Critical safety design method of fluidized bed in nuclear fuel post-treatment

A design method and criticality safety technology, applied in the field of criticality safety design of fluidized bed in nuclear fuel reprocessing, can solve problems not related to criticality safety design of fluidized bed, achieve multi-parameter optimal design and save design work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

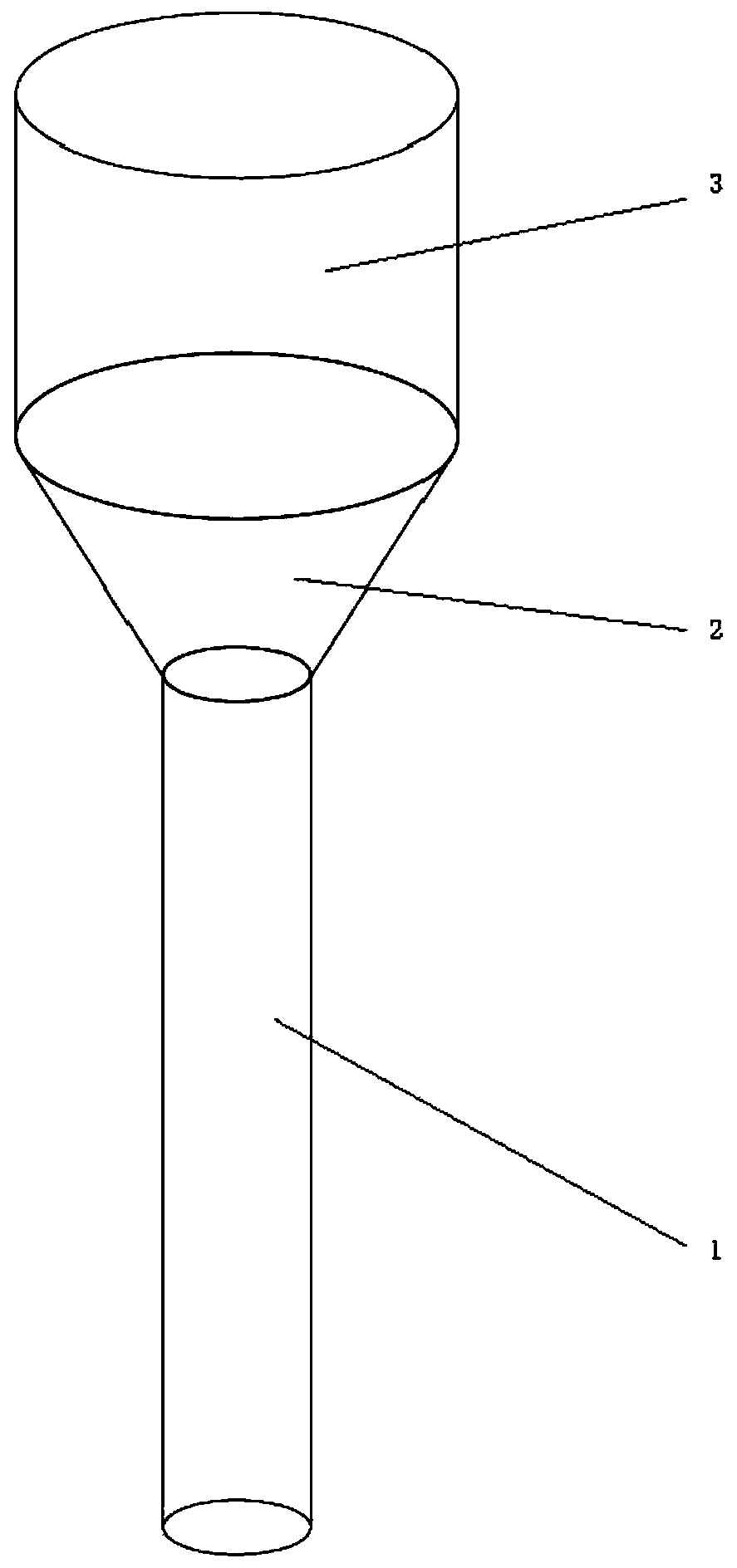

[0032] Exemplary nuclear fuel reprocessing uses a fluidized bed configuration such as figure 1 As shown, it includes a heating section 1, a transition section 2 and an expanding section 3 connected in sequence from bottom to top.

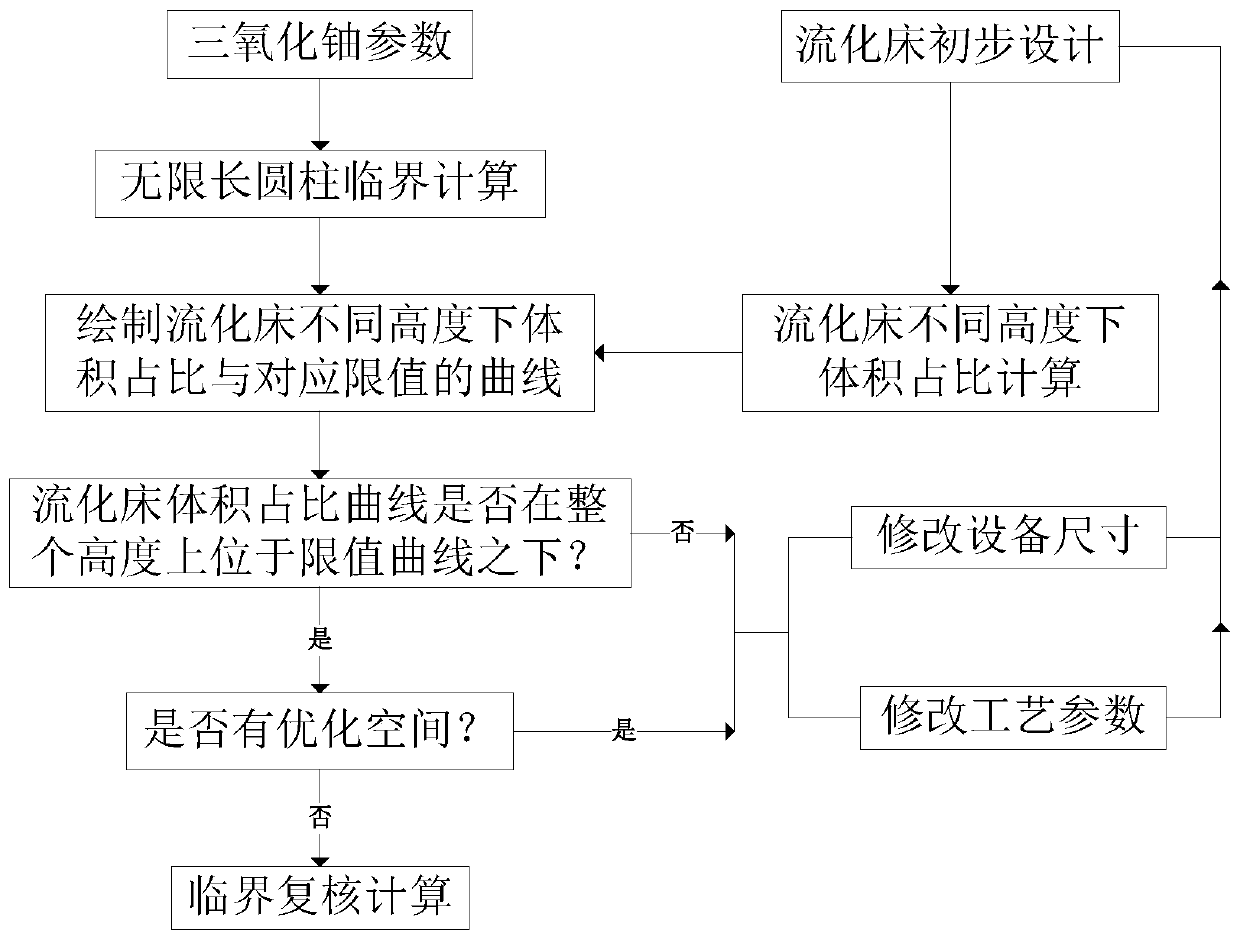

[0033] The flow process of the criticality safety design method of the fluidized bed in the exemplary nuclear fuel reprocessing of the present invention is as follows figure 2 shown, including the following steps:

[0034] (1) Determine the preliminary design parameters: determine the parameters of uranium trioxide, such as uranium trioxide density, particle size range, etc., and conduct a preliminary design of the fluidized bed, mainly the dimensions and process parameters of the fluidized bed.

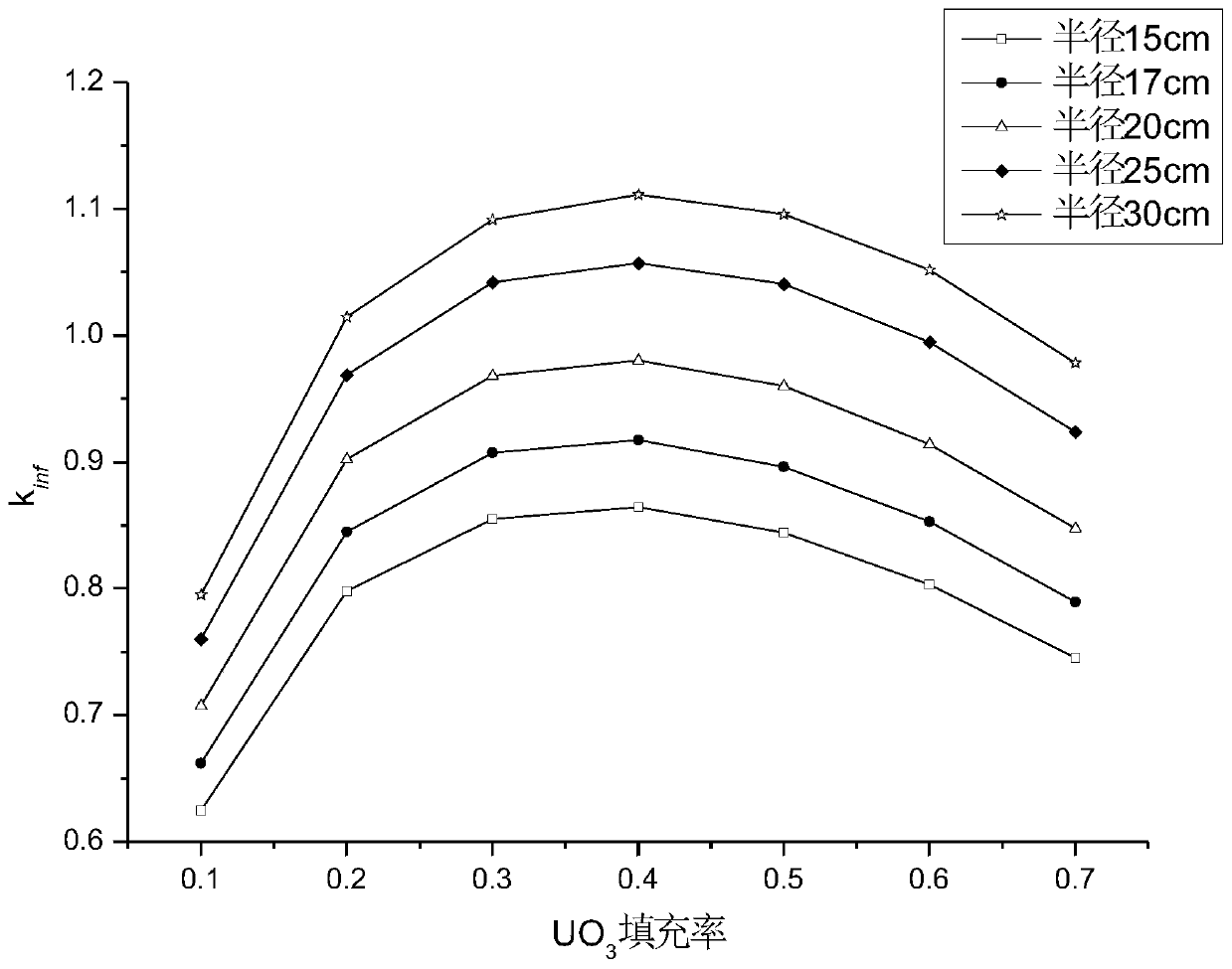

[0035] (2) Critical calculation of infinitely long cylinders: according to the determined uranium trioxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com