Intelligent power module and packaging method of intelligent power module

A technology of intelligent power modules and sealing layers, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve problems such as large tolerances of aluminum substrates, cracks in insulating layers, and increased defective rate of module production, so as to reduce stress and improve finished products Yield rate, the effect of avoiding poor packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] It should be noted that, under the condition that there is no conflict in structure or function, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below based on examples.

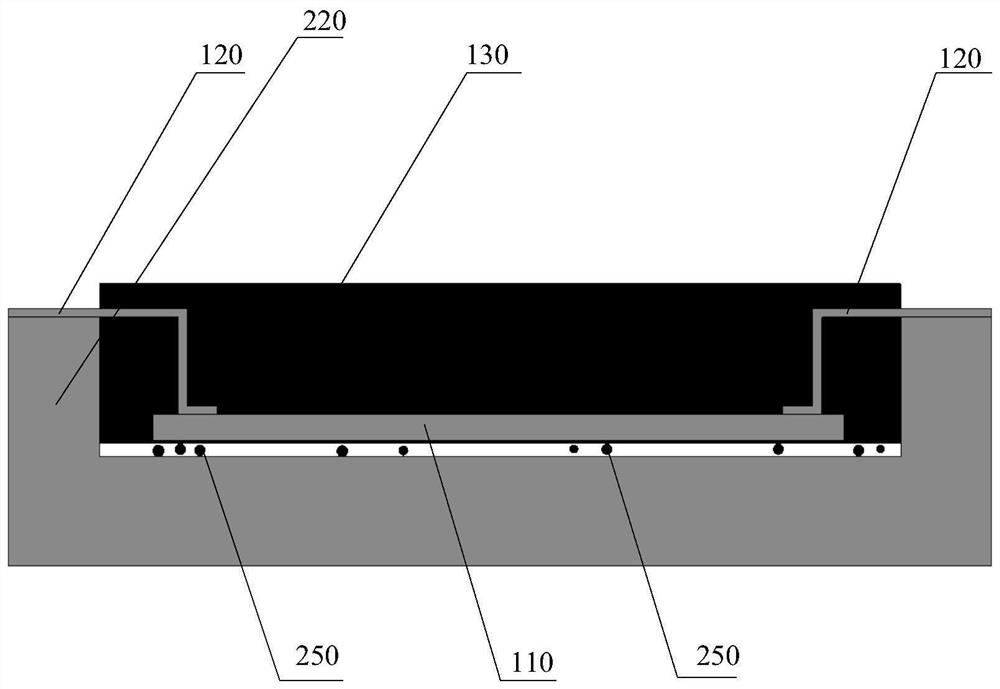

[0042] The invention provides an intelligent power module. figure 2 A schematic diagram showing the packaging structure of the IPM module according to the embodiment of the present invention. refer to figure 2 , the IPM module 100 includes a substrate 110 , a plurality of electronic components (not shown in the figure), a plurality of pins 120 and a sealing layer 130 .

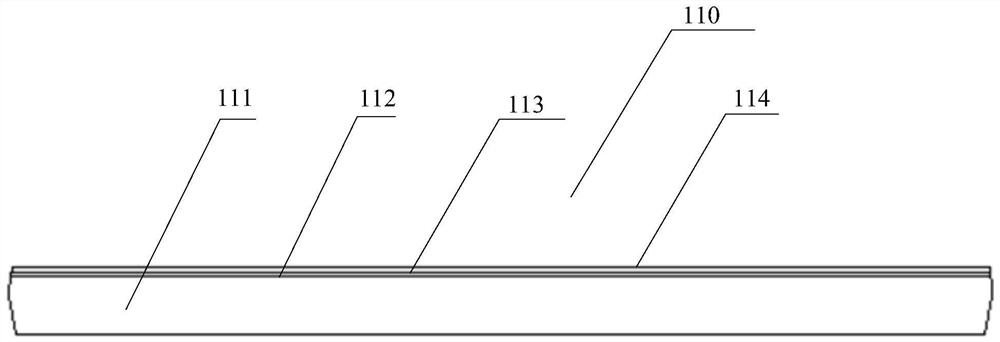

[0043] The substrate 110 includes a metal heat dissipation layer 111 , an insulating layer 112 , a wiring layer 113 and a green oil layer 114 connected in sequence. The specific structure of the substrate 110 is as image 3 As shown, the lowermost metal heat dissipation layer 111 occupies most of the volume of the subs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com