Improved slide valve in hydraulic copying general pipe for controlling motion of punch hammer in punch

A hammer and header technology, applied in the field of hydraulic profiling header slide valve, can solve the problems of unable to calibrate the support, affecting the accuracy of machining operations, affecting the impact hammer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

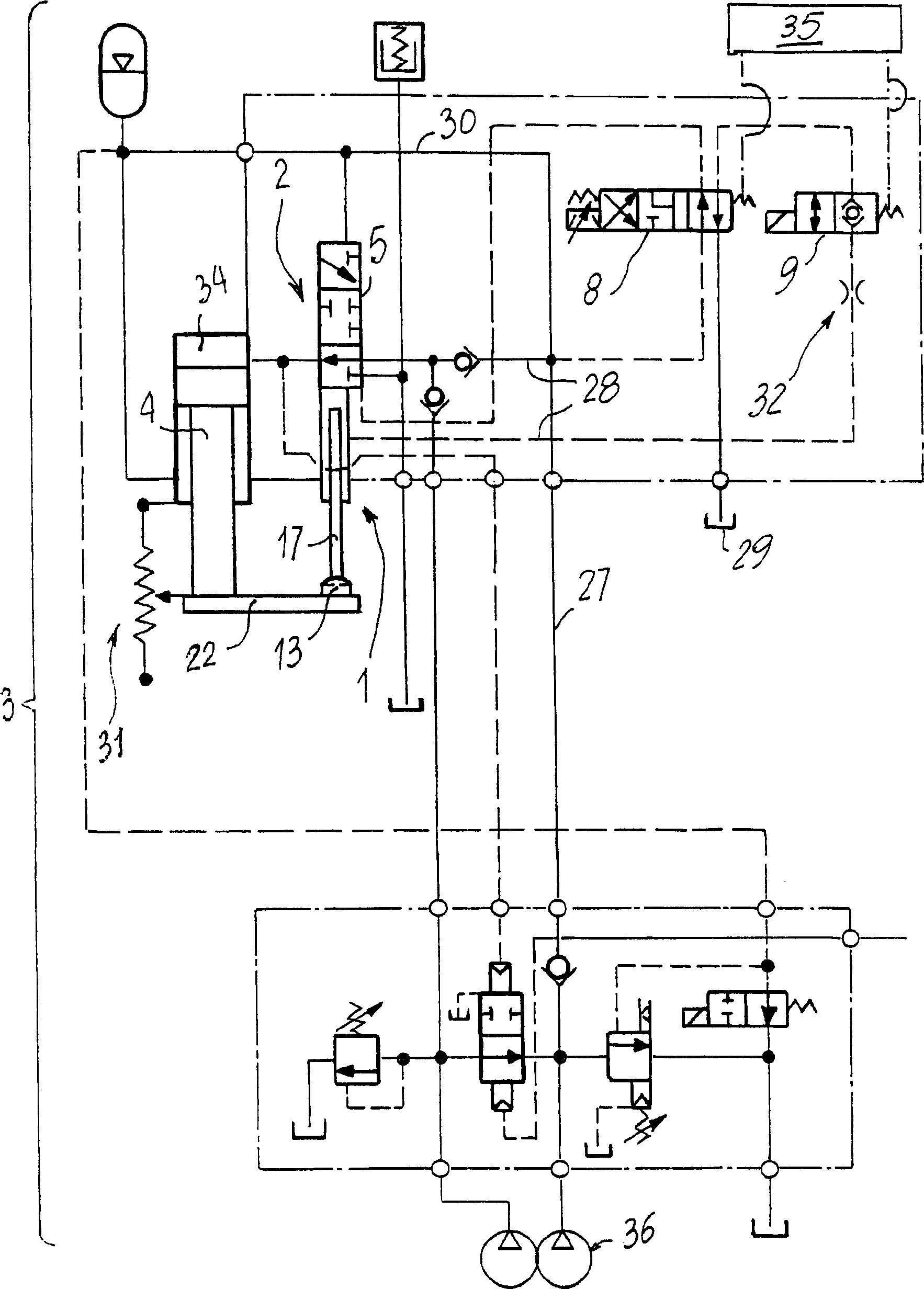

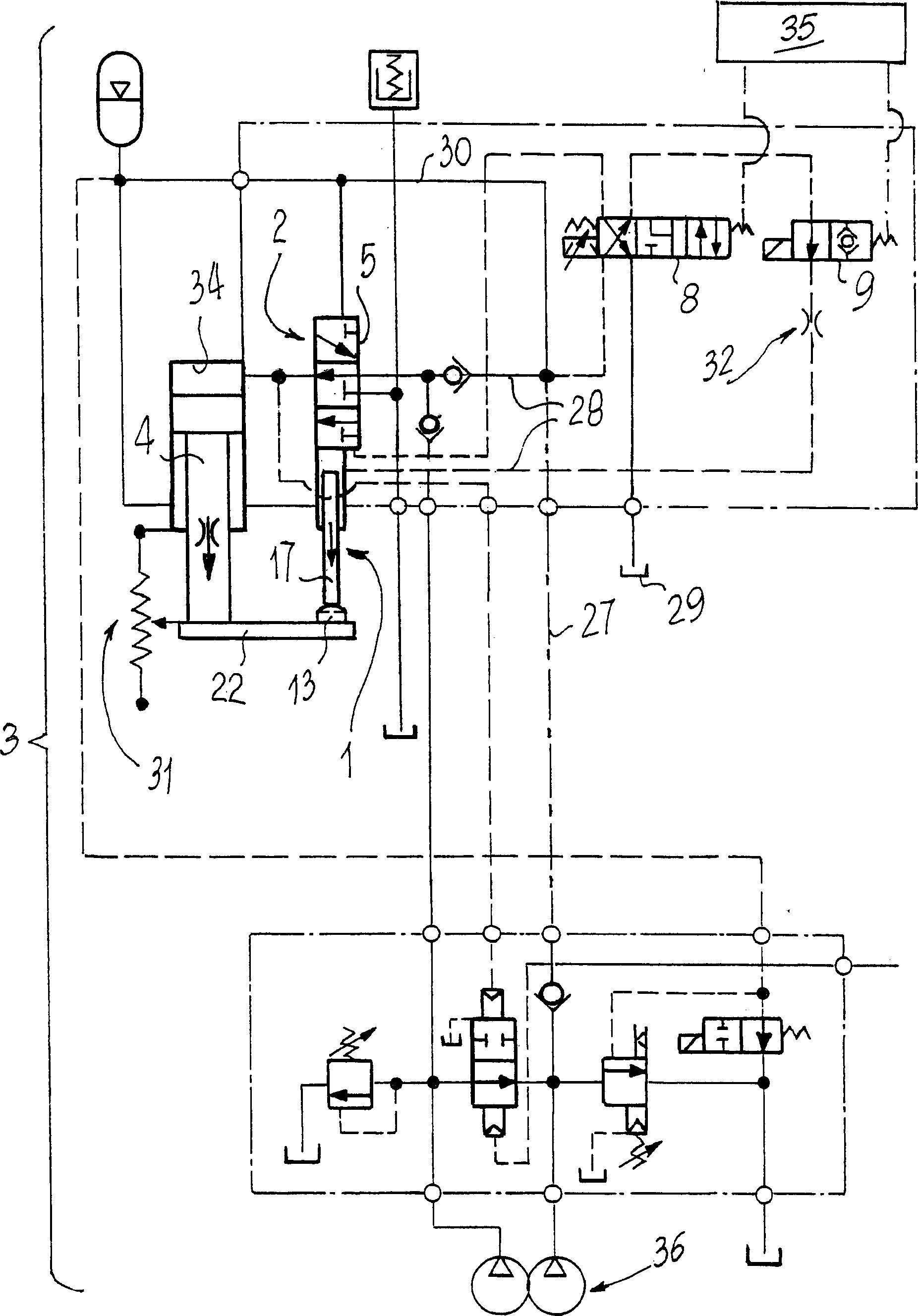

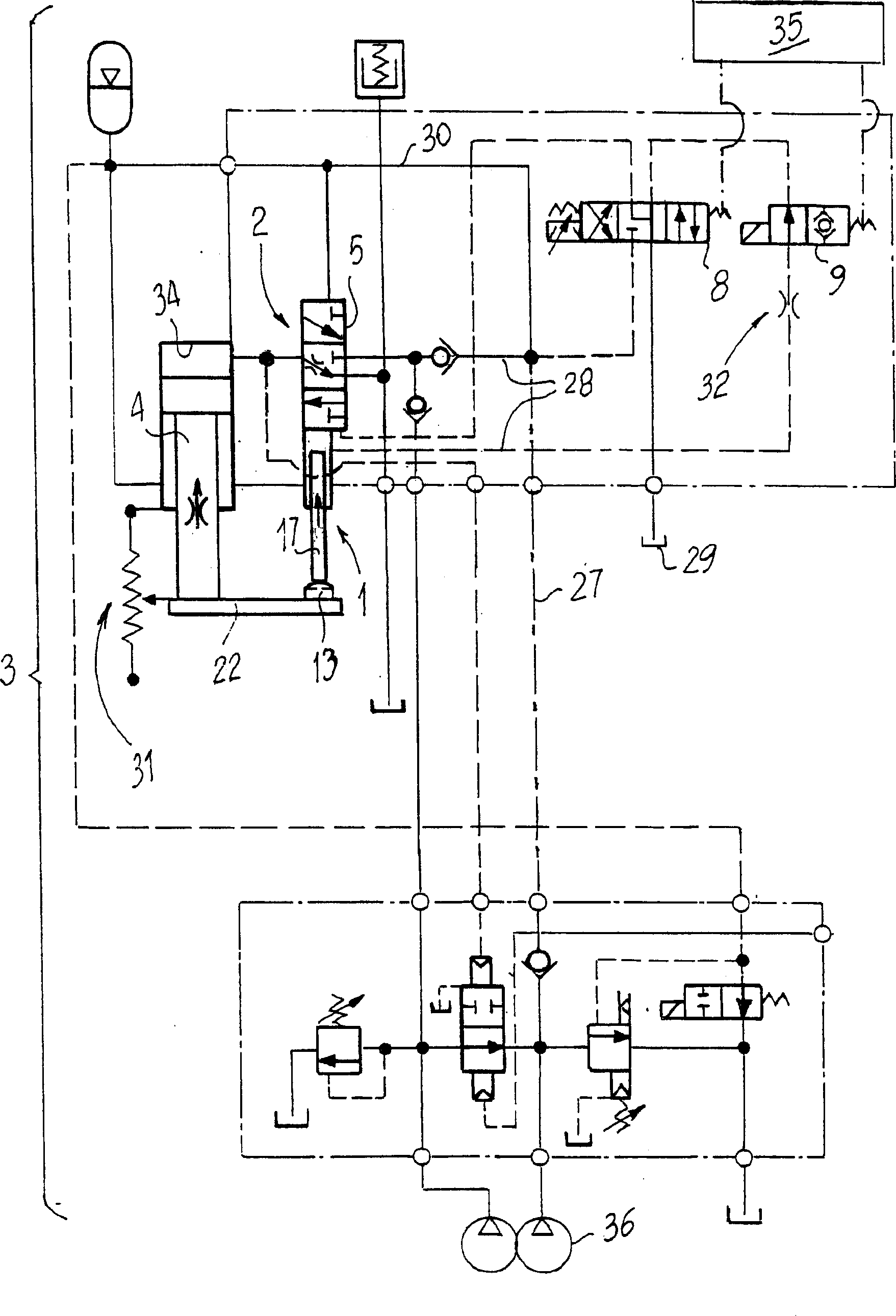

[0023] For the above figures, 1 indicates the slide valve of the profile manifold 2, which slide valve is installed in a hydraulic circuit 3 for controlling the mast movement of the hammer 4 in the press.

[0024] The manifold 2 comprises a body 5 connected by means of hoses with fittings (not shown in the figures) to the hydraulic circuit 3 and equipped with supply holes 6 for pressurized fluid (hydraulic oil) connected to said fittings and discharge hole 7.

[0025] The spool valve 1 is driven by at least one pair of valves 8 and 9 constituting said valve unit, each of which is installed in the hydraulic circuit 3; moreover, the spool valve is movably mounted inside the body 5, machined in a specific bracket 10 Shaped, the spool determines the periodic opening and closing of the holes 6, 7 and 33.

[0026] The movable end 11 of the spool valve 1 communicates with the outside of the body 5 by means of a provided calibration hole 12, and plays the role of cooperating with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com