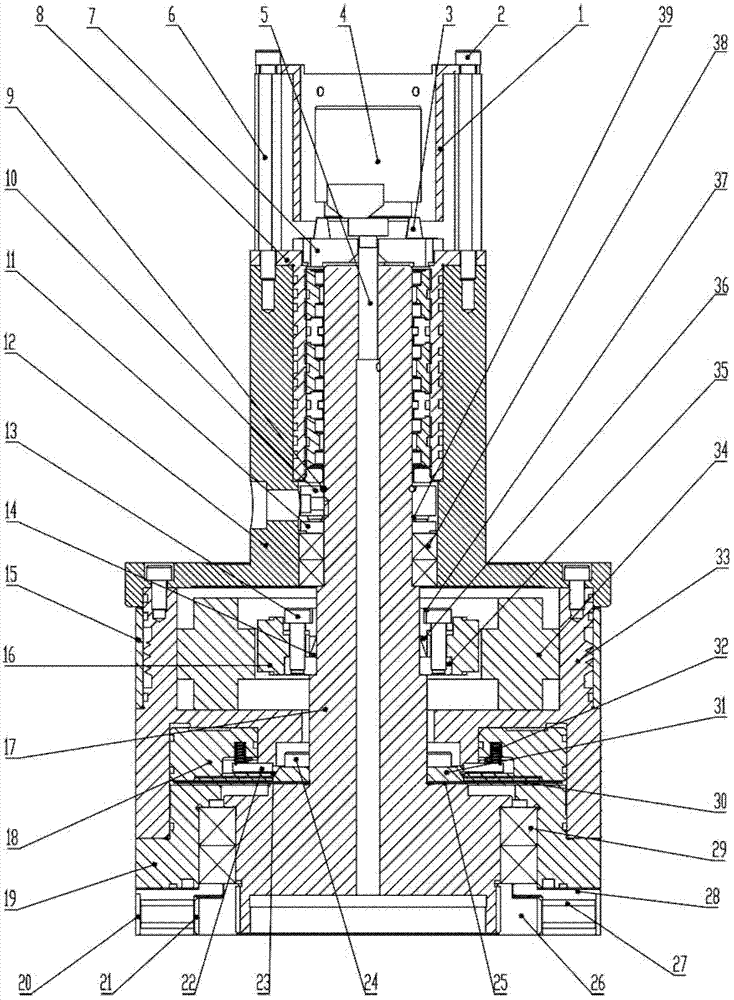

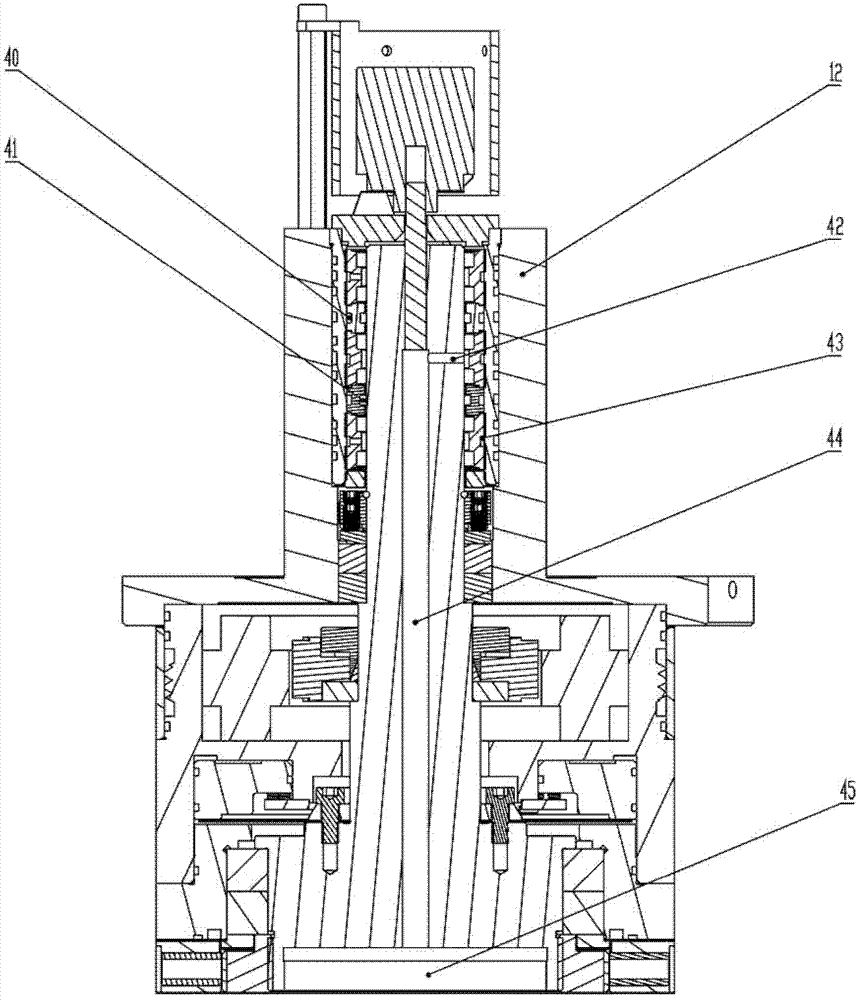

Precise numerical control indexing rotating shaft for electric discharge machining

A precision numerical control, indexing and rotating technology, applied in electric processing equipment, metal processing equipment, manufacturing tools, etc., to achieve the effect of improving processing efficiency, high indexing accuracy and servo response performance, and shortening the transmission chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0025] figure 1 and figure 2 The cross-sectional views of the precision numerical control indexing rotary shafts for electric discharge machining according to the embodiments of the present invention are respectively shown. The shaft body of this embodiment combines the precision numerical control indexing shaft and the high-speed rotating shaft required for EDM, and mainly includes the main shaft body 17, the permanent magnet AC servo torque motor, the grating encoder 4, the power feeding device, and the brake. device, spindle flushing cooling device, gas circuit device, etc., the bottom of the spindle body 17 is provided with a spindle body clamping part 45, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com