Linear guide rail pair structure with high dust prevention performance

A linear guide rail pair, dust-proof technology, applied in the direction of linear motion bearings, connecting components, threaded fasteners, etc., can solve the problems of shortened service life and reduced accuracy of linear guide rail pairs, and achieve long service life and simple structure , the effect of high exercise efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

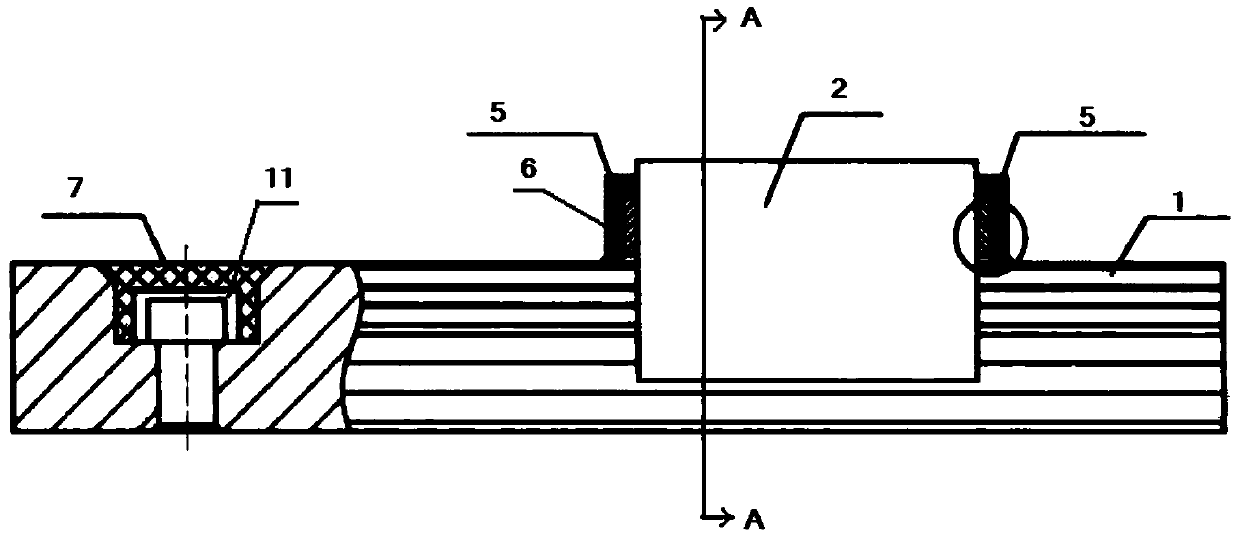

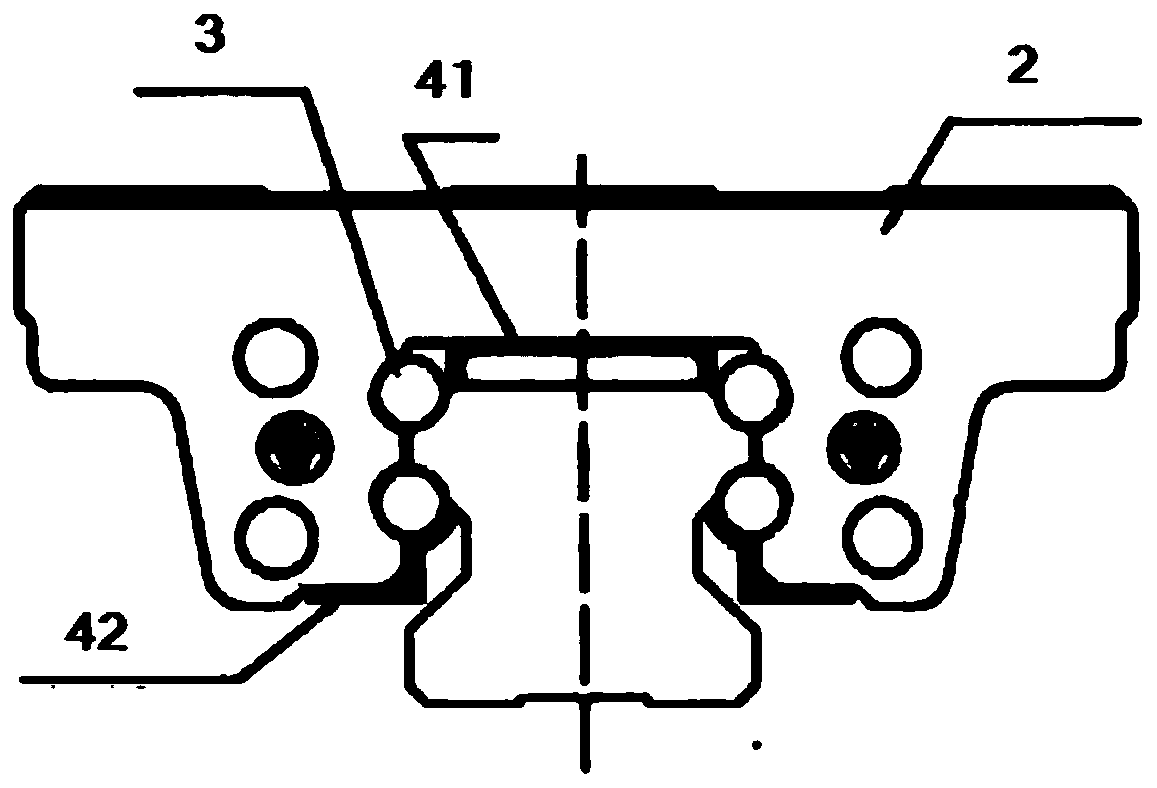

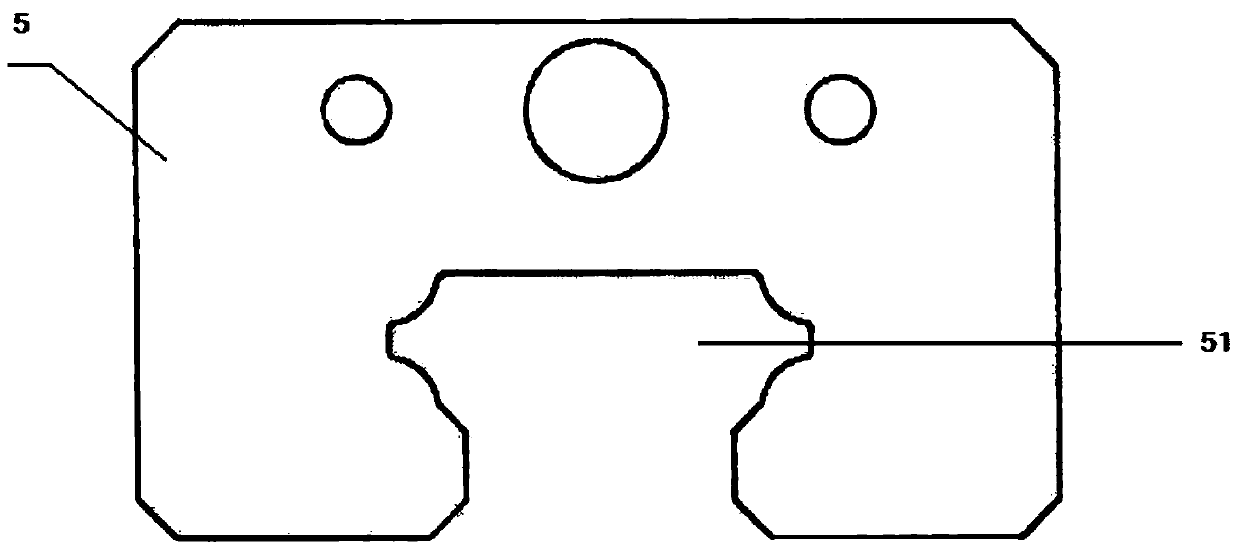

[0025] see Figure 1-9 , The invention discloses a high dustproof performance structure of a linear guide rail pair. like Figure 1-4 Shown: it includes a guide rail 1, a sliding block 2 mounted on the guide rail 1 and slidable on the guide rail 1, a rolling body 3 and a rolling body cage arranged between the guide rail 1 and the sliding block 2. In addition, it can also be equipped with a grease nozzle (not shown in the figure). The present invention is characterized in that: the front and rear sides of the sliding block 2 in the moving direction are provided with end-face double-lip scraper plates 5 made of elastic wear-resistant materials. The double kissing lip scraping hole 51, the orifice of the double kissing lip scraping hole 51 is the double kissing lip 52, and the double kissing lips 52 are all inclined tongue structures with the tongue tip outward.

[0026] When in use, as the slider 2 slides on the guide rail 1 , the end-face double-lip scraper 5 can also be dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com