Detergent composition containing low-temperature bleaching and activation system

A technology for activating systems and detergents, which is applied in the direction of surface-active detergent compositions, detergent compositions, organic detergent compositions, etc., can solve the problems of increasing formula costs, achieve good bleaching and washing effects, improve activation efficiency, and improve The effect of washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

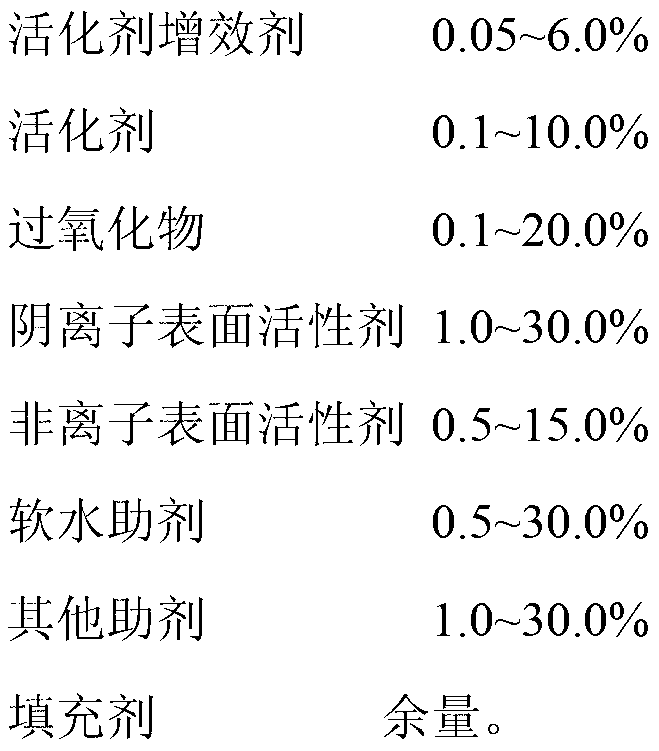

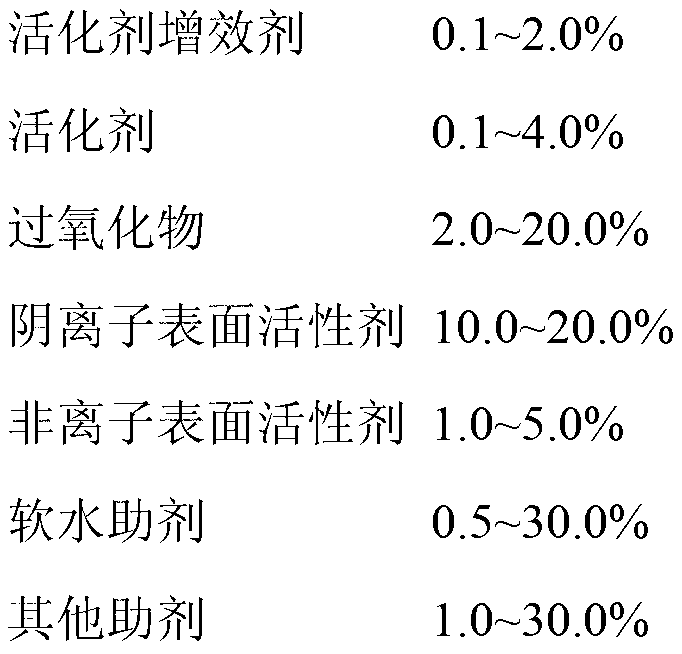

Method used

Image

Examples

Embodiment 1~2

[0051] The composition of the present embodiment is shown in Table 2, and its production steps are as follows:

[0052] (1) Add process water, C 11 ~C 13 Sodium alkylbenzene sulfonate, C12~C18 fatty acid sodium, sodium citrate, sodium silicate, soda ash, Acusol445N, whitening agent CBS-X, sodium sulfate, activator synergist (EDTMPAS) start stirring, mix well Form a slurry with a solid content of 65%-75%, and control the temperature of the slurry at 65°C-75°C;

[0053] (2) After the slurry is aged and filtered, it is transported to the top of the powder spraying tower through the pipeline to obtain the base powder of washing powder by spray drying;

[0054] (3) The base powder is transported to the post-equipment device system through wind blowing and screening;

[0055] (4) Add C to the base powder according to the proportion 12 ~C 14 Fatty alcohol polyoxyethylene ether (EO=7), peroxide, enzyme preparation, essence, and TAED are prepared as raw materials, mixed and stirre...

Embodiment 3~4

[0060] The composition of the present embodiment is shown in Table 3, and its production steps are as follows:

[0061] (1) Add process water, C 11 ~C 13 Sodium alkylbenzene sulfonate, C12~C18 fatty acid sodium, sodium citrate, sodium silicate, soda ash, Acusol445N, whitening agent CBS-X, sodium sulfate, activator synergist (EDTMPAS) start stirring, mix well Form a slurry with a solid content of 65%-75%, and control the temperature of the slurry at 65°C-75°C;

[0062] (2) After the slurry is aged and filtered, it is transported to the top of the powder spraying tower through the pipeline to obtain the base powder of washing powder by spray drying;

[0063] (3) The base powder is transported to the post-equipment device system through wind blowing and screening;

[0064] (4) Add C to the base powder according to the proportion 12 ~C 14 Fatty alcohol polyoxyethylene ether (EO=7), enzyme preparation, essence, and TAED are prepared as raw materials, mixed and stirred evenly, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com