Method of eliminating driving gap and resilient deform in heavy load gearbox

A technology of elastic deformation and gearbox, applied in the direction of components with teeth, transmission device control, belt/chain/gear, etc., to achieve the effect of convenient operation, simple method, and solution to instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

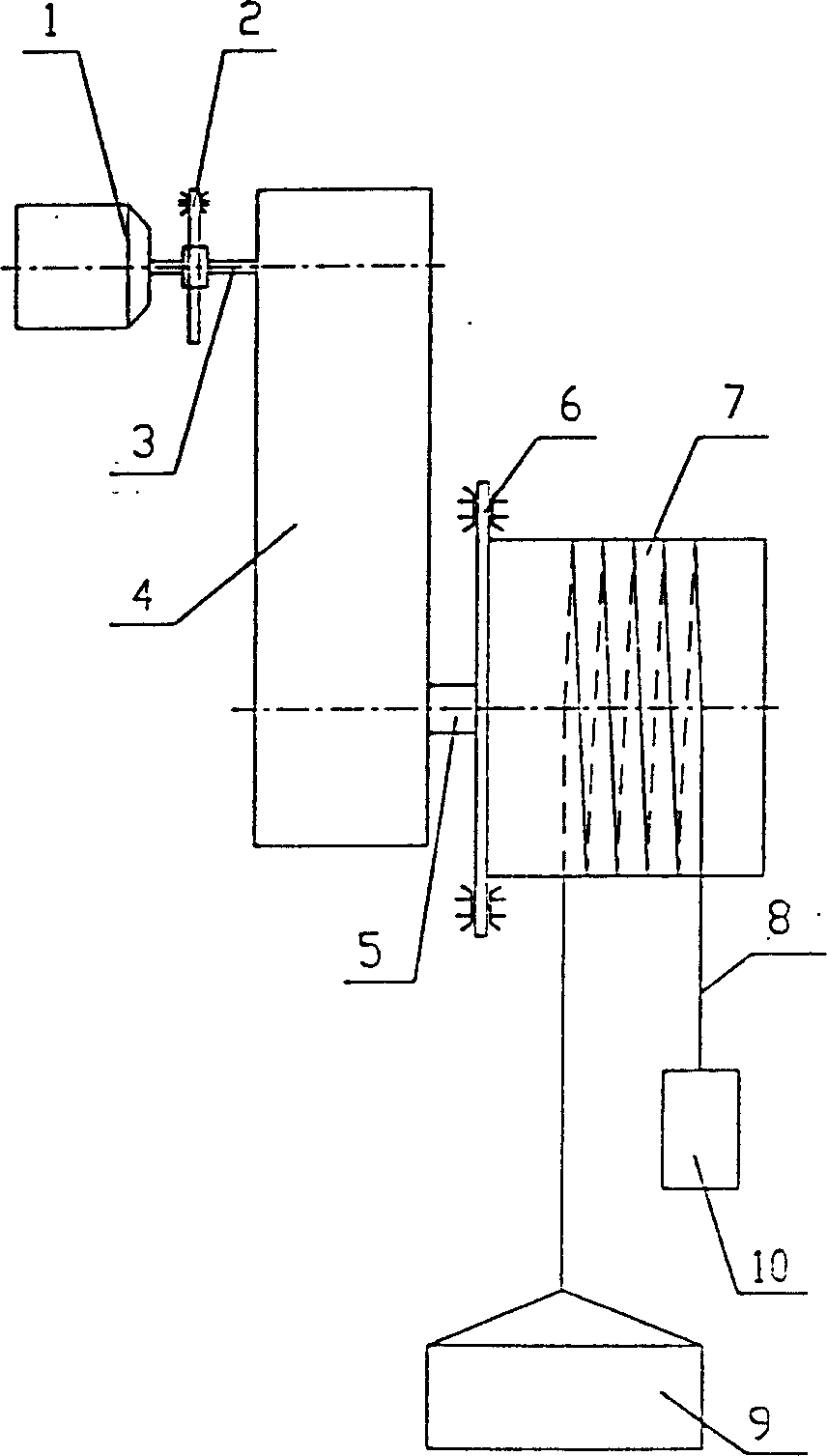

[0013] What the above accompanying drawing shows is the transmission system of an embodiment of the present invention and the relation diagram of operating sequence.

[0014] figure 1 Serial number in: 1: electric motor; 2: working brake; 3: high-speed input shaft of reduction gearbox; 4: reduction gearbox; 5: low-speed output shaft of reduction gearbox; 6: safety brake; 7: reel; 8: wire rope ;9: Ship compartment; 10: Balance weight

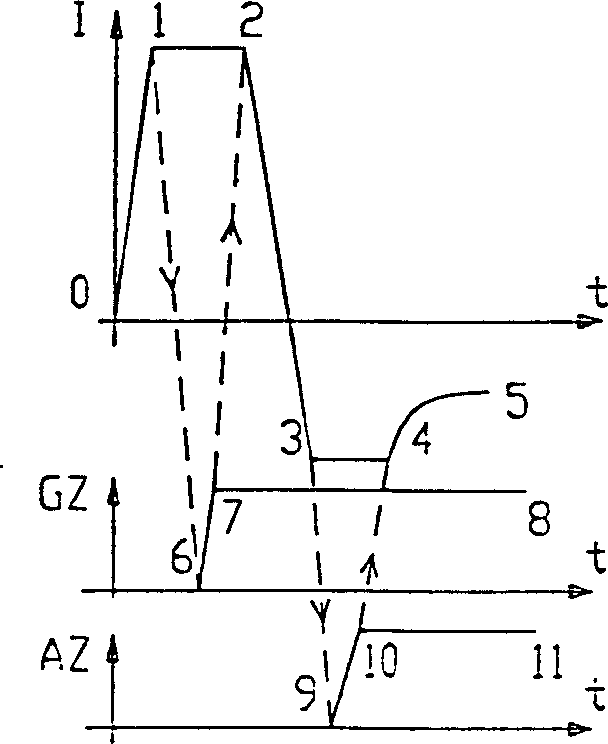

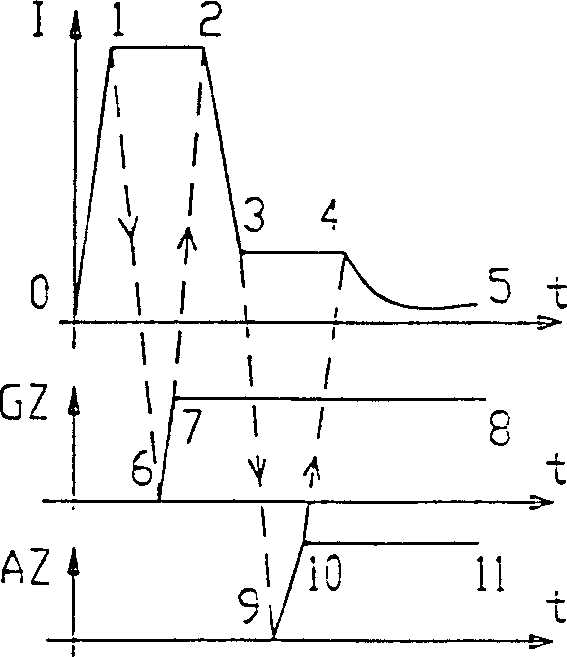

[0015] figure 2 , 3 Symbols in: t: time; I: pre-torque current; GZ: working brake; AZ: safety brake.

[0016] figure 2 , 3 The line segment 0-1 in : the initial pre-torque current is established; 1-2: the initial pre-torque current is maintained; 2-3: the initial pre-torque current is converted to the current pre-torque current; 3-4: the current pre-torque Add torque current to hold.

[0017] figure 2 , 3 Line segment 6-7 in : the release process of the working brake; 7-8: the release state of the working brake.

[0018] figure 2 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com