Porous arch bridge water bag pre-pressing construction method

A construction method and preloading technology, which is applied to bridges, bridge construction, infrastructure engineering, etc., can solve problems such as potential safety hazards, time-consuming and labor-consuming, sand or gravel bagging, and a large amount of manual work, so as to ensure construction safety and improve construction efficiency. The effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A water bag preloading construction method for a porous arch bridge, comprising the following steps:

[0027] S1: Preloading control tonnage and load classification. According to the requirements of "Technical Specifications for Highway Bridge and Culvert Construction", the preloading coefficient is set to 1.2, and the preloading weight is calculated according to 1.2 times the upper load of each span;

[0028] S2: Water bags are used for preloading, and water is flushed in the water bags. The construction area of porous arch bridges is mostly close to rivers and lakes, and the water source is sufficient. Custom water bags can be used for preloading. The water bags are easy to lift and place. The water bag can be filled with water, and the water in the water bag can be discharged when unloading;

[0029] S3: Preload implementation and observation;

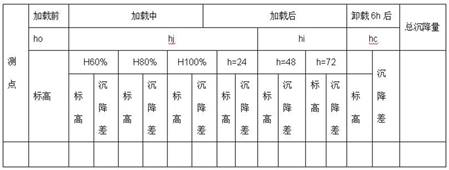

[0030] S4: Monitoring of foundation and support preload.

[0031] In the solution of the present invention, in the step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com