Pressure welding machine and pressure welding method

a welding machine and pressure welding technology, applied in the direction of welding auxiliaries, applications, kitchen equipment, etc., can solve the problems of large design effort, limited undesired deformations that cannot be absorbed, etc., and achieve the effect of reducing design effort, improving accessibility of the workplace, and widening the working rang

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

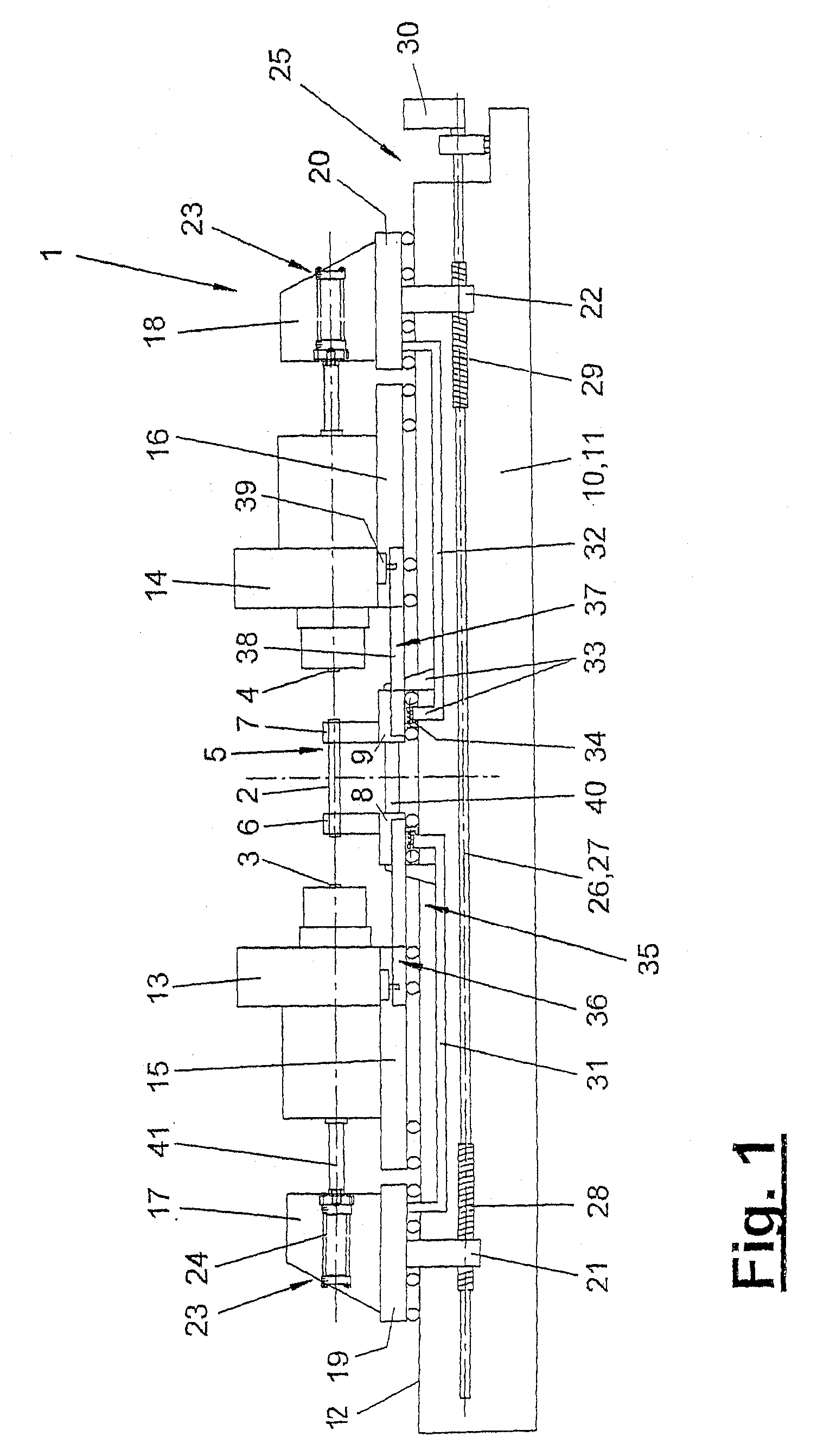

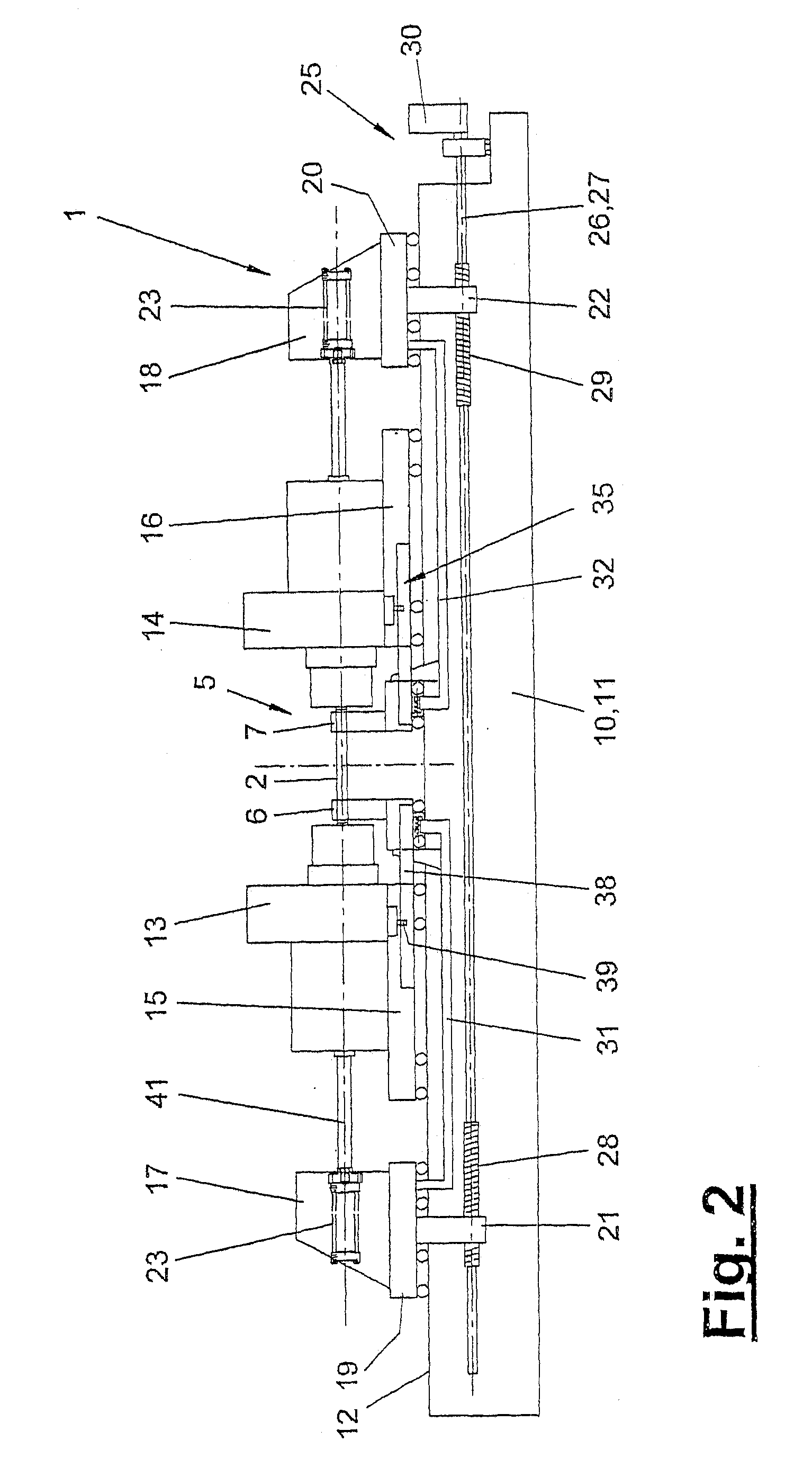

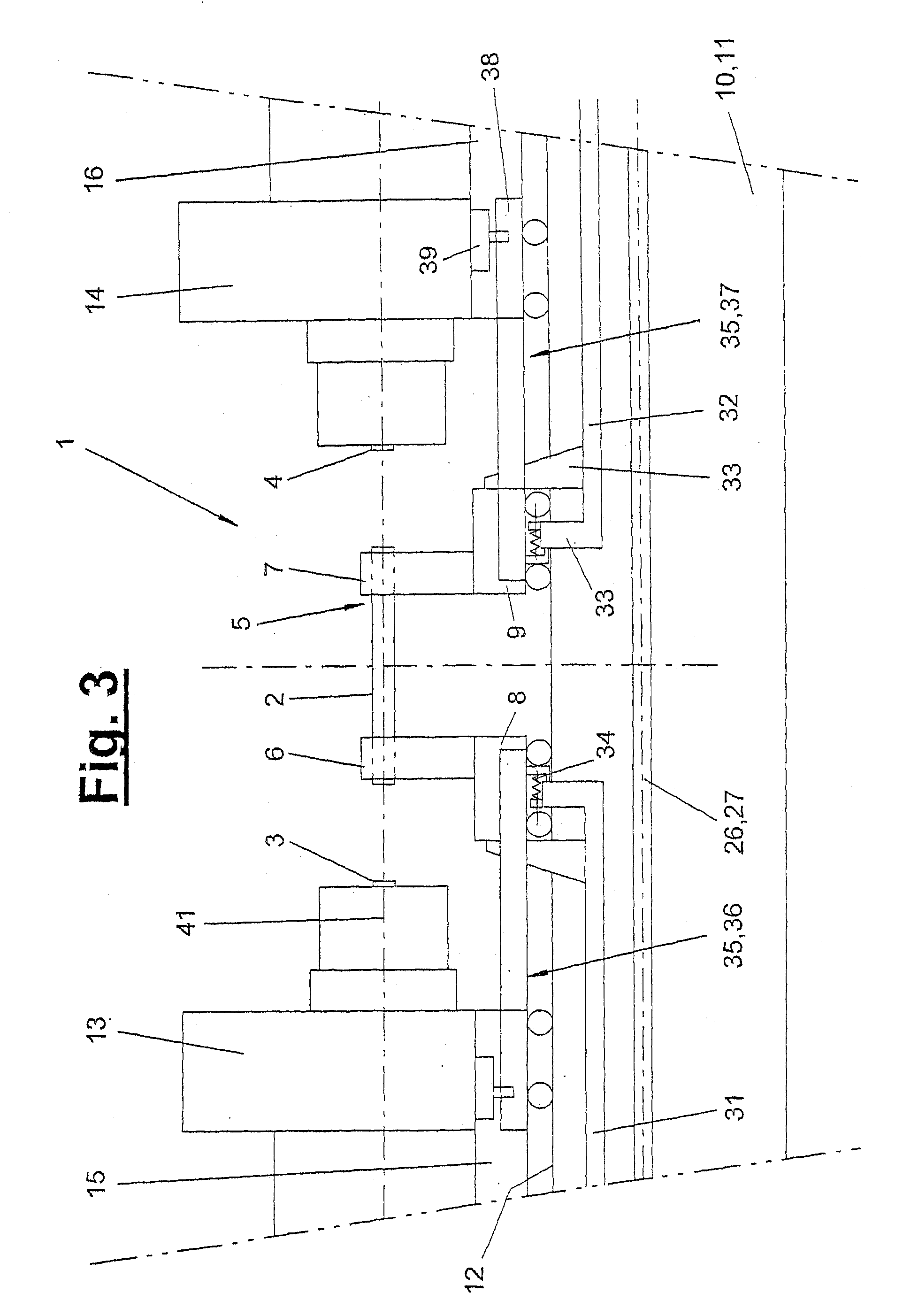

[0016] Referring to the drawings in particular, FIGS. 1 through 3 show schematic side views and different operating positions of a pressure welding machine (1). The pressure welding machine (1) is used to weld two, three or more workpieces (2, 3, 4), wherein one or more outer workpieces (3, 4) are welded to a central workpiece (2) at both ends. The pressure welding technique may be of any desired type. For example, it may be friction welding with direct motor drive or flywheel drive or welding with an arc moved magnetically or in another way, etc. The workpieces (2, 3, 4) are arranged along a preferably common feed axis or upsetting axis (41) and are moved toward one another and connected to one another at the end of the pressure welding operation by an upsetting stroke.

[0017] The pressure welding machine (1) is designed as a so-called double-head machine. It comprises a frame (10) with a central clamping device (5) for the central workpiece (2), two mobile welding heads (13, 14) a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic deformation | aaaaa | aaaaa |

| pressure welding forces | aaaaa | aaaaa |

| lengths | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com