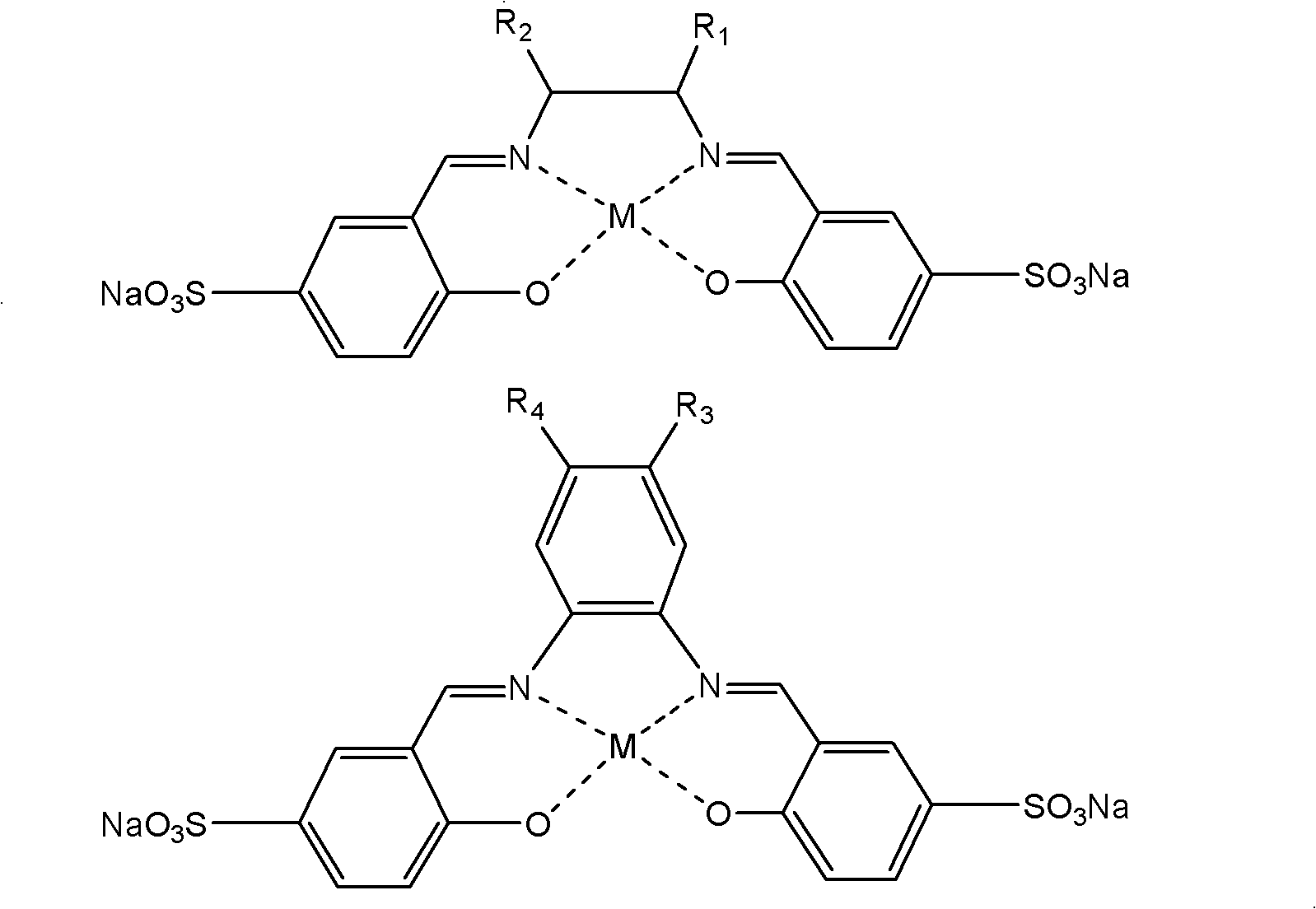

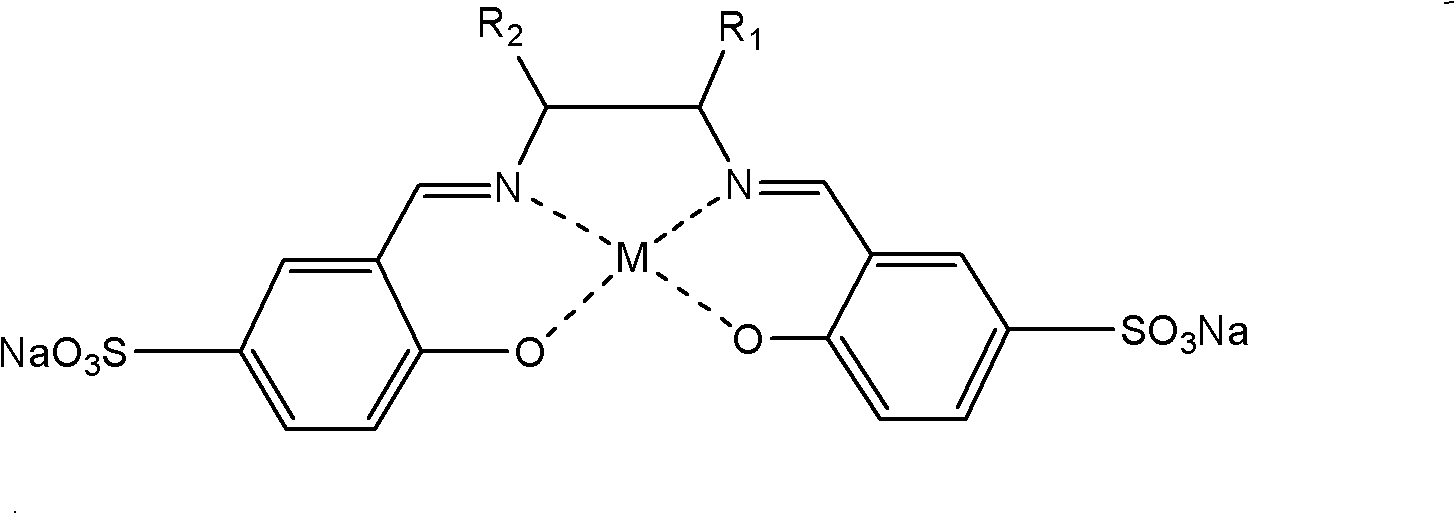

Method for low-temperature activated bleaching by using Schiff base metal complexes

A technology of alkali metal complexes and metal complexes, applied in the field of low-temperature activated bleaching, can solve the problems of immature application, difficult penetration, low process temperature, etc., and achieve the effect of reducing the pH of the working liquid and shortening the stacking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

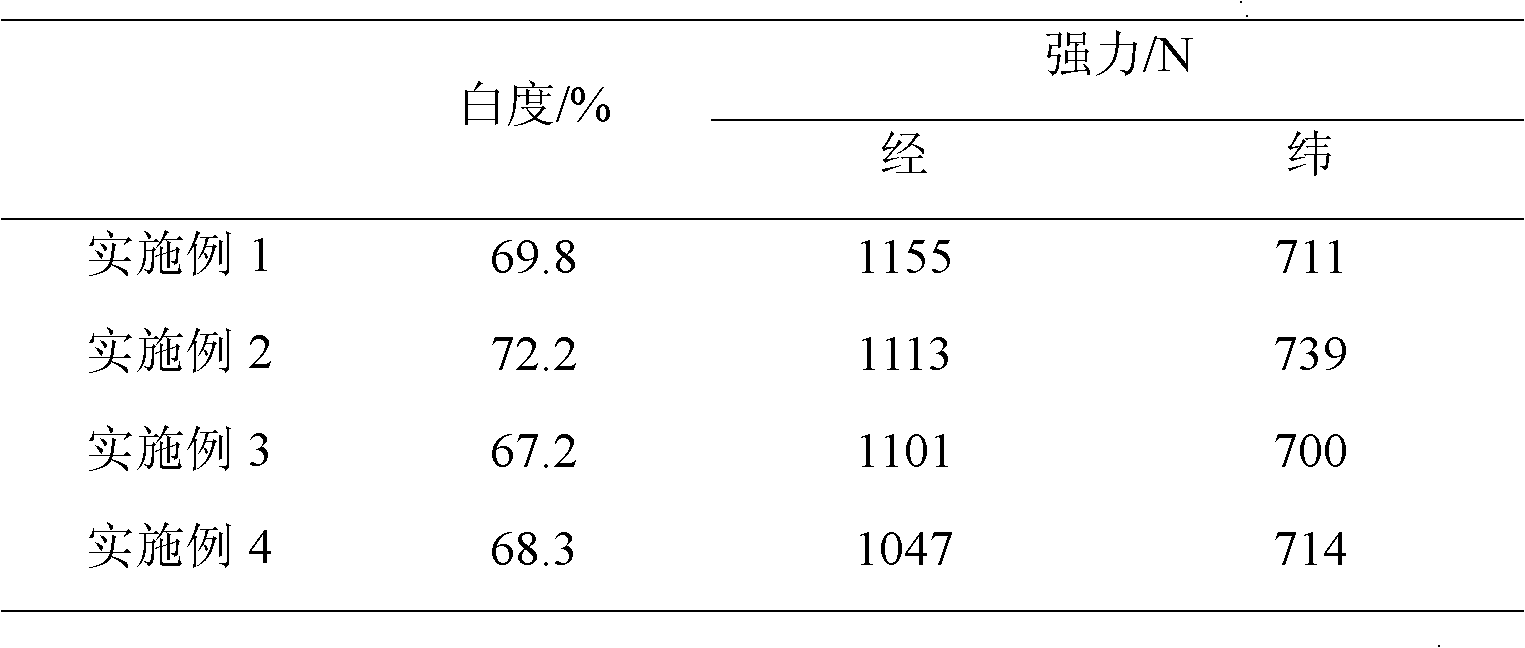

Embodiment 1

[0037] (1) Preparation and padding steps of bleaching working solution: the composition ratio of this bleaching working solution is: 30% H 2 o 2 Dosage: 30g / L; Dosage of sulfosalicylaldehyde ethylenediamine Schiff base copper complex: 21μmol / L; Dosage of penetrant: 2g / L; Dosage of stabilizer: 0.2g / L; Adjust the pH of the working solution to 7.

[0038] (2) Padding step: the pure cotton semi-bleached cloth is soaked and rolled twice in a uniform padding machine with the working solution prepared in the above (1), and the liquid-carrying rate is 95%.

[0039] (3) Steaming step: the steaming temperature is 80° C., and the steaming time is 1 hour.

[0040] (4) Water washing: wash the steamed cotton fabric twice with hot water at 50° C. to 80° C., and then fully wash it with cold water.

Embodiment 2

[0042] (1) Preparation and padding steps of bleaching working solution: the composition ratio of this bleaching working solution is: 30% H 2 o 2 Dosage: 30g / L; Dosage of sulfosalicylaldehyde ethylenediamine Schiff base copper complex: 18μmol / L; Dosage of penetrant: 2g / L; Dosage of stabilizer: 0.2g / L; Adjust the pH of the working solution to 9.

[0043] (2) Padding step: the pure cotton semi-bleached cloth is soaked and rolled twice in a uniform padding machine with the working solution prepared in the above (1), and the liquid-carrying rate is 95%.

[0044] (3) Steaming step: the steaming temperature is 80° C., and the steaming time is 1.5 hours.

[0045] (4) Water washing: wash the steamed cotton fabric twice with hot water at 50° C. to 80° C., and then fully wash it with cold water.

Embodiment 3

[0047] (1) Preparation and padding steps of bleaching working solution: the composition ratio of this bleaching working solution is: 30% H 2 o 2 Dosage: 30g / L; Dosage of sulfosalicylaldehyde ethylenediamine Schiff base copper complex: 15μmol / L; Dosage of penetrant: 2g / L; Dosage of stabilizer: 0.2g / L; Adjust the pH of the working solution to 9.

[0048] (2) Padding step: the pure cotton semi-bleached cloth is soaked and rolled twice in a uniform padding machine with the working solution prepared in the above (1), and the liquid-carrying rate is 95%.

[0049] (3) Steaming step: the steaming temperature is 75° C., and the steaming time is 1 hour.

[0050] (4) Water washing: wash the steamed cotton fabric twice with hot water at 50° C. to 80° C., and then fully wash it with cold water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com