Oil mist removing method with automatic cleaning and device thereof

An automatic cleaning and oil mist technology, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of high fan power, high operating costs, and easy noise generation, and achieve low flow resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

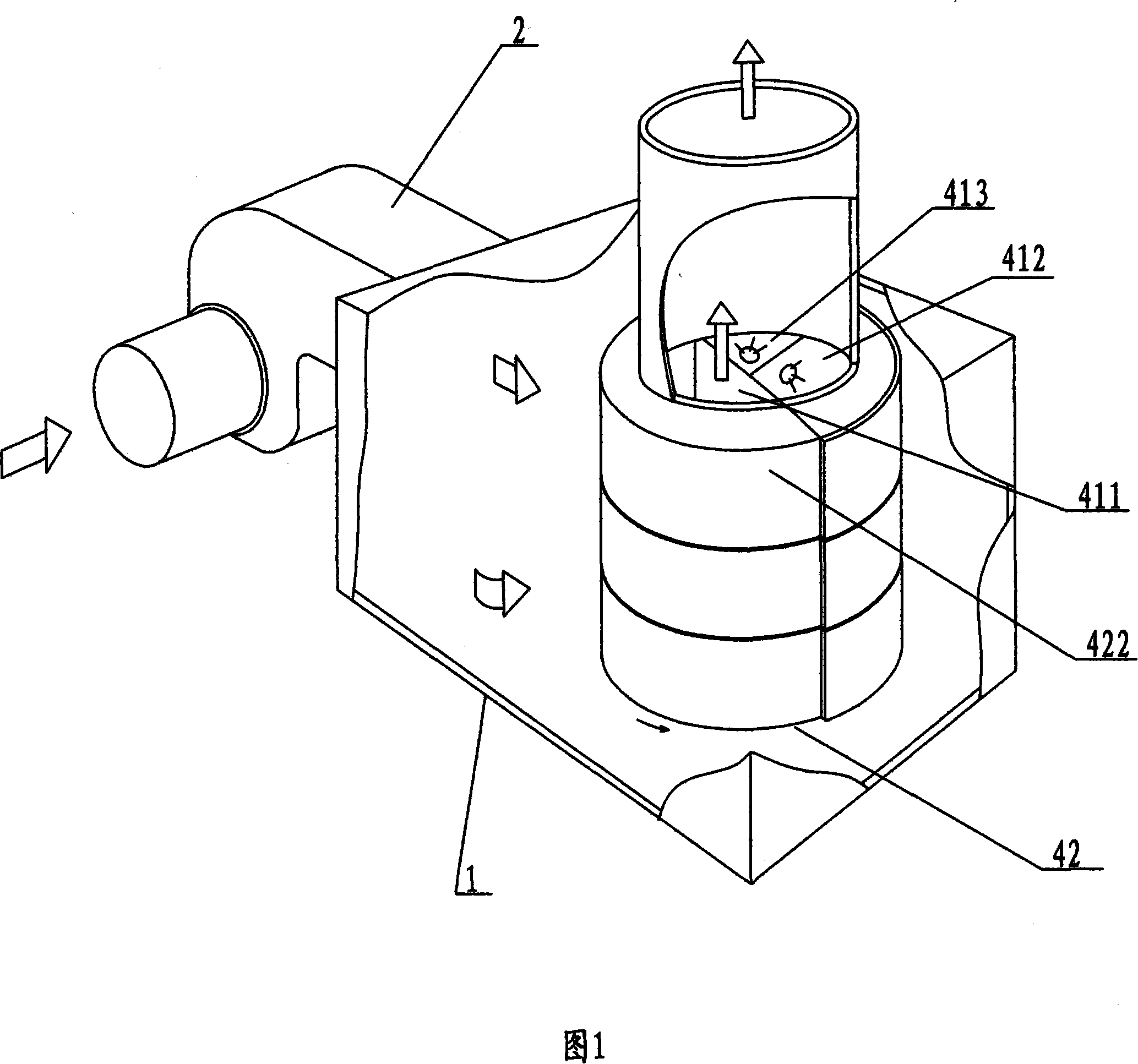

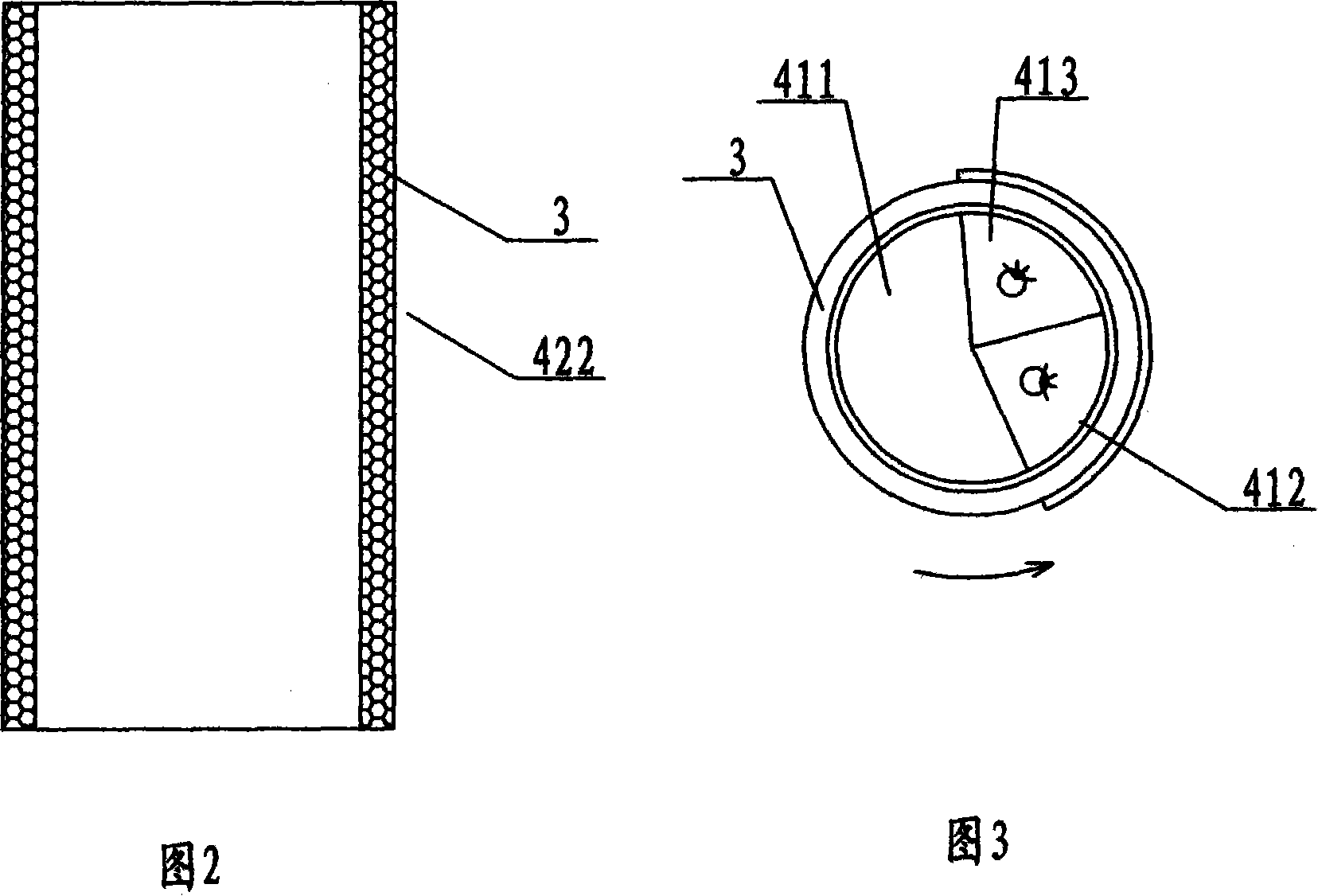

[0022] In the figure: 1, shell, 2, fan, 3, filter material, 411, gas treatment area, 412, liquid cleaning area, 413, gas backflushing area, 42, filter drum, 422, annular body.

[0023] As shown in the figure, the degreasing mist device with automatic cleaning in this embodiment includes a casing 1, a fan 2, and a filter material 3. A rotating mechanism 4 is arranged in the casing 1. The rotating mechanism includes a wheel frame and is arranged on the wheel frame. The filter drum 42 and the motor that drives the filter drum 42 to rotate, wherein,

[0024] The filter material 3 is installed on the filter drum 42, corresponding to the filter material 3 positions on the wheel frame, and is divided into a fan-shaped gas processing area 411, a liquid cleaning area 412, a gas backflushing area 413, and a liquid cleaning area 412 by a partition plate. The gas backflushing area 413 is not communicated with the gas to be treated entering the shell 1, and a cleaning agent and a spray dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com