Oil mist separator

a technology of oil mist separator and separator, which is applied in the field of separator to achieve the effect of enhancing the performance of oil mist separation from blow-by gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

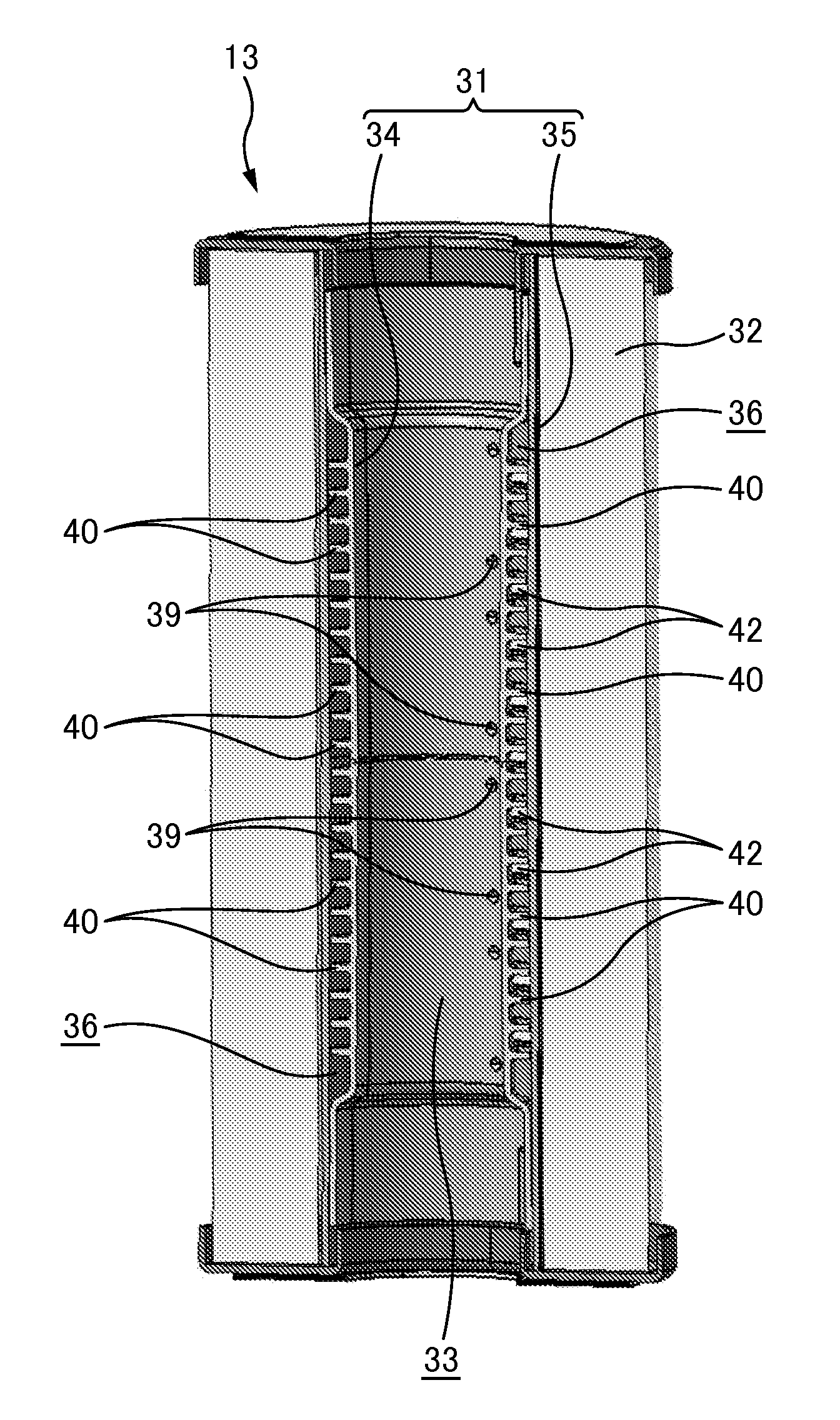

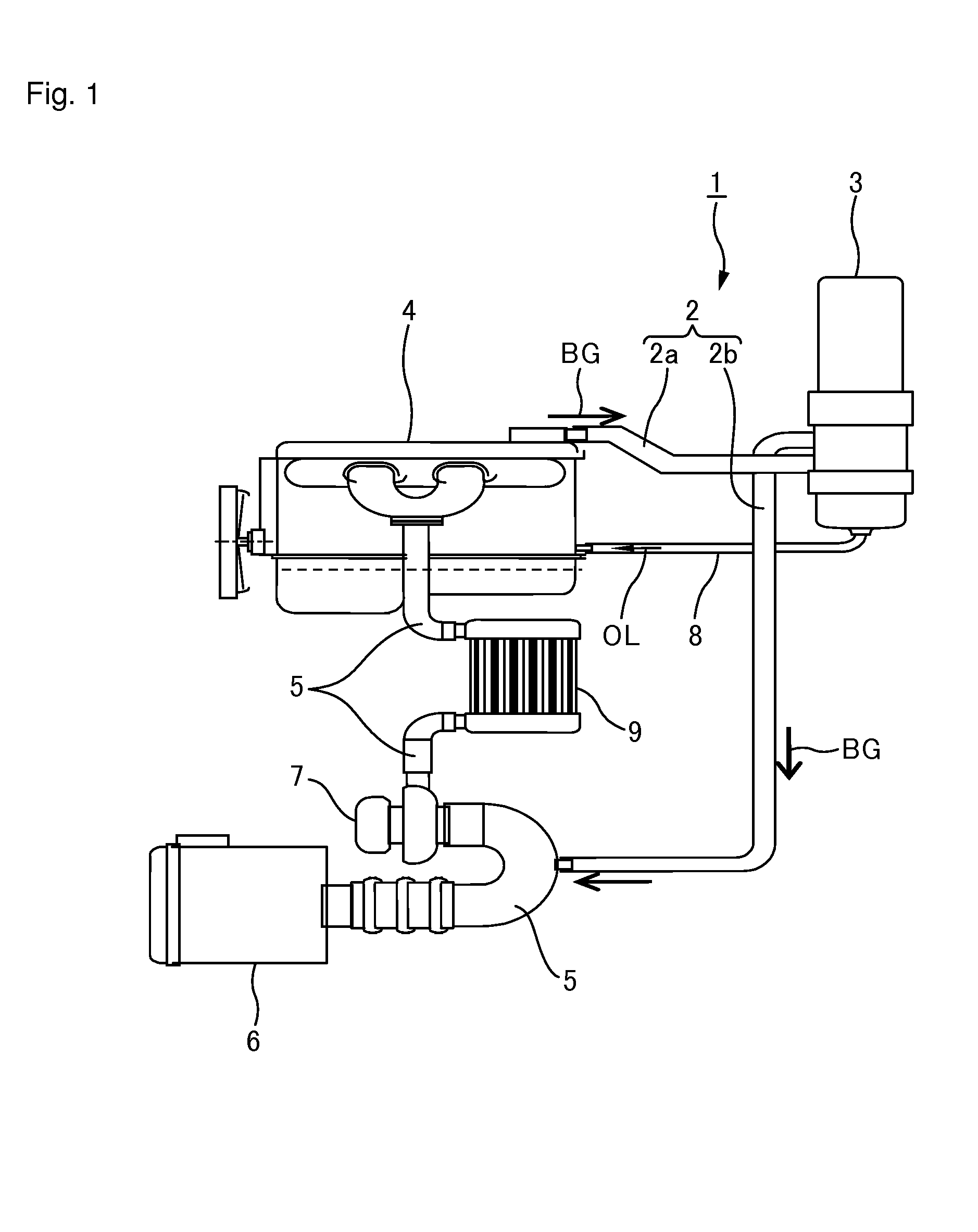

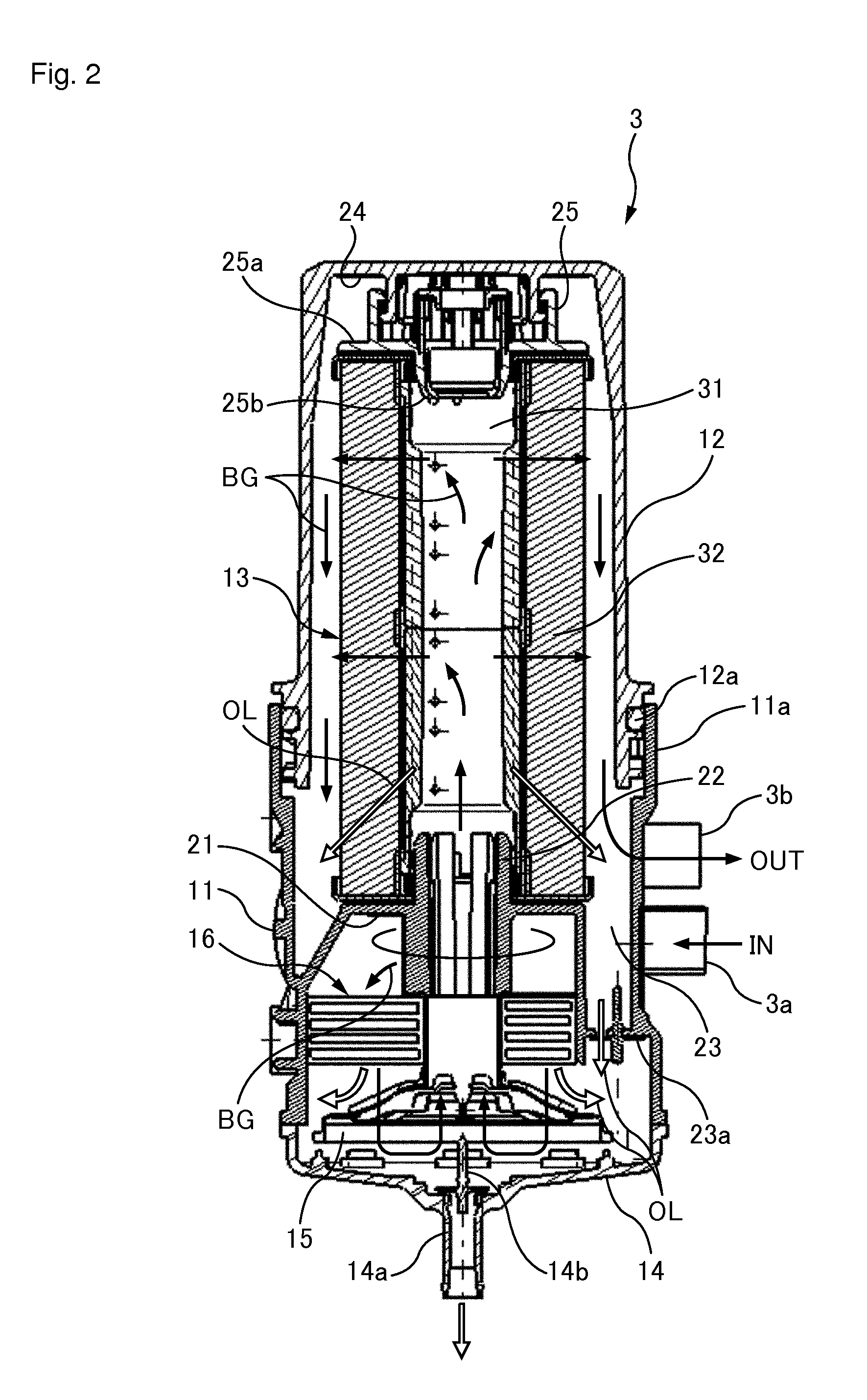

[0041]An embodiment of the present invention is described below with reference to the drawings. Here, an explanation is given on a closed crankcase ventilation system (hereinafter, referred to as a ventilation system).

[0042]As shown in FIG. 1, a ventilation system 1 includes a breather pipe 2 and an oil separator unit 3. The breather pipe 2 partitions a returning channel for returning blow-by gas BG (oil-containing gas) discharged from a crankcase of an engine 4 to an air inlet side channel 5 that is in communication with the engine 4. The breather pipe 2 of the present embodiment returns the blow-by gas BG to a part of the air inlet side channel 5, at a position connecting an air filter 6 and a turbocharger 7. The oil separator unit 3 is provided halfway along the breather pipe 2, and separates and collects oil OL from the blow-by gas BG and returns the oil to the engine 4.

[0043]With this ventilation system 1, the blow-by gas GB discharged from the engine 4 flows into the oil separ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flow rate | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com