Fiber discharging device suitable for automatic optical fiber winding machine

An optical fiber winding machine and automatic technology, applied in the coupling of optical waveguide, Sagnac effect gyroscope, etc., can solve the problems of unguaranteed winding quality, unstable transmission control, low precision of fiber arrangement, etc., and achieve excellent Transmission and control characteristics, stable fiber arrangement process, and the effect of reducing the natural frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings.

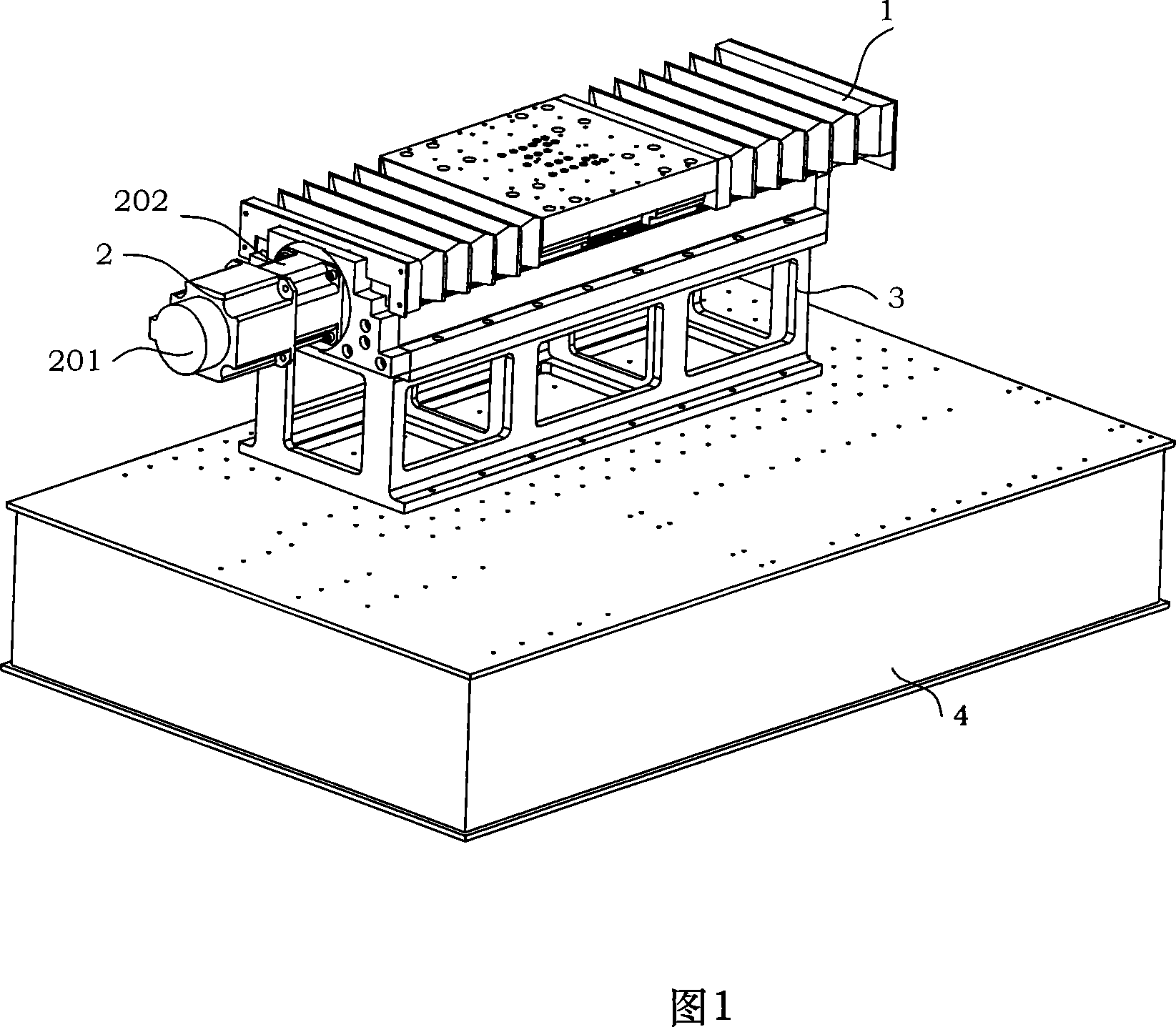

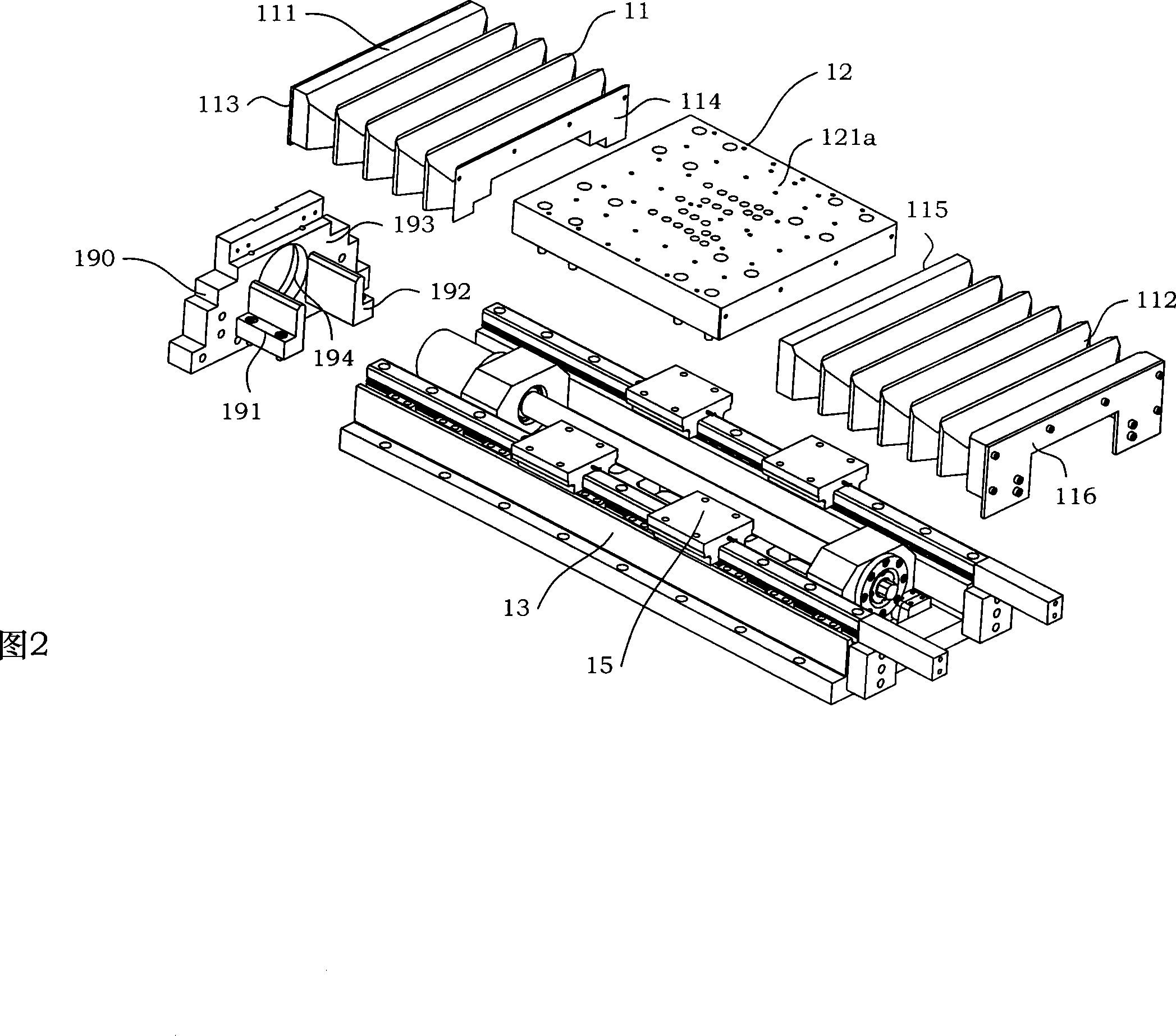

[0040] Please refer to Fig. 1 and Fig. 2, the present invention is a fiber-discharging mechanism applicable to an automatic optical fiber looping machine, the fiber-discharging mechanism is composed of a fiber-discharging assembly 1, a drive assembly 2 and a platform support 3; the platform support 3 The lower mounting surface 302 is fixedly installed on the precision platform 4, and the upper mounting surface 301 of the platform bracket 3 is fixed to the slide table base 13 of the fiber arrangement assembly 1; On the outer side, the motor 201 drives the workbench 12 to move back and forth on the slide base 13 to ensure the precise winding of the optical fiber on the fiber pay-off ring, guide wheel and fiber take-up ring.

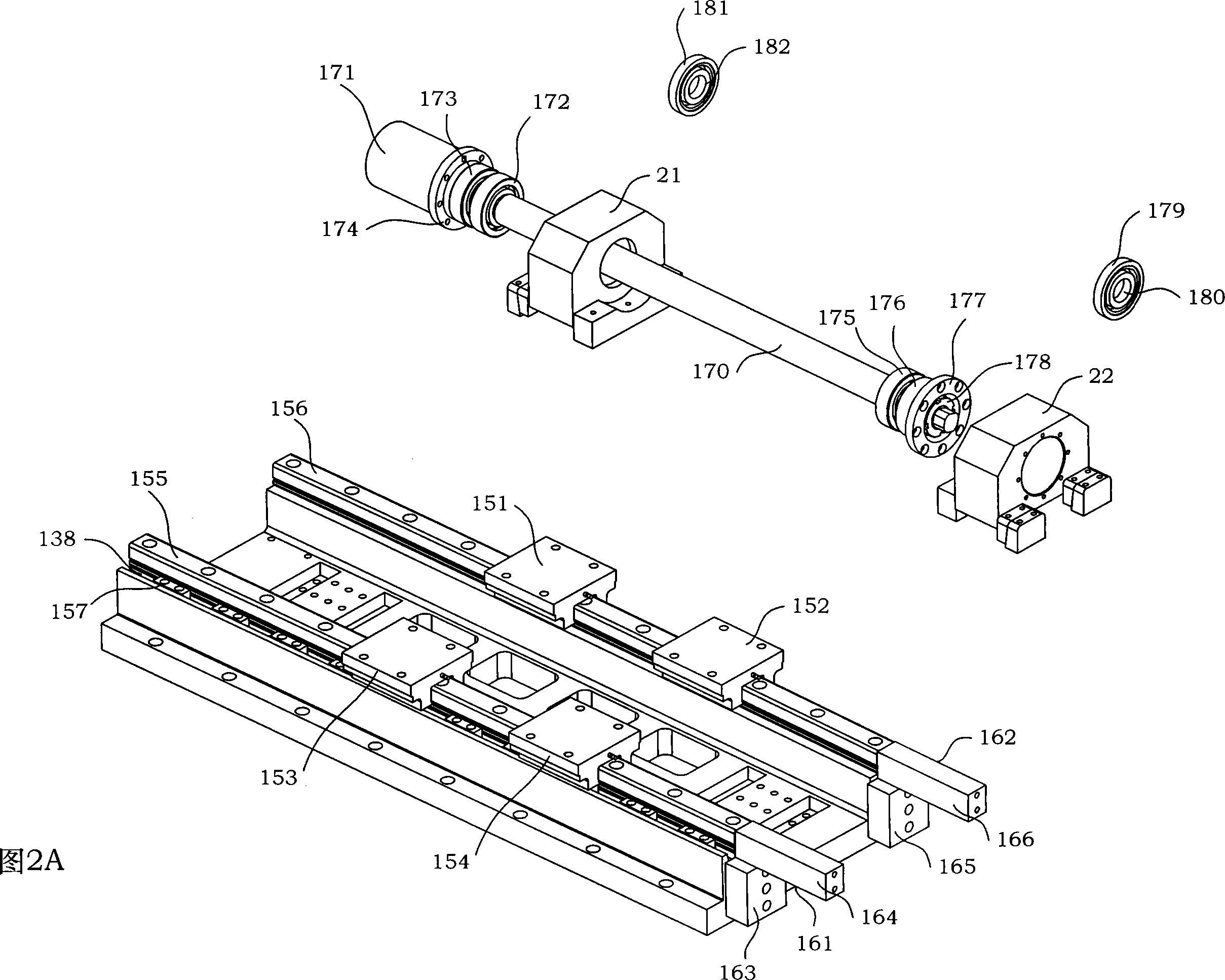

[0041] Please refer to FIG. 2 and FIG. 2A to FIG. 2F , the fiber arrangement assembly 1 in the present invention has the function of prec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com