Zero gap speed changing mechanism

A speed change mechanism, no gap technology, applied in mechanical equipment, transmission parts, belts/chains/gears, etc., can solve the problems of small driving torque, reduced robot operation accuracy, high price, etc., and achieve the effect of high transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

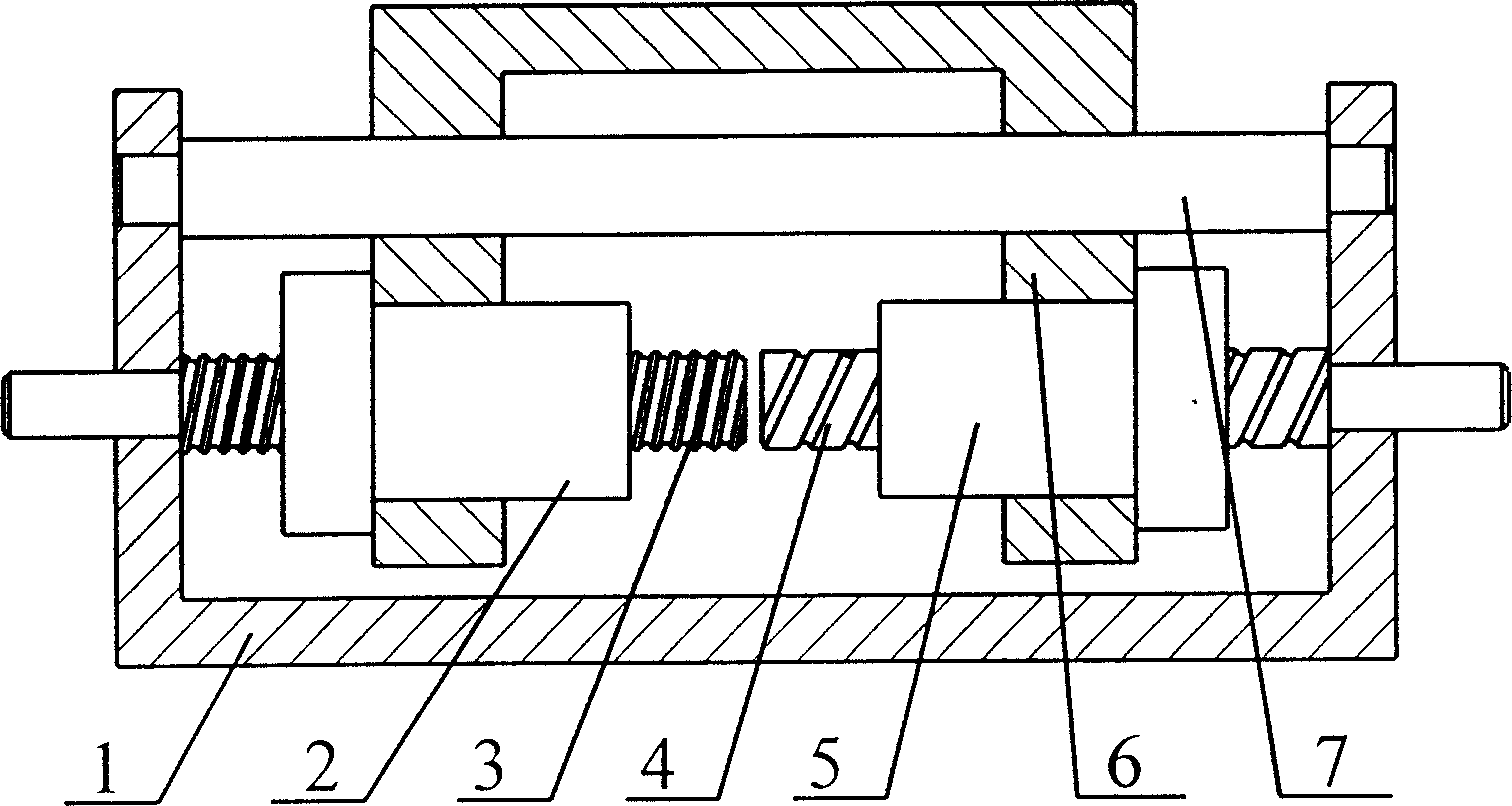

[0014] figure 1 Two rolling screw screws (3) and (4) and guide rails (7) with different leads are installed in parallel on the upper axis of the support (1) of a kind of gapless transmission mechanism of the present invention, and the rolling screw screws (3) and ( 4) Install the pre-tightening nuts (2) and (5) respectively, the transmission block (6) installed on the guide rail (7) is connected with the pre-tightening nuts (2) and (5), and the two rolling screws (3) It is coaxial with the axis of (4).

[0015] figure 1 The working principle of the gapless transmission mechanism of the present invention shown is: if the rolling screw (3) turns, the preload nut (2) moves left and right, driving the transmission block (6) and the preload nut (5) along the guide rail (7) Move left and right, and the left and right movement of the pre-tightening nut (5) makes the rolling screw (4) rotate. If the leads of the rolling screw (3) and the rolling screw (4) are different, the rotatio...

Embodiment 2

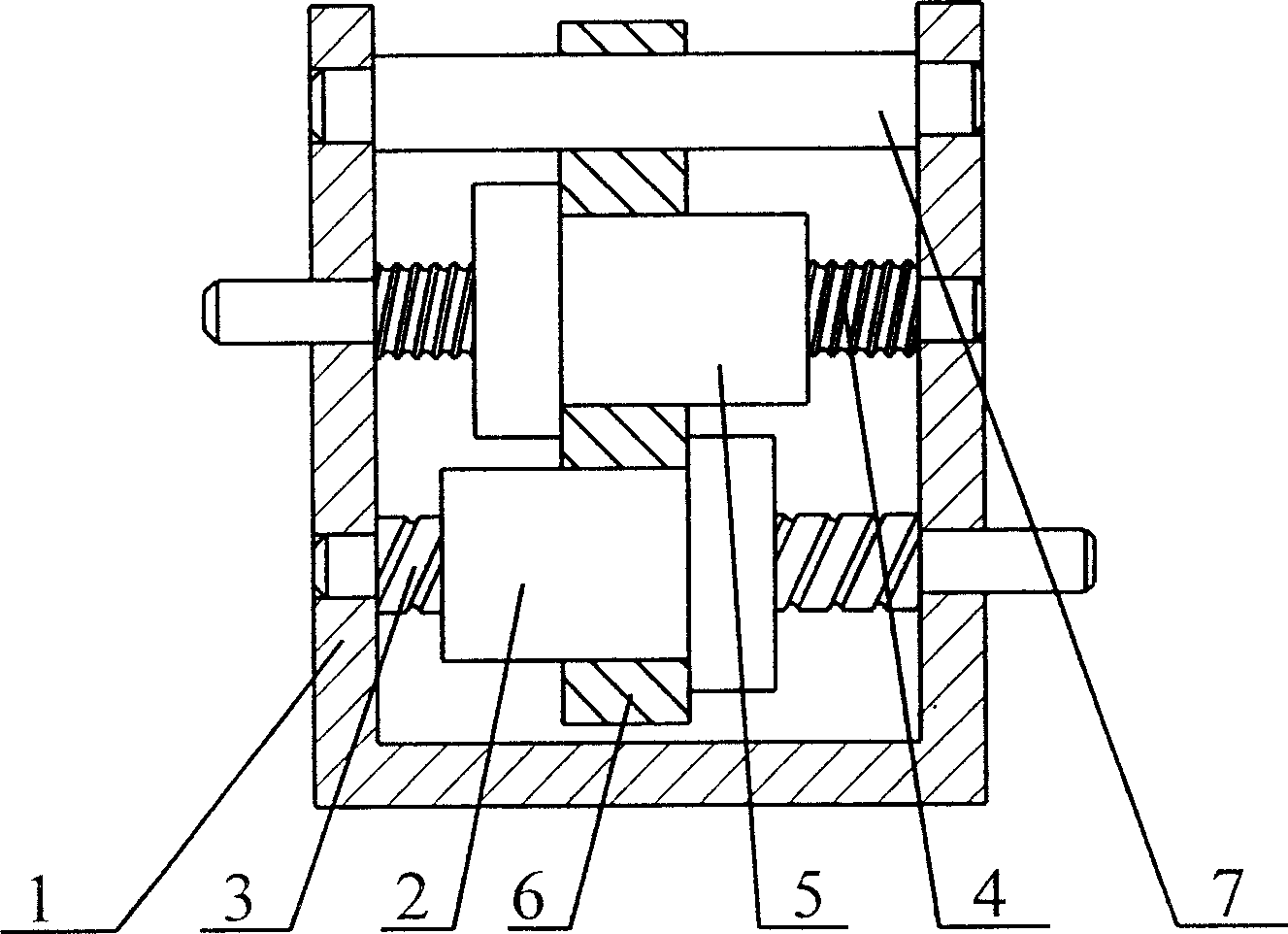

[0017] figure 2 Two rolling screw screws (3) and (4) and guide rails (7) with different leads are installed in parallel on the upper axis of the support (1) of a kind of gapless transmission mechanism of the present invention, and the rolling screw screws (3) and ( 4) Install the pre-tightening nuts (2) and (5) respectively, the transmission block (6) installed on the guide rail (7) is connected with the pre-tightening nuts (2) and (5), and the two rolling screws (3) And the axis of (4) is different from the axis.

[0018] figure 2 The working principle of the gapless transmission mechanism of the present invention shown is: if the rolling screw (3) turns, the preload nut (2) moves left and right, driving the transmission block (6) and the preload nut (5) along the guide rail (7) Move left and right, and the left and right movement of the pre-tightening nut (5) makes the rolling screw (4) rotate. If the leads of the rolling screw (3) and the rolling screw (4) are differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com