Method for automatically eliminating limited angle gear backlash

A gear tooth and side clearance technology, which is applied in belts/chains/gears, transmission parts, mechanical equipment, etc., can solve the problems that cannot meet the needs of anti-backlash gear mechanisms, research on dynamic characteristics of electromechanical systems, unfavorable space utilization and assembly realization and other issues, to achieve the effect of reducing processing costs and materials, compact structure, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the objectives, technical solutions, and advantages of the embodiments of the present invention clearer, the following describes the embodiments of the present invention in further detail with reference to the embodiments and the drawings. Here, the exemplary embodiments of the present invention and the description thereof are only used to explain the present invention, but not as a limitation to the present invention.

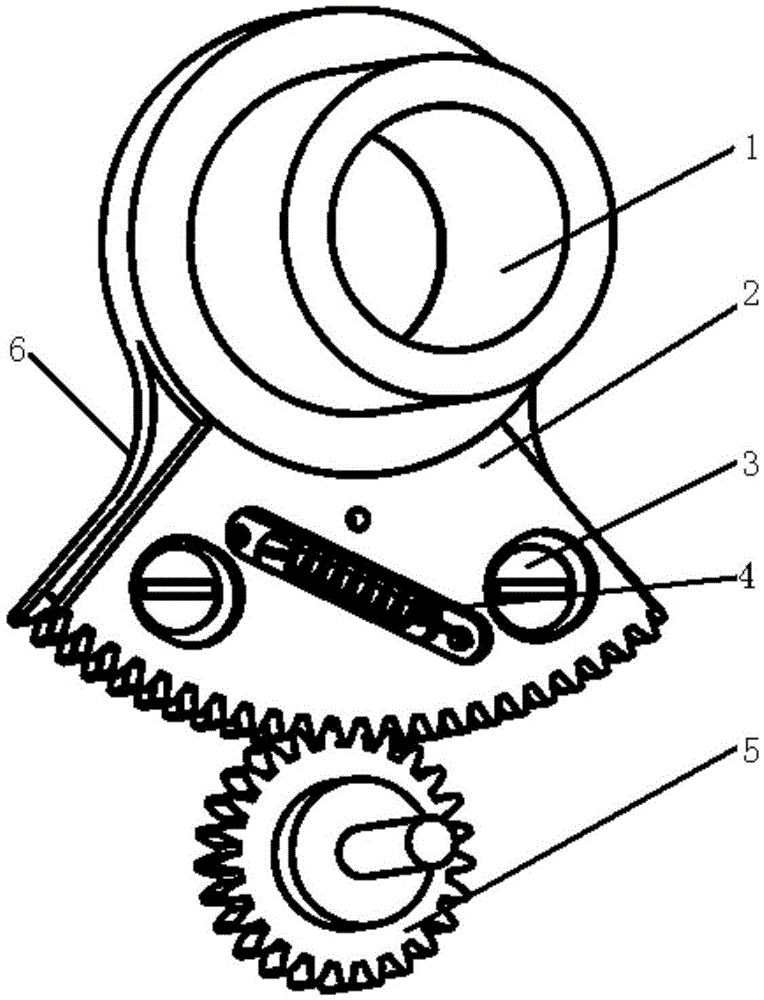

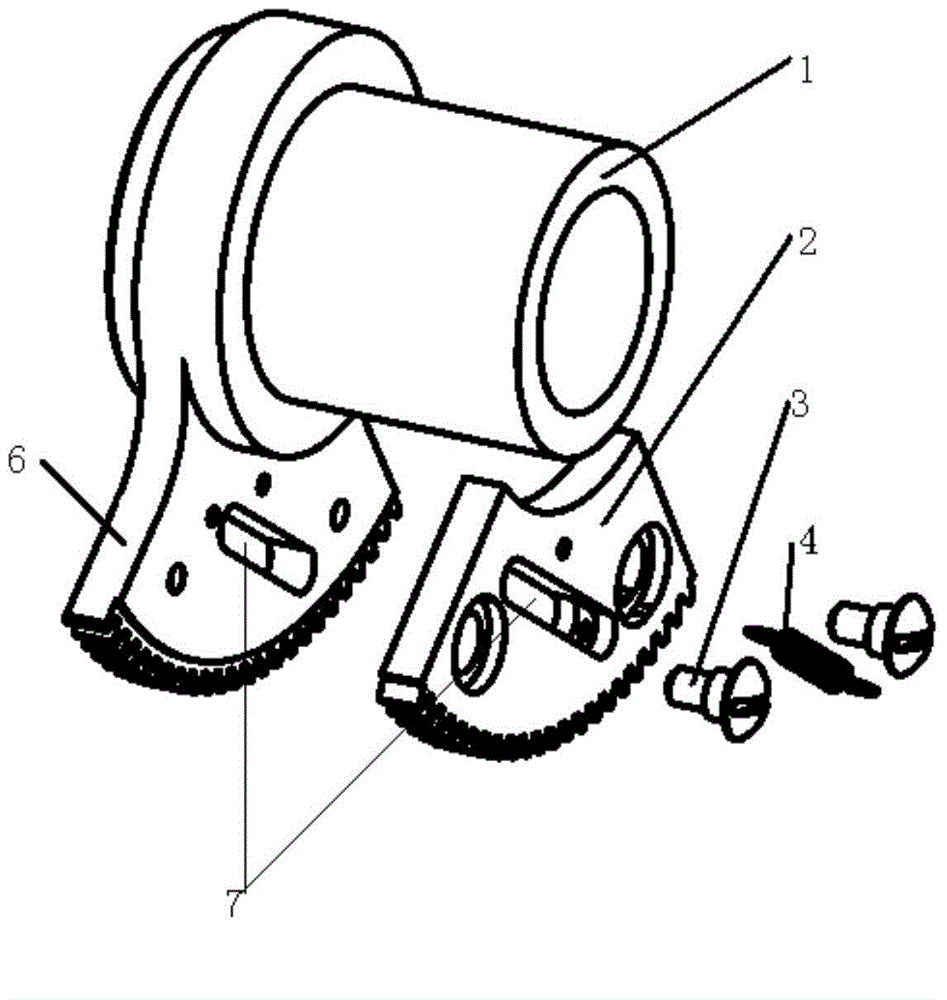

[0019] Refer to figure 1 , figure 2 . A pair of gears with a fixed rotation axis and meshing with each other are the driving gear and the driven gear 5 respectively. Among them, the driving gear is composed of two pieces, the gear shape is the same, and the effective working parts are all fan-shaped. Both the primary and secondary teeth of the driving gear can adopt straight cylindrical teeth, the same as that of the driven gear 5. The bottom cylindrical surface of the secondary tooth has the same radius as the cylindrical step surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com