Cold rolling oil composition and use thereof

An oil composition, cold rolling technology, applied in the field of cold rolling oil composition, can solve the problems of poor surface cleanliness after rolling, poor annealing cleanliness, heavy oil mist, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~11

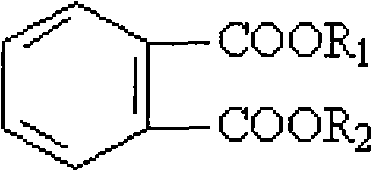

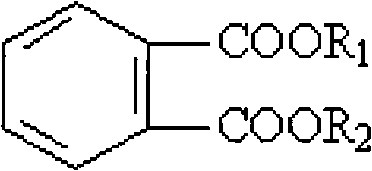

[0029] Mix the required amount of base oil, aromatic acid diester, fatty acid monoester, antioxidant, metal deactivator, extreme pressure agent and anti-fogging agent, heat to 50°C, stir at constant temperature for 90 minutes, and pack in cans after passing the inspection . Wherein each component and its parts by weight are shown in Table 1, and the product properties are shown in Table 2 and Table 3.

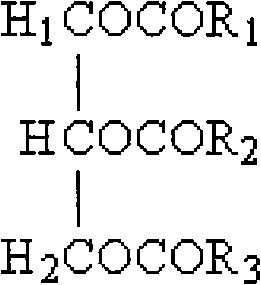

[0030] Fatty acid monoesters in Table 1, wherein butyl laurate is synthesized from lauric acid and butanol, amyl stearate is synthesized from stearic acid and amyl alcohol, and octyl palmitate is synthesized from palmitic acid and octanol , Butyl oleate is synthesized from oleic acid and butanol, octyl linoleate is synthesized from linoleic acid and octyl ester, heptyl myristate is synthesized from myristic acid and heptanol, butyl stearate Esters are synthesized from stearic acid and butanol, and hexyl laurate is synthesized from lauric acid and hexanol. Its synthesis proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com