Low temperature water mist and oil mist cutting cooling lubrication supply system

A cooling lubrication and supply system technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of quality affecting tool life processing, impact of tool life, loss of lubrication, etc., to achieve good lubrication and cooling effect, tool life extension, cutting temperature reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

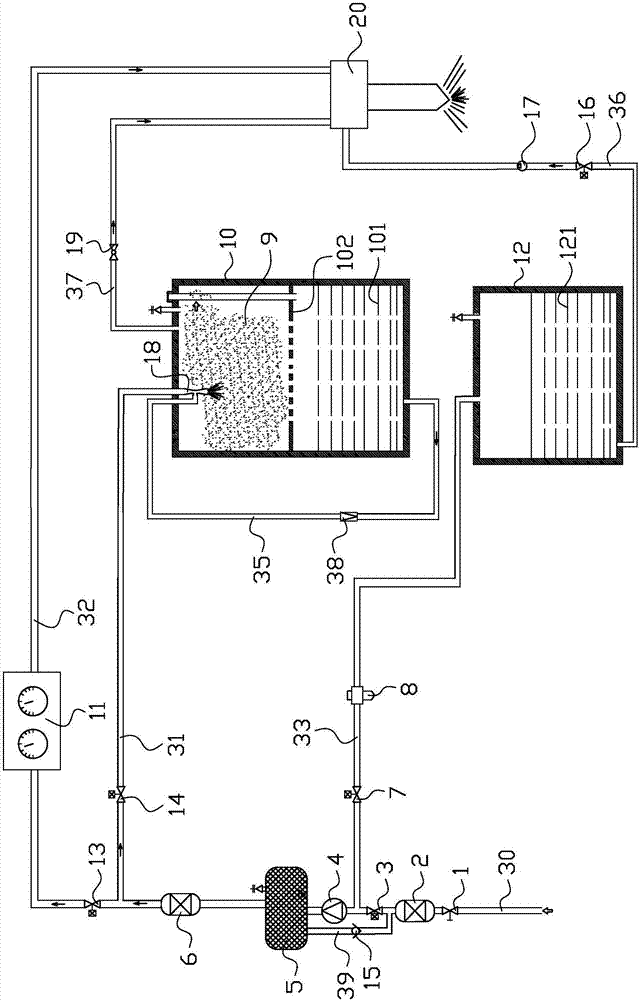

[0034] Such as figure 1 , figure 2 , Figure 4 As shown, the low-temperature water mist oil mist cutting cooling and lubrication supply system provided by the first embodiment of the present invention is suitable for providing cooling and lubrication for cutting of difficult-to-machine materials. The system includes:

[0035] Air booster pump 4 and gas tank 5, the inlet end of air booster pump 4 is connected with compressed air source, the outlet end of air booster pump 4 is connected with air tank 5, and air booster pump 4 increases the gas of compressed air source Store in the gas tank 5 after pressing;

[0036] Water tank 12, water 121 is housed in the water tank 12;

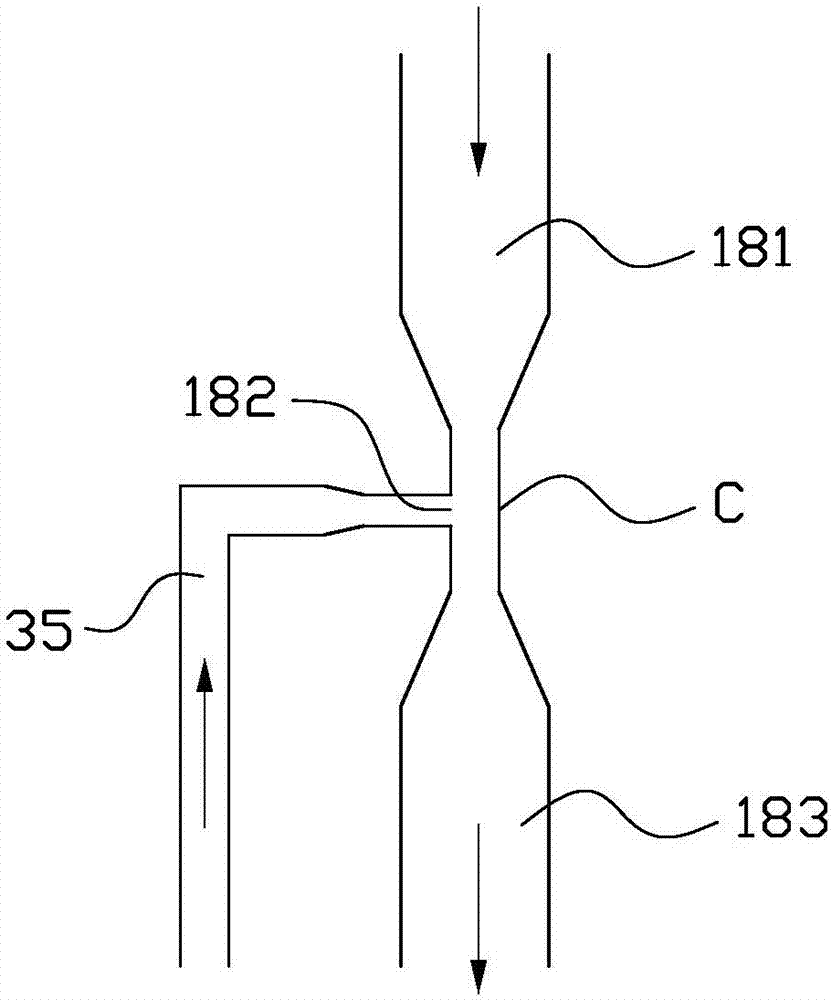

[0037] Atomization chamber 10, cutting oil 101 is installed in the atomization chamber 10, a Venturi atomization nozzle 18 is arranged on the inner cavity of the atomization chamber 10, and the Venturi atomization nozzle 18 has an air inlet 181, an oil suction port 182 and an injection outlet 183, the air ...

no. 2 example

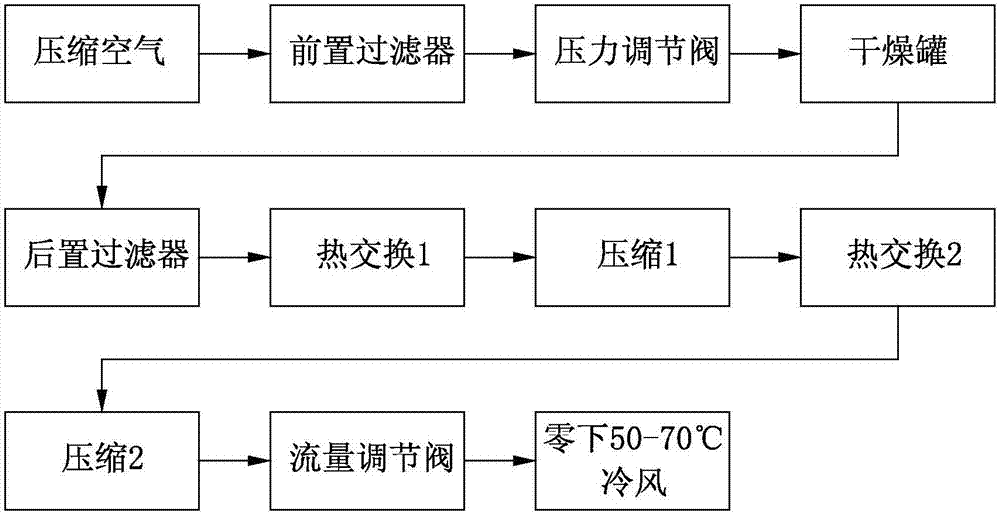

[0078] Such as Figure 5 As shown, the low-temperature water mist oil mist cutting cooling lubrication supply system provided by the second embodiment of the present invention is basically the same as the first embodiment above, the difference is that in this embodiment, the water tank 12 and the air intake pipe 30 are eliminated. The third air delivery pipe 33 between them also cancels the electromagnetic valve 7 and the pressure regulating valve 8 arranged on the third air delivery pipe 33 simultaneously. This embodiment relies on the suction force produced by the water pump 17 and the oil-water mixing Venturi tube 220 to draw water from the water tank 12, which can also achieve the purpose of the present invention. The remaining structures and working principles of this embodiment are the same as those of the first embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com