Method and device for removing oil mist and volatile organic matter in oil smoke

A technology for volatile organic compounds and oily fumes, applied in chemical instruments and methods, separation methods, and separation of dispersed particles, can solve problems such as complex structures, hazards, and incomplete degradation, and achieve high purification efficiency, strong economy, and easy promotion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

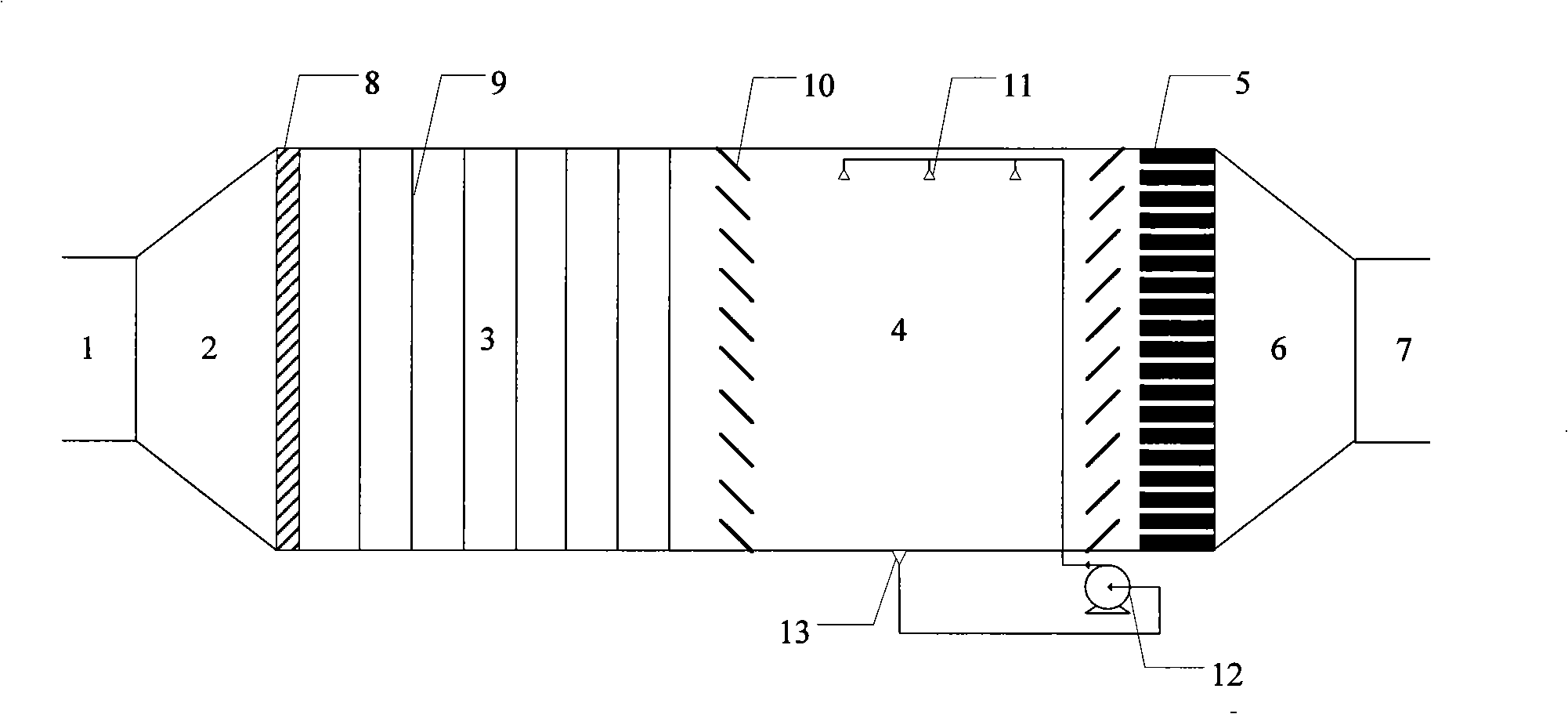

[0045] Combine below figure 2 The technical scheme of the present invention is described further, figure 2 is only one means to implement the method.

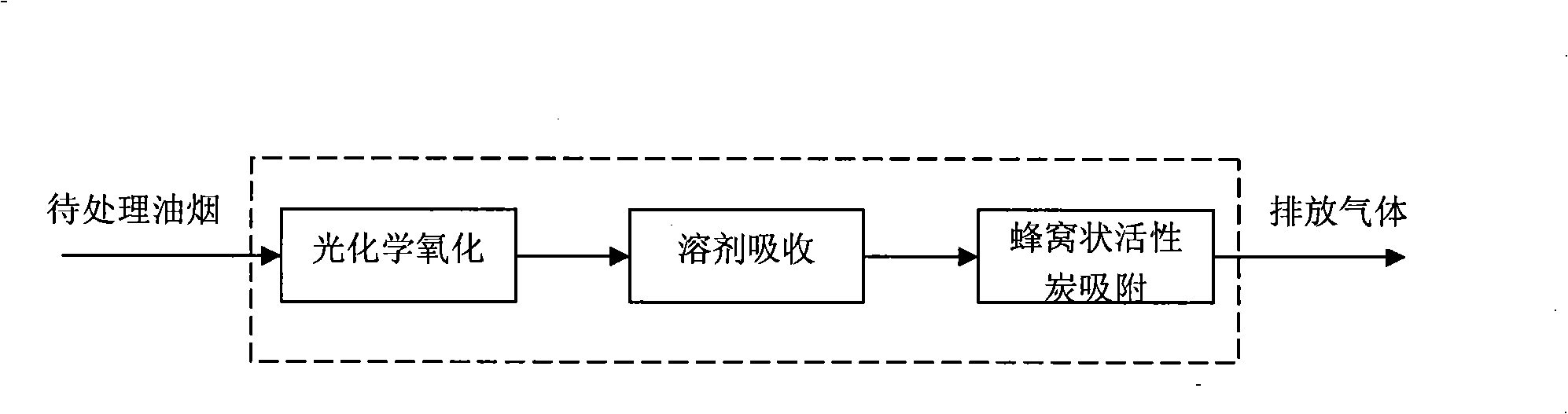

[0046] As shown in the figure, the main body of the purifier is a cylindrical or prismatic container, the outer wall is made of stainless steel, and it is installed on the oil fume exhaust pipe. The gas path is narrowed through the air intake adjustment area 2 in the front and rear of the container so as to be connected with the exhaust pipe and to make the gas flow evenly distributed in the reactor. After the air flows in through the air inlet 1, it passes through the air inlet adjustment area 2, the photochemical oxidation area 3, the spray absorption area 4, the honeycomb activated carbon adsorption area 5, the air outlet adjustment area 6, and finally is discharged through the air outlet 7.

[0047] There is a metal filter grid 8 at the front end of the photochemical oxidation zone, which is only used to block the large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com