Electric operator for general-purpose mechanical automatic transmission clutch

A technology of electric actuators and automatic transmissions, applied in the direction of mechanical drive clutches, non-mechanical drive clutches, electric clutches, etc., can solve the problems of high production cost of parts, low transmission efficiency, large starting inertia, etc., and achieve small frictional resistance and control The effect of adjustable precision and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

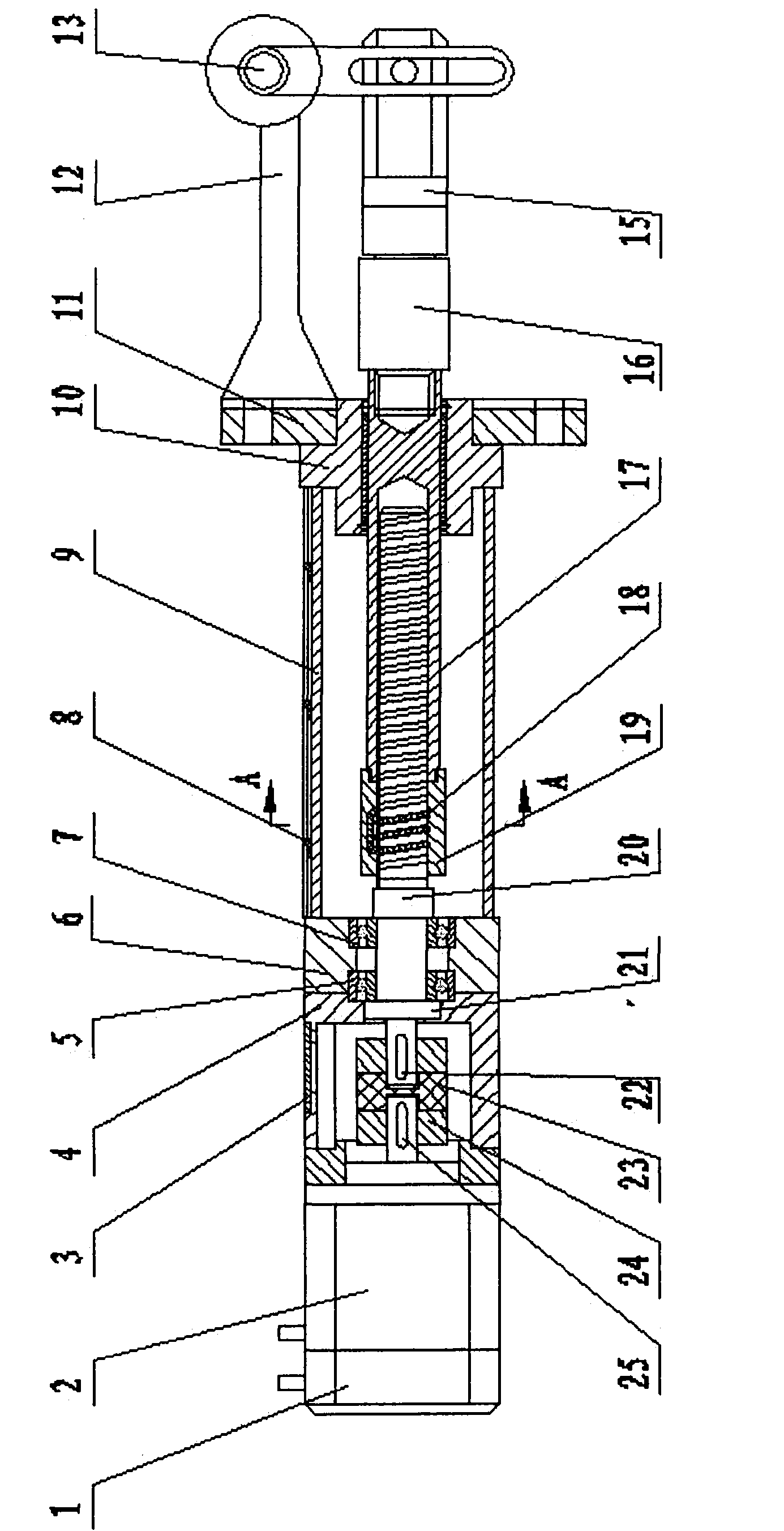

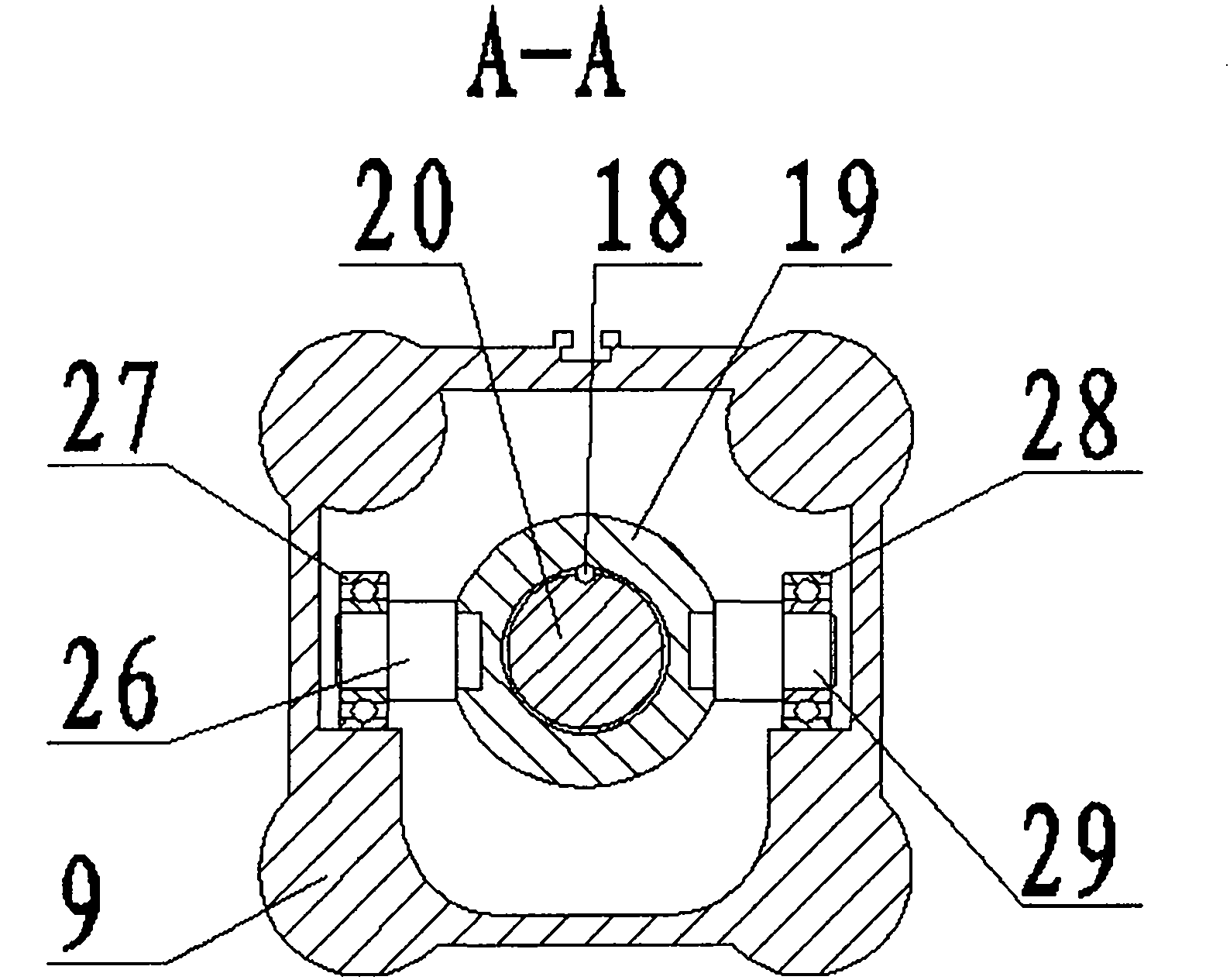

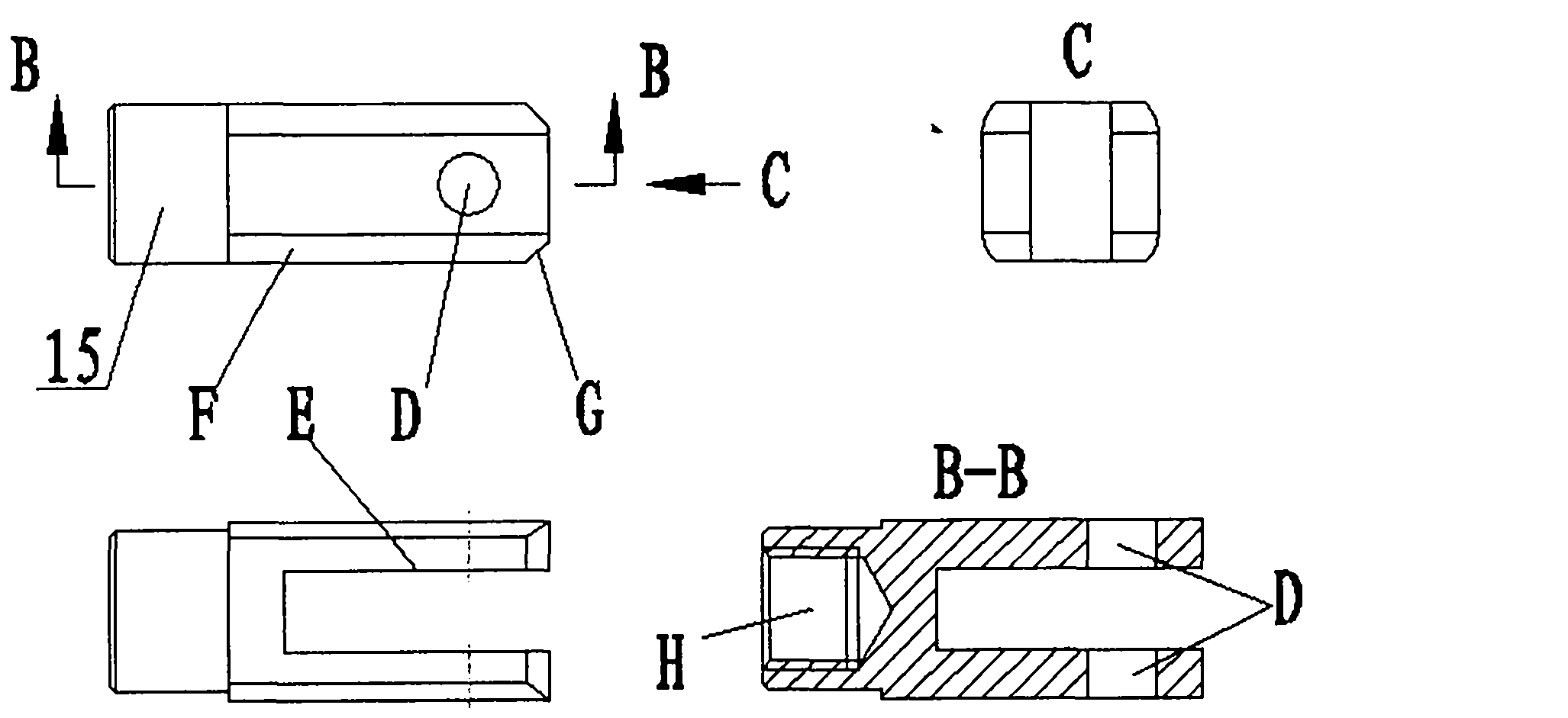

[0021] Such as figure 1 As shown, the power transmission sequence of the actuator is that the servo motor 2 is used as the power source to provide power. The output shaft of the servo motor 2 is connected to one end of the plum blossom coupling 24 through a flat key 25. A nylon sleeve 23 is installed in the middle of the plum blossom coupling 24. The other end of the plum blossom coupling 24 is connected with the lead screw 20 through the flat key 22, so that the servo motor 2 drives the lead screw 20 to rotate through the connection of the plum blossom coupling 24, and the power is passed by the lead screw 20 through the steel ball 18 and the lead screw bushing. 19 connection, the rotational movement of the lead screw 20 can be transformed into the motion of the screw bushing 19 in the linear direction, the screw bushing 19 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com