Chemically activated dental bleaching trays

a technology of chemical activation and dental bleaching strips, which is applied in dentistry, tooth rinsing, funeral devices, etc., can solve the problems of difficulty for users to maintain the bleaching strip in its proper position, prone to slippage of conventional bleaching strips, and impediment to successful bleaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

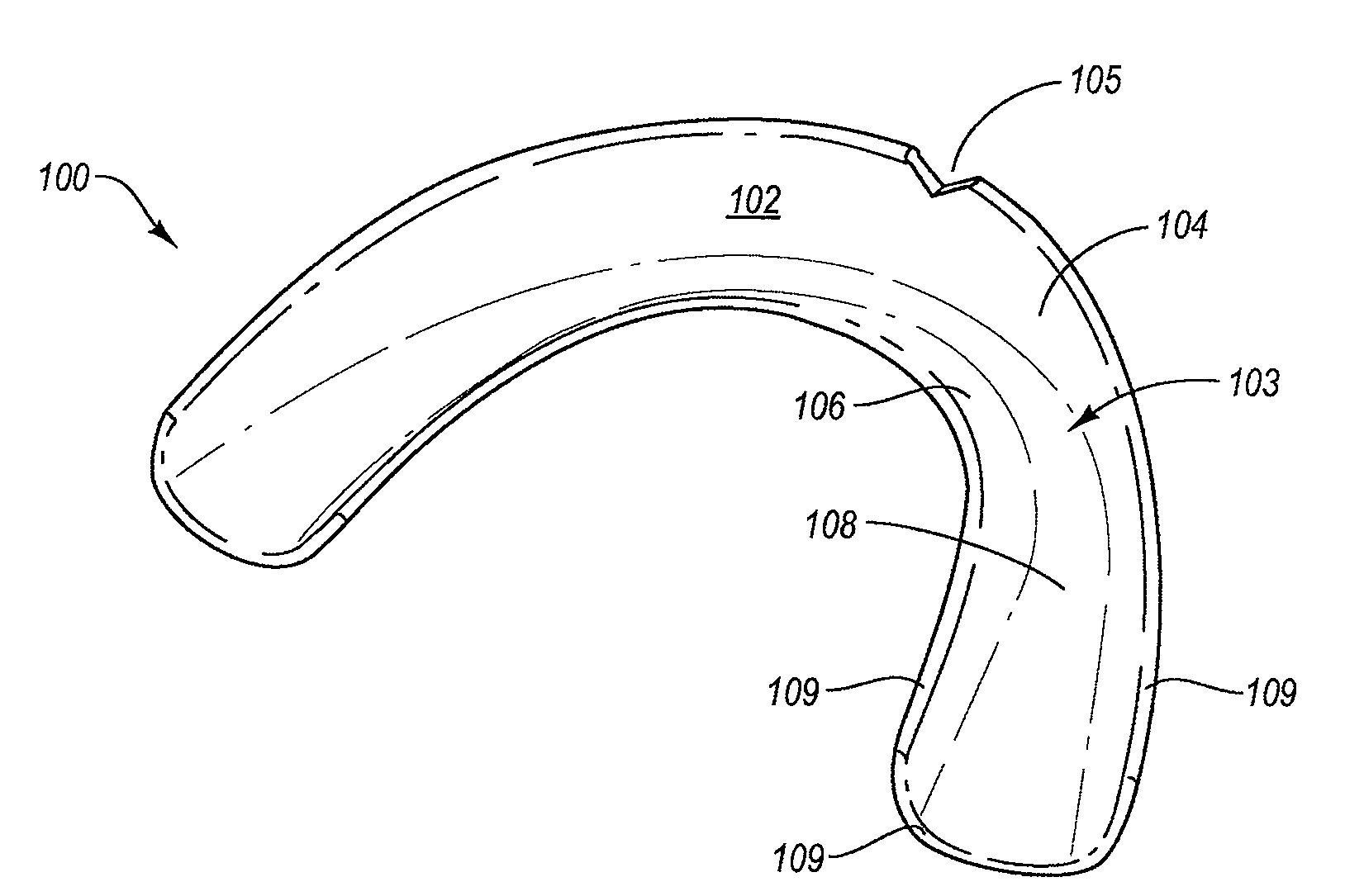

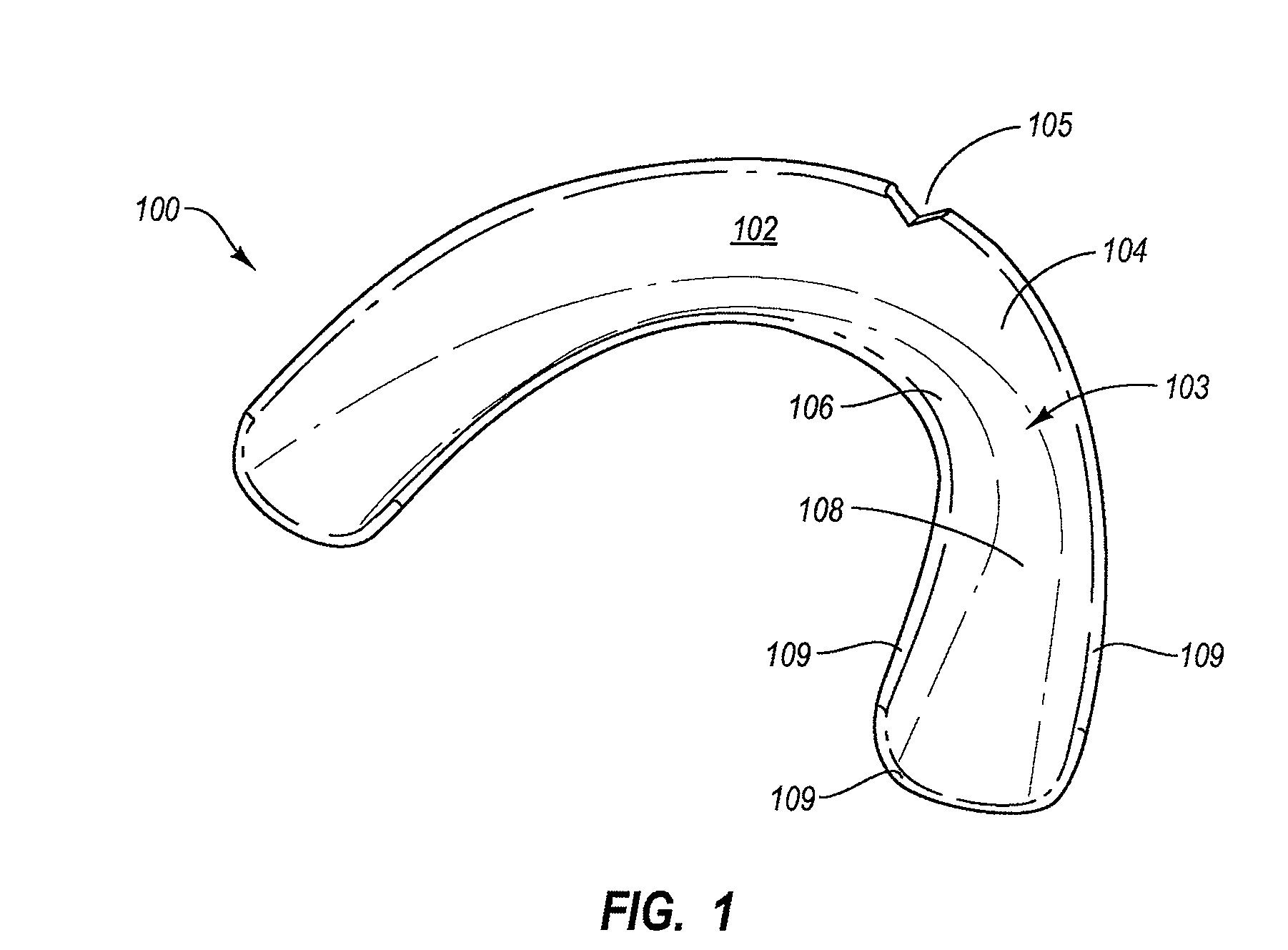

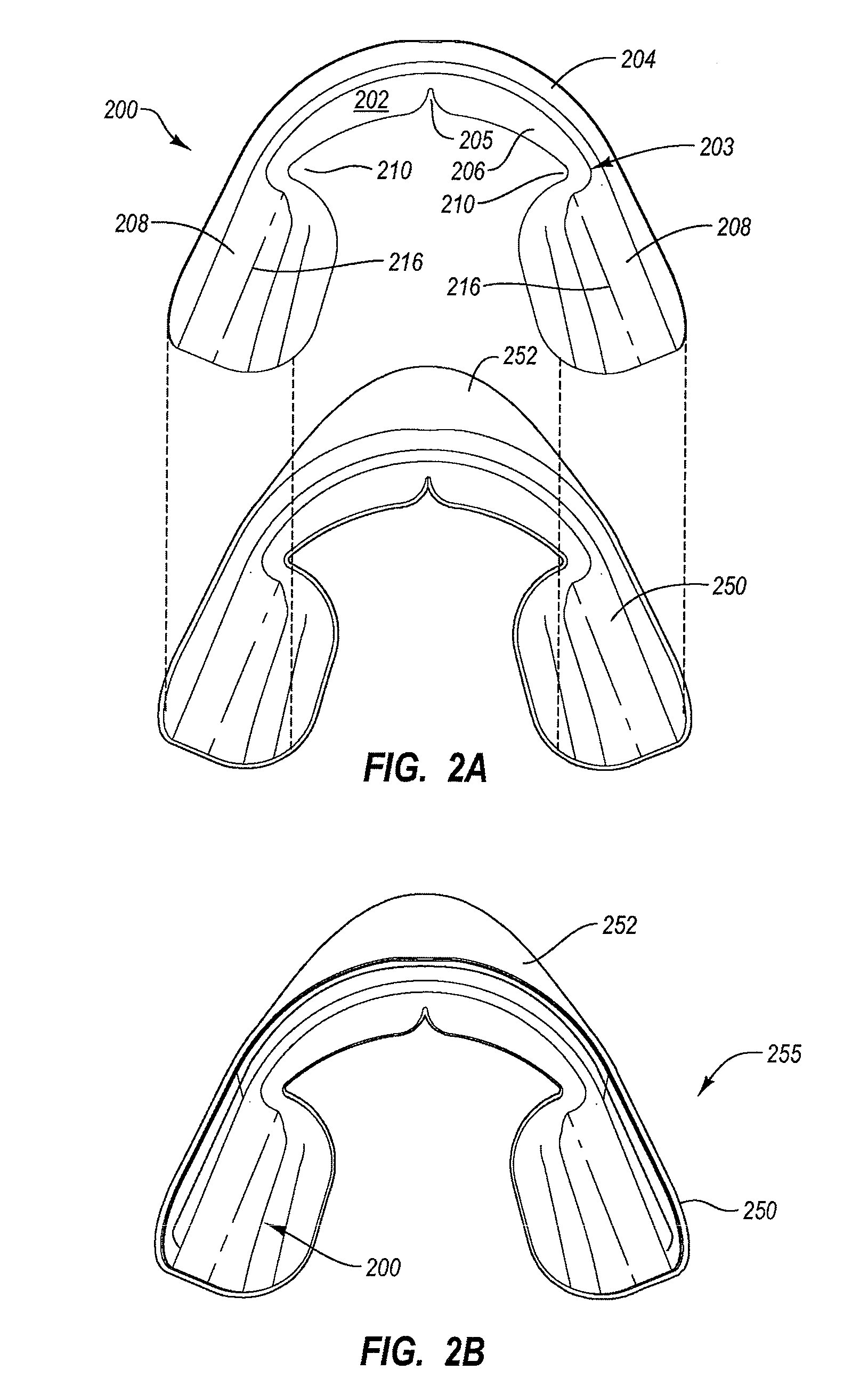

Image

Examples

example 1

[0062]A composition for injection molding a silicone dental treatment tray was formed from Shin-Etsu's KEG2000-50A / B two part thermoset silicone material. Part A containing the activator / hardener had a viscosity of about 1700 Pa-s, while part B containing the siloxane had a viscosity of about 1600 Pa-s. At least one part included a platinum catalyst.

[0063]The two parts of the silicone composition were pumped out of storage drums through hoses to a static mixing head where the two parts were mixed together. The mixed silicone material exits the static mixer and was forced into the screw and barrel of the injection molding machine. The mixed silicone material was injected into the heated mold (e.g., about 375° F.), at which point the material quickly polymerized. The tray was removed from the hot mold after polymerization was substantially complete. Exemplary formed trays exhibited excellent adaptability, flexibility, elasticity, and softness, while also being resilient. The molded tr...

example 2

[0064]A composition for injection molding a dental treatment tray was formed from SEBS TPE 45A material. The heated material was pumped so as to be forced into the screw and barrel of the injection molding machine. The material was injected into the mold. The cooled tray was removed from the mold. Exemplary formed SEBS trays exhibited excellent adaptability, flexibility, elasticity, and softness, while also being resilient, similar to the silicone tray of Example 1. The molded trays were translucent, had a Shore A durometer hardness of about 45, an elasticity of about 800% and a wall thickness of about 0.020 inch (0.5 mm). The trays were found to be very comfortable when worn over a person's dental arch, with excellent adaptability, flexibility, elasticity, softness, and resiliency. A bleaching agent destabilizer (e.g., about 0.1 percent to about 5 percent by weight) may be compounded with the SEBS material prior to molding so that the finished trays include the bleaching agent dest...

example 3

[0065]A composition for injection molding a dental treatment tray is formed from VERSAFLEX CL30. The heated TPE material is pumped so as to be forced into the screw and barrel of the injection molding machine. The material is injected into the mold. The cooled tray is removed from the mold. Exemplary formed VERSAFLEX CL30 trays exhibit excellent adaptability, flexibility, elasticity, and softness, while also being resilient, similar to the silicone tray of Example 1. The molded trays are translucent, have a Shore A durometer hardness of about 30, an elasticity of about 780% and a wall thickness of about 0.020 inch (0.5 mm). The trays are very comfortable when worn over a person's dental arch, with excellent adaptability, flexibility, elasticity, softness, and resiliency A bleaching agent destabilizer (e.g., about 0.1 percent to about 5 percent by weight) may be compounded with the VERSAFLEX material prior to molding so that the finished trays include the bleaching agent destabilizer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com