-springback broaching; afte...

specific Embodiment approach 2

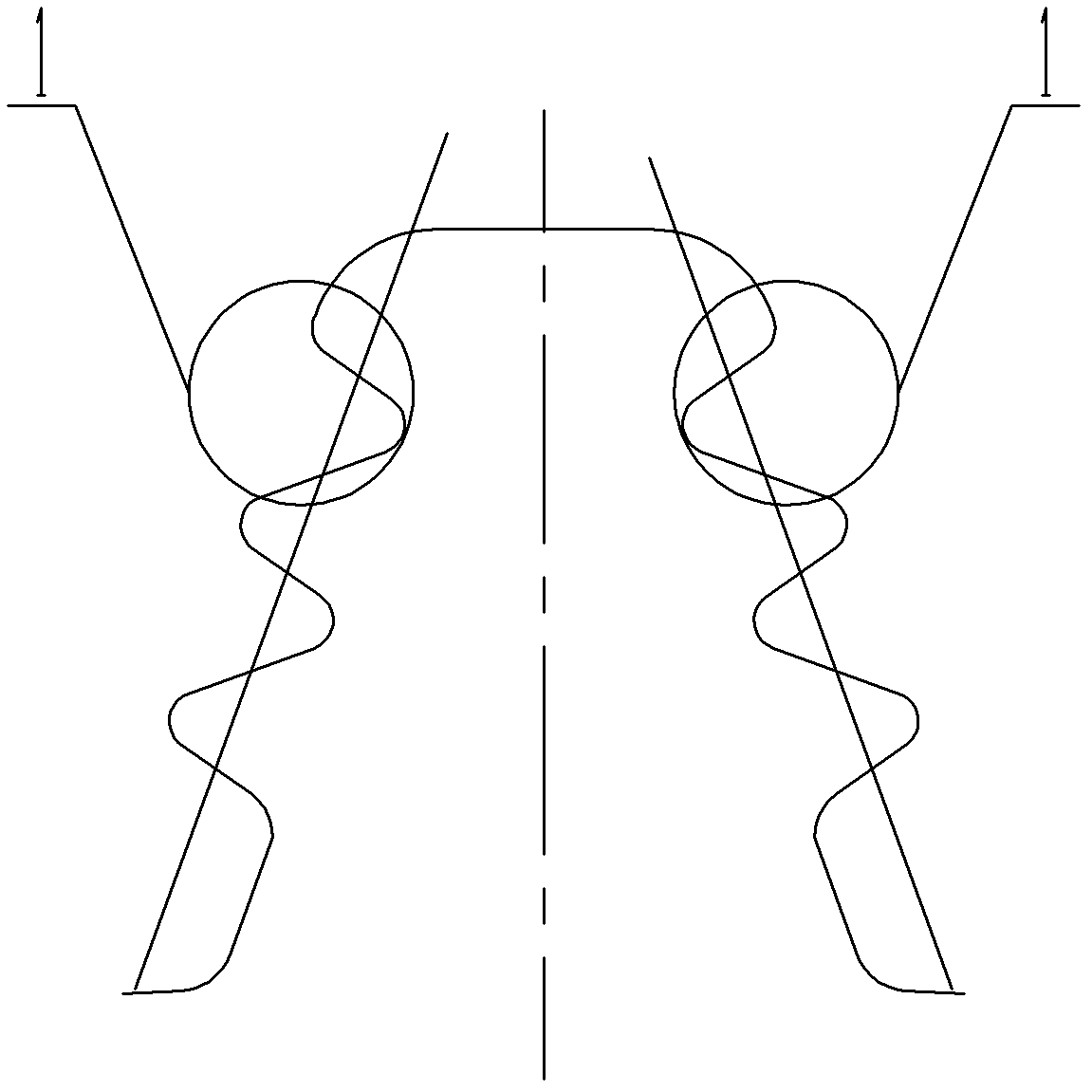

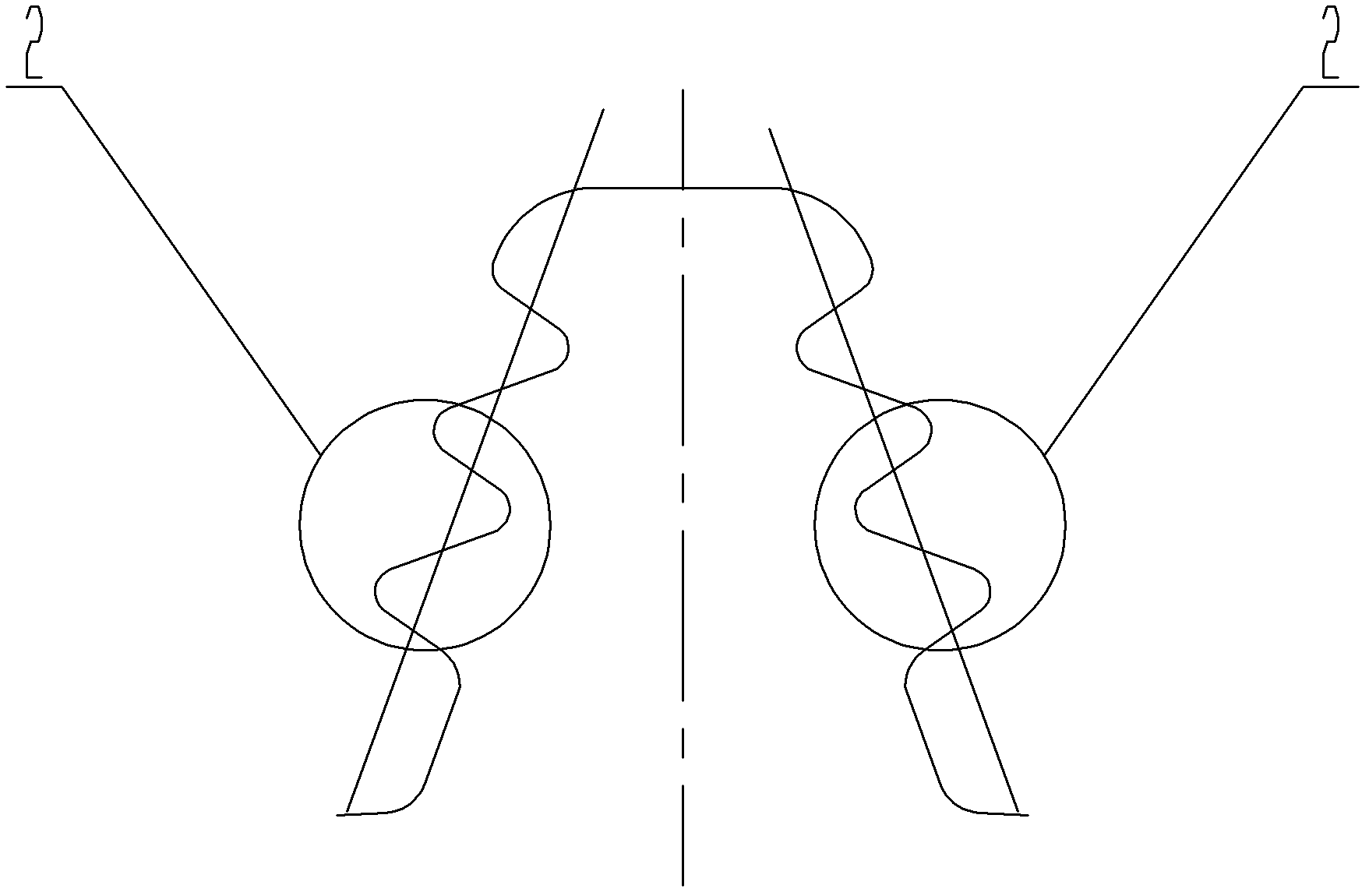

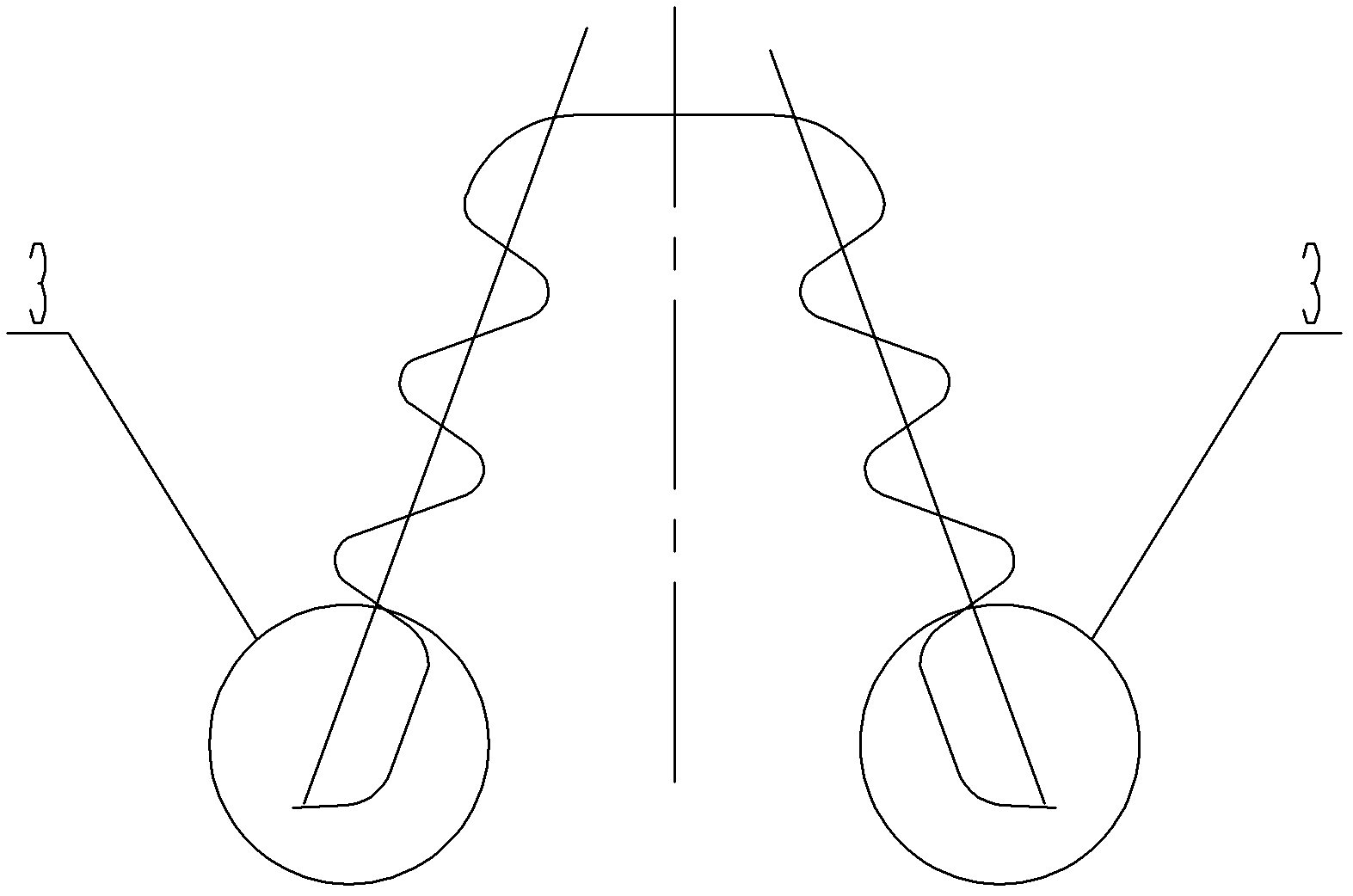

[0023] Specific implementation mode two: combination Figure 1-Figure 3 Description, in step one of the present embodiment, the profile line of the wheel groove of the superalloy turbine disk to be broached is divided into three broaching sections, and the three broaching sections are respectively the first broaching section 1, the second broaching section Cutting section 2 and the third broaching section 3, the profile line near the bottom of the wheel groove of the superalloy turbine disk is set as the first broaching section 1, and the profile line at the middle section of the wheel groove of the superalloy turbine disk is set Set as the second broaching segment 2, the profile line near the top of the wheel groove of the superalloy turbine disc is set as the third broaching segment 3; When cutting the teeth, the tooth entity widths of the second broaching section 2 and the third broaching section 3 are 0.1mm smaller than the maximum entity width of the finishing broach; Wh...

specific Embodiment approach 3

[0024] Specific embodiment three: In step two of this embodiment, the broaching force of the anti-rebound broach is:

[0025] F=CF·af·∑aw·Ze·K1·K2·K3·K4,

[0026] In the formula, F-the broaching force of the anti-rebound broach, Kg;

[0027] af-tooth lift, mm;

[0028] ∑aw-cutting edge width of each tooth of anti-springback broaches, mm;

[0029] Ze-the number of working teeth of the anti-springback broach, Ze=L / t+1, where L is the broaching length, mm; t is the tooth pitch;

[0030] CF - working material coefficient;

[0031] x-index;

[0032] K1, K2, K3, K4-respectively represent the correction coefficients of the broach wear degree, cutting fluid, broach rake angle and back angle. Other method steps are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com