Direct drive type precise micro displacement actuator for polar environment

A direct-drive, micro-displacement technology, used in instruments, installations, optics, etc., to achieve compact structure, improve output accuracy, and facilitate manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

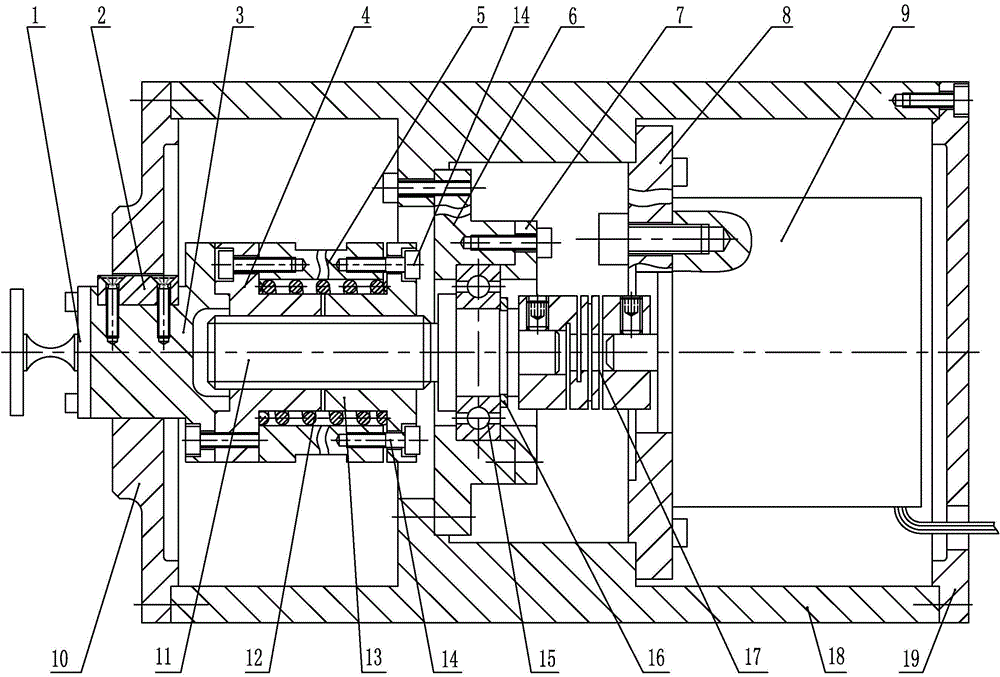

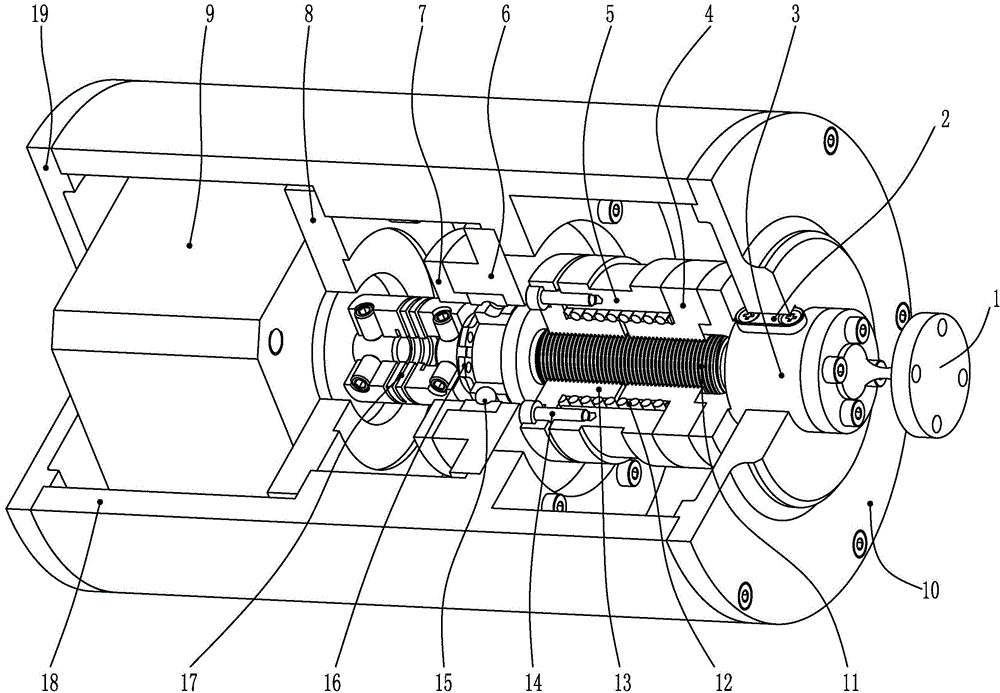

[0020] Specific implementation mode one: combine figure 1 , figure 2 and image 3 Explain that a direct-drive precision micro-displacement actuator for polar environments in this embodiment includes a motion support mechanism, a drive mechanism and an anti-backlash screw transmission mechanism;

[0021] The motion support mechanism includes a flexible shaft 1, an end cover 10, a housing 18 and a bottom cover 19, the housing 18 is a housing with open ends, and the end cover 10 and the bottom cover 19 are respectively mounted on both ends of the housing 18;

[0022] The driving mechanism includes an elastic coupling 17, a motor connecting plate 8 and a stepping motor 9, the motor connecting plate 8 is installed in the housing 18, the stepping motor 9 is installed on the motor connecting plate 8, and the output shaft of the stepping motor 9 is horizontal arrangement, an elastic coupling 17 is installed on the output shaft of the stepper motor 9;

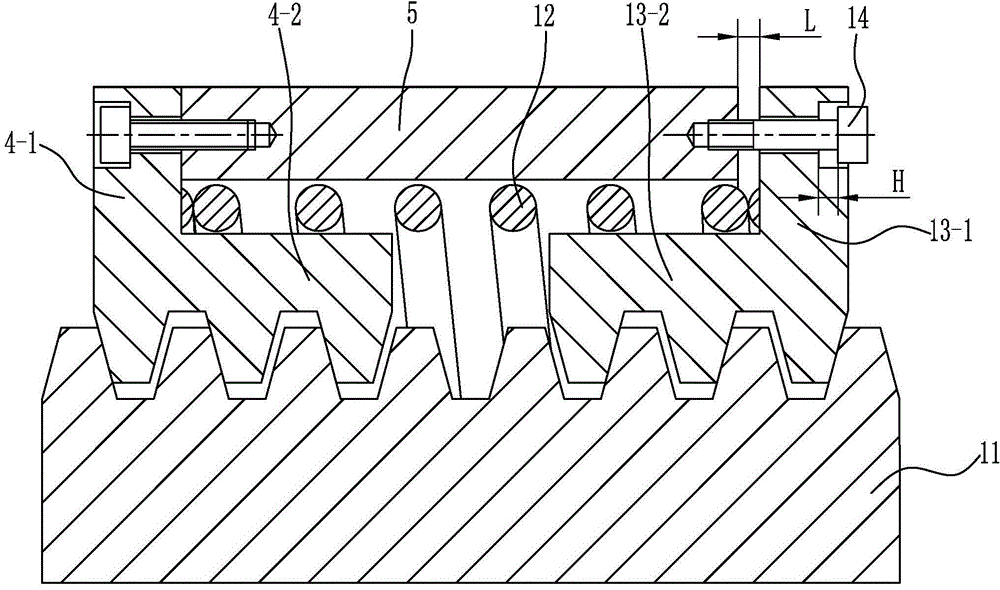

[0023] The anti-backlash scr...

specific Embodiment approach 2

[0028] Specific implementation mode two: combination Figure 1-Figure 2 Note that the threads of the drive nut 4, the threads of the anti-backlash nut 13 and the threads of the screw rod 11 in this embodiment are all precision trapezoidal threads with a small pitch of 0.1mm-0.2mm.

[0029] The screw rod 11, transmission nut 4 and anti-backlash nut 13 of this embodiment all adopt precision trapezoidal thread, which has a small pitch, which can ensure that the stepper motor 9 outputs a small displacement for each revolution of the transmission nut 4, and cooperates with electric subdivision control. The stepper motor has a unidirectional output displacement accuracy of less than 1 micron. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Specific implementation mode three: combination Figure 1-Figure 2 Note that between the transmission nut 4 and the screw rod 11 , between the anti-backlash nut 13 and the screw rod 11 , and between the drive rod 3 and the end cover 10 are all coated with a layer of low-temperature extreme pressure grease.

[0031] In this embodiment, between the drive nut 4 and the screw rod 11, between the anti-backlash nut 13 and the screw rod 11, and between the drive rod 3 and the end cover 10 are all coated with low-temperature extreme pressure grease, which can reduce the size of the drive rod 3, the end Cover 10, screw rod 11, transmission nut 4 and anti-backlash nut 13 wear, and ensure that the actuator still has a good lubrication effect under the special conditions of outputting a large load force and low temperature in the polar region, and the actuator can be stable in the polar alpine region , Low-wear operation. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com