Direct-drive manipulator for pen-based force display

a direct-drive, force display technology, applied in the direction of electric programme control, program control, instruments, etc., can solve the problems of inability to accurately make and break contact, inability to use direct-drive geared actuators as force displays, and inability to achieve realistic making and breaking contact, no friction or backlash, and no backlash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Overview

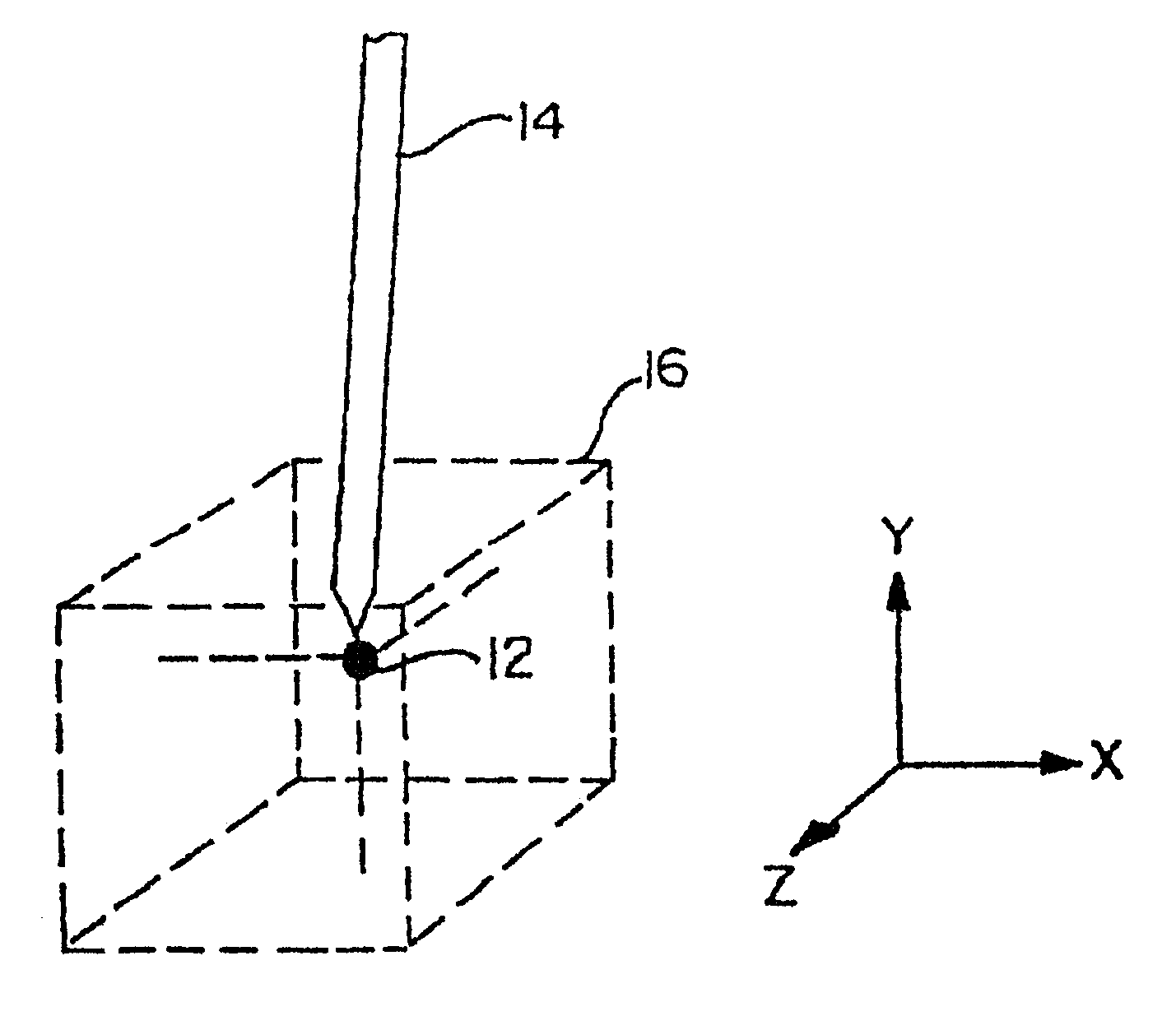

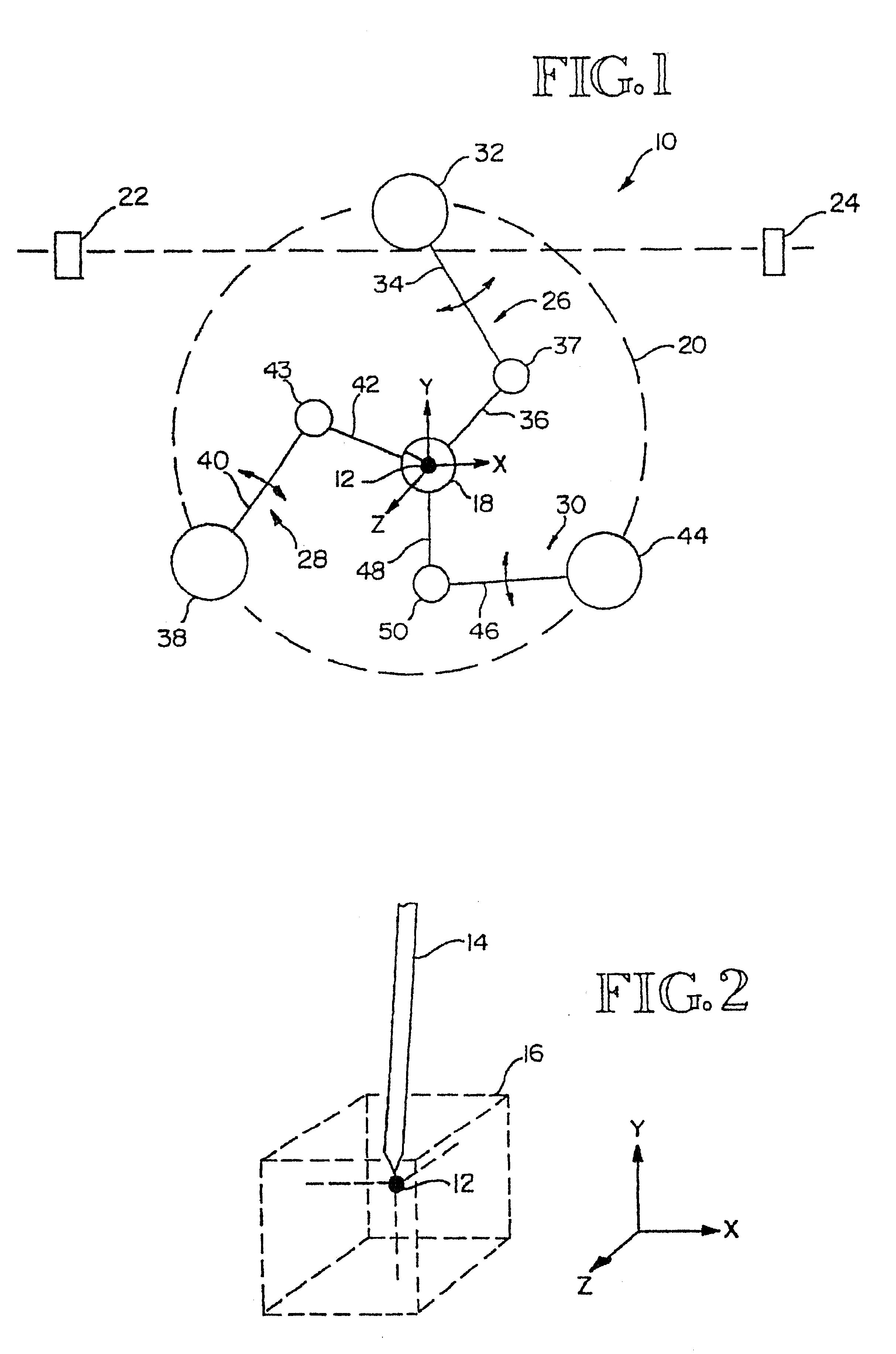

FIG. 1 shows a schematic diagram of the pen-based direct-drive manipulator 10 according to one embodiment of the invention. The function of the manipulator 10 is to enable precision manipulation and force display at a control point 12. Referring to FIG. 2, an operator uses a pen-like or other tool 14 to apply forces / displacements to the control point 12. The manipulator 10 responds to the applied forces allowing control point 12 movement with three degrees of freedom within a workspace 16. The control point 12 is defined at an end-effector 18. The manipulator 10 includes a planar structure 20 enabling motion in an xy plane to define two degrees of freedom. The planar structure 20 is moved along a z-axis by actuators 22, 24 to define a third degree of freedom.

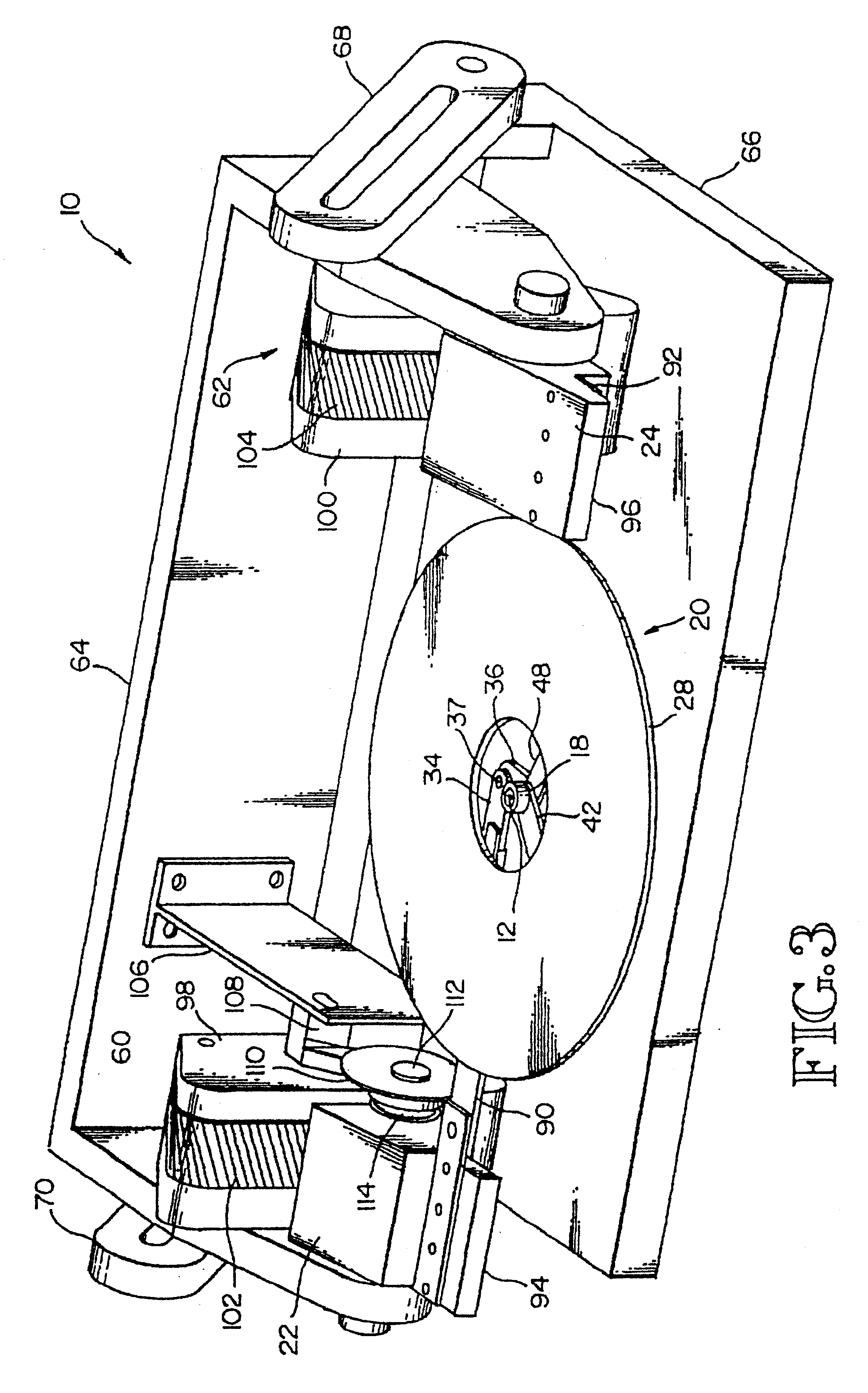

FIG. 3 shows an assembled direct-drive manipulator 10 according to an embodiment of this invention. The manipulator includes a planar assembly 20 mounted to rotational actuation assemblies 60, 62. The rotational actuatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com