Patents

Literature

122results about How to "Superior emission lifetime" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

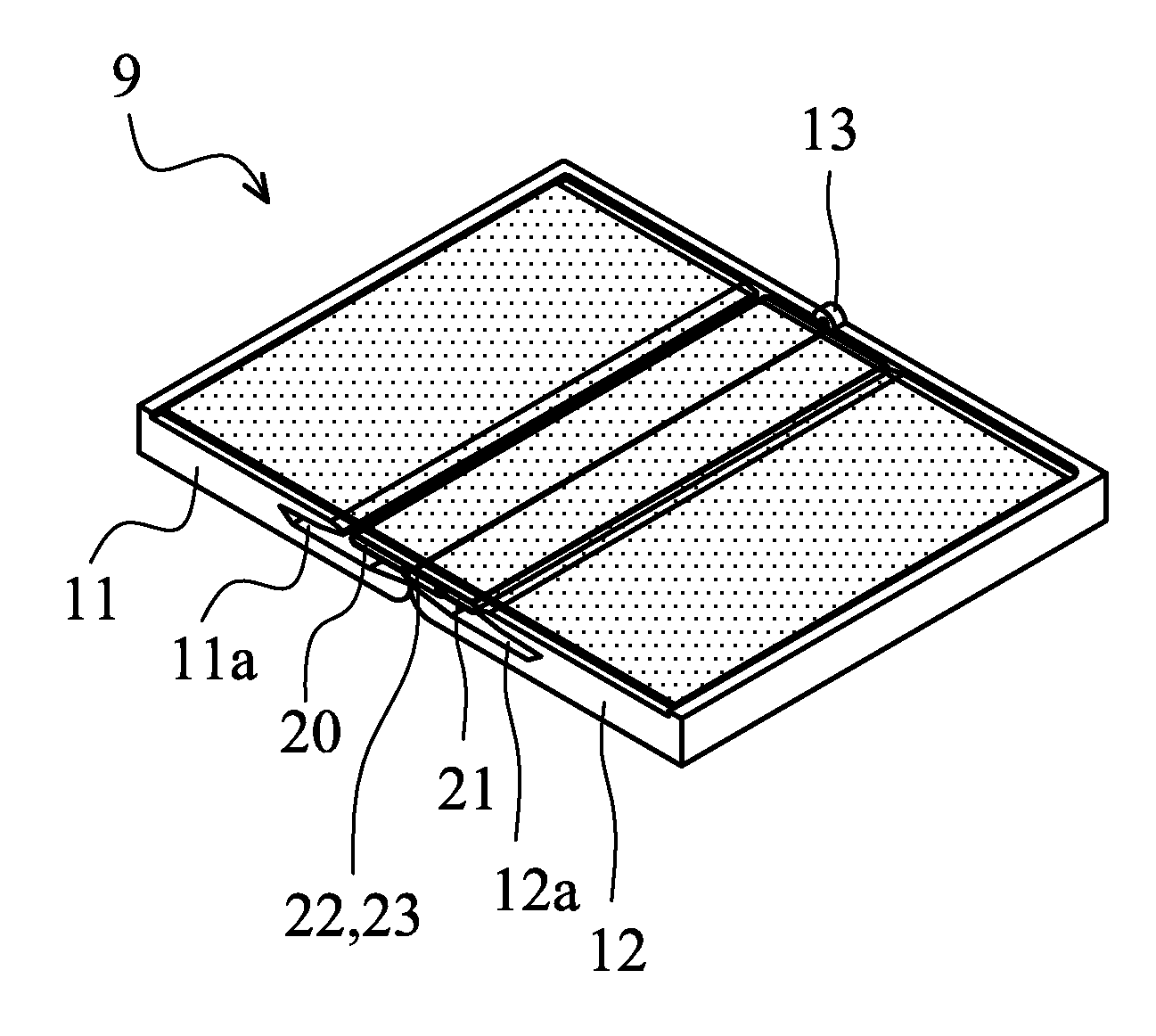

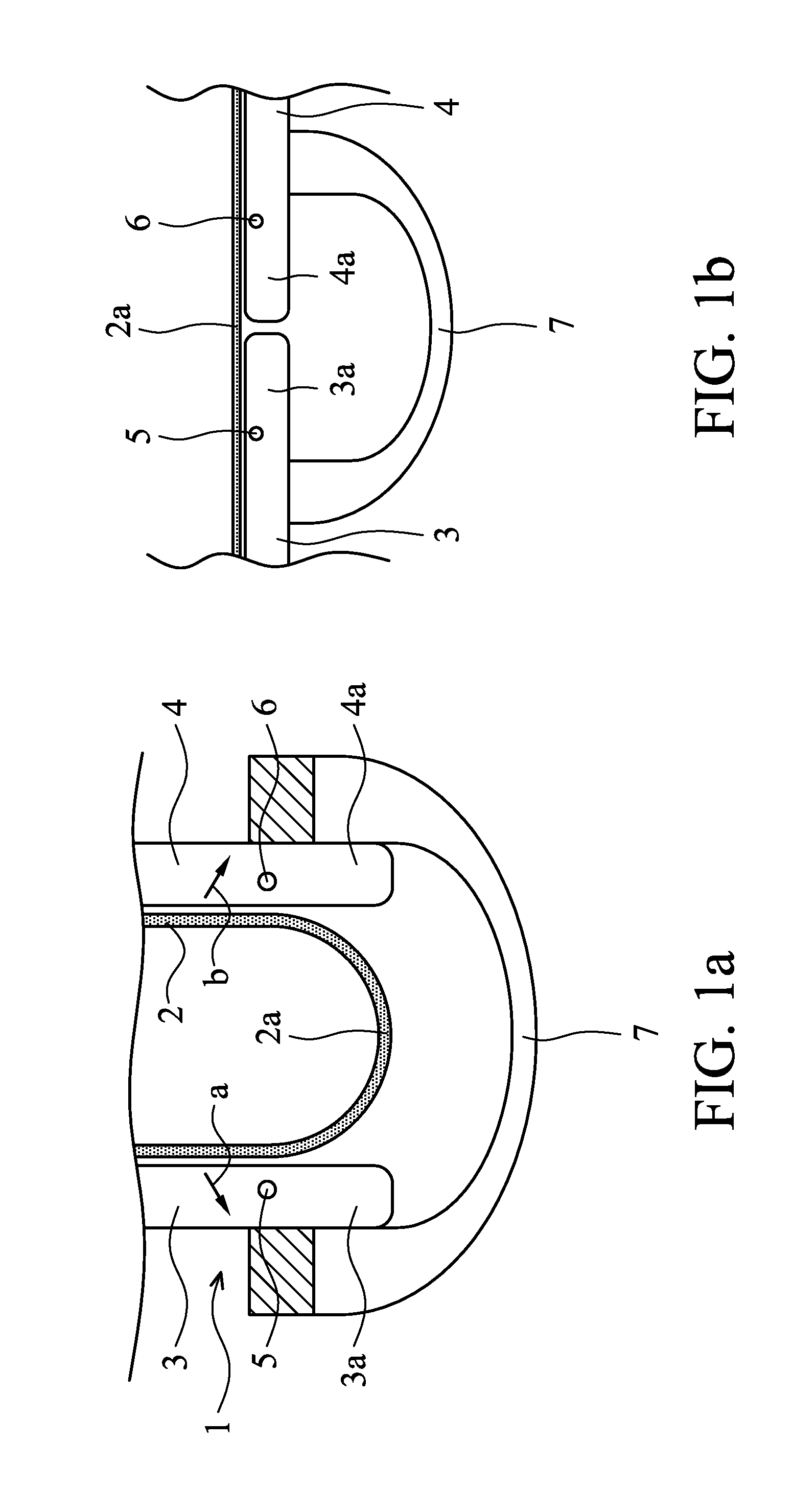

Flexible display with display support

ActiveUS20130021762A1Less likely can be damagedGood quality perceptionDigital data processing detailsCasings with display/control unitsDisplay deviceFlexible display

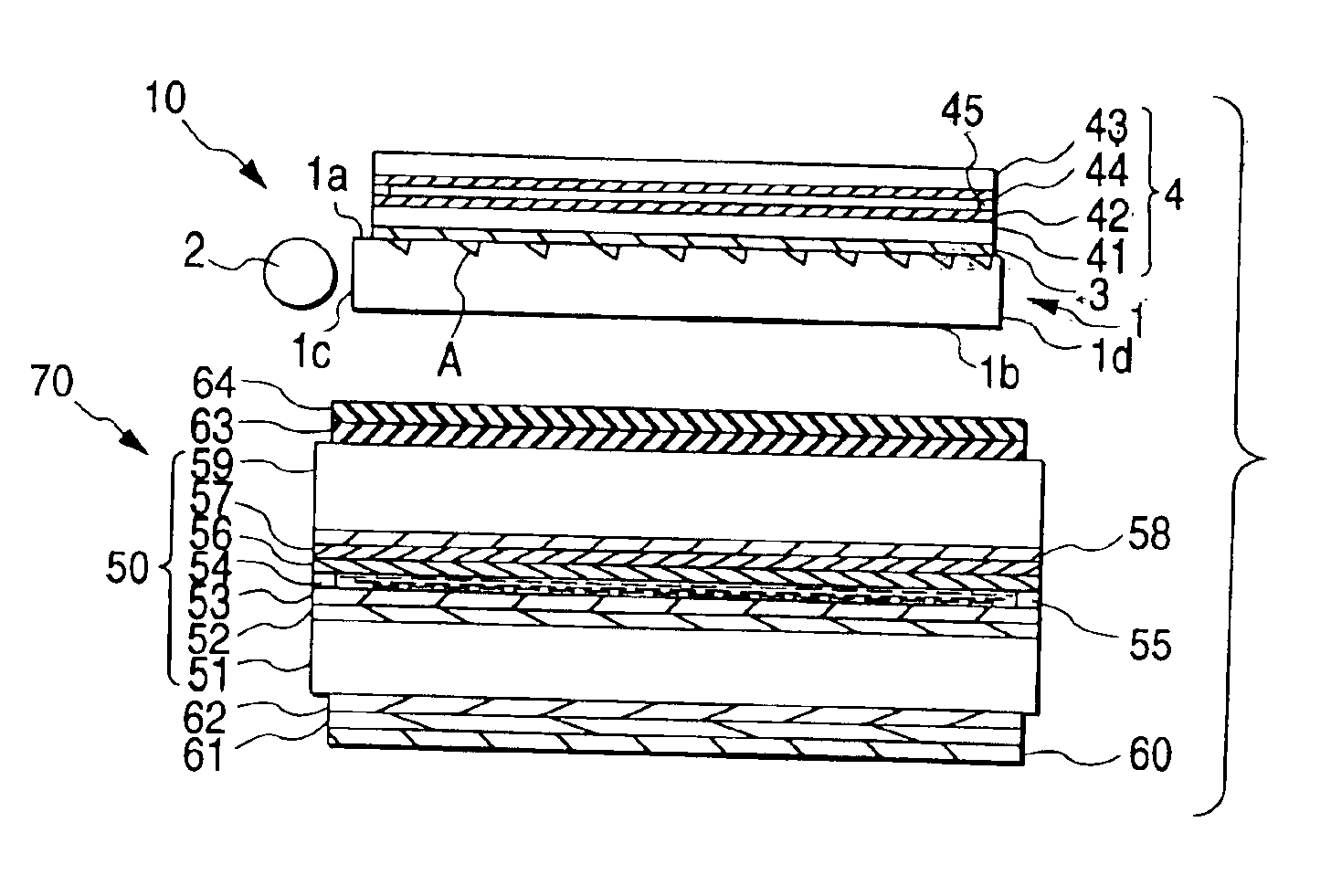

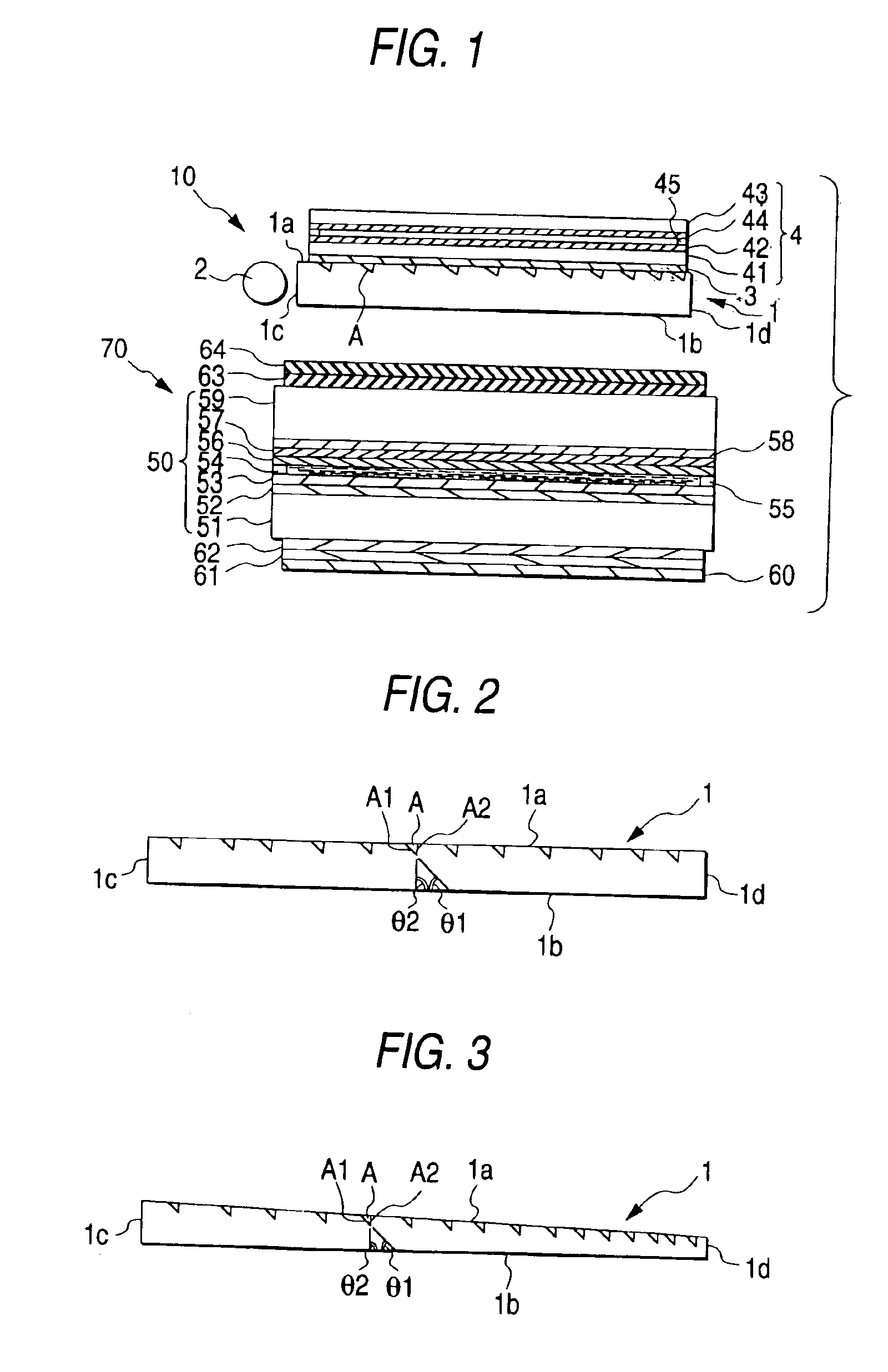

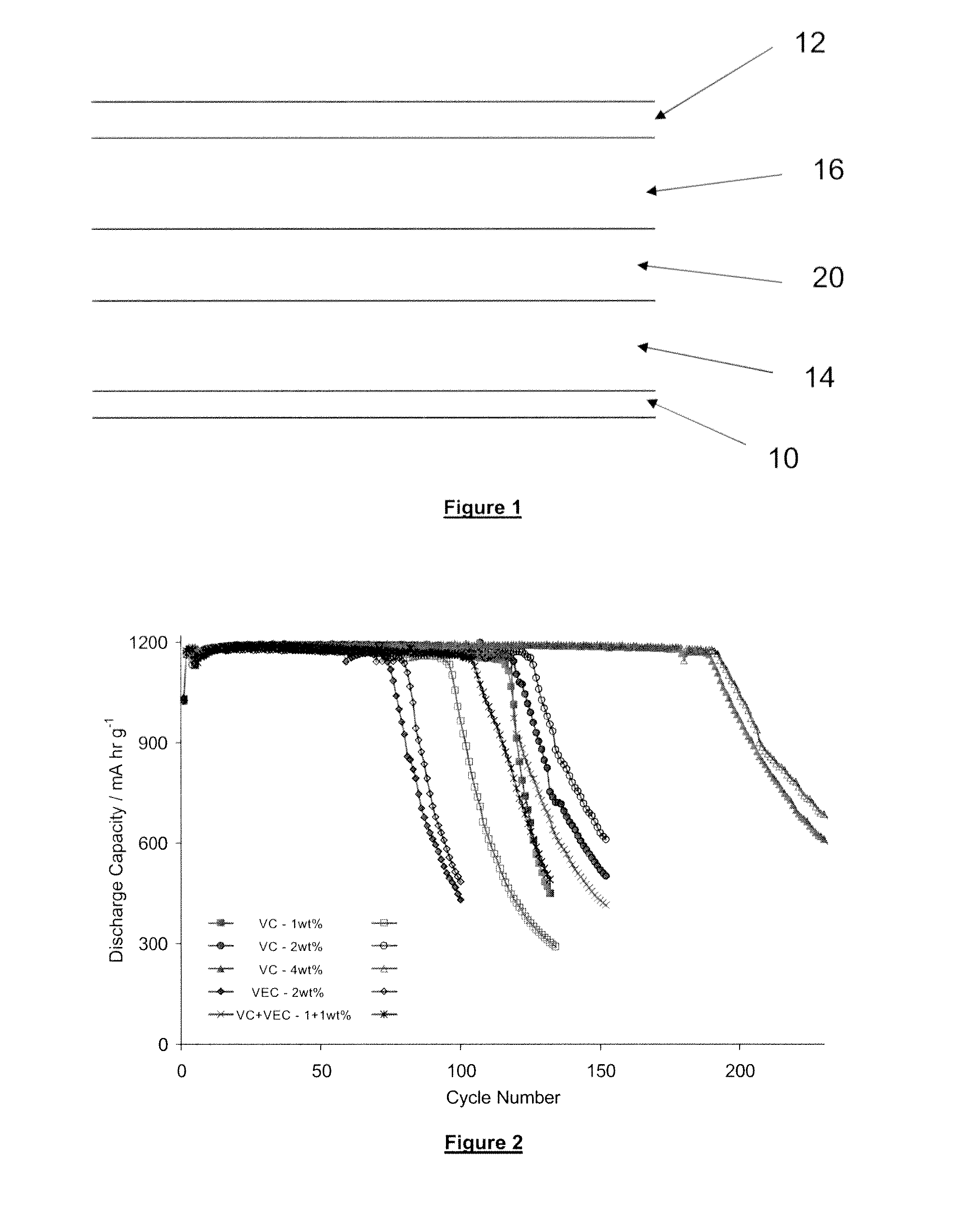

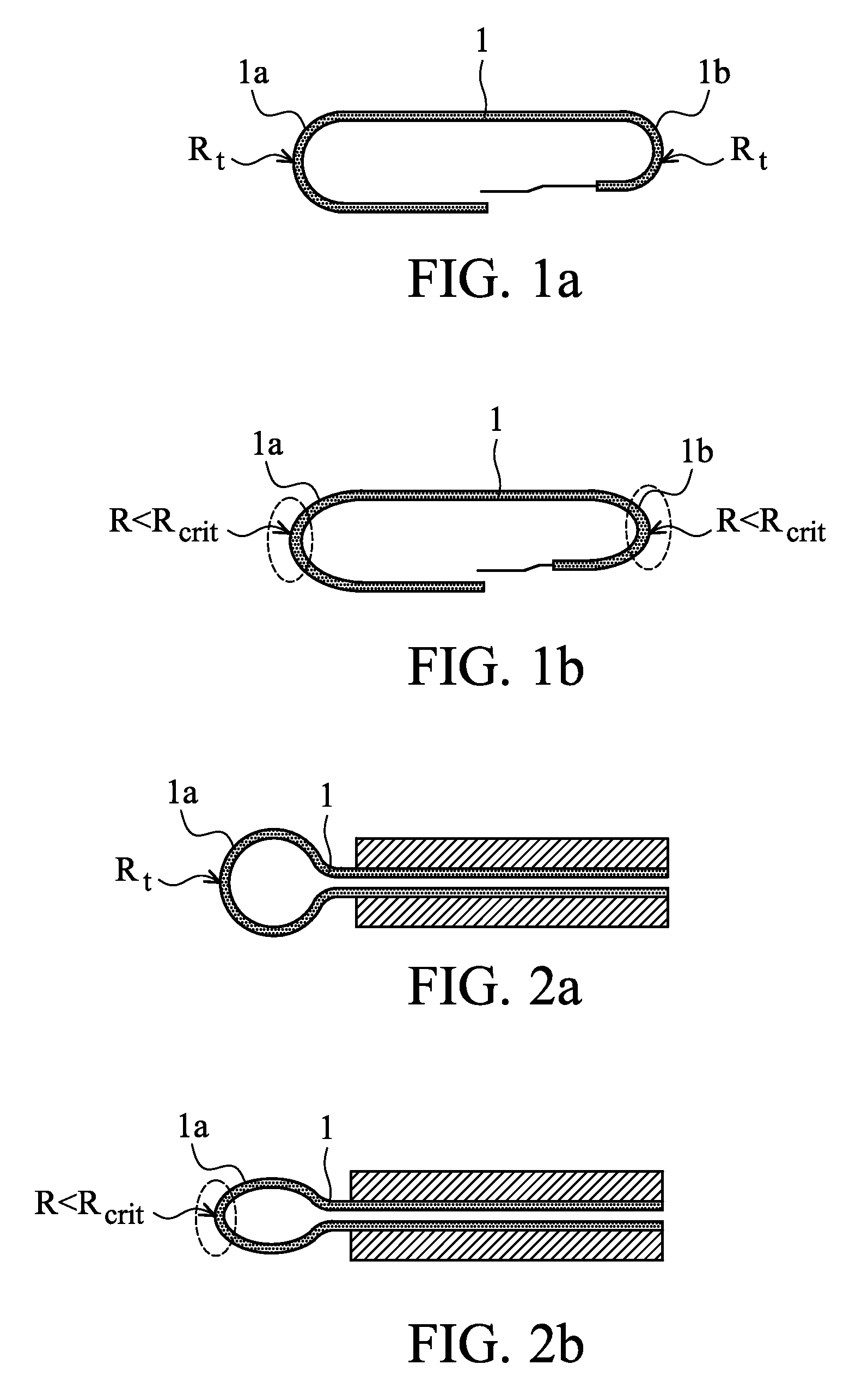

A display system includes a continuous flexible display and two main display supports being hingeable with respect to each other between a closed storage position and a planar configuration for fixing the flexible display in an open position. At least one additional display support supports a segment of the flexible display located between the said respective portions of the flexible display in the open position. This additional display support is movable with respect to the display segment between a non-operational position and a support position when the two main display supports are moved between the storage position and the planar position, such that in the open position substantially the whole surface of the display is supported by the respective display supports.

Owner:SAMSUNG ELECTRONICS CO LTD

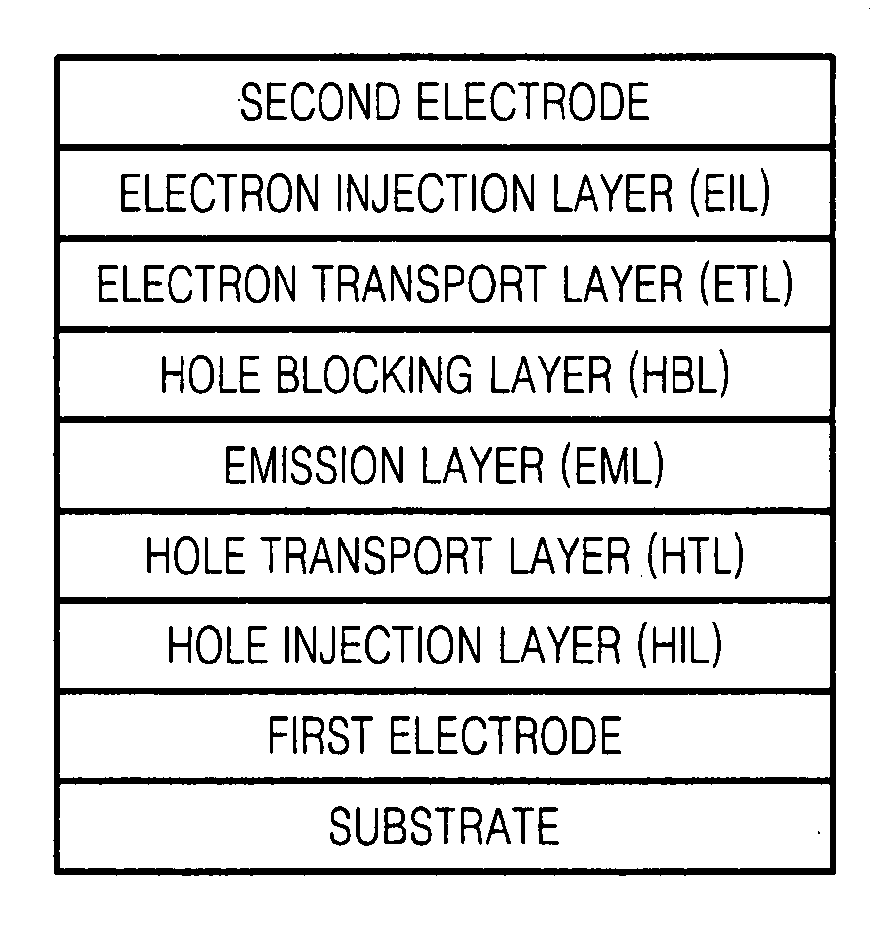

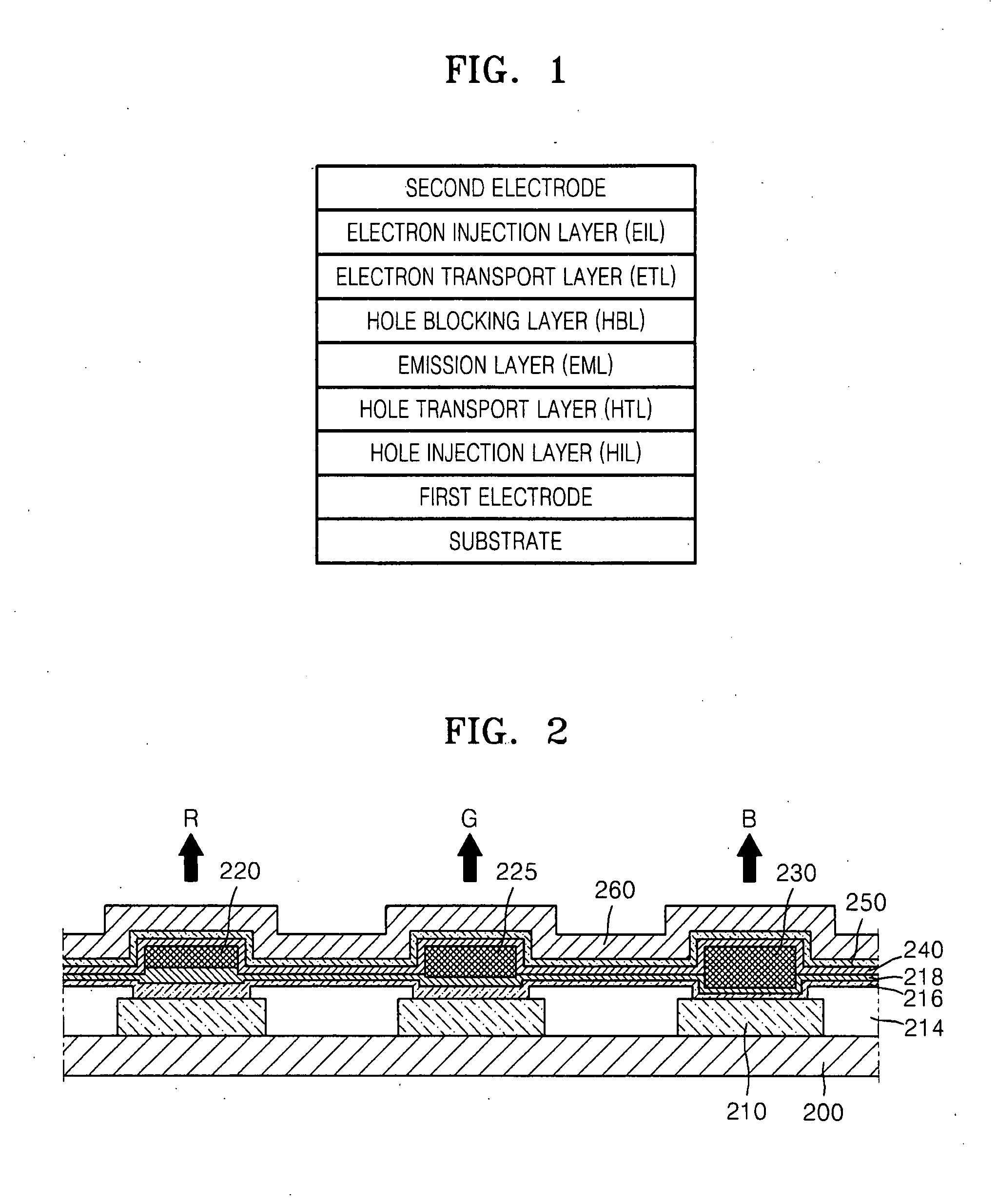

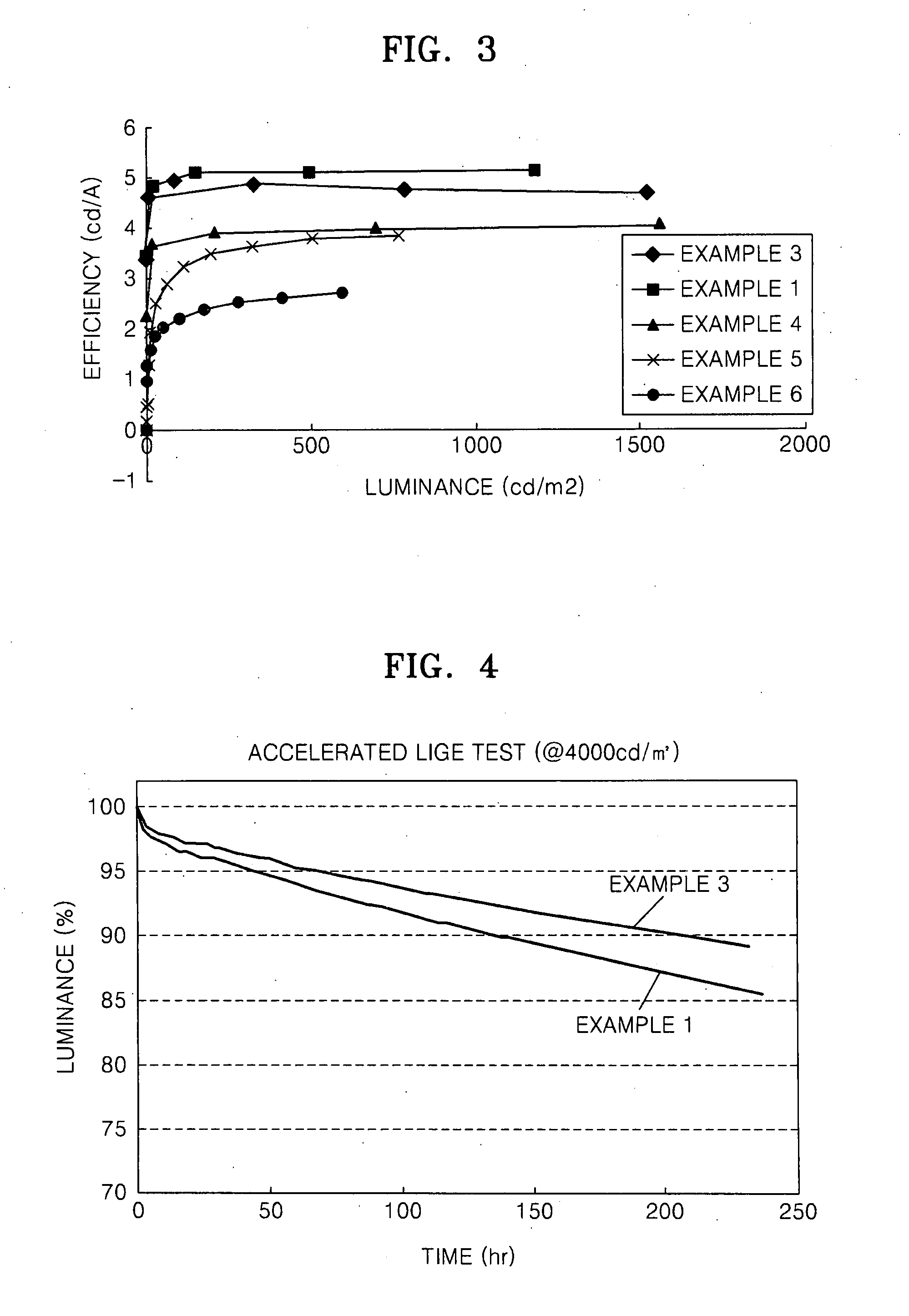

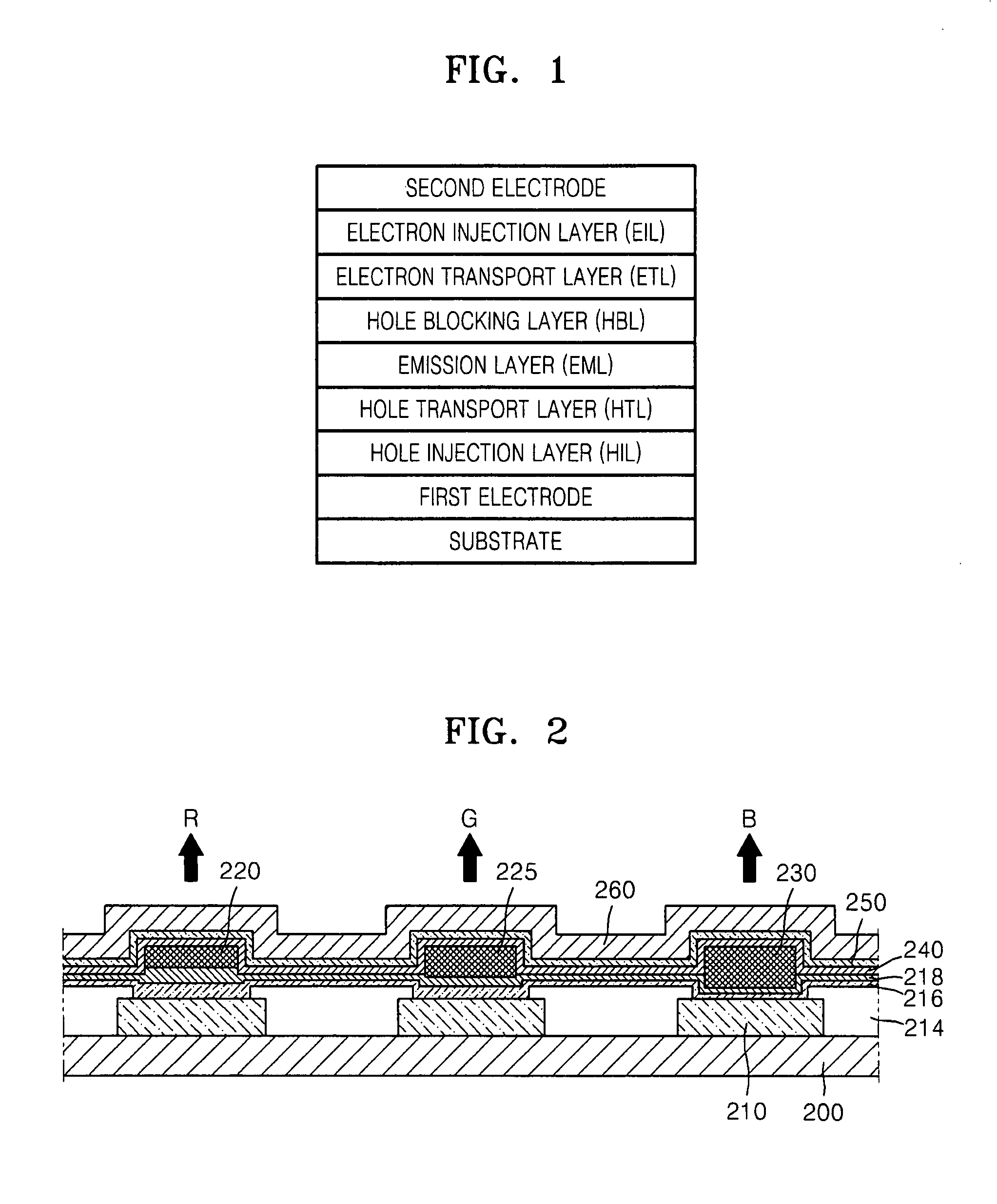

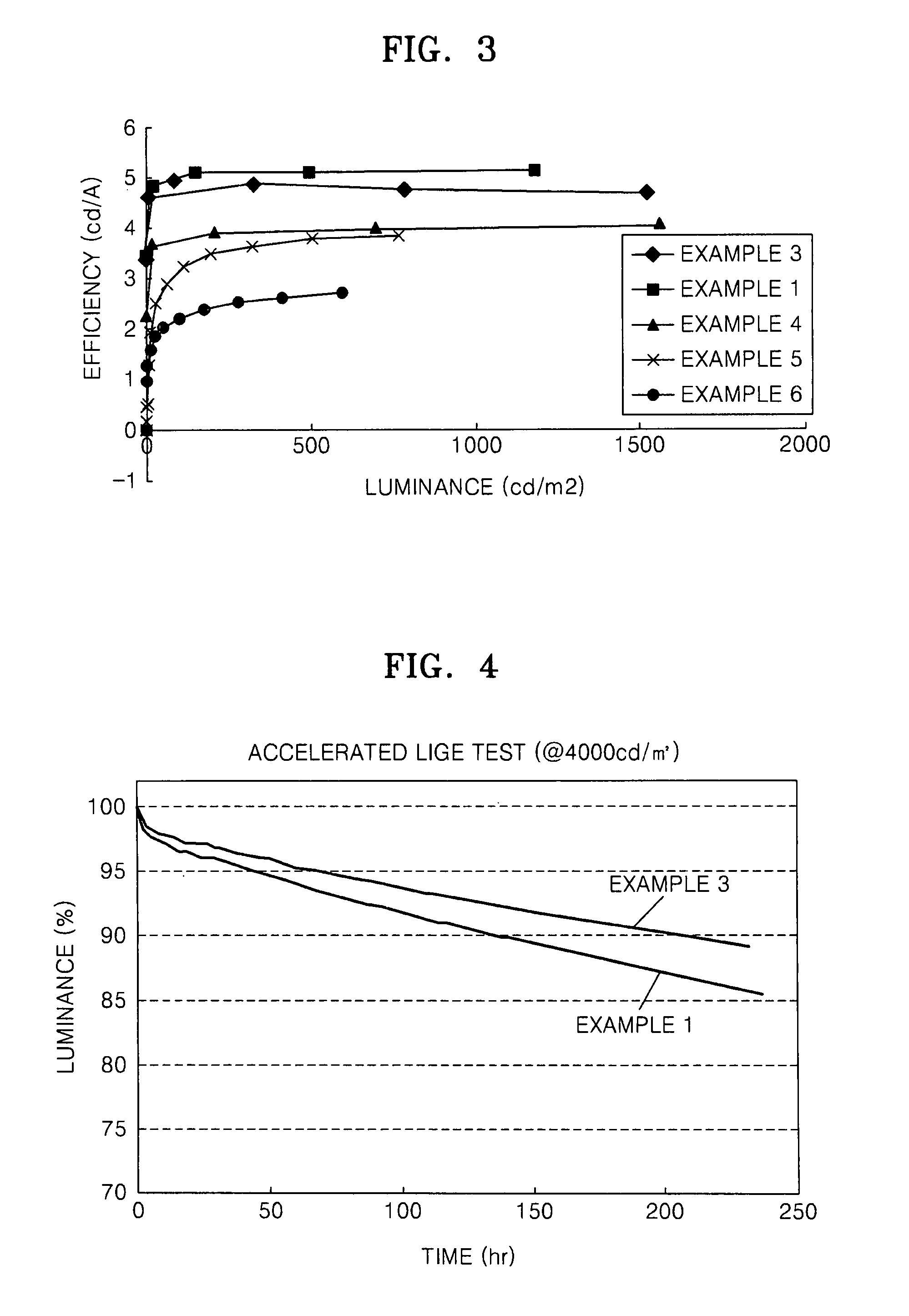

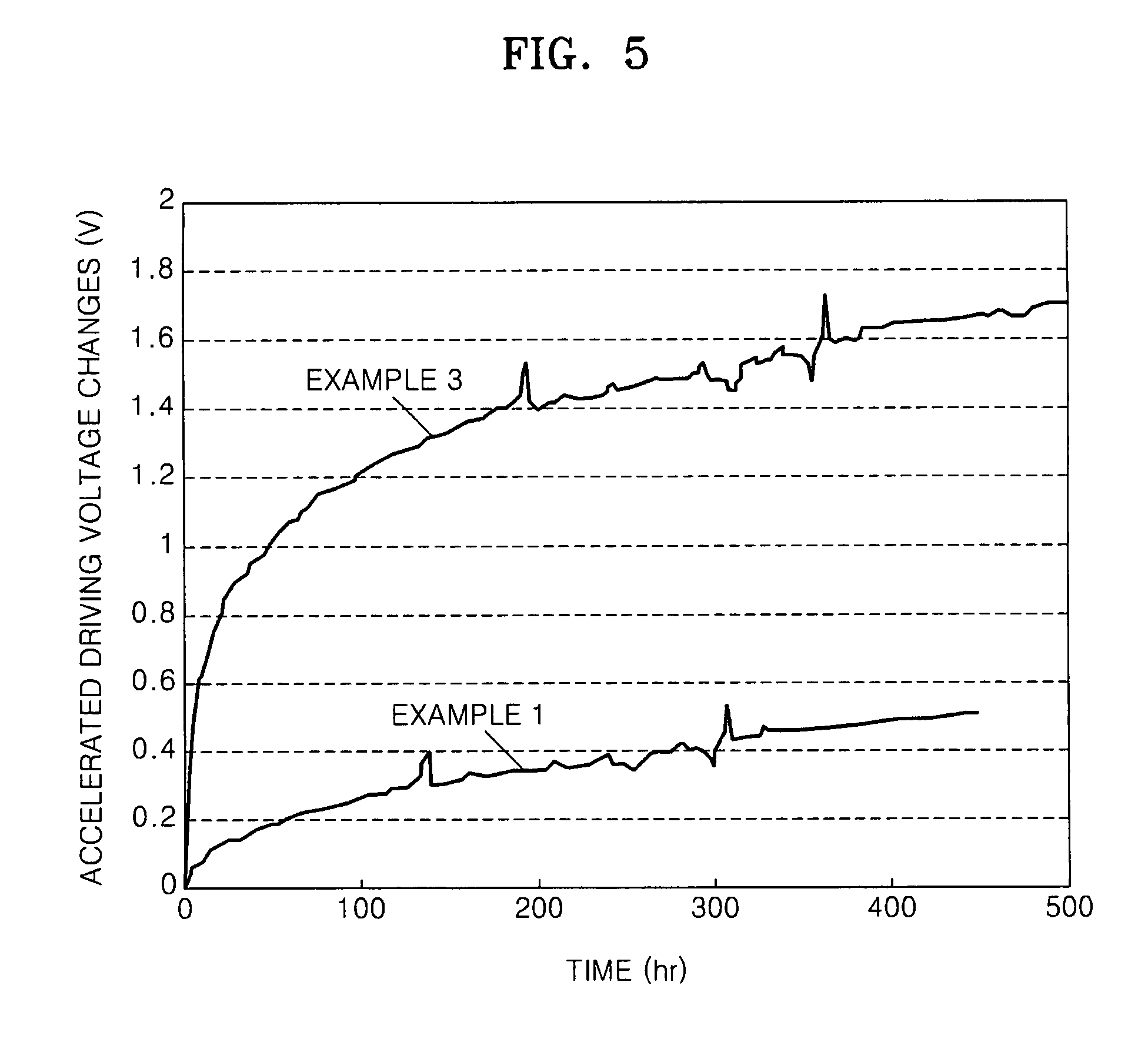

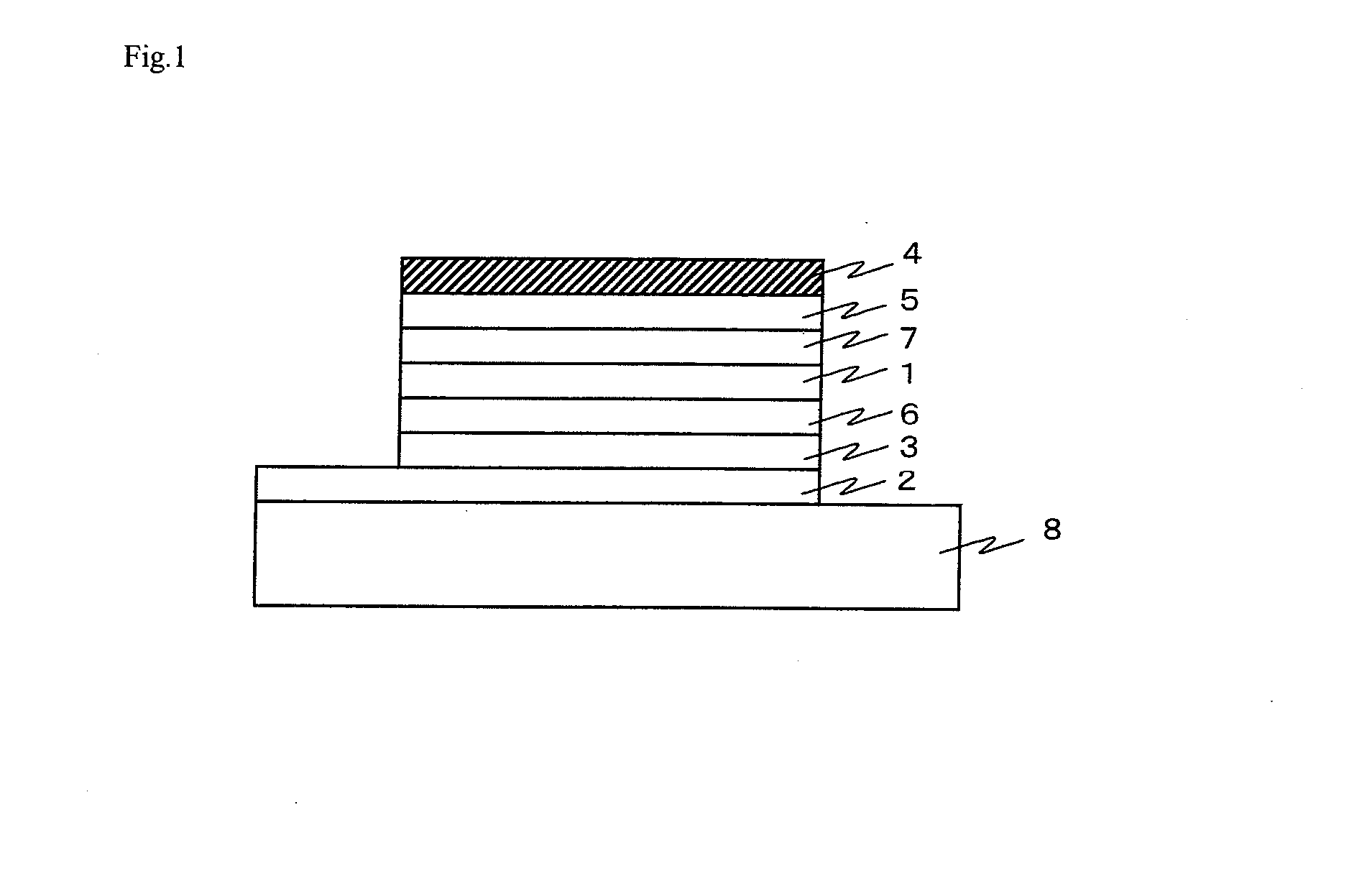

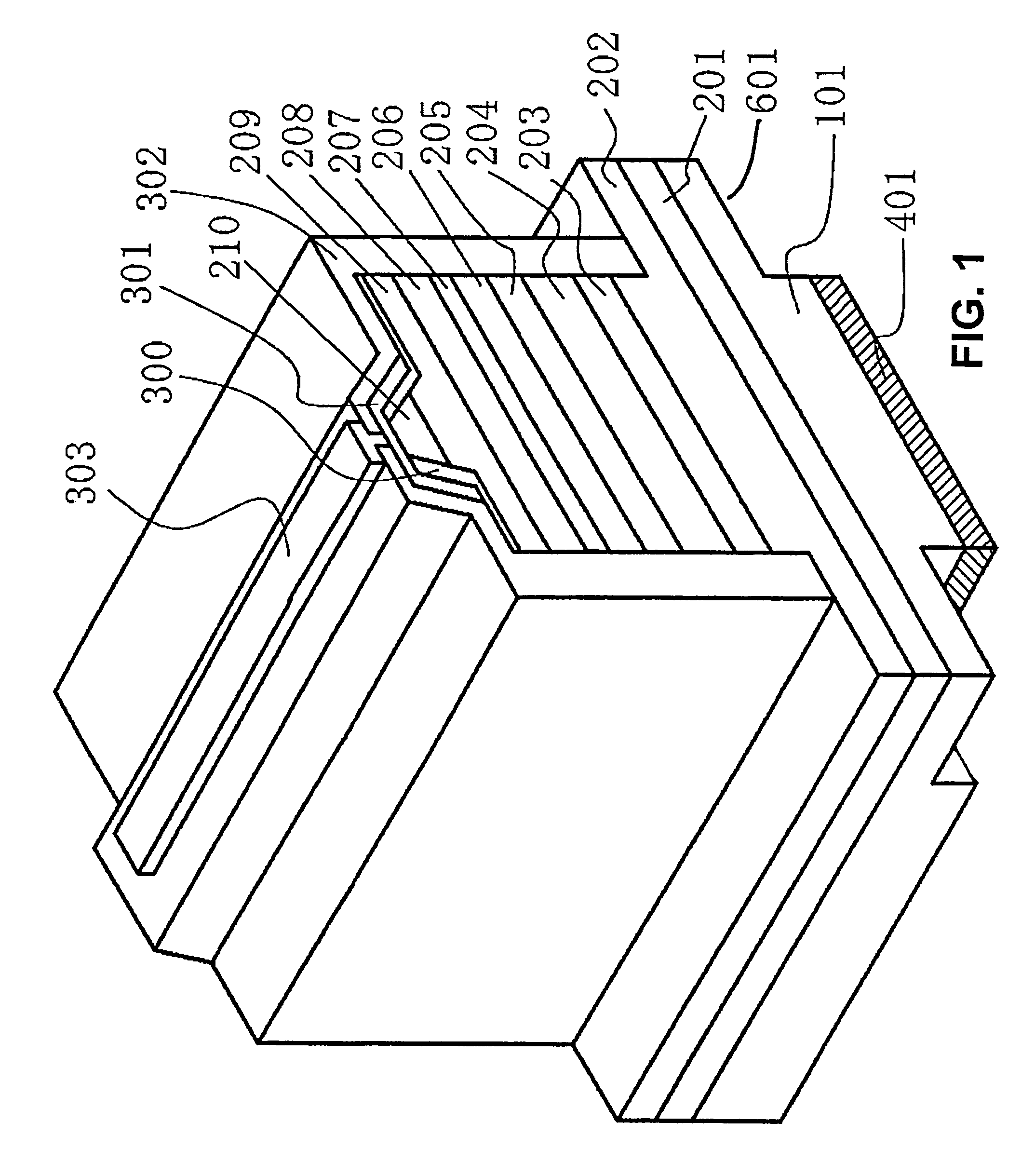

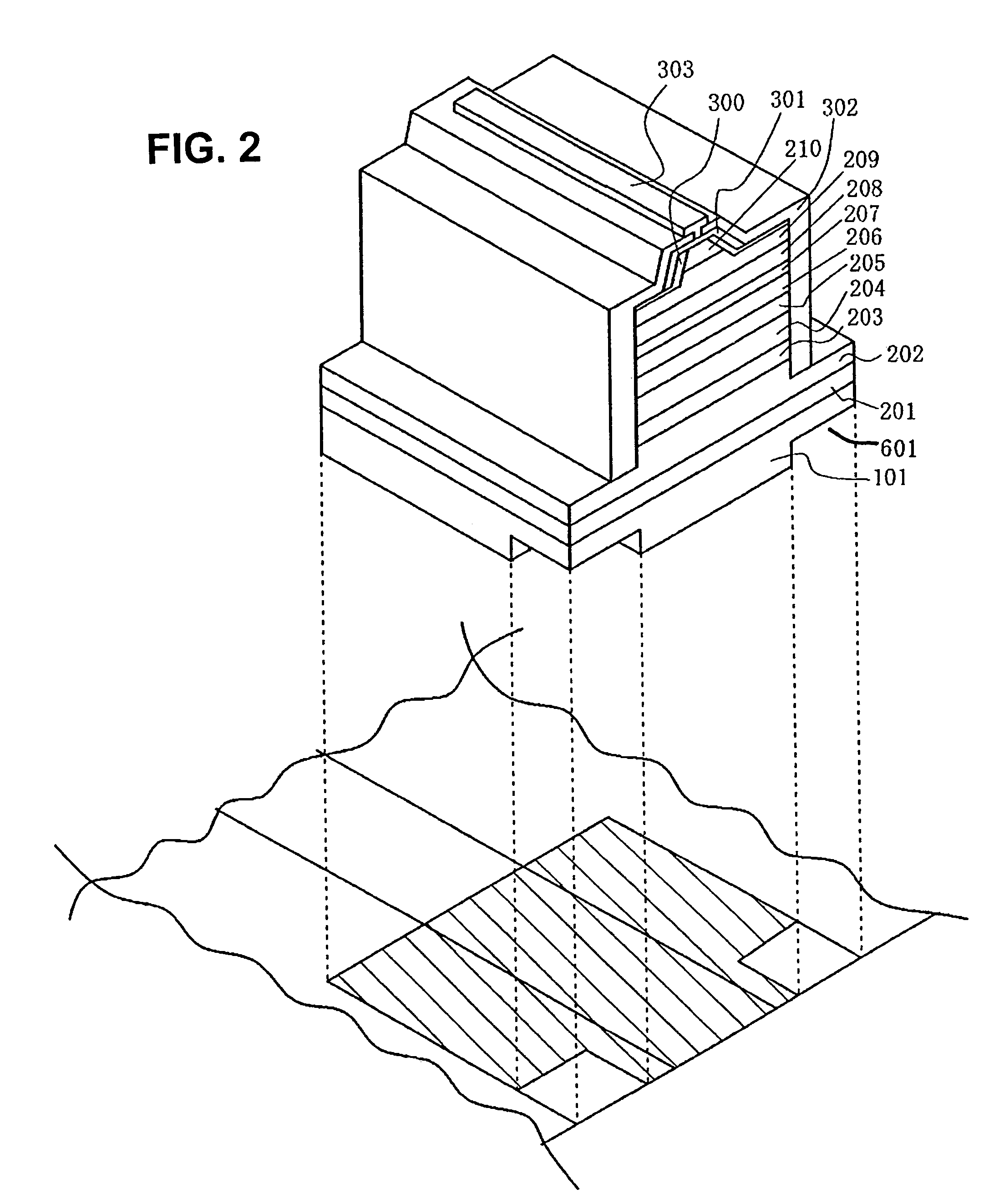

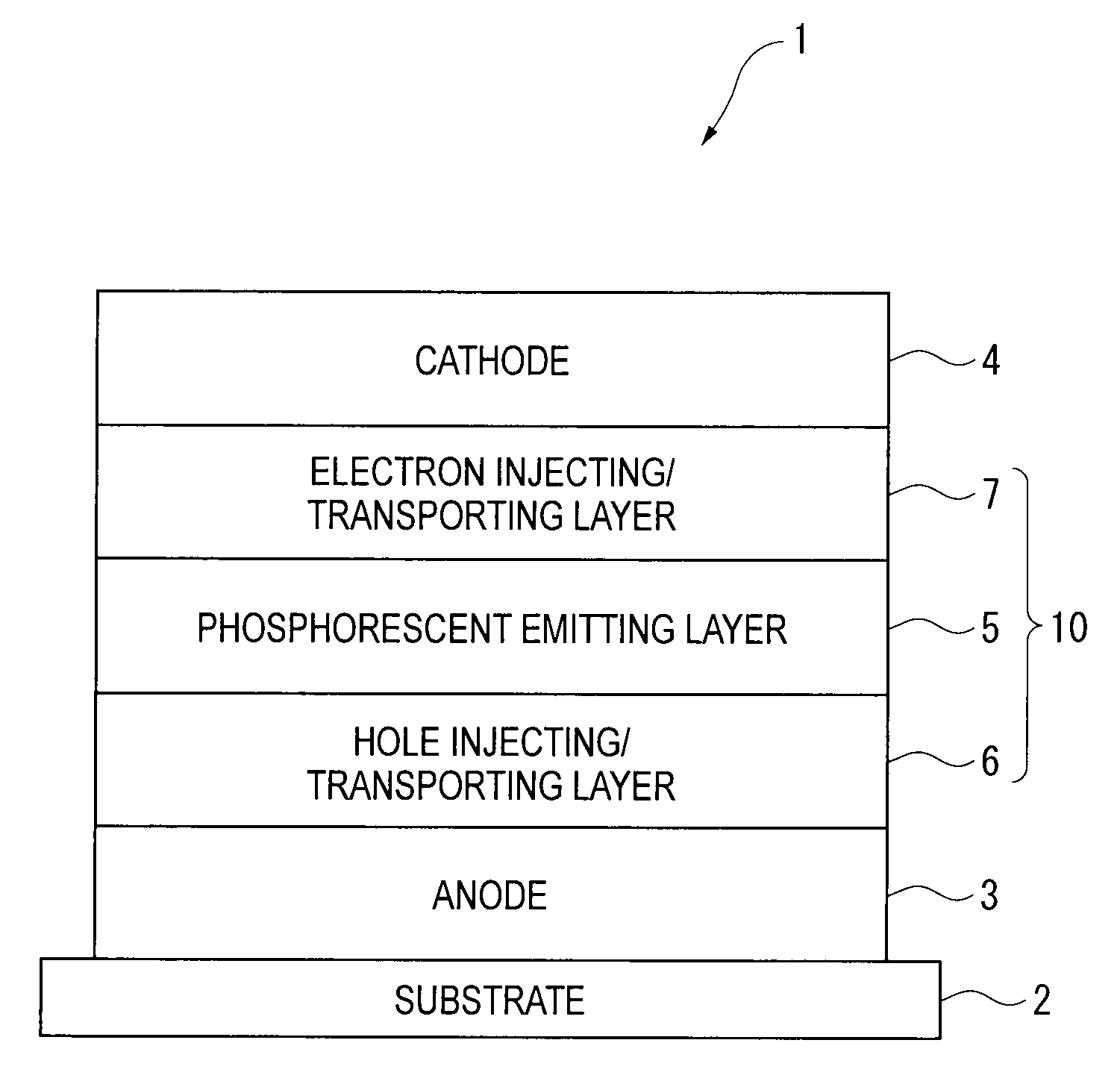

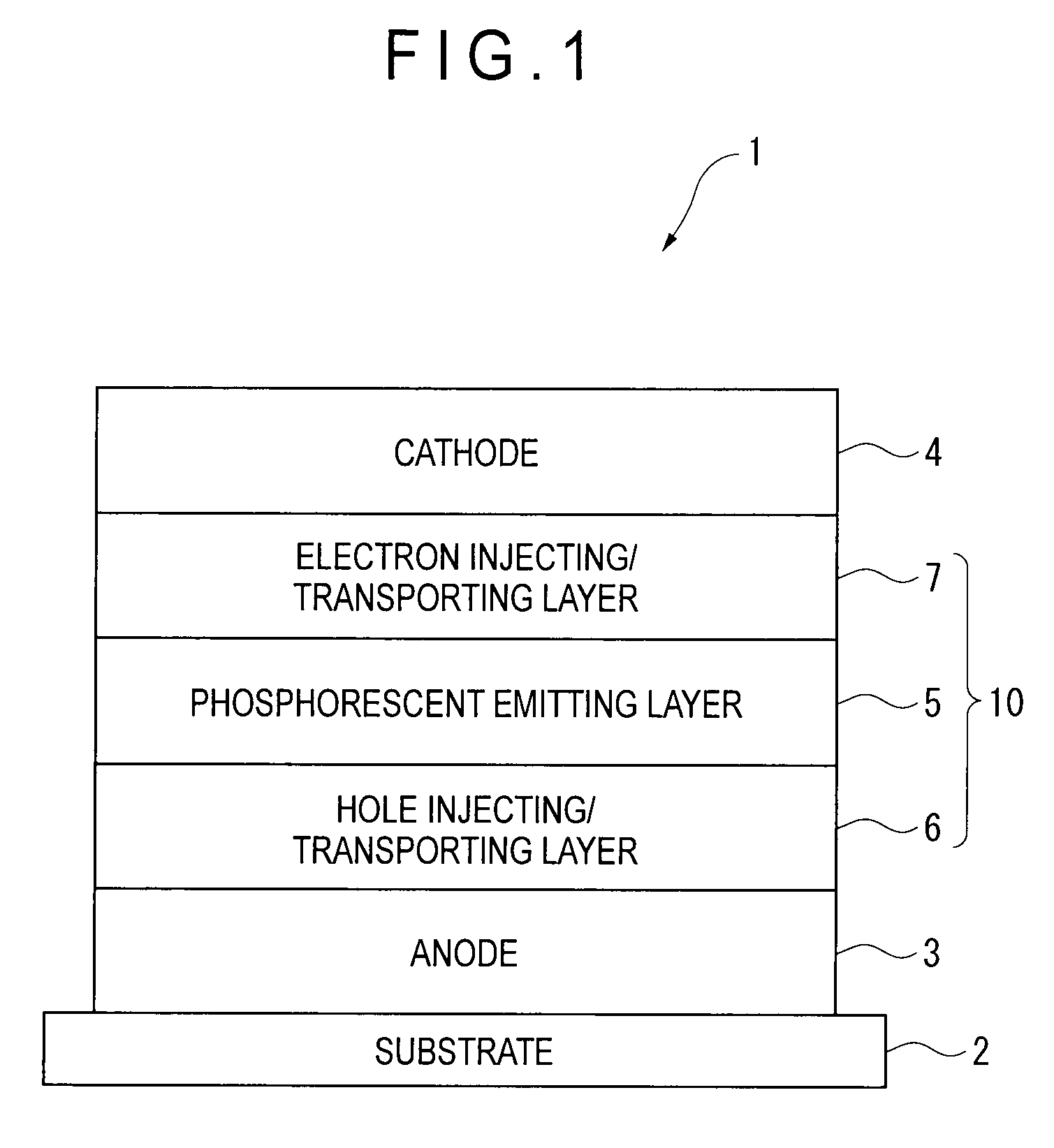

Organic light emitting device and flat panel display device comprising the same

ActiveUS20070231503A1Reduce the driving voltageHigh densityLiquid crystal compositionsOrganic chemistryOrganic light emitting deviceOrganic layer

Provided are an organic light emitting device including: a substrate; a first electrode; a second electrode; and an organic layer interposed between the first electrode and the second electrode and including an emission layer, wherein one of the first electrode and the second electrode is a reflective electrode and the other is a semitransparent or transparent electrode, and wherein the organic layer includes a layer having at least one of the compounds having at least one carbazole group, and a flat panel display device including the organic light emitting device. The organic light emitting device has low driving voltage, excellent current density, high brightness, excellent color purity, high efficiency, and long lifetime.

Owner:SAMSUNG DISPLAY CO LTD

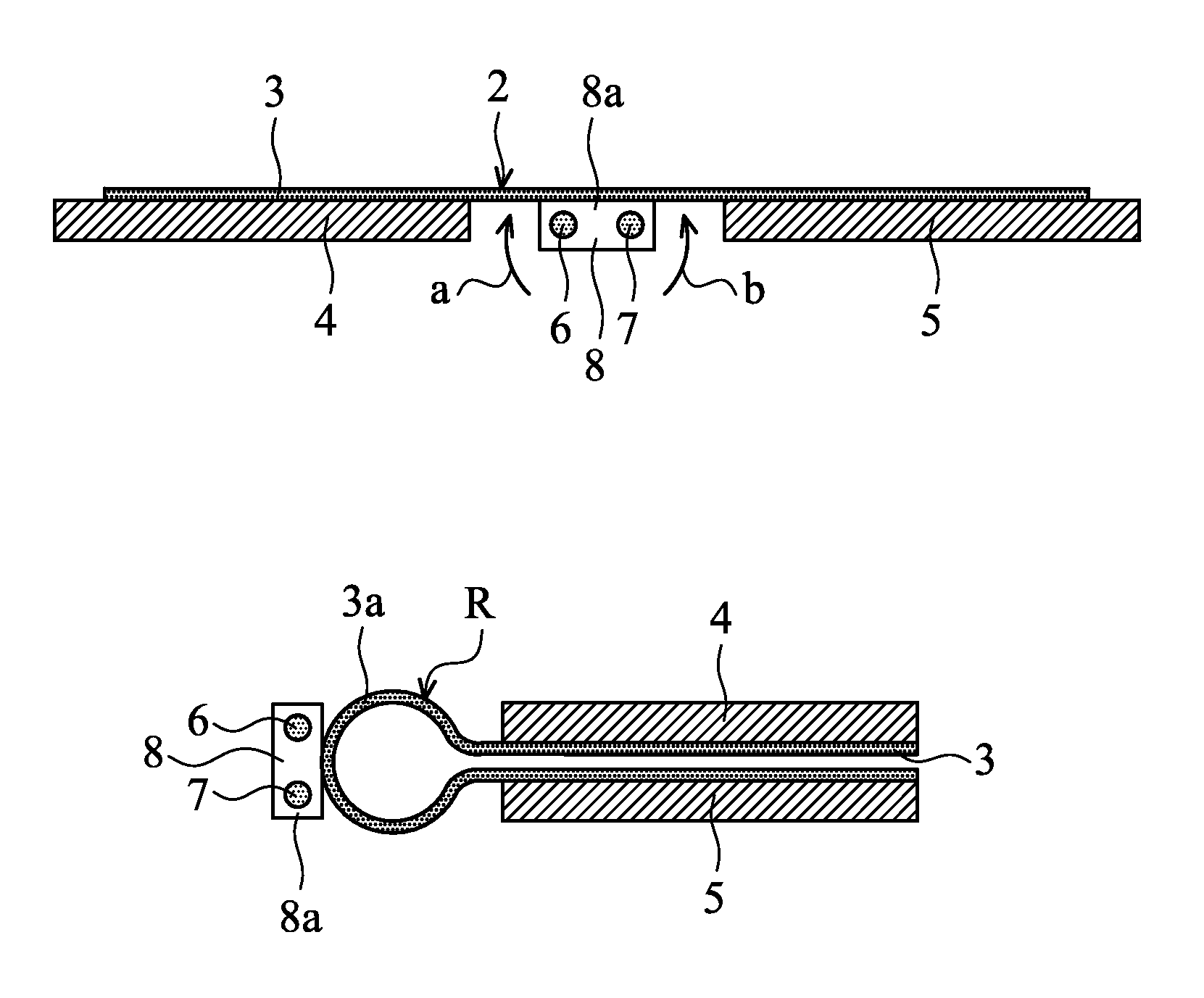

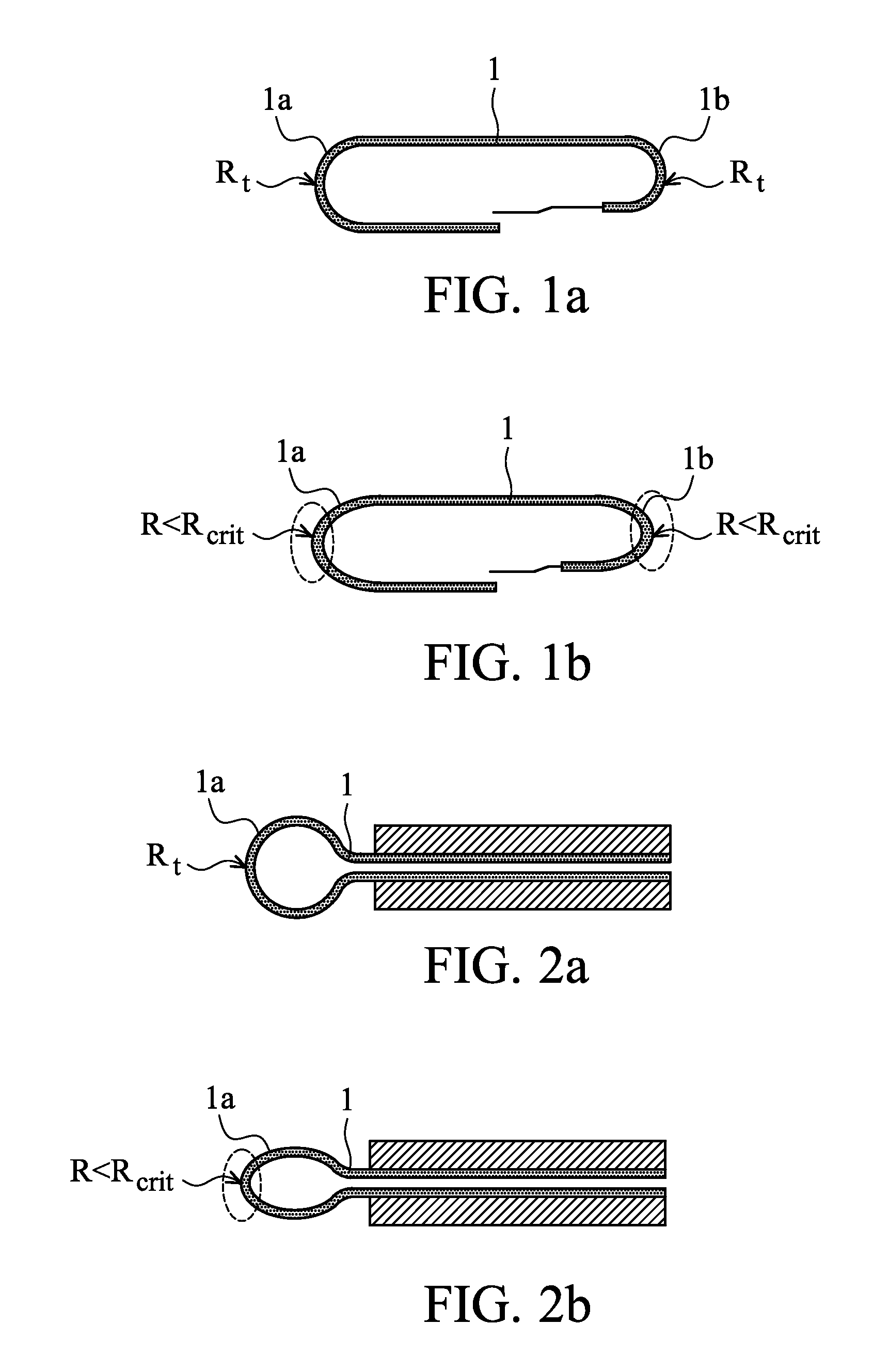

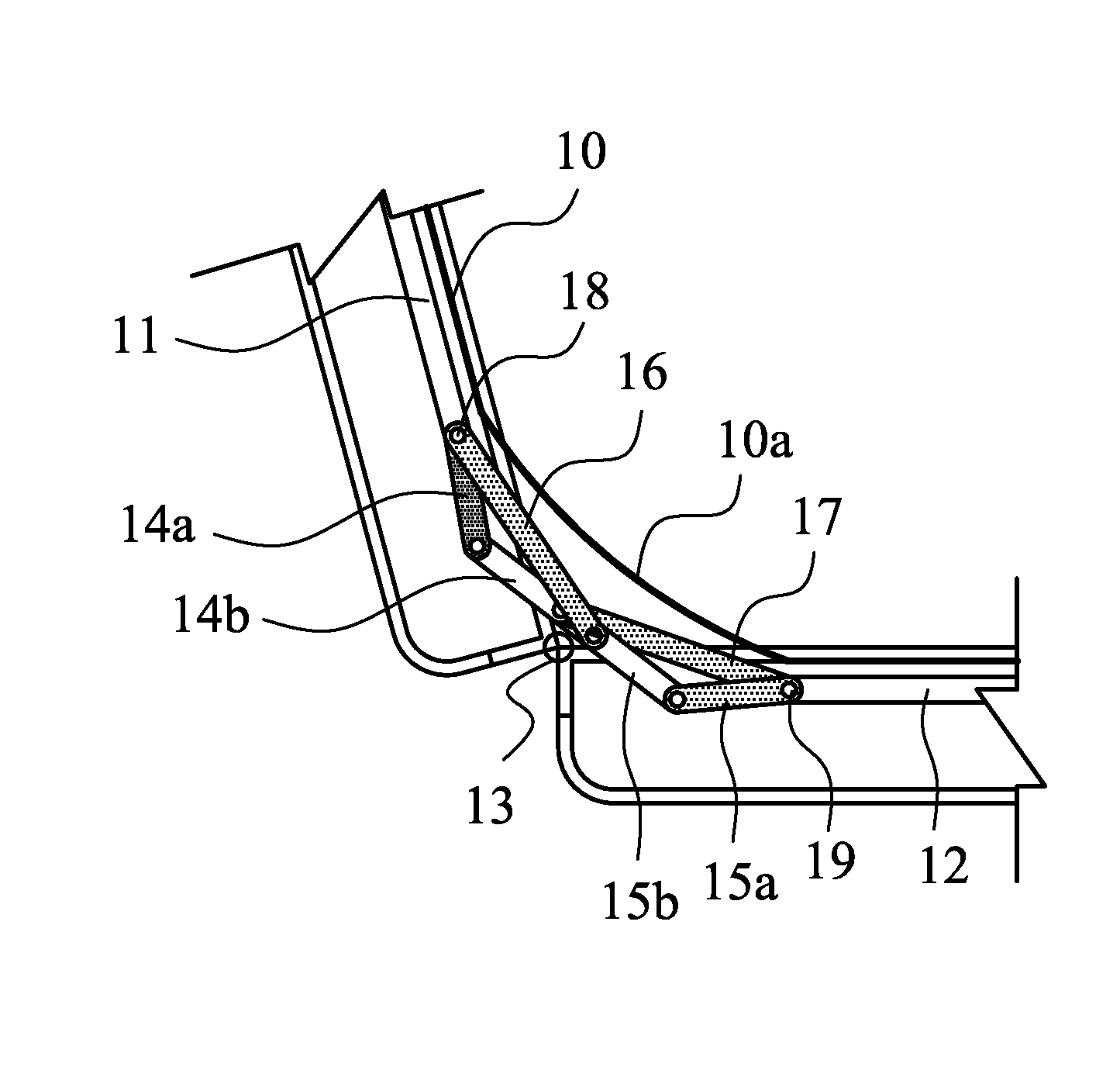

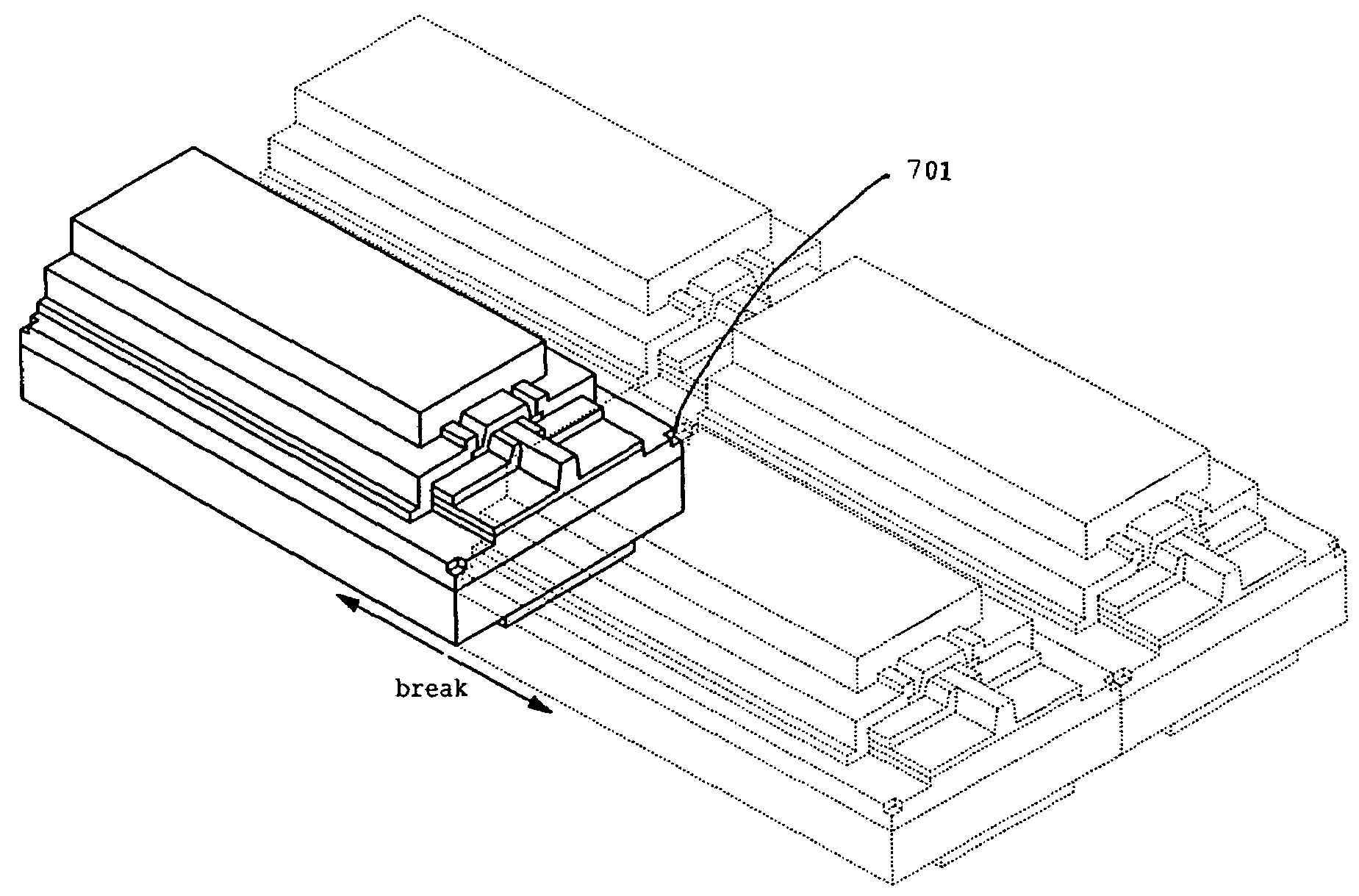

Flexible display with display support

ActiveUS20130037228A1Promote sportsSuperior emission lifetimeScreensDigital data processing detailsDisplay deviceEngineering

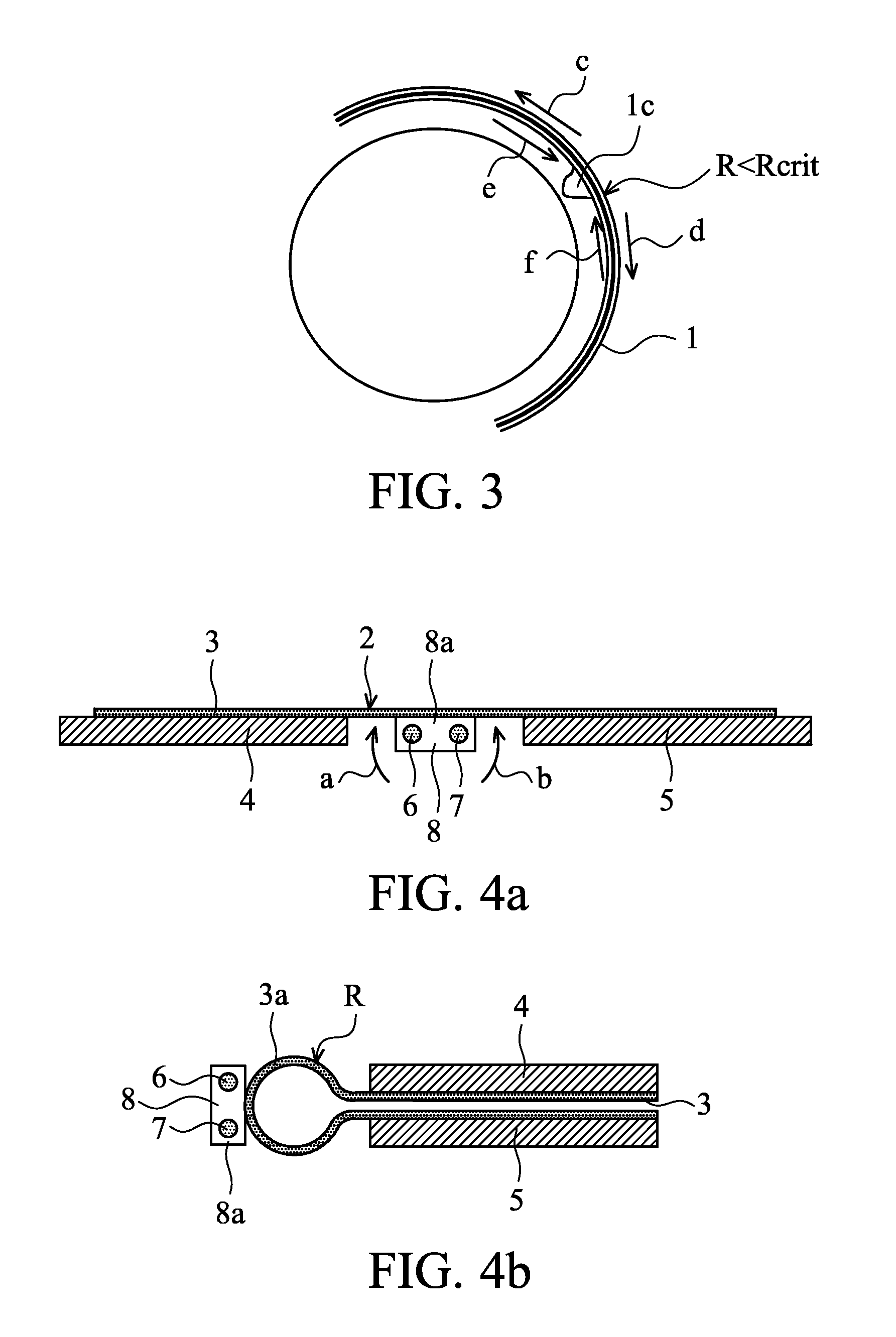

A display system includes a continuous flexible display, two main display supports each structurally configured to support a respective portion of the flexible display, a segment of the flexible display being located between the said respective display portions. The two main display supports are hingeable between a closed configuration for fixing the flexible display in a storage position and an open configuration for fixing the flexible display in an open position. In the storage position between the main display supports there is a free space enabling a partial curvature of said display segment without conflicting with the respective main display support. At least one additional display support is configured to support said segment of the flexible display in the storage position and facilitates the curvature of the display segment with a predefined radius which is larger than the critical radius Rcrit for the flexible display.

Owner:SAMSUNG ELECTRONICS CO LTD

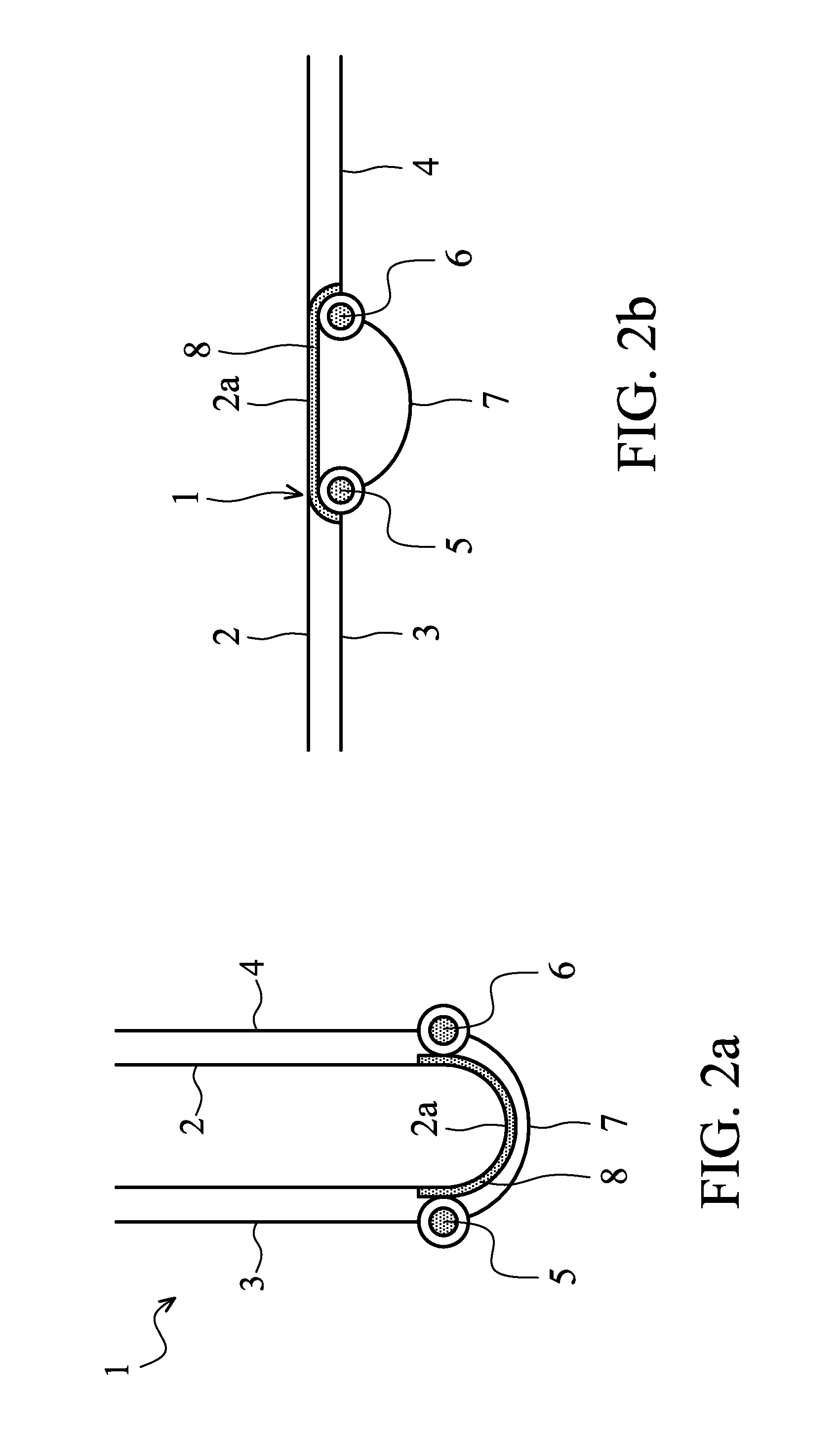

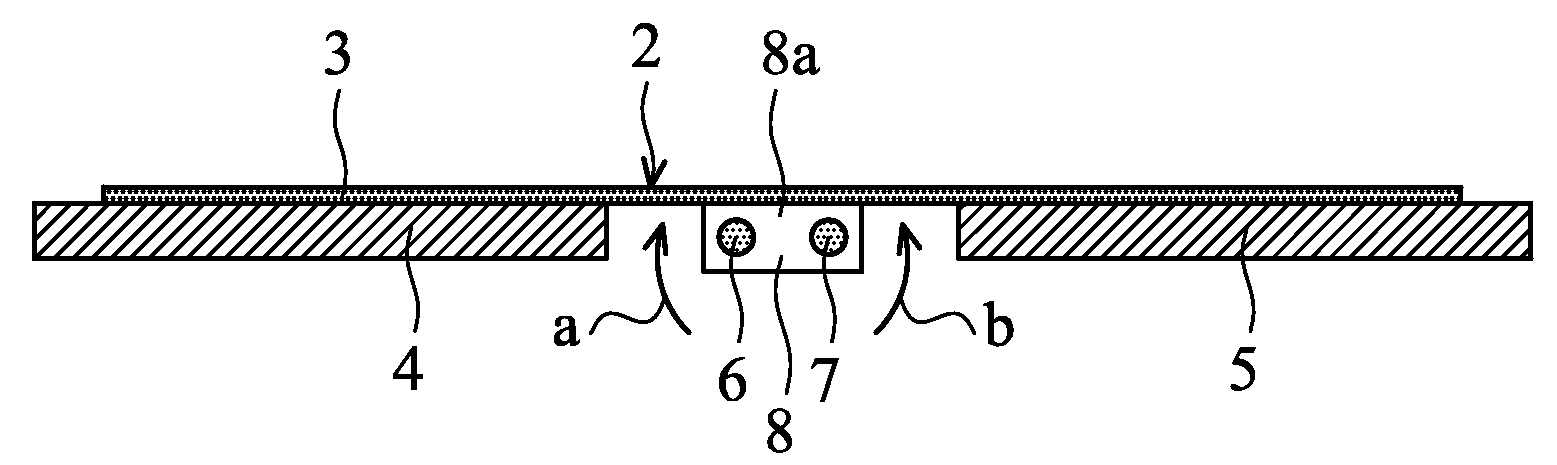

Touch panel-including illuminator and reflective liquid-crystal display device

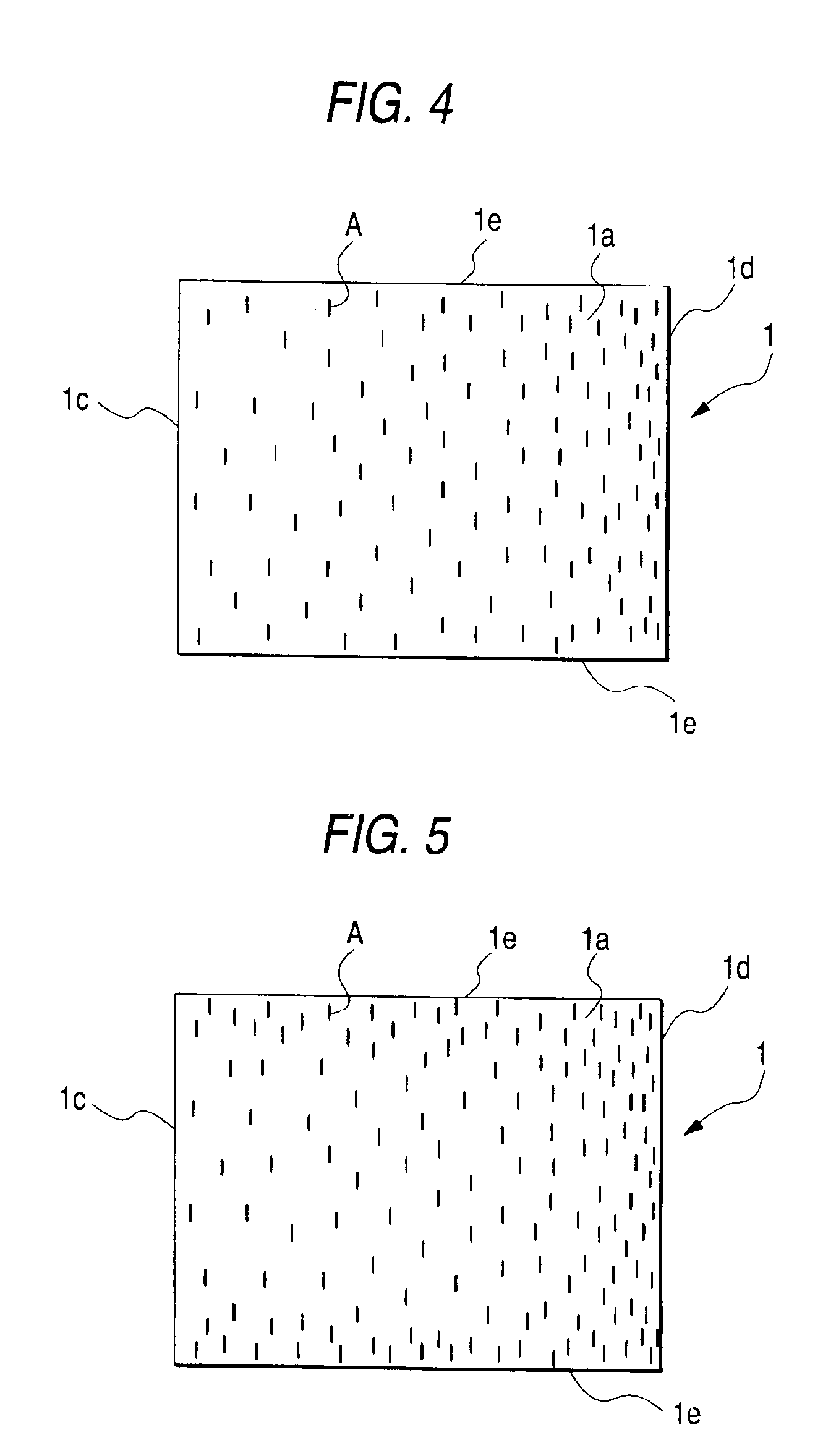

InactiveUS6891530B2Good perpendicular directivityDisplay brightMechanical apparatusElongate light sourcesLiquid-crystal displayLight pipe

A touch panel-including illuminator having: a light pipe made of a transparent plate-like material having an upper surface, a lower surface and at least one incidence side surface, the upper surface being provided with light output means through which light incident on the incidence side surface is made to emerge from the lower surface; a light source disposed on the incidence side surface of the light pipe; an adhesive layer; and a touch panel bonded to the upper surface of the light pipe through the adhesive layer; wherein the light output means are constituted by fine grooves which are disposed discontinuously, each of which is made of a concave portion, and each of which is shaped like an approximate triangle in section; and wherein each of the fine grooves has an optical path changing slope and a steep slope.

Owner:NITTO DENKO CORP

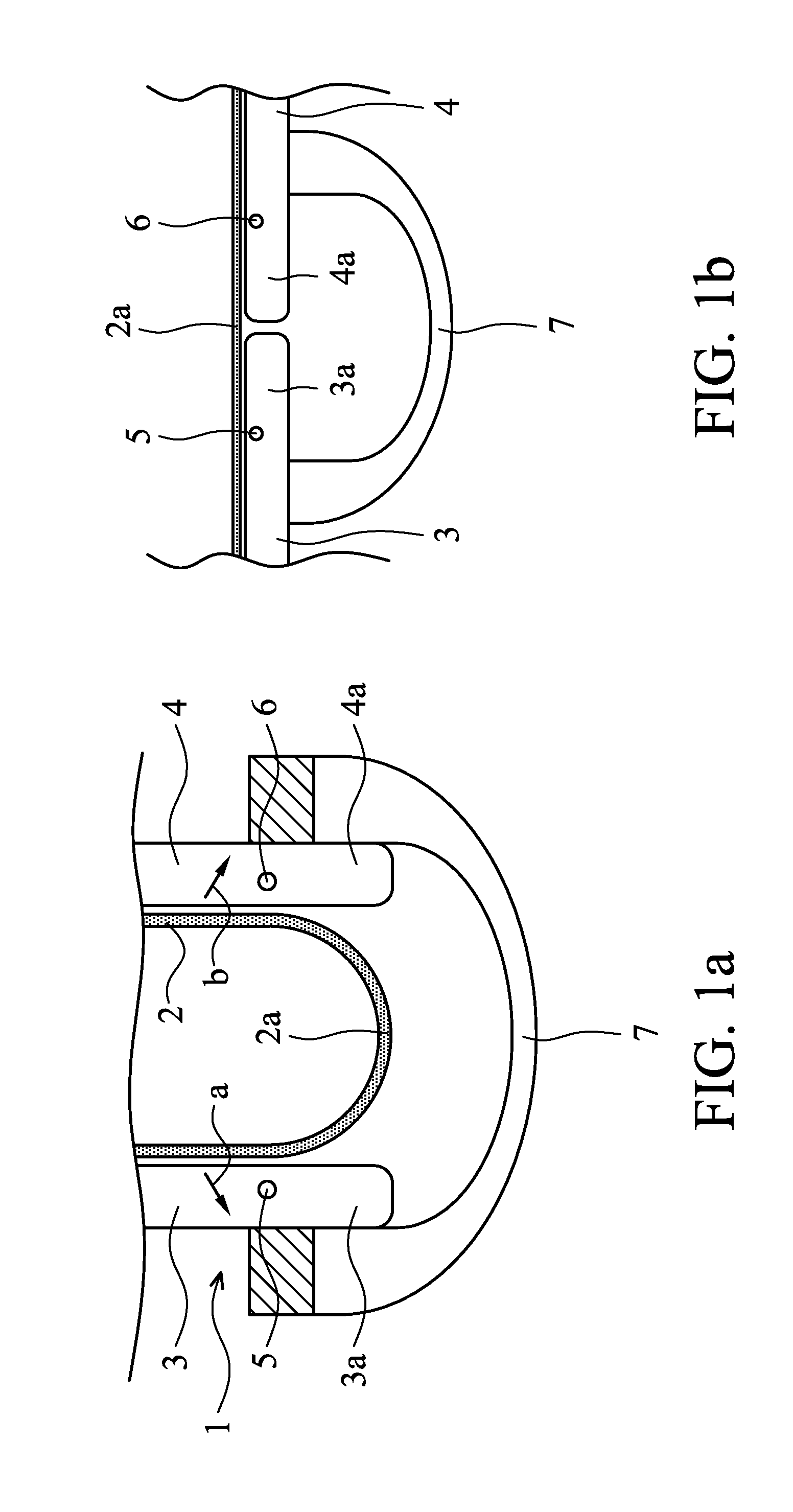

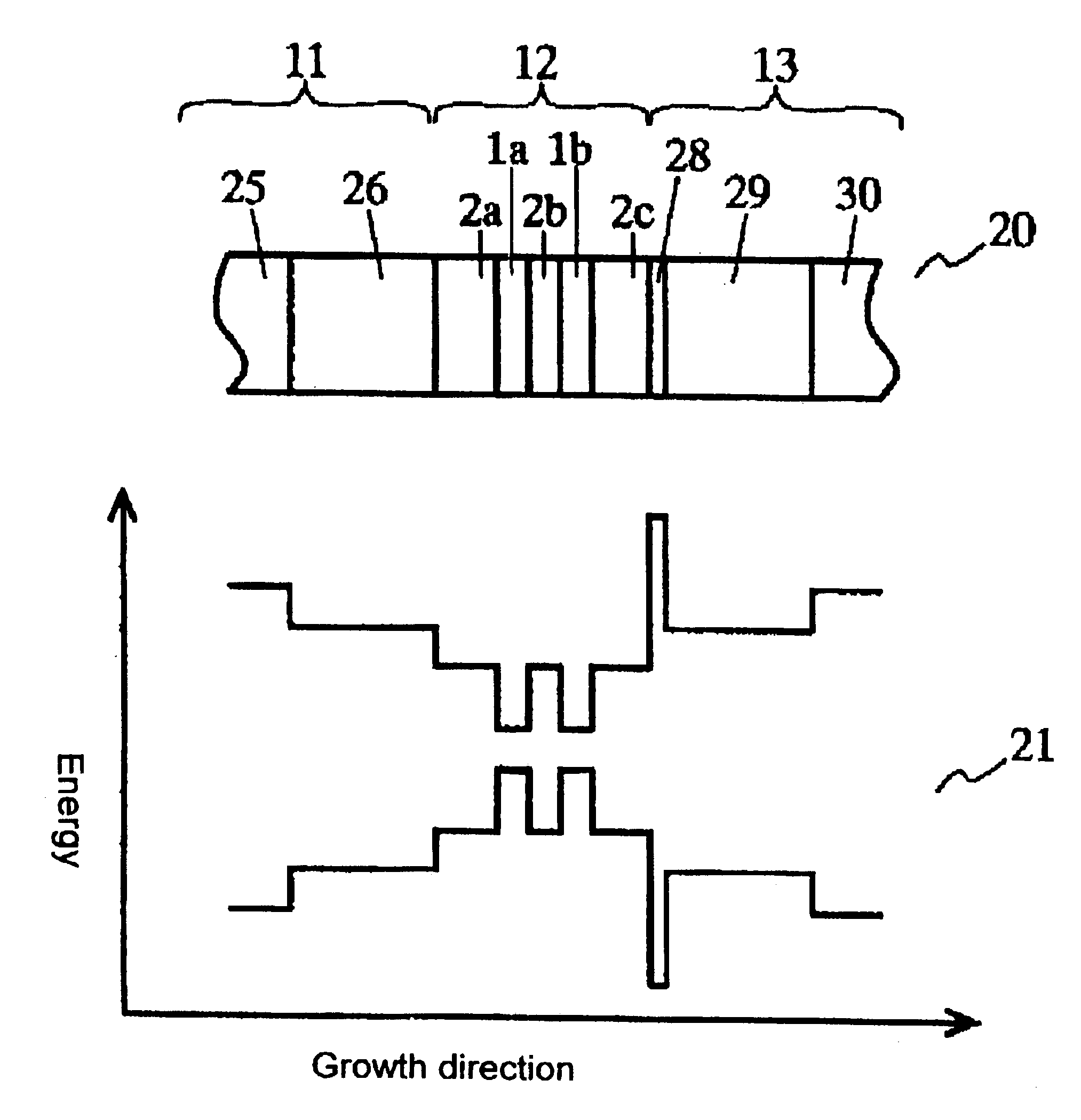

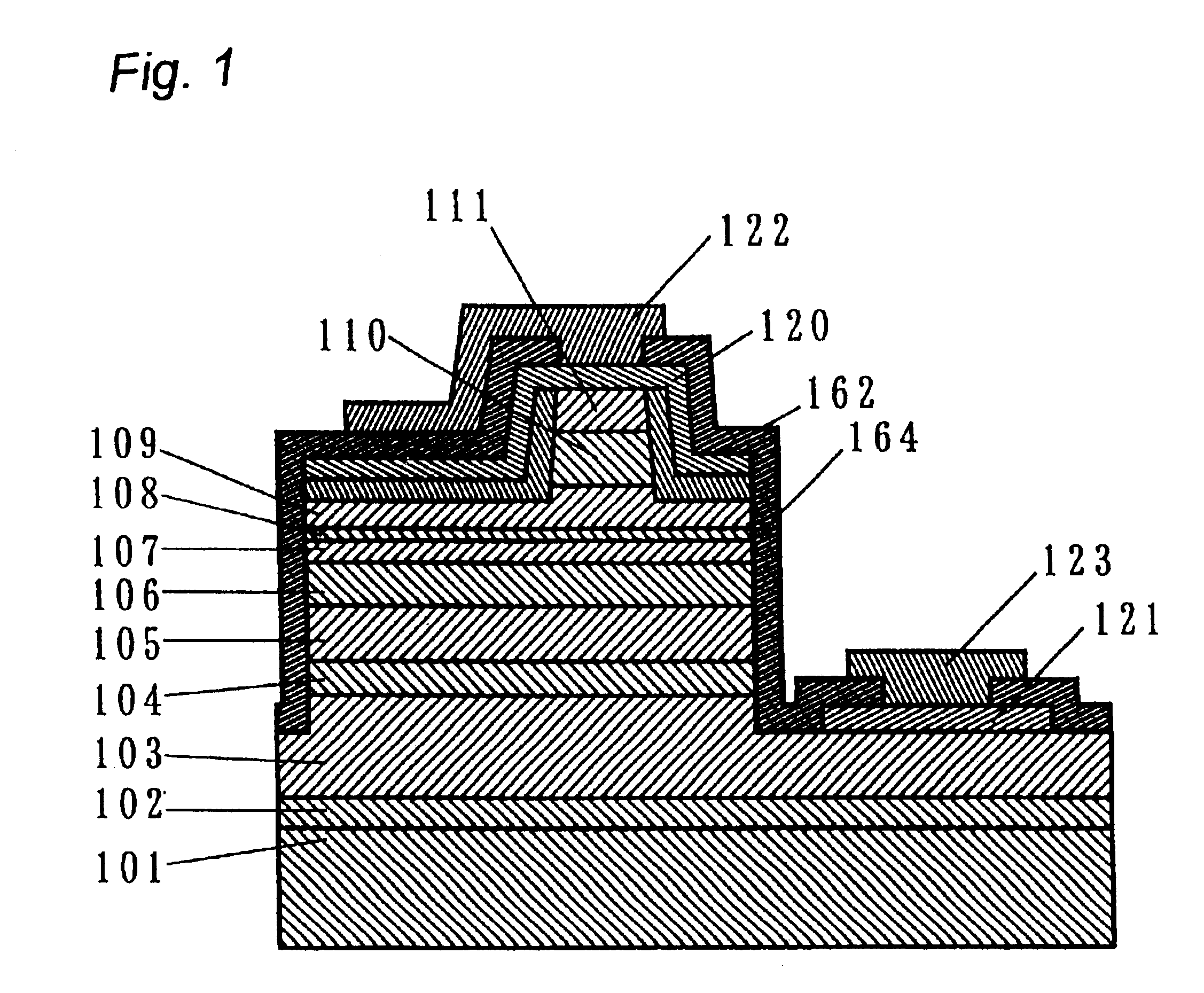

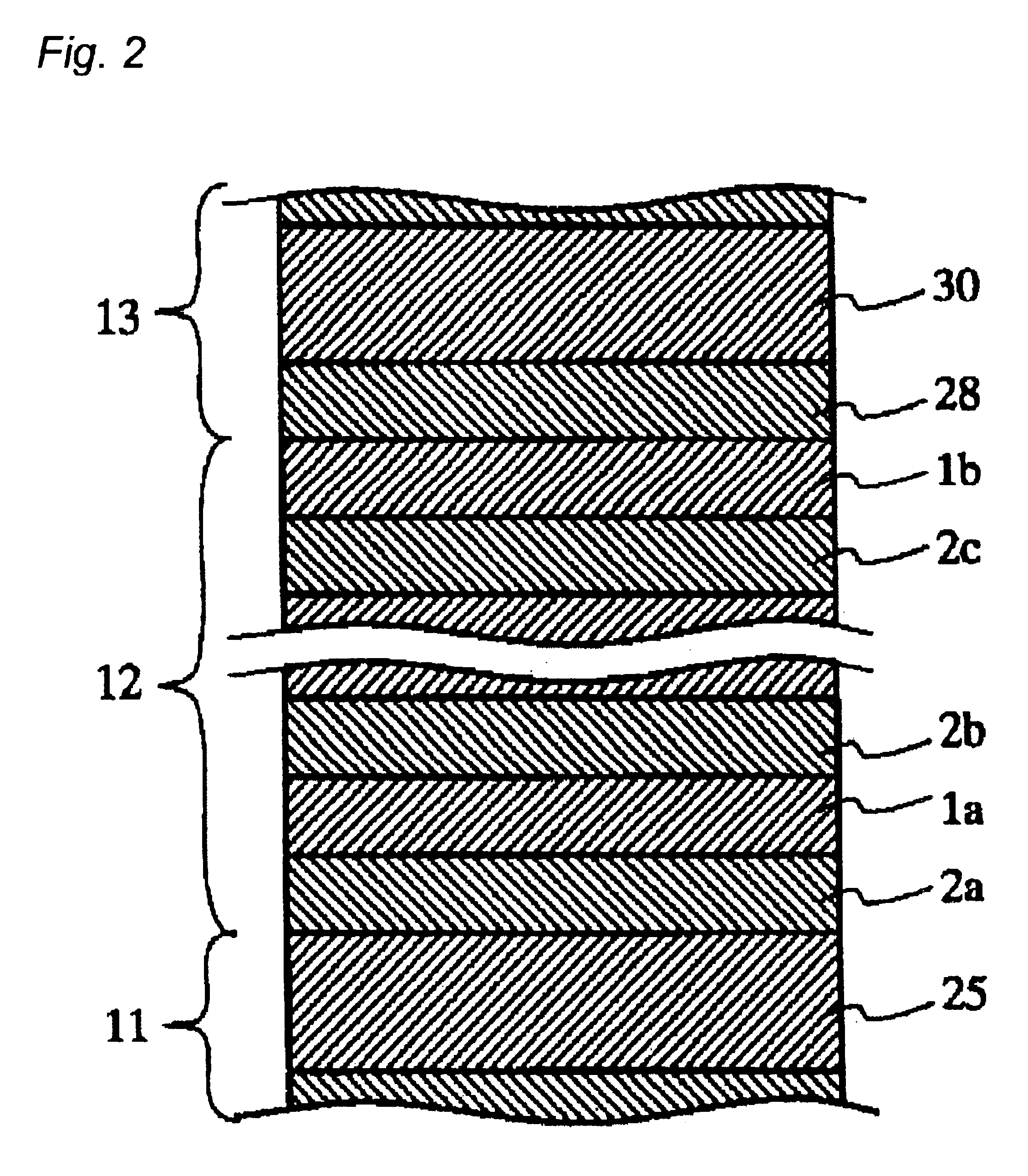

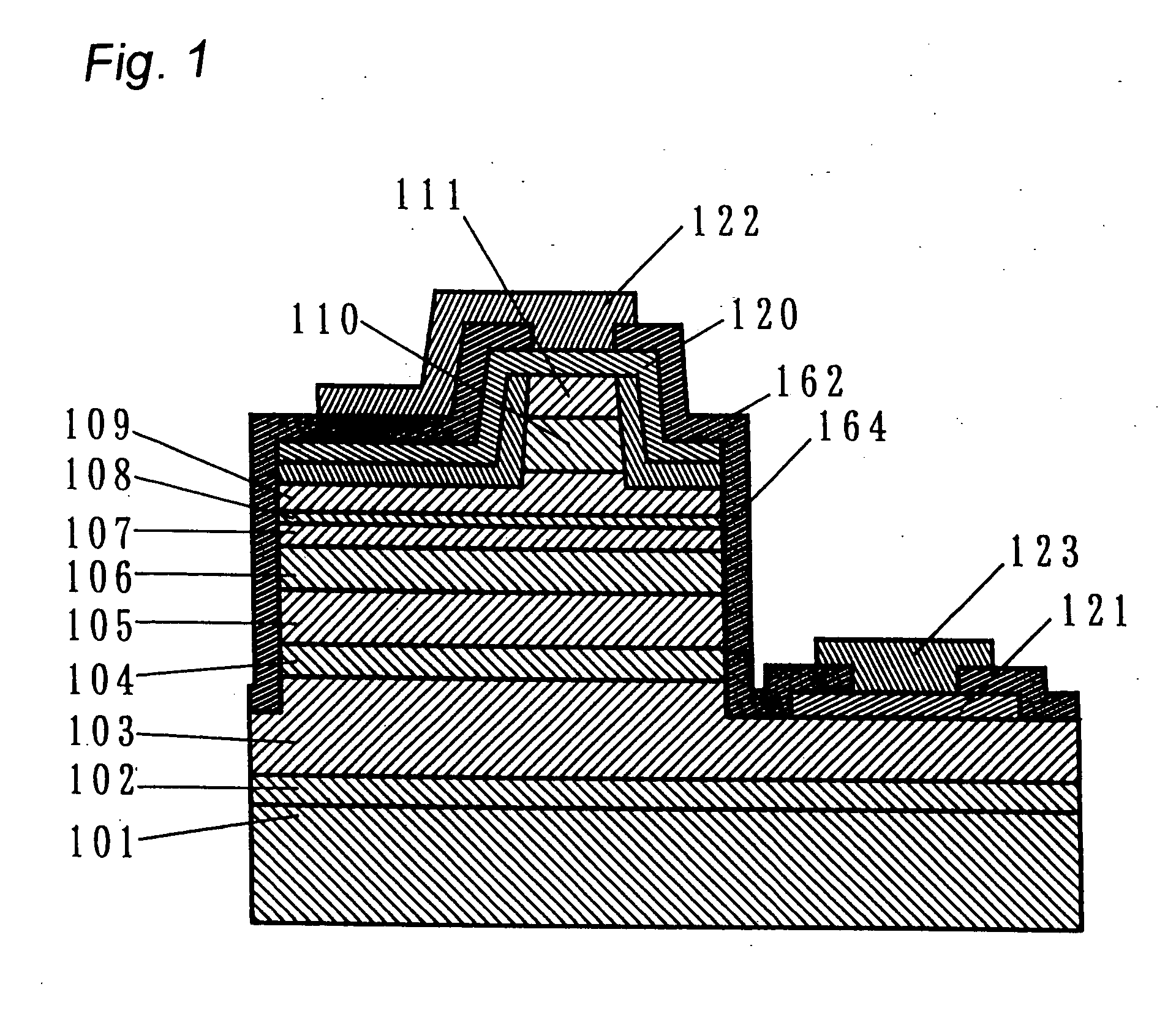

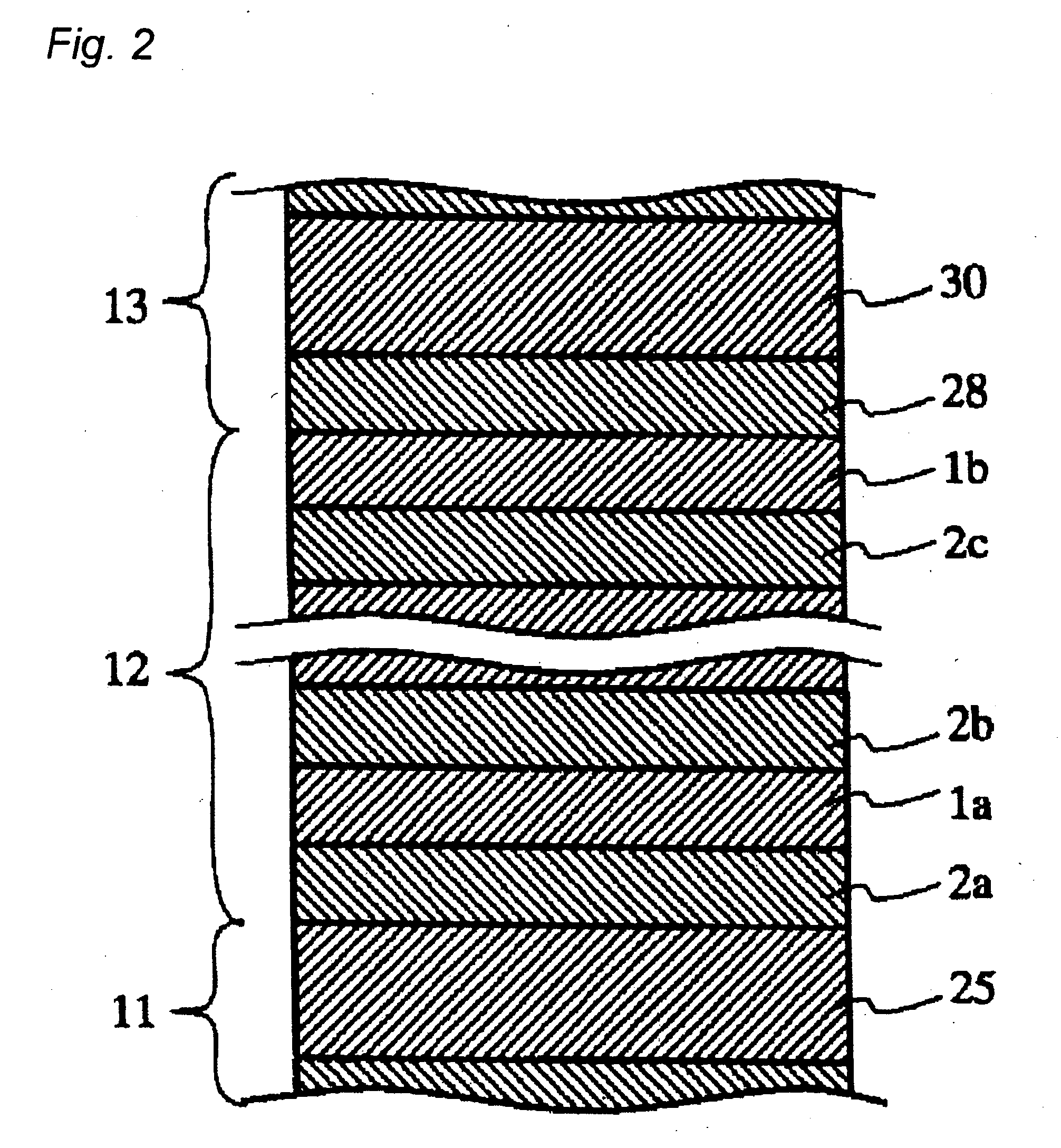

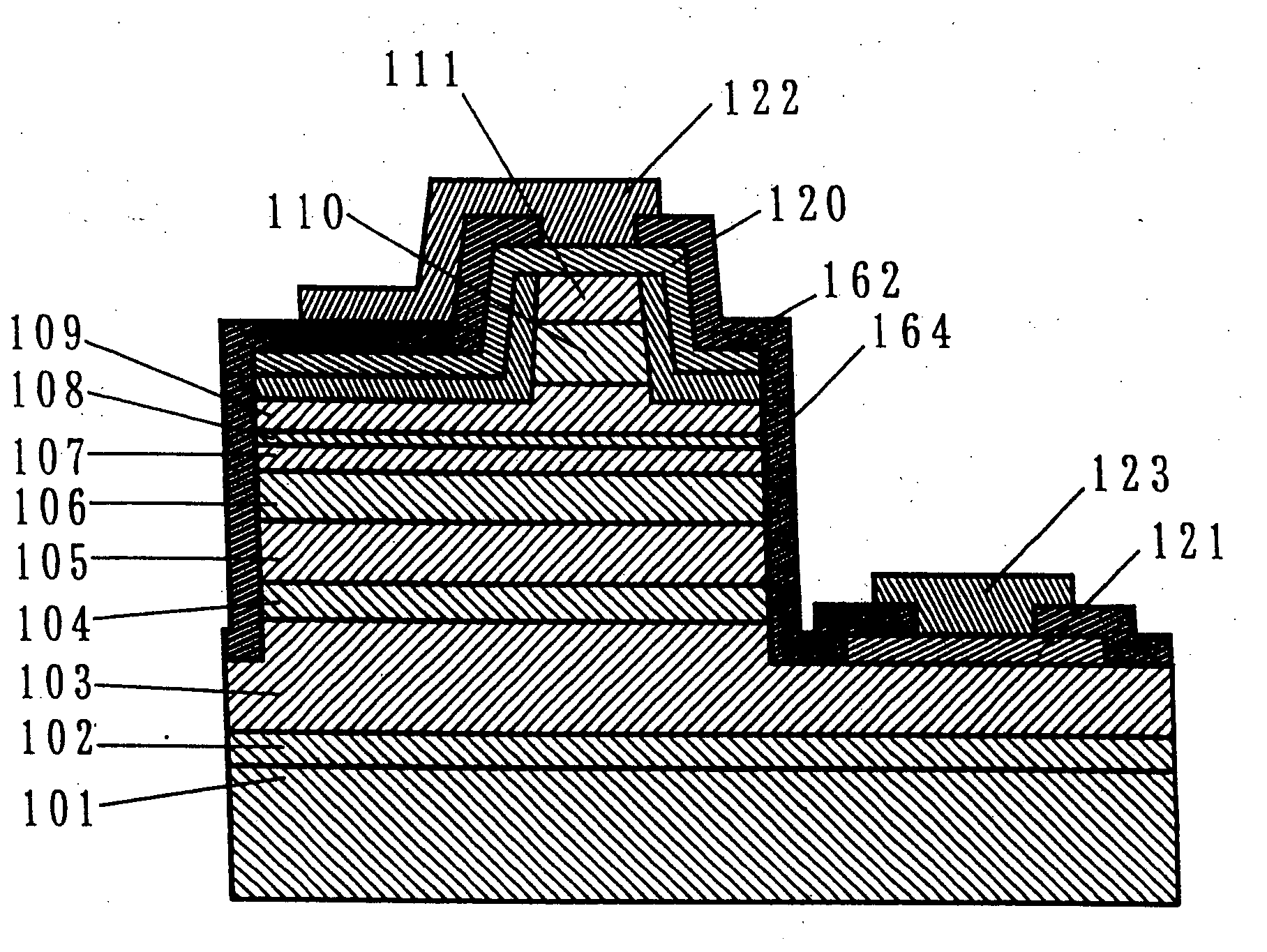

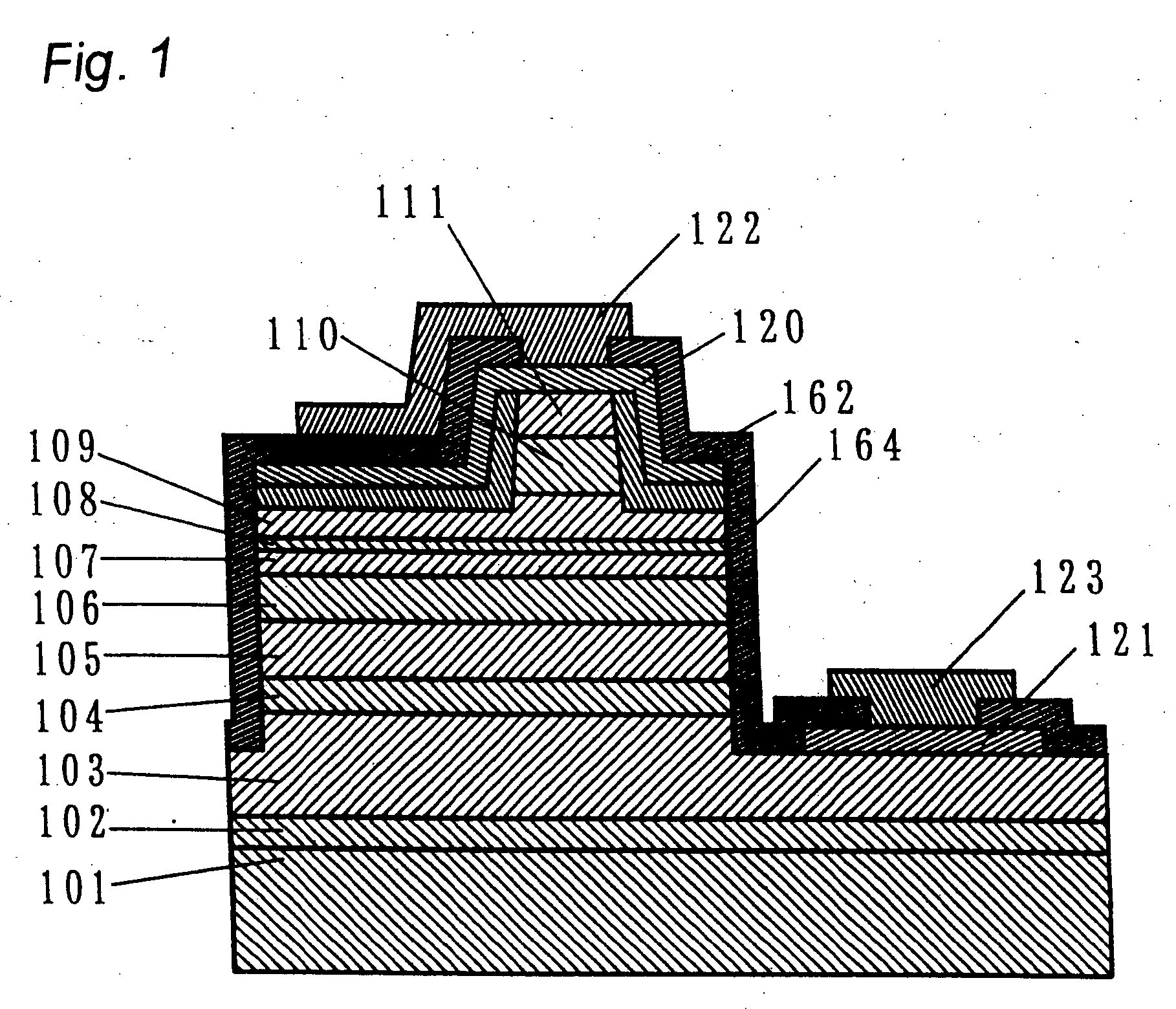

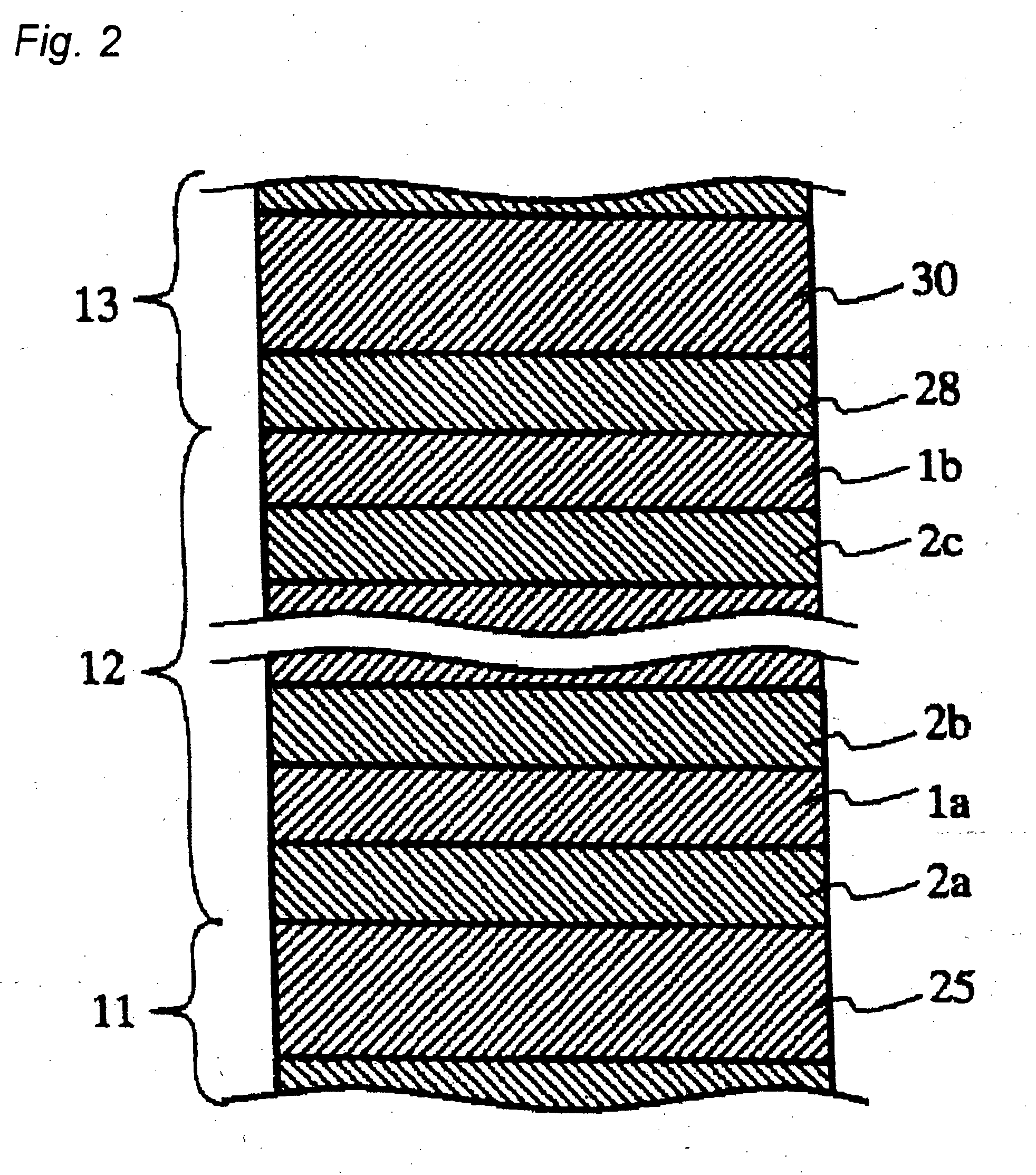

Nitride semiconductor device

InactiveUS6838693B2Improve emission efficiencyIncrease electron concentrationOptical wave guidanceLaser detailsActive layerImpurity

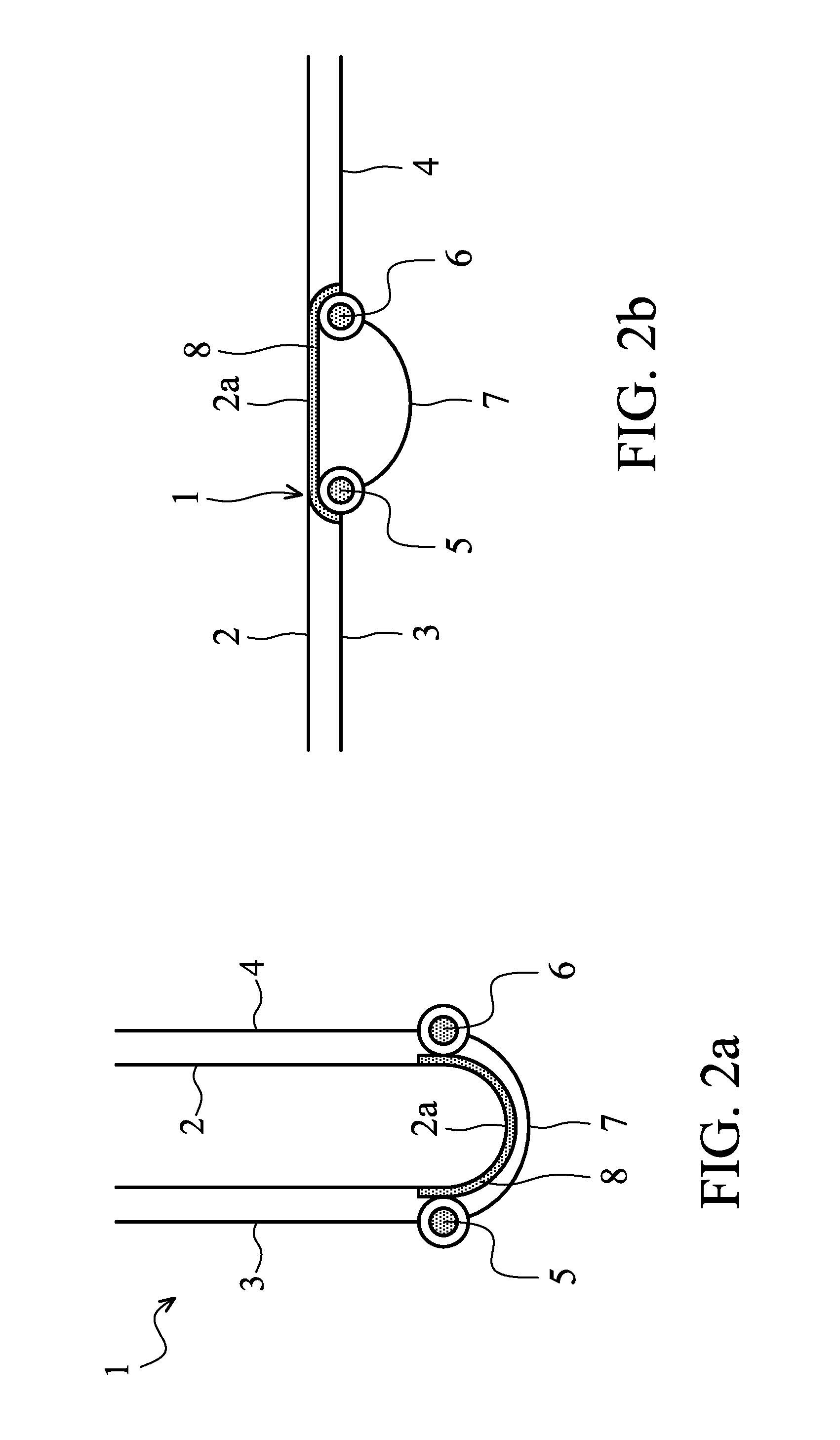

In the nitride semiconductor device of the present invention, an active layer 12 is sandwiched between a p-type nitride semiconductor layer 11 and an n-type nitride semiconductor layer 13. The active layer 12 has, at least, a barrier layer 2a having an n-type impurity; a well layer 1a made of a nitride semiconductor that includes In; and a barrier layer 2c that has a p-type impurity, or that has been grown without being doped. An appropriate injection of carriers into the active layer 12 becomes possible by arranging the barrier layer 2c nearest to the p-type layer side.

Owner:NICHIA CORP

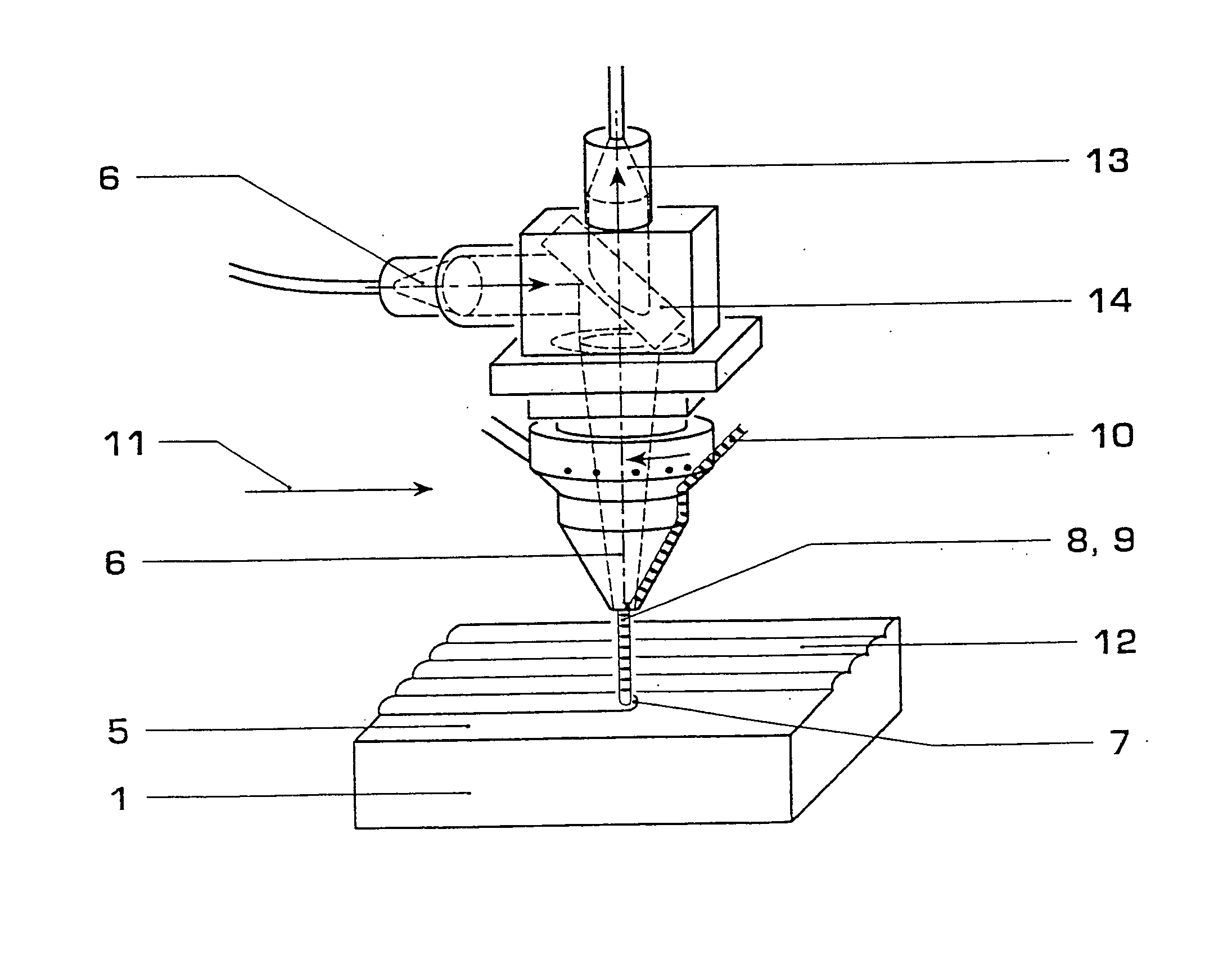

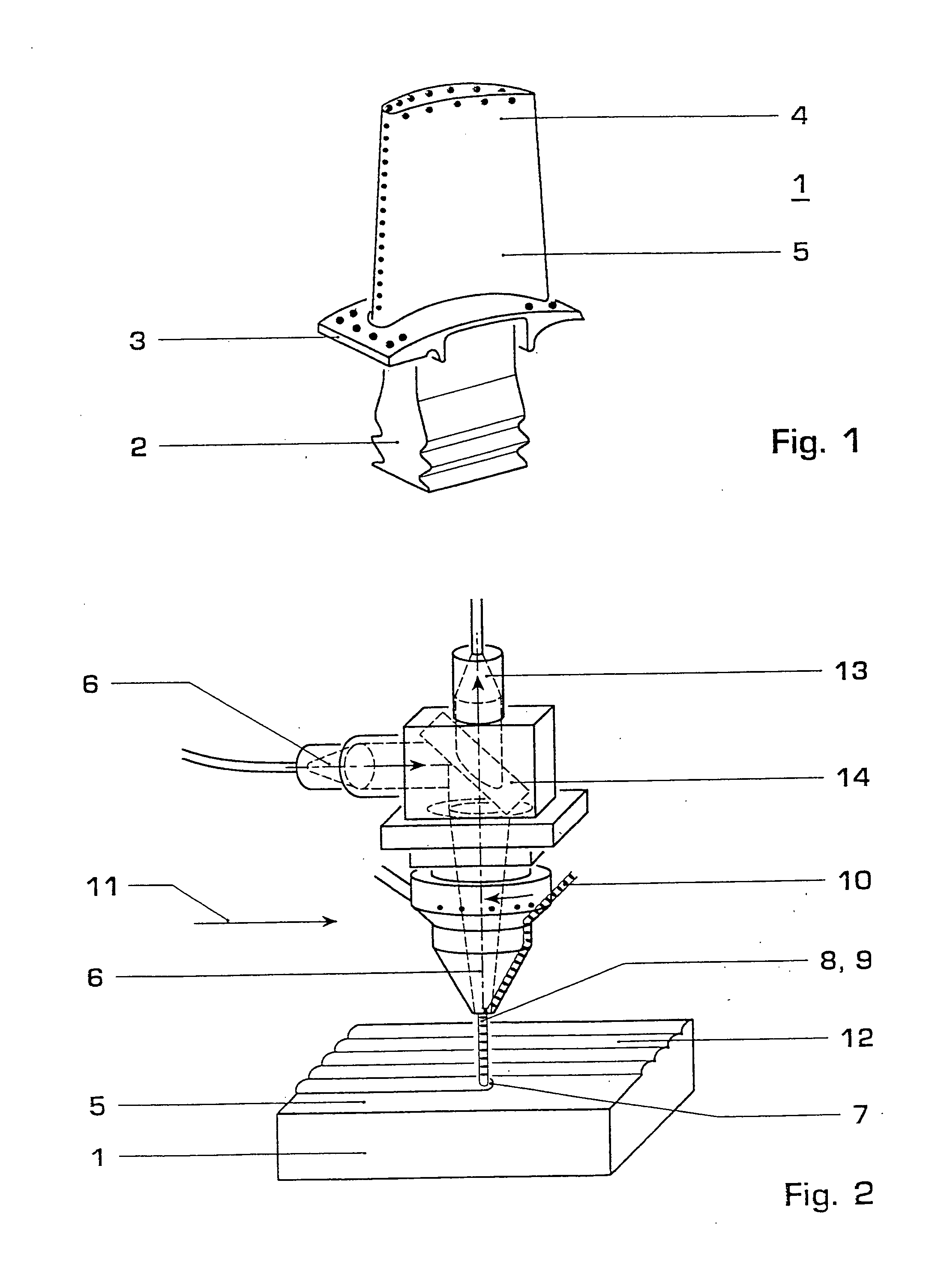

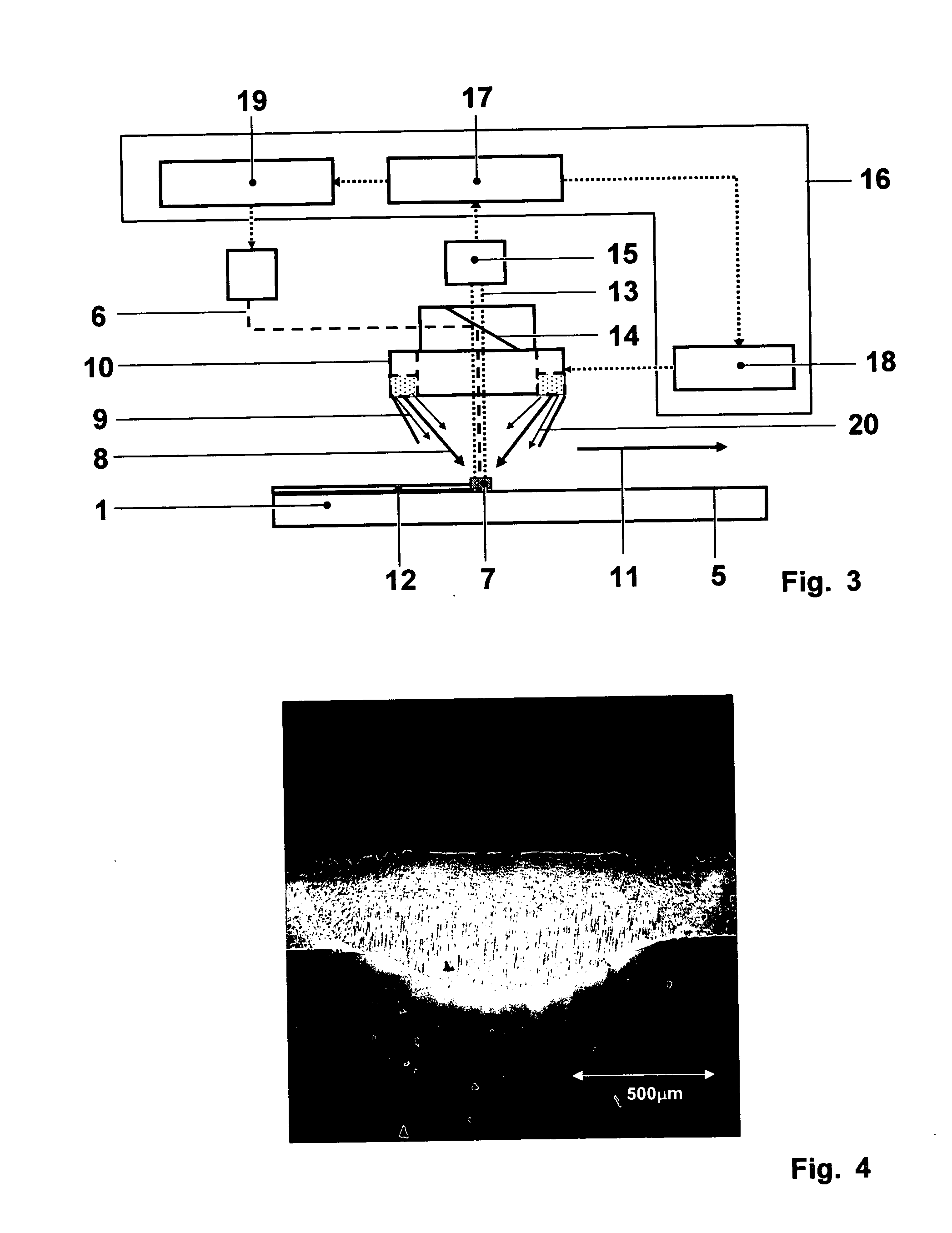

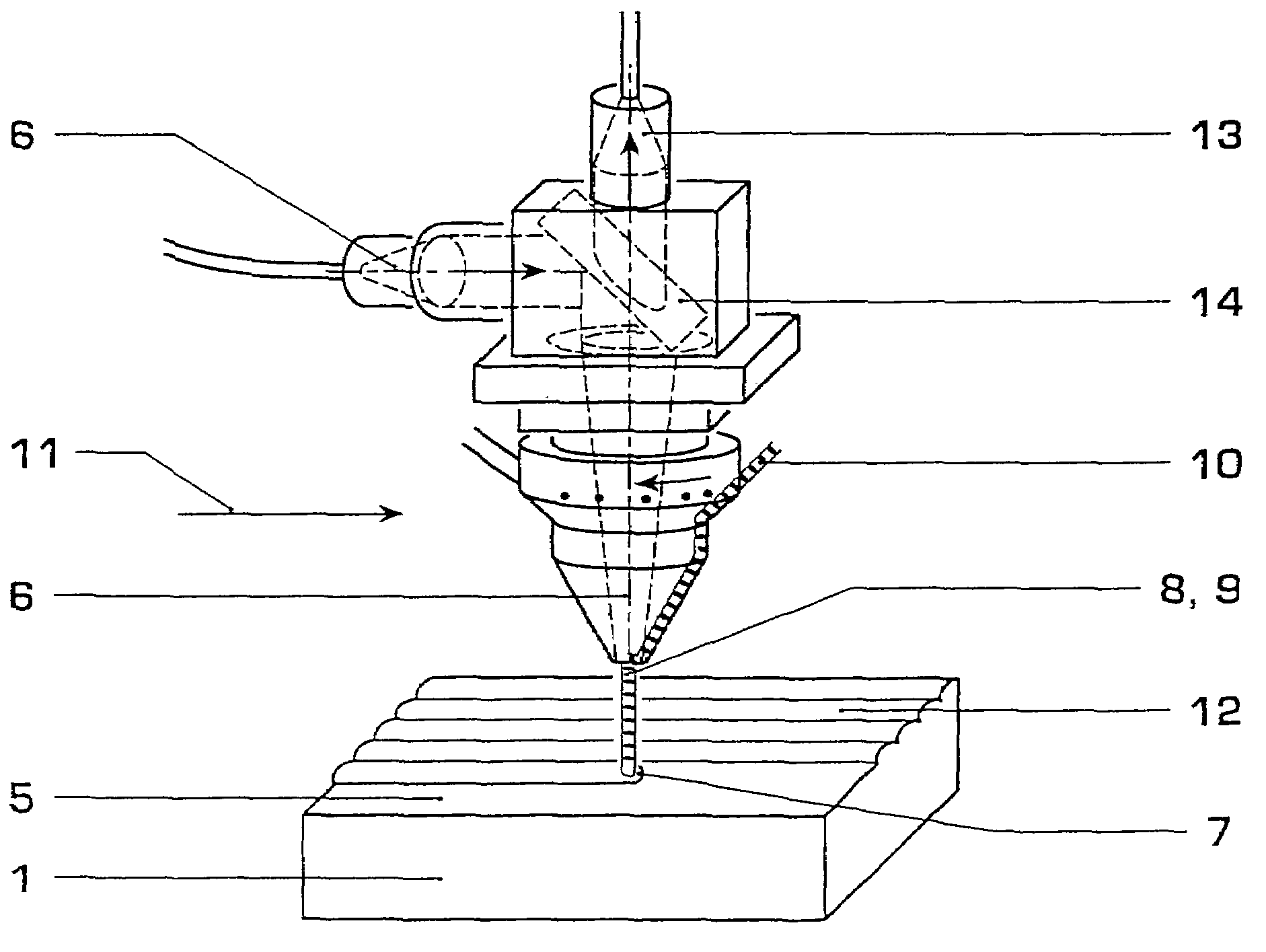

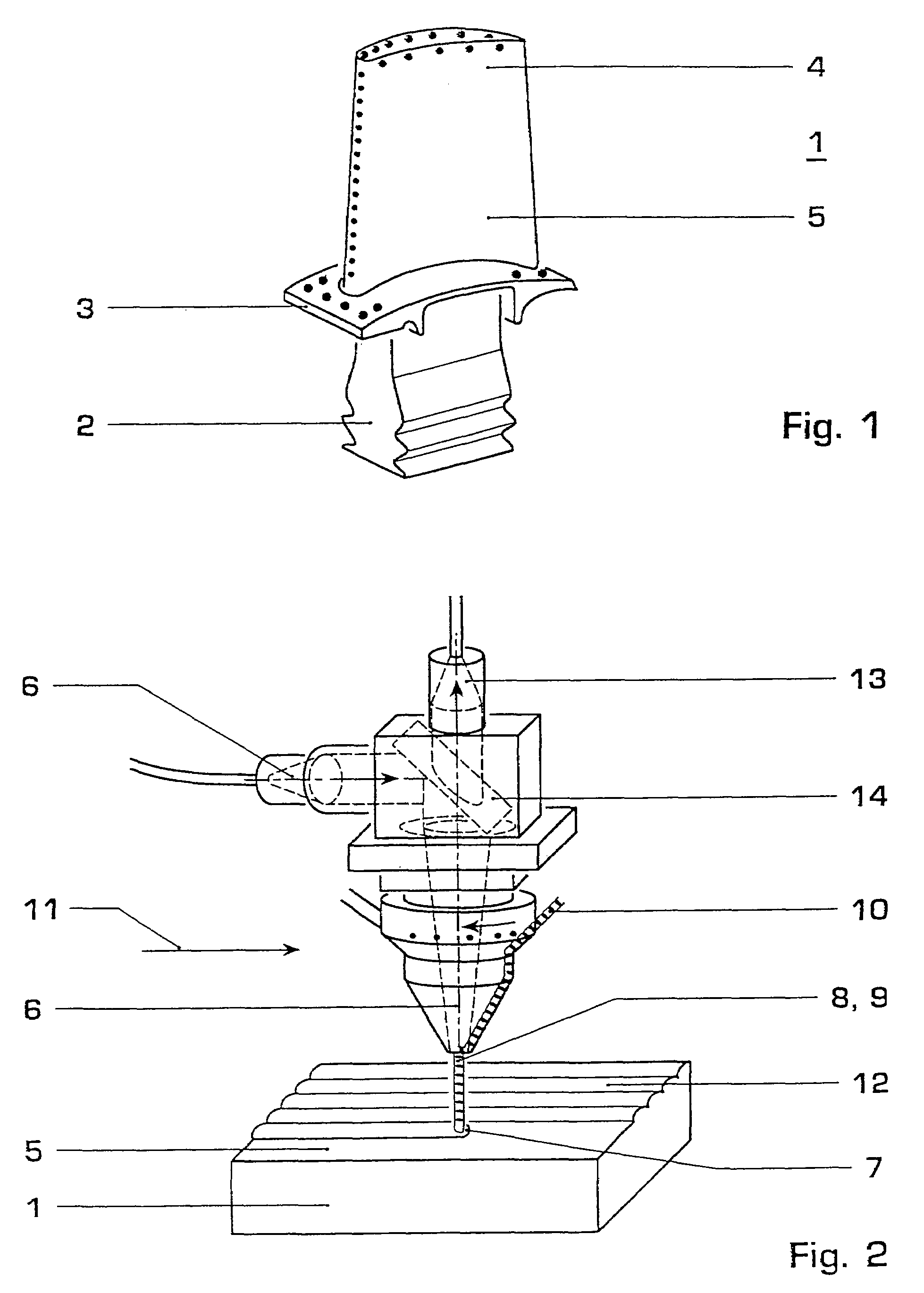

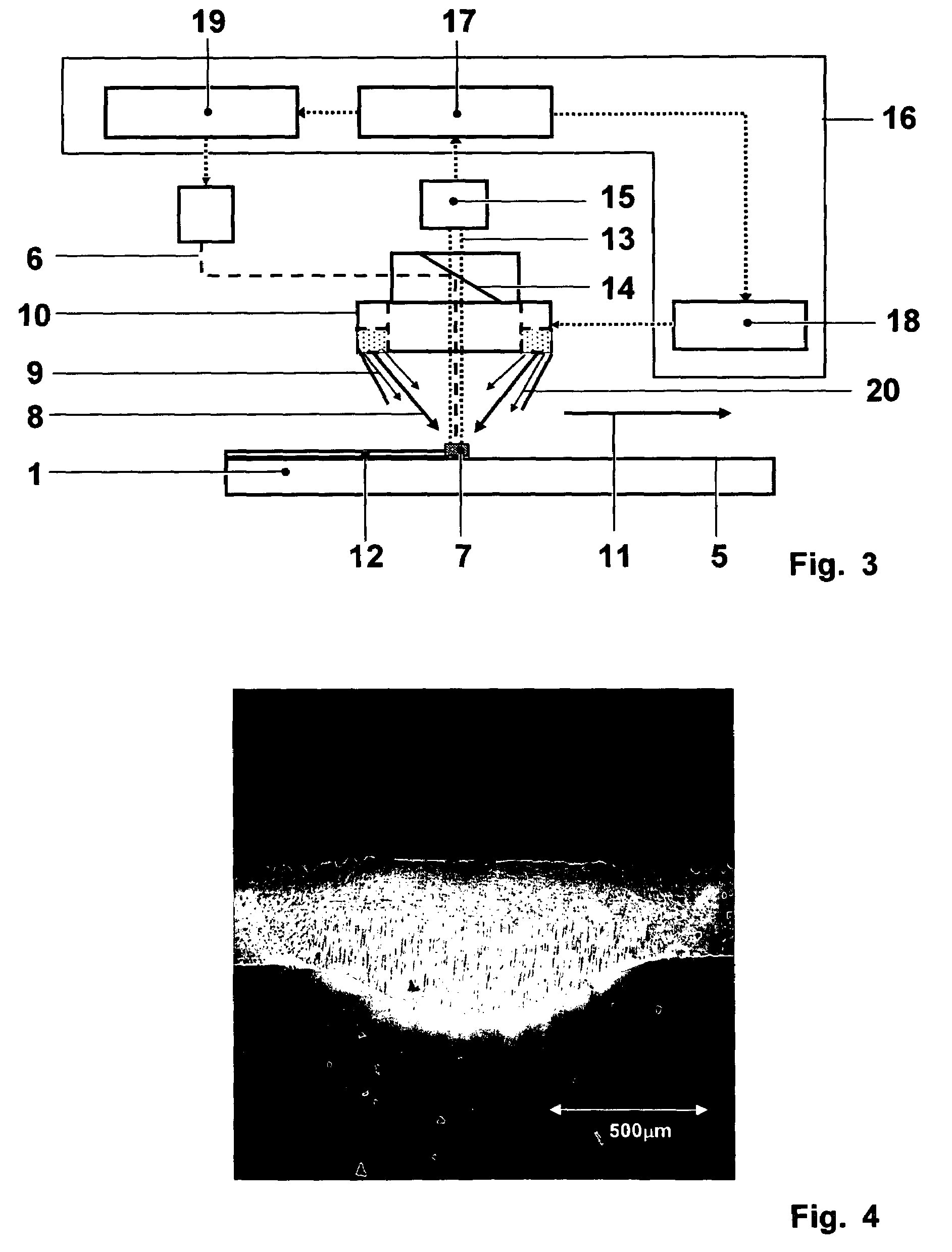

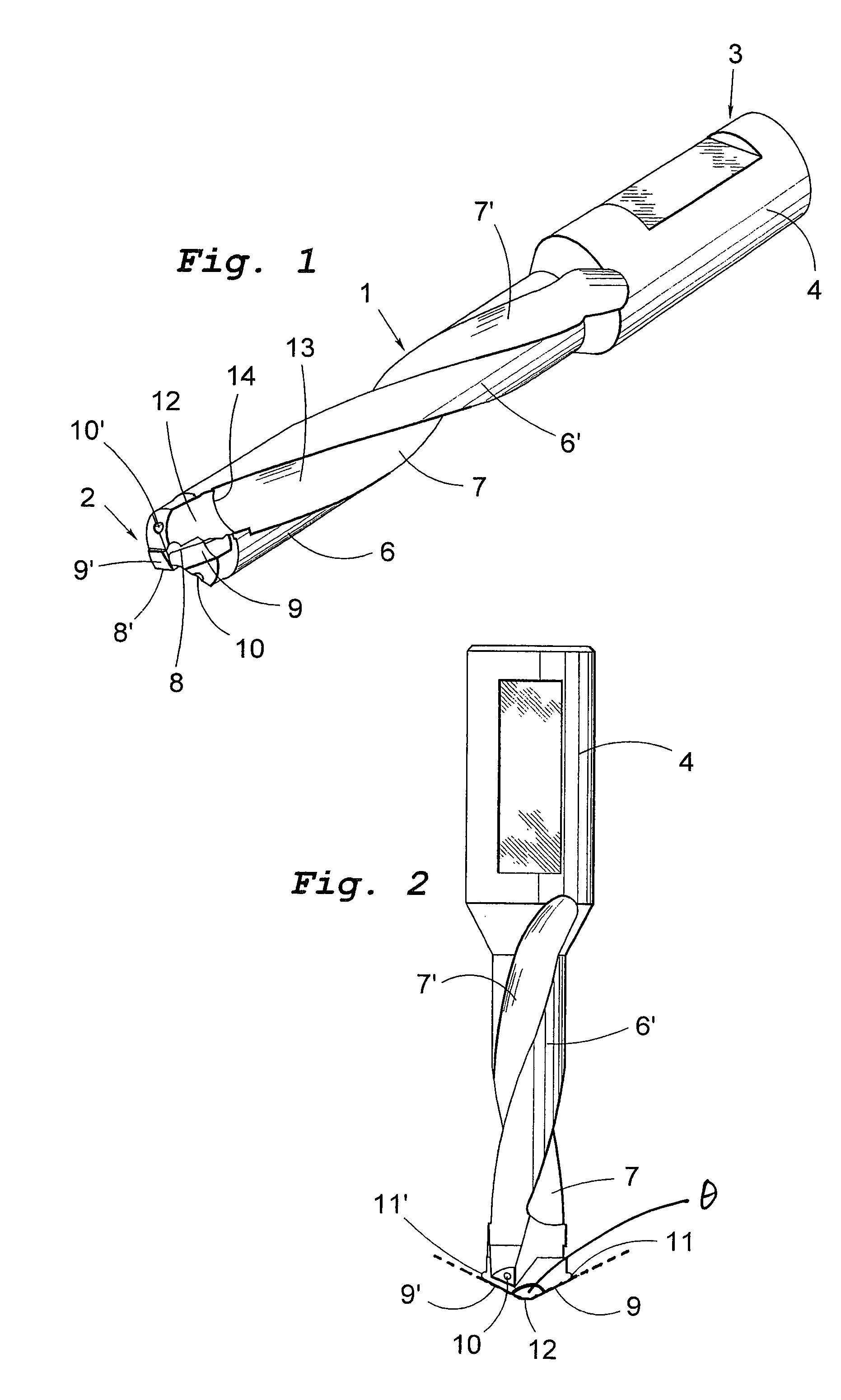

Method of controlled remelting of or laser metal forming on the surface of an article

InactiveUS20050040147A1Superior emission lifetimeRelieve pressurePolycrystalline material growthMolten spray coatingMetal formingControl system

A method for controlled remelting of or laser metal forming on the surface (5) of an article (1) can include moving a light source and a signal capturing apparatus over the article (1). The light source having a specific power can be used to melt the surface (5) of the article (1) locally and to form a melt pool (7). Thereby an optical signal (13) is captured by the signal capturing apparatus from the melt pool (7), and the monitored optical signal (13) is used for the determination of temperature and temperature fluctuations as properties of the melt pool (7). Furthermore, a control system (16) with a feedback circuit is used to adjust at least one process parameter such as the power of the light source such that desired melt pool properties are obtained. Subsequently the melt pool (7) solidifies.

Owner:ANSALDO ENERGIA IP UK LTD

Flexible display with display support

ActiveUS9235239B2Stiff feelQuality improvementDigital data processing detailsCasings with display/control unitsDisplay deviceEngineering

A display system includes a continuous flexible display and two main display supports being hingeable with respect to each other between a closed storage position and a planar configuration for fixing the flexible display in an open position. At least one additional display support supports a segment of the flexible display located between the said respective portions of the flexible display in the open position. This additional display support is movable with respect to the display segment between a non-operational position and a support position when the two main display supports are moved between the storage position and the planar position, such that in the open position substantially the whole surface of the display is supported by the respective display supports.

Owner:SAMSUNG ELECTRONICS CO LTD

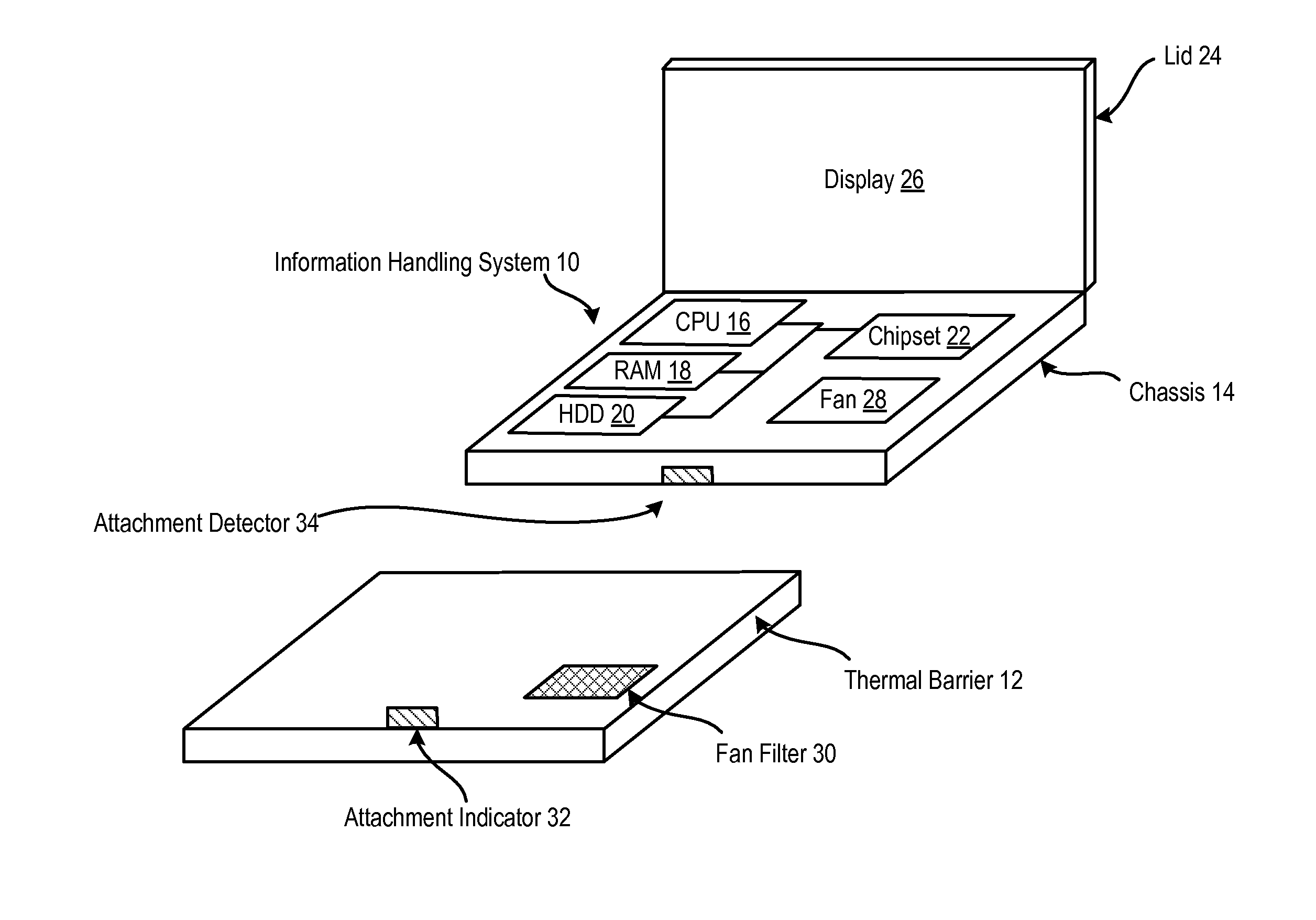

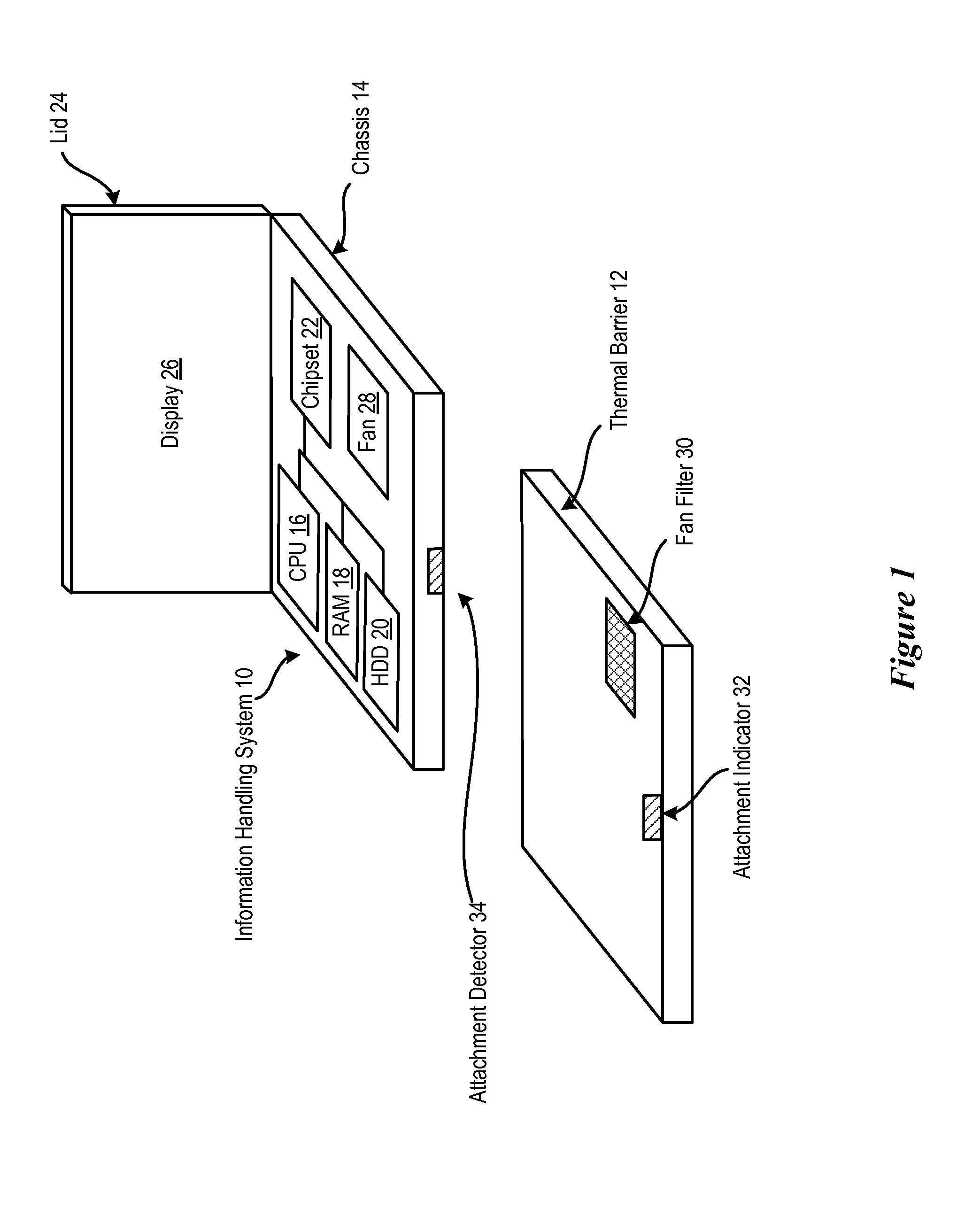

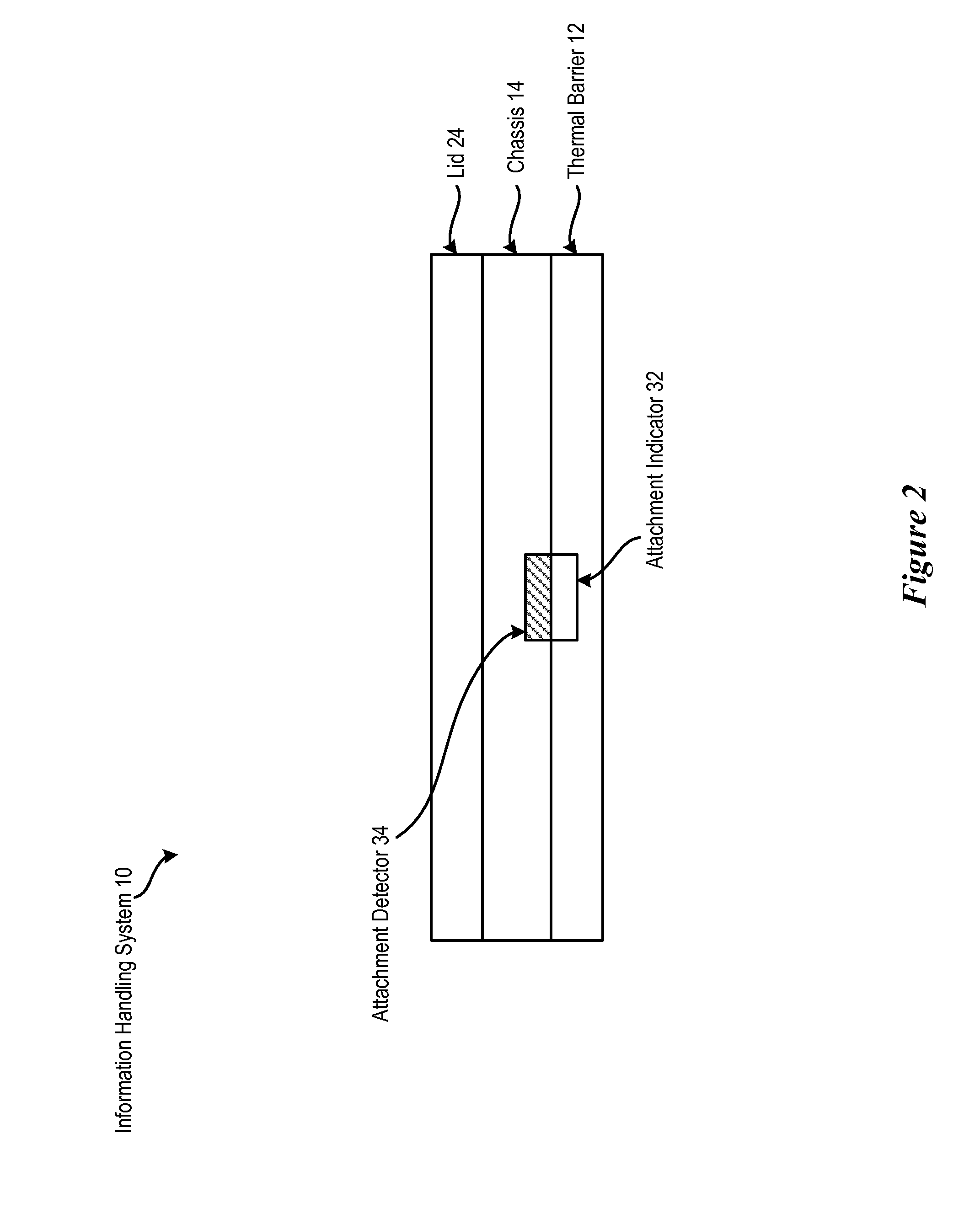

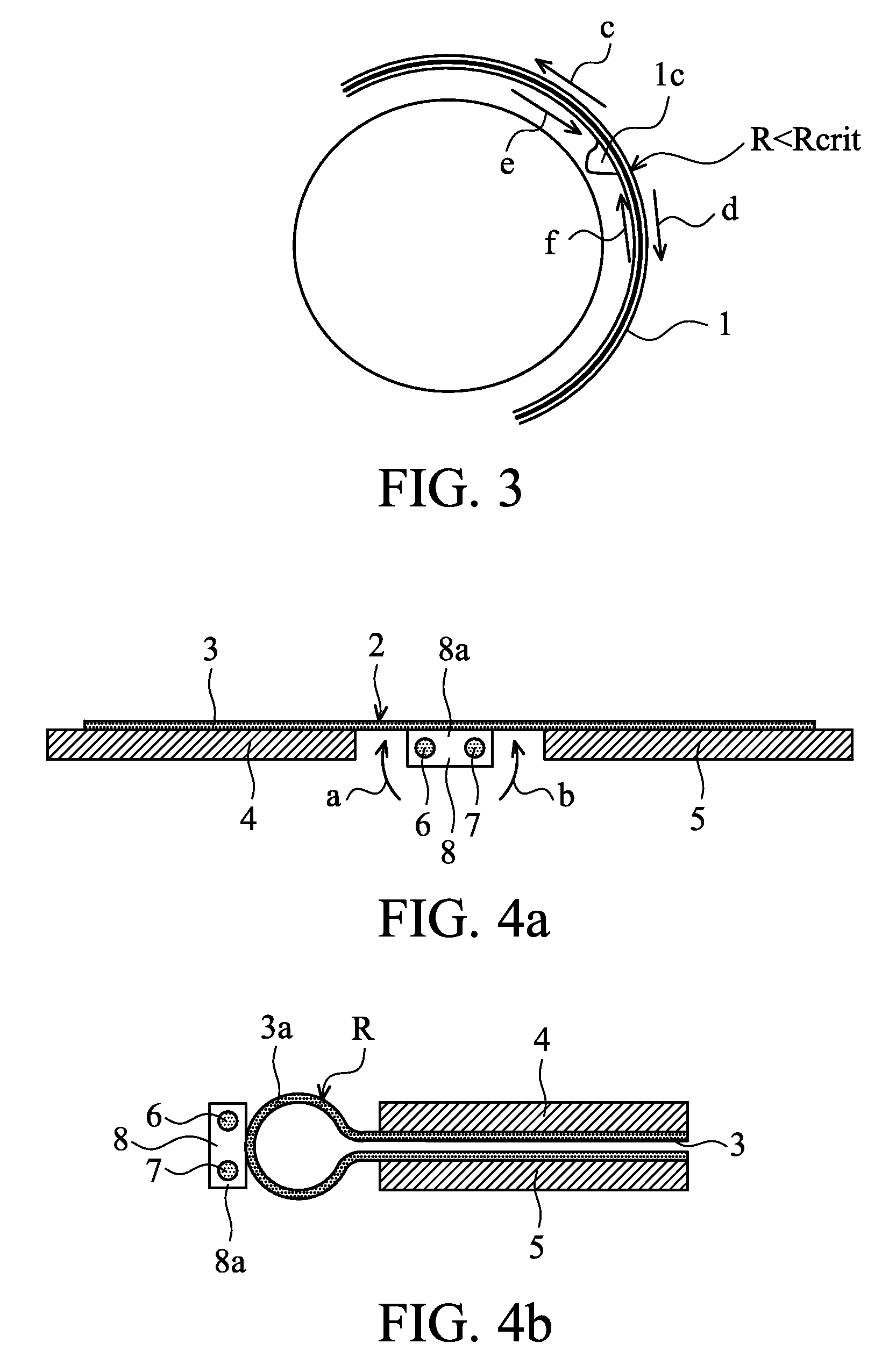

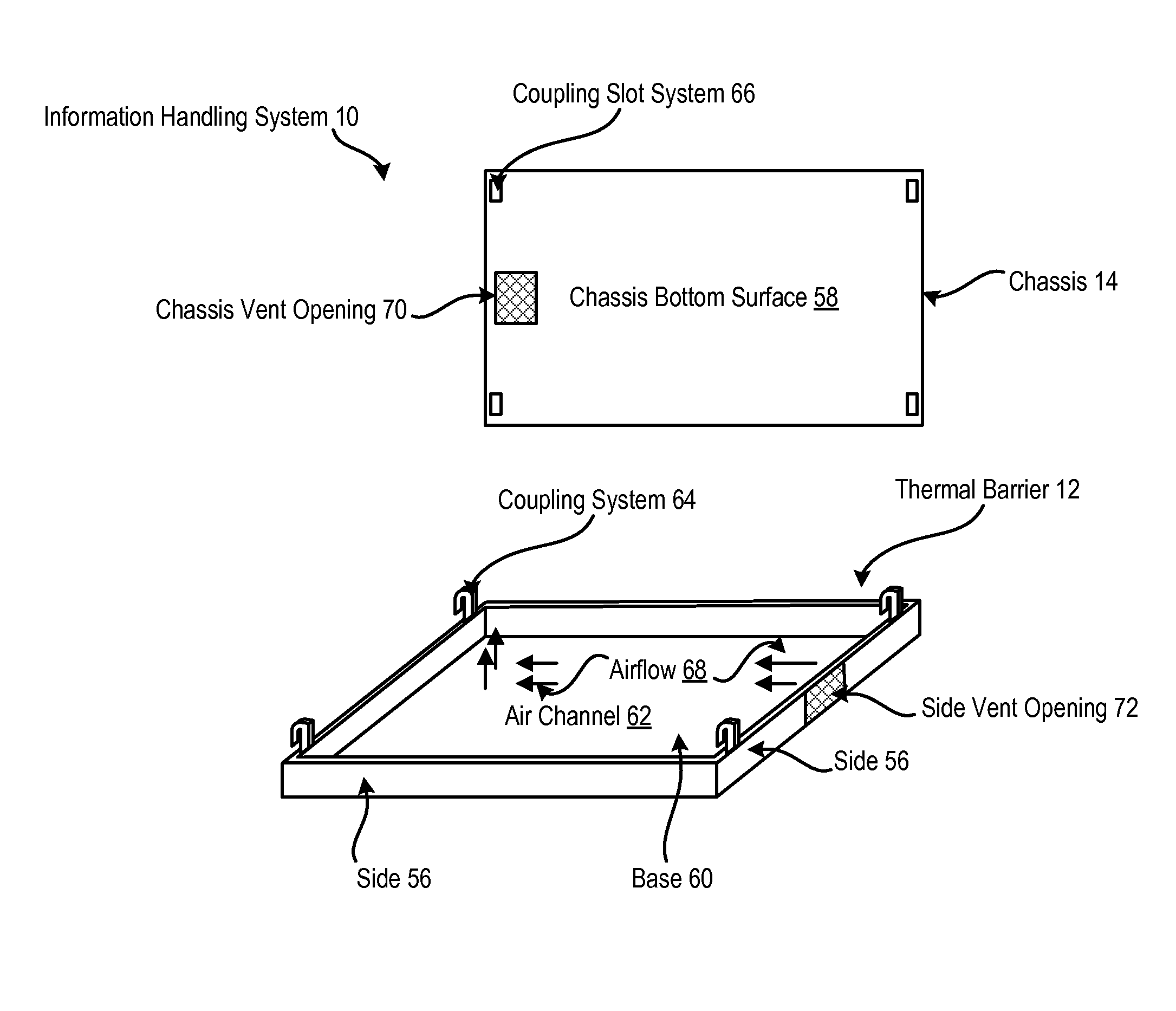

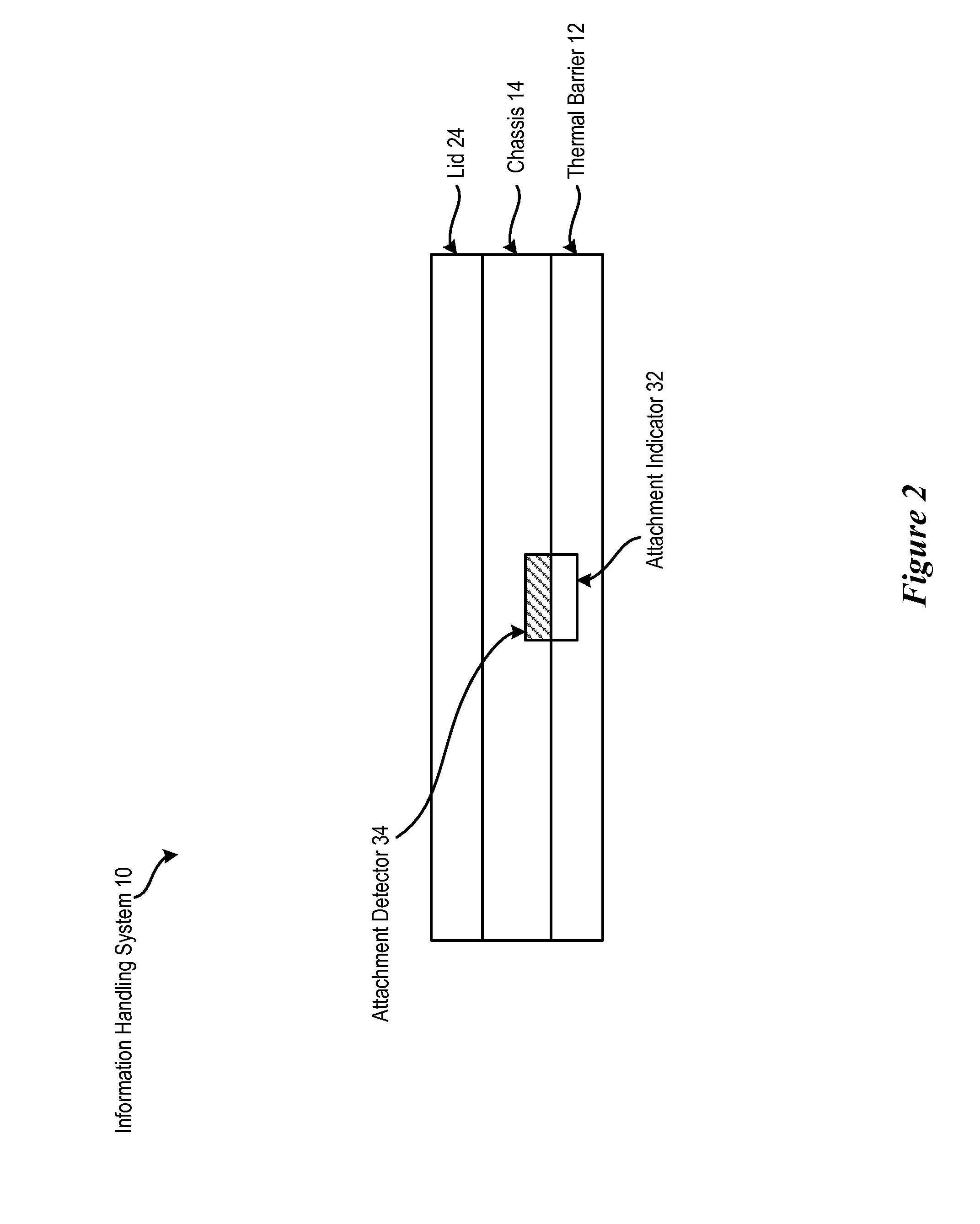

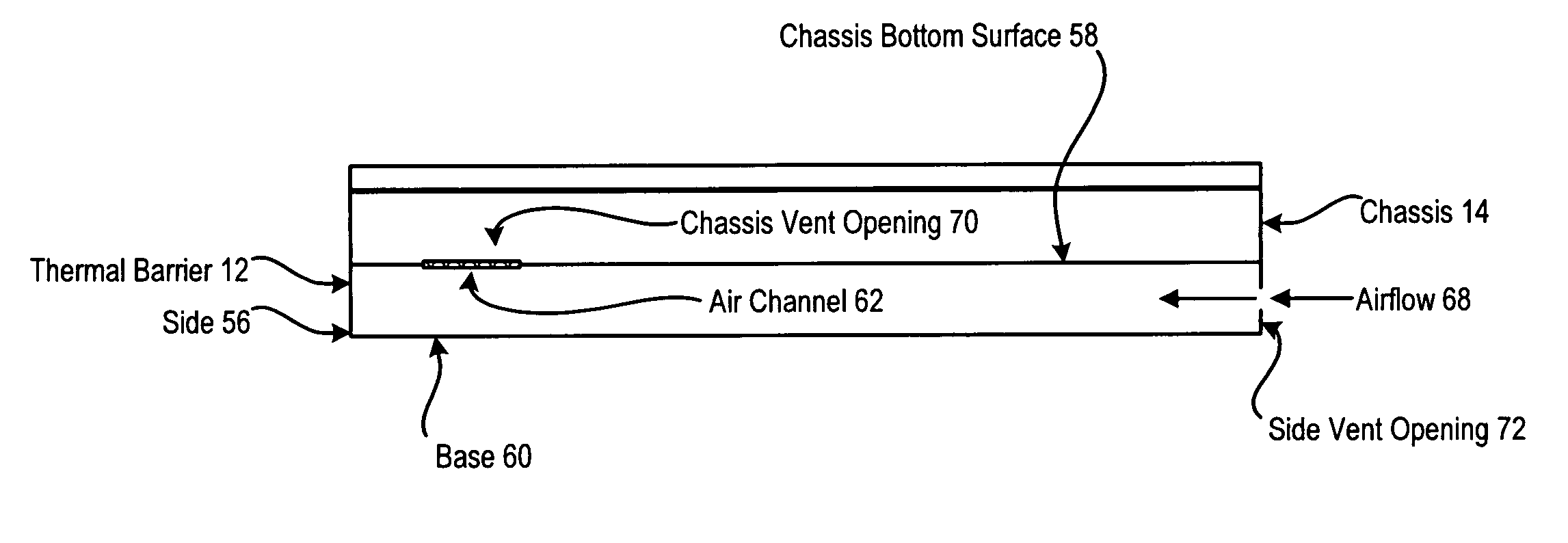

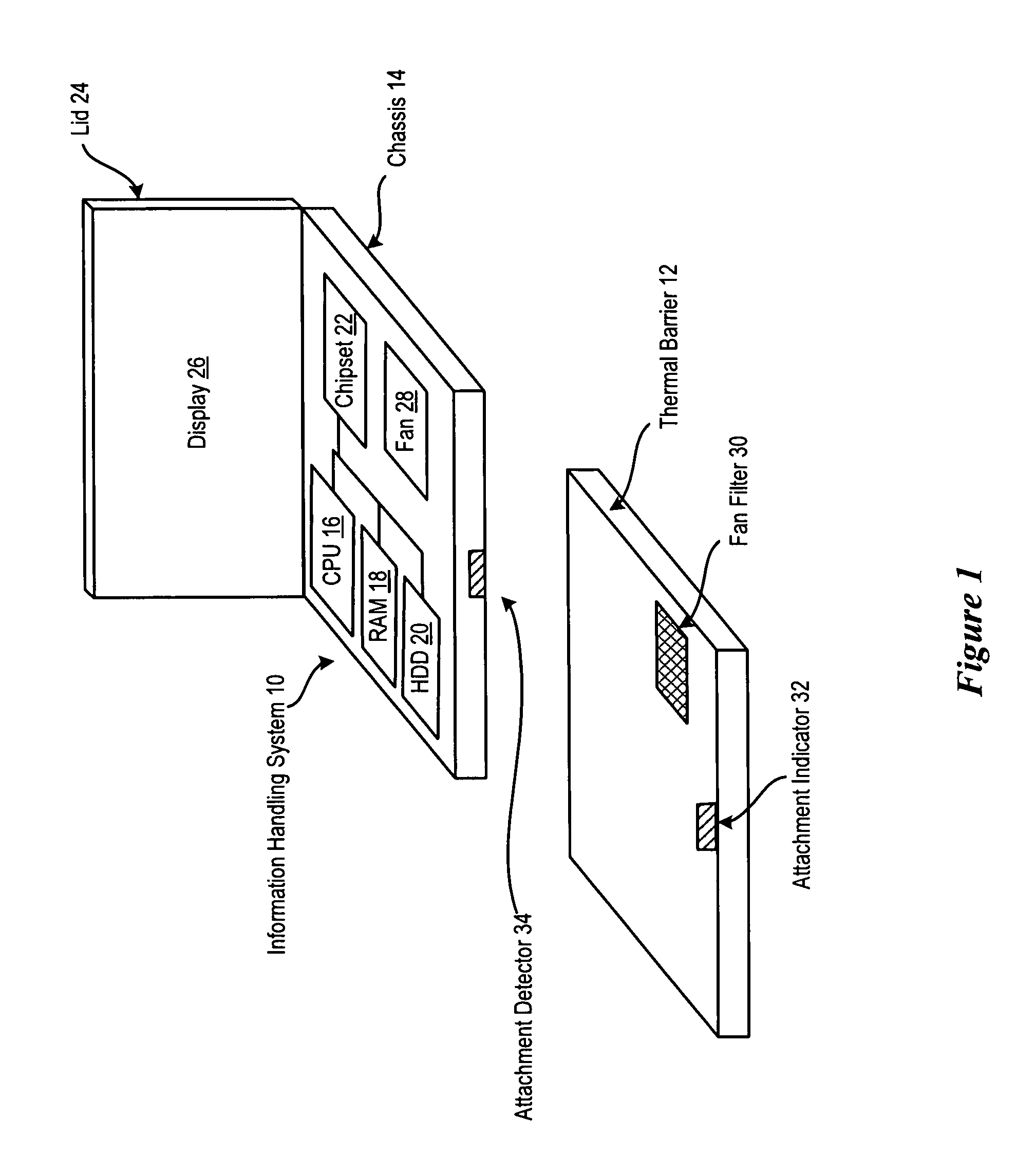

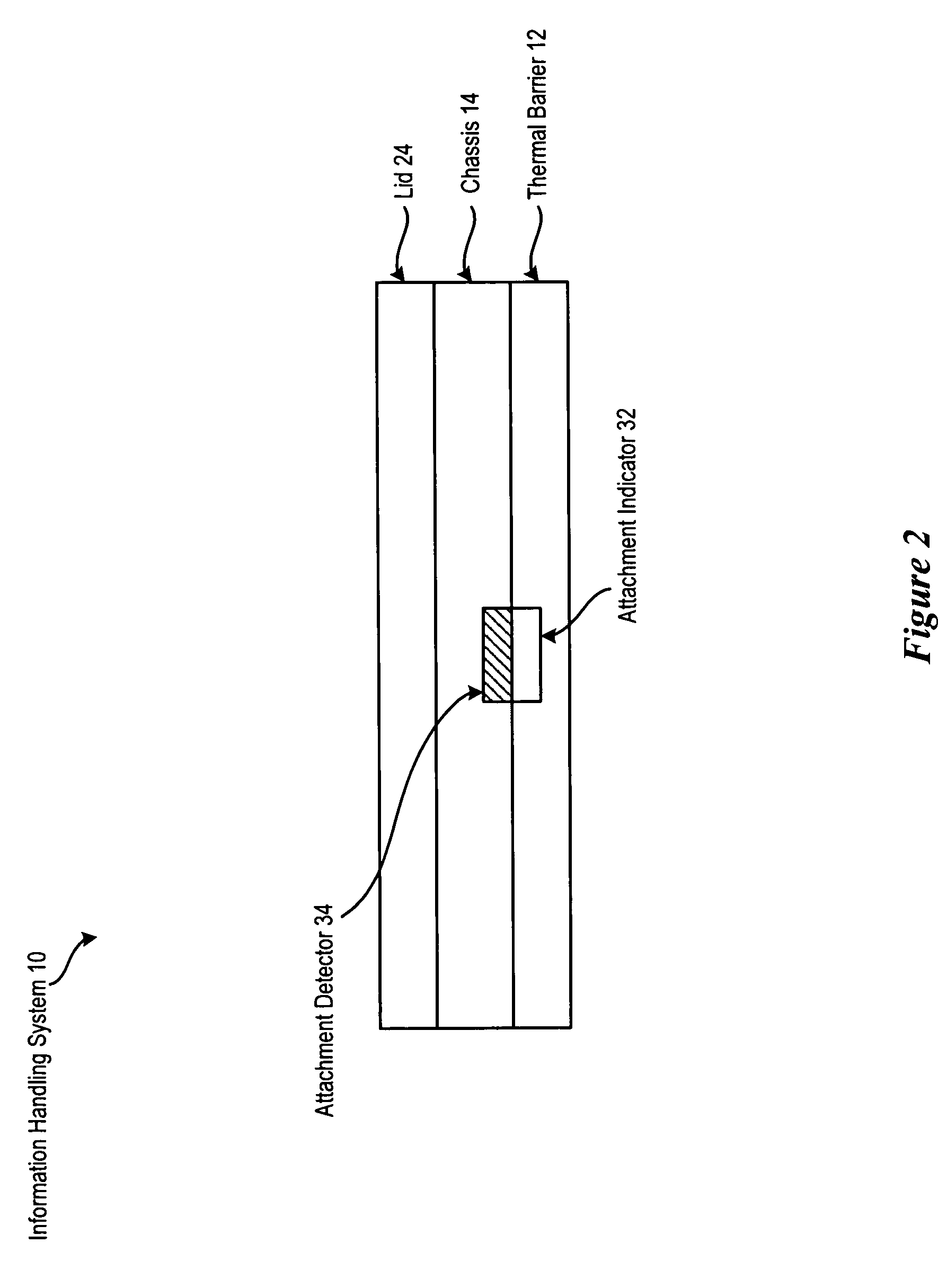

System and Method for Portable Information Handling System Parallel-Wall Thermal Shield

ActiveUS20090323275A1Reduce disadvantagesReduce problemsEnergy efficient ICTDigital data processing detailsThermal energyEngineering

An information handling system's thermal management is selectively altered by coupling a thermal barrier to the bottom surface of the information handling system chassis so that an air channel insulates against the passage of thermal energy from the bottom surface. A vent opening in a side of the thermal barrier allows airflow through the air channel to a vent opening of the information handling system. The airflow through the air channel cools the base of the thermal barrier so that an end user will experience reduced thermal energy if the information handling system rests on the end user, such as in the end user's lap.

Owner:DELL PROD LP

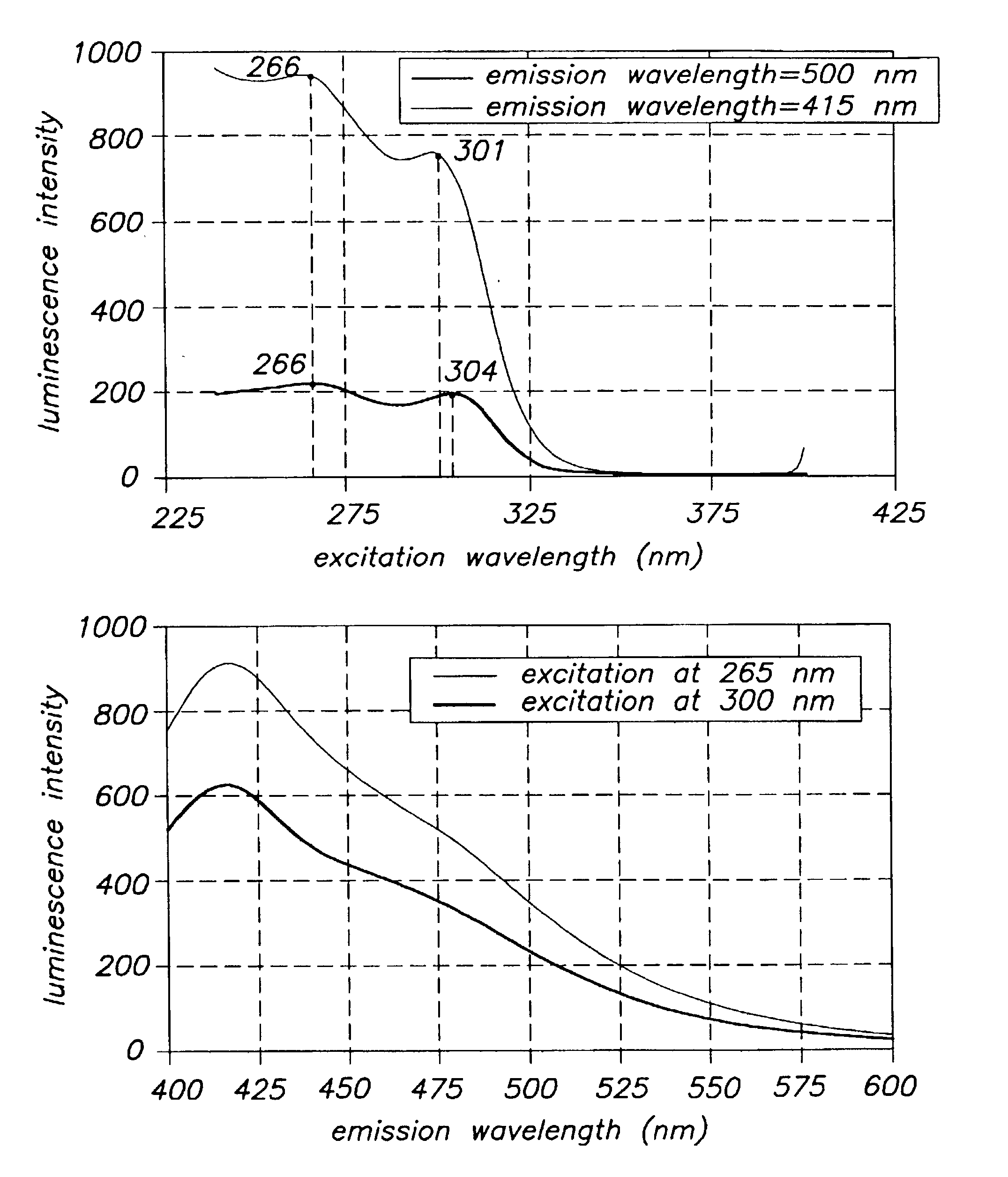

Rare-earth doped alkaline-earth silicon nitride phosphor, method for producing and radiation converting device comprising such a phosphor

InactiveUS20100288972A1A large amountImprove conversion efficiencyLuminescent compositionsRare-earth elementAlkaline earth metal

The invention relates to a method of manufacturing a rare-earth doped alkaline-earth silicon nitride phosphor of a stoichiometric composition. Said method comprising the step of selecting one or more compounds each comprising at least one element of the group comprising the rare-earth elements (RE), the alkaline-earth elements (AE), silicon (Si) and nitrogen (N) and together comprising the necessary elements to form the rare-earth doped alkaline-earth silicon nitride phosphor (AE2Si5N8:RE). The method further comprises the step of bringing the compounds at an elevated temperature in reaction for forming the rare-earth doped alkaline-earth silicon nitride phosphor (AE2Si5N8:RE). In such a method normally a small amount of oxygen, whether intentionally or not-intentionally added, will be incorporated in the rare-earth doped alkaline-earth silicon nitride phosphor (AE2Si5N8:RE). According to the invention the creation of defects by formation of a non-stoichiometric oxygen containing phosphor is at least partly prevented by partly substituting for the ions (AE, Si, N) of the alkaline-earth silicon nitride phosphor (AE2Si5N8:RE) suitable further elements of the periodic system by which vacancies are created, filled or annihilated resulting in the formation of a modified alkaline-earth silicon nitride phosphor (AE2Si5N8:RE) having a stoichiometric composition. In this way a modified phosphor is obtained having excellent and stable optical properties. The invention further relates to a modified phosphor obtainable by the above-mentioned method and a radiation converting device comprising such a phosphor.

Owner:LEUCHTSTOFFWERK BREITUNGEN +1

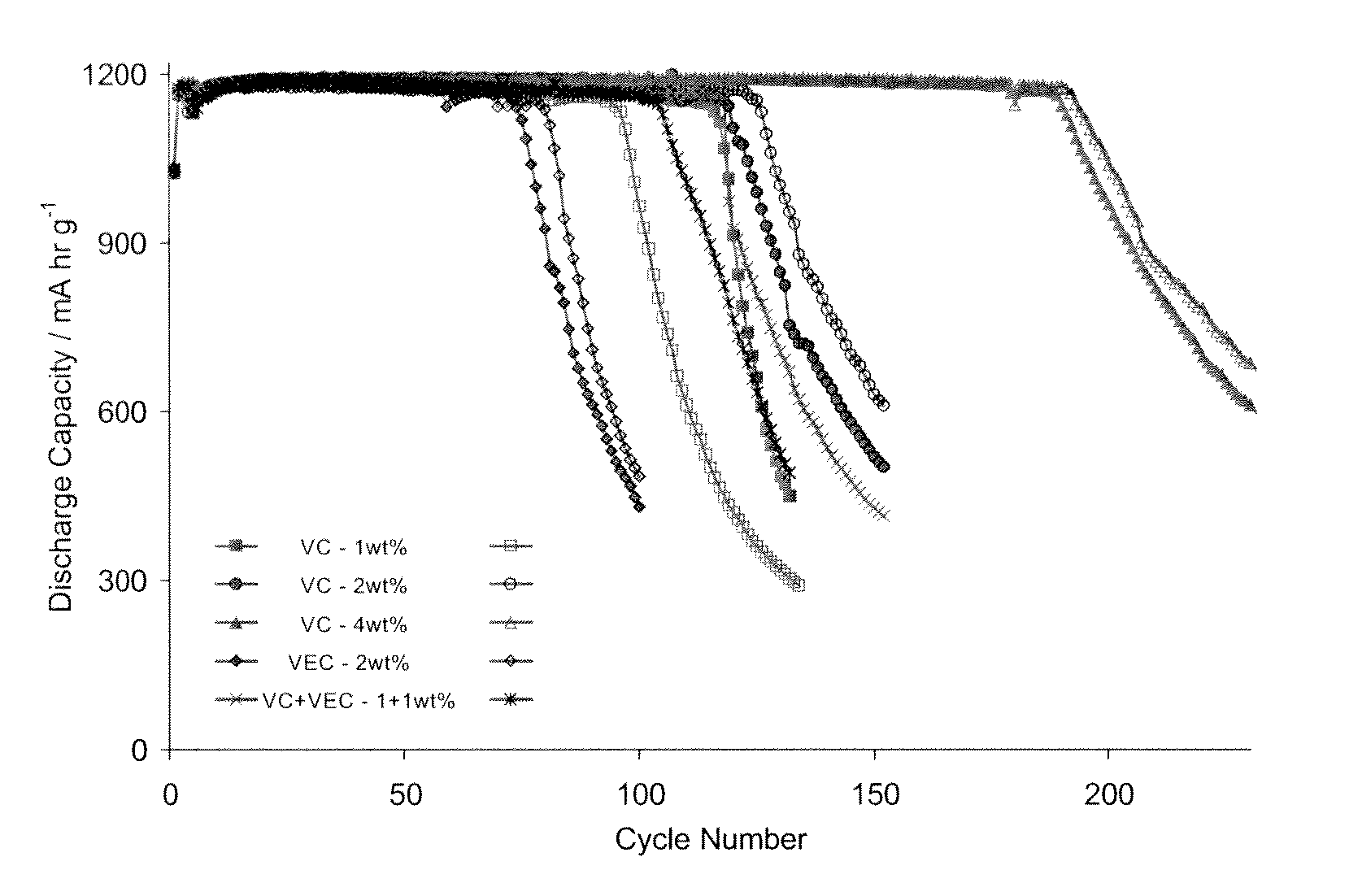

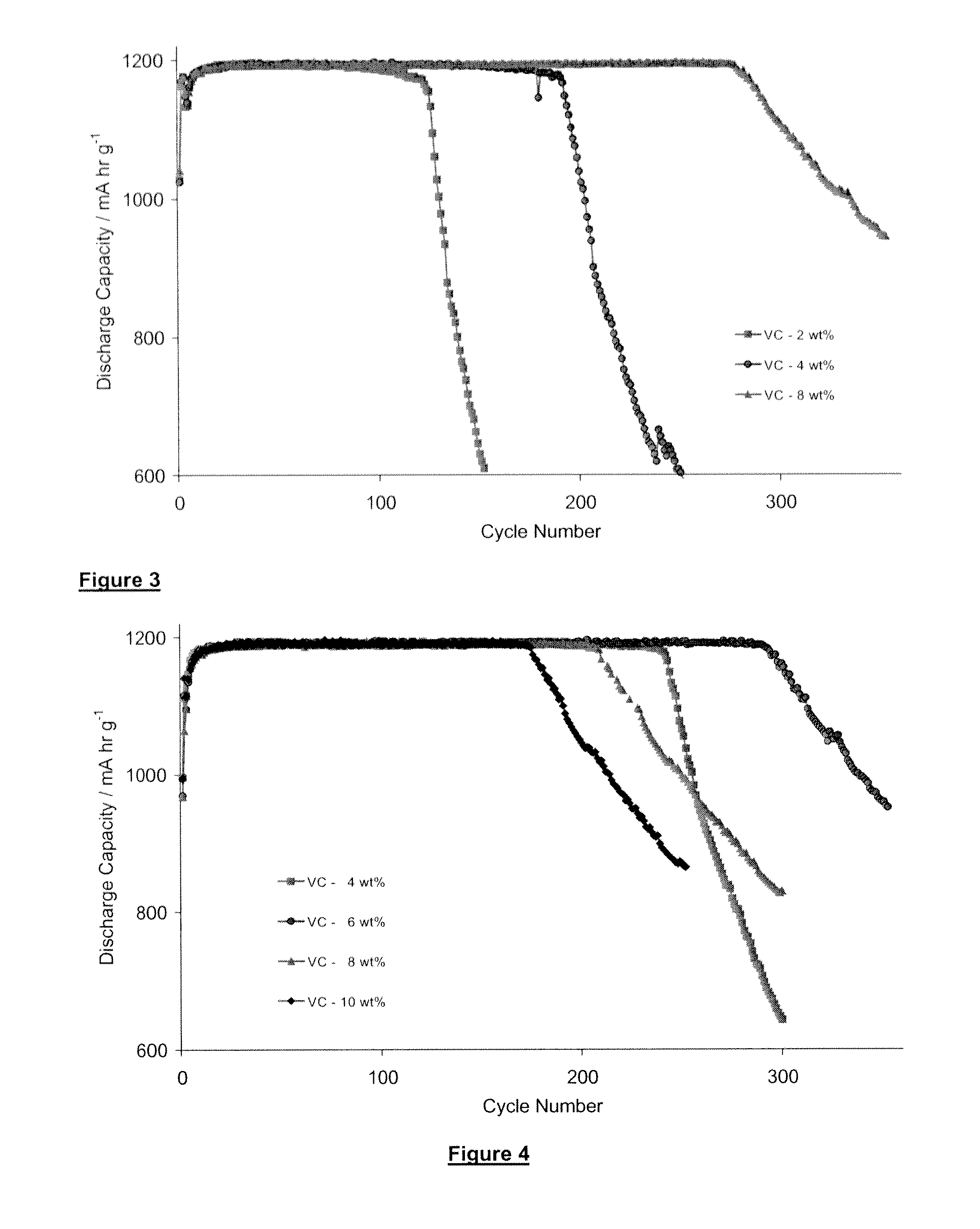

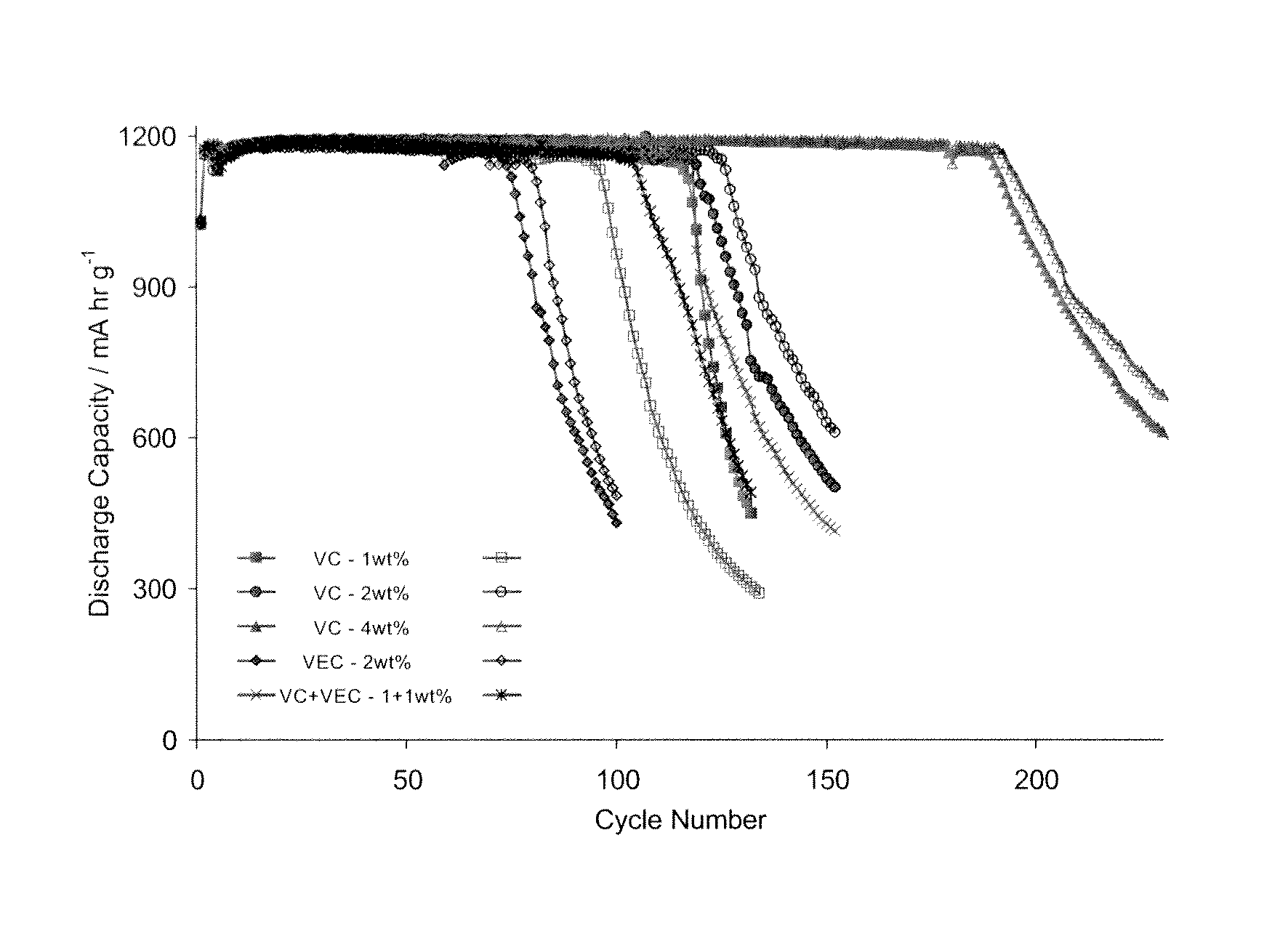

Additive for lithium ion rechageable battery cells

ActiveUS20130069601A1Electronic conductivityLow resistivityBatteries circuit arrangementsCell electrodesPhysical chemistryLithium-ion battery

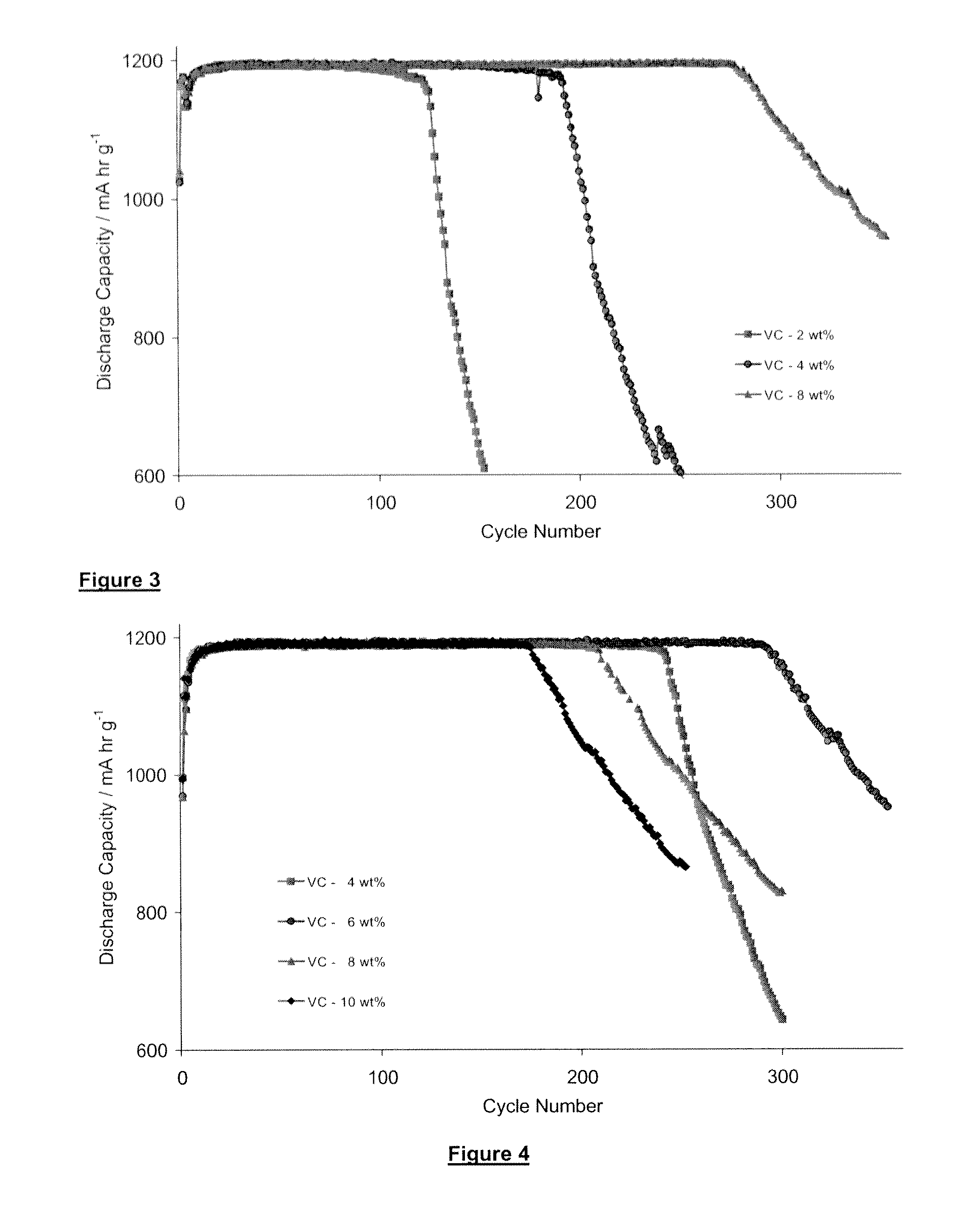

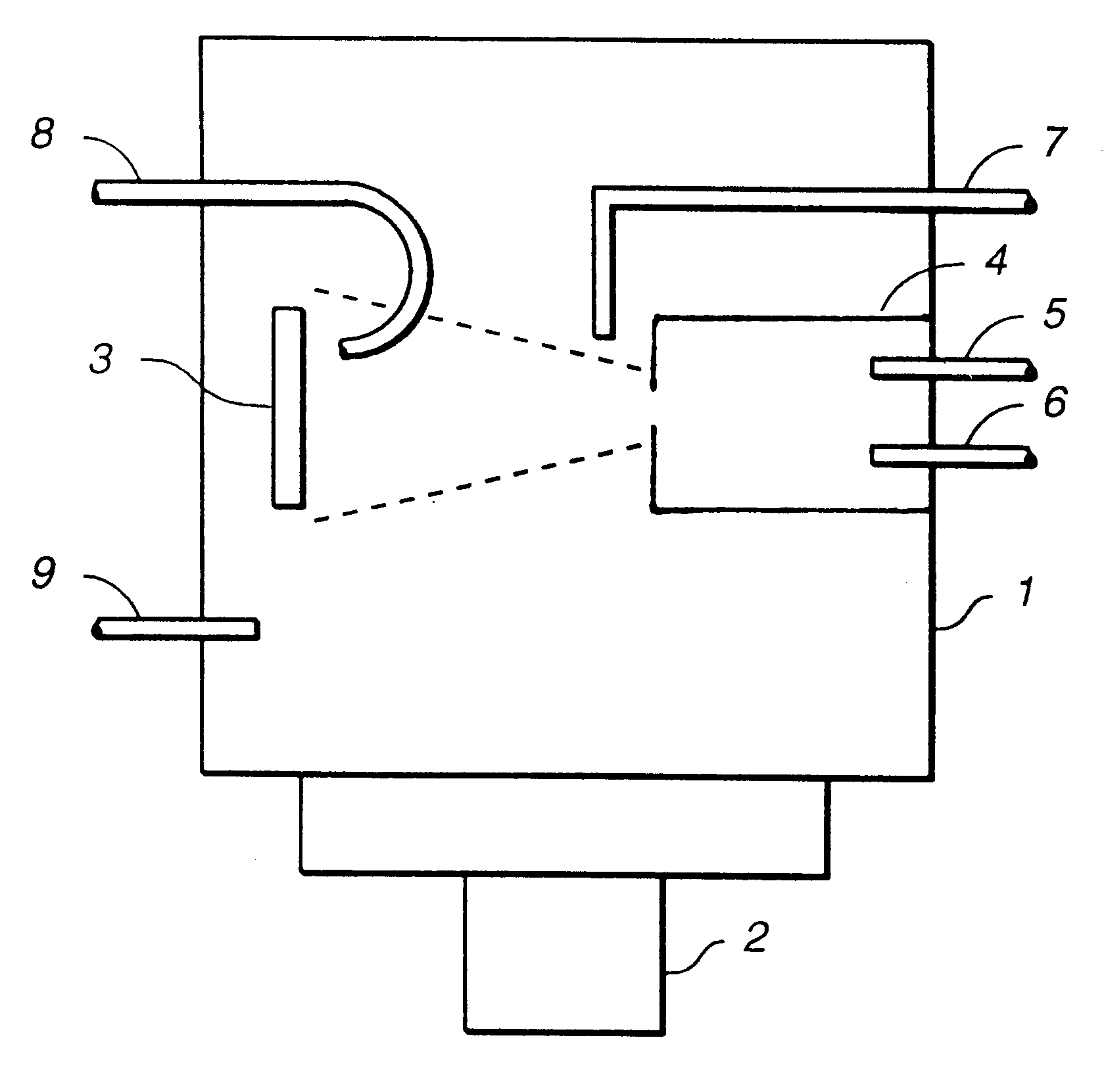

The present invention claims the addition of vinylene carbonate (VC) and optionally also fluoroethylene carbonate to the electrolyte of lithium ion cells having a structural silicon composite anode, i.e. an anode containing fibres or particles of silicon. The additive significantly improves the cycling performance of the cells. A VC content in the range 3.5-8 wt % based on the weight of the electrolyte has been found to be optimum.

Additive for lithium ion rechageable battery cells

ActiveUS8945774B2StructuredImprove performanceBatteries circuit arrangementsOrganic electrolyte cellsFiberPhysical chemistry

The present invention claims the addition of vinylene carbonate (VC) and optionally also fluoroethylene carbonate to the electrolyte of lithium ion cells having a structural silicon composite anode, i.e. an anode containing fibers or particles of silicon. The additive significantly improves the cycling performance of the cells. A VC content in the range 3.5-8 wt % based on the weight of the electrolyte has been found to be optimum.

Owner:SK ON CO LTD

Ion beam process for deposition of highly abrasion-resistant coatings

InactiveUSRE37294E1High hardnessReduce coefficient of frictionLayered productsVacuum evaporation coatingEye lensVacuum chamber

An ion beam deposition method is provided for manufacturing a coated substrate with improved abrasion resistance, and improved lifetime. According to the method, the substrate is first chemically cleaned to remove contaminants. In the second step, the substrate is inserted into a vacuum chamber, and the air in said chamber is evacuated. In the third step, the substrate surface is bombarded with energetic ions to assist in the removal of residual hydrocarbons and surface oxides, and to activate the surface. <DEL-S DATE="20010724" ID="DEL-S-00001">Alter<DEL-E ID="DEL-S-00001"> <INS-S DATE="20010724" ID="INS-S-00001">After <INS-E ID="INS-S-00001">the substrate surface has been sputter-etched, a protective, abrasion-resistant coating is deposited by ion beam deposition. The ion beam-deposited coating may contain one or more layers. Once the chosen thickness of the coating has been achieved, the deposition process on the substrates is terminated, the vacuum chamber pressure is increased to atmospheric pressure, and the coated substrate products having improved abrasion-resistance are removed from the vacuum chamber. The coated products of this invention have utility as plastic sunglass lenses, ophthalmic lenses, bar codes scanner windows, and industrial wear parts that must be protected from scratches and abrasion.

Owner:MORGAN ADVANCED CERAMICS

Organic light emitting device and flat panel display device comprising the same

ActiveUS8188315B2Reduce the driving voltageHigh densityOrganic chemistryElectroluminescent light sourcesCarbazoleOrganic light emitting device

Provided are an organic light emitting device including: a substrate; a first electrode; a second electrode; and an organic layer interposed between the first electrode and the second electrode and including an emission layer, wherein one of the first electrode and the second electrode is a reflective electrode and the other is a semitransparent or transparent electrode, and wherein the organic layer includes a layer having at least one of the compounds having at least one carbazole group, and a flat panel display device including the organic light emitting device. The organic light emitting device has low driving voltage, excellent current density, high brightness, excellent color purity, high efficiency, and long lifetime.

Owner:SAMSUNG DISPLAY CO LTD

Method of controlled remelting of or laser metal forming on the surface of an article

InactiveUS7586061B2Superior emission lifetimeRelieve pressurePolycrystalline material growthMolten spray coatingMetal formingControl system

A method for controlled remelting of or laser metal forming on the surface (5) of an article (1) can include moving a light source and a signal capturing apparatus over the article (1). The light source having a specific power can be used to melt the surface (5) of the article (1) locally and to form a melt pool (7). Thereby an optical signal (13) is captured by the signal capturing apparatus from the melt pool (7), and the monitored optical signal (13) is used for the determination of temperature and temperature fluctuations as properties of the melt pool (7). Furthermore, a control system (16) with a feedback circuit is used to adjust at least one process parameter such as the power of the light source such that desired melt pool properties are obtained. Subsequently the melt pool (7) solidifies.

Owner:ANSALDO ENERGIA IP UK LTD

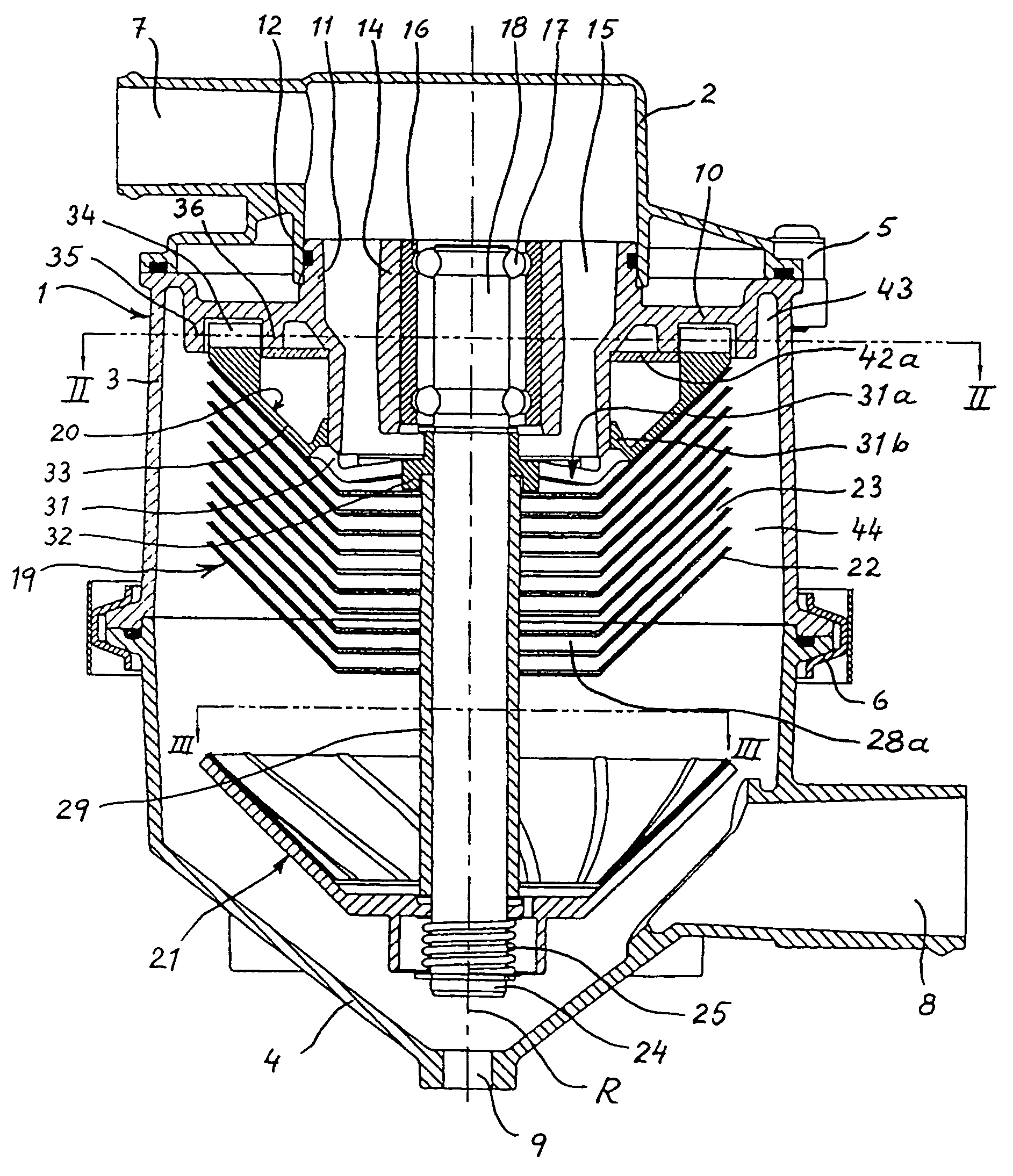

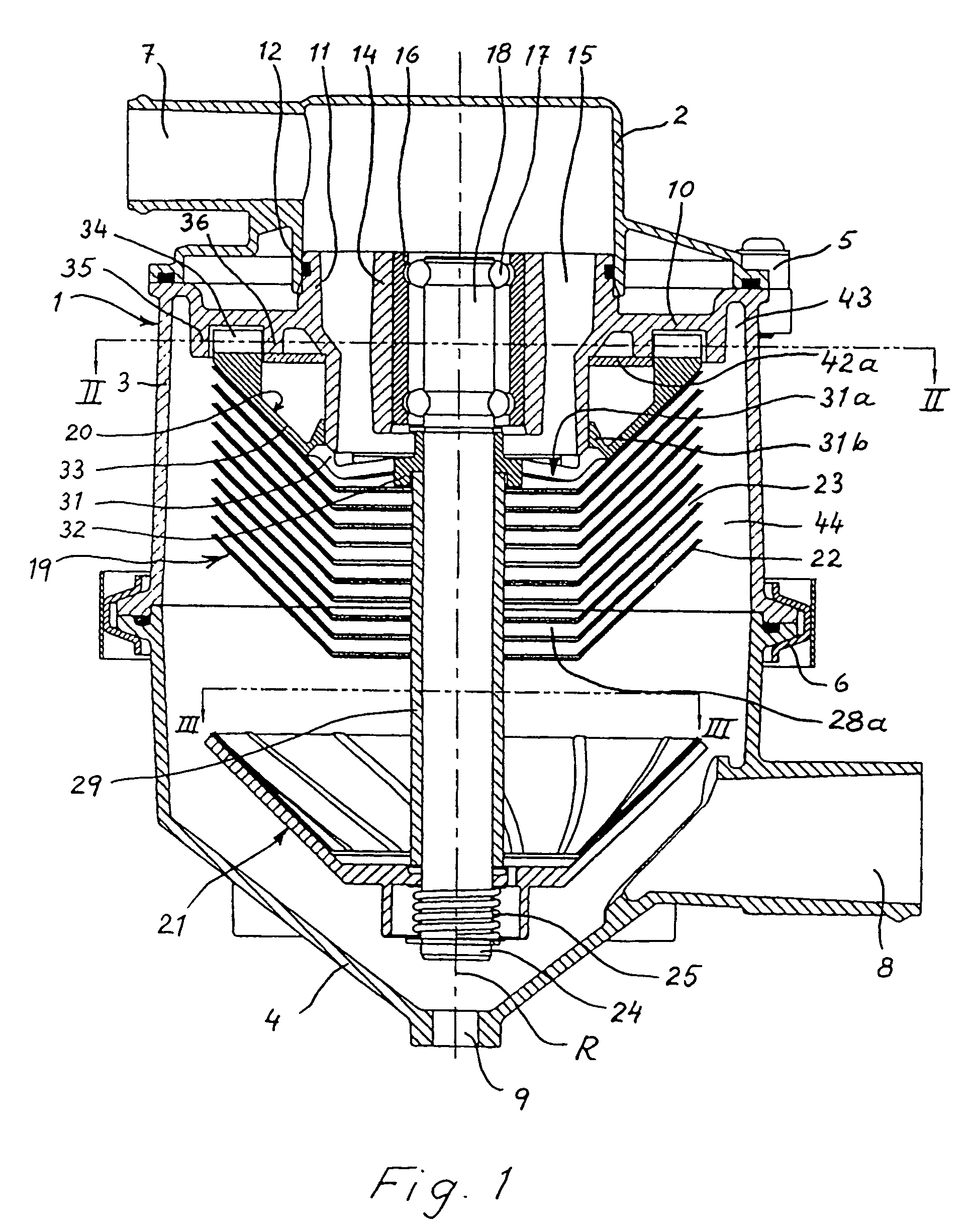

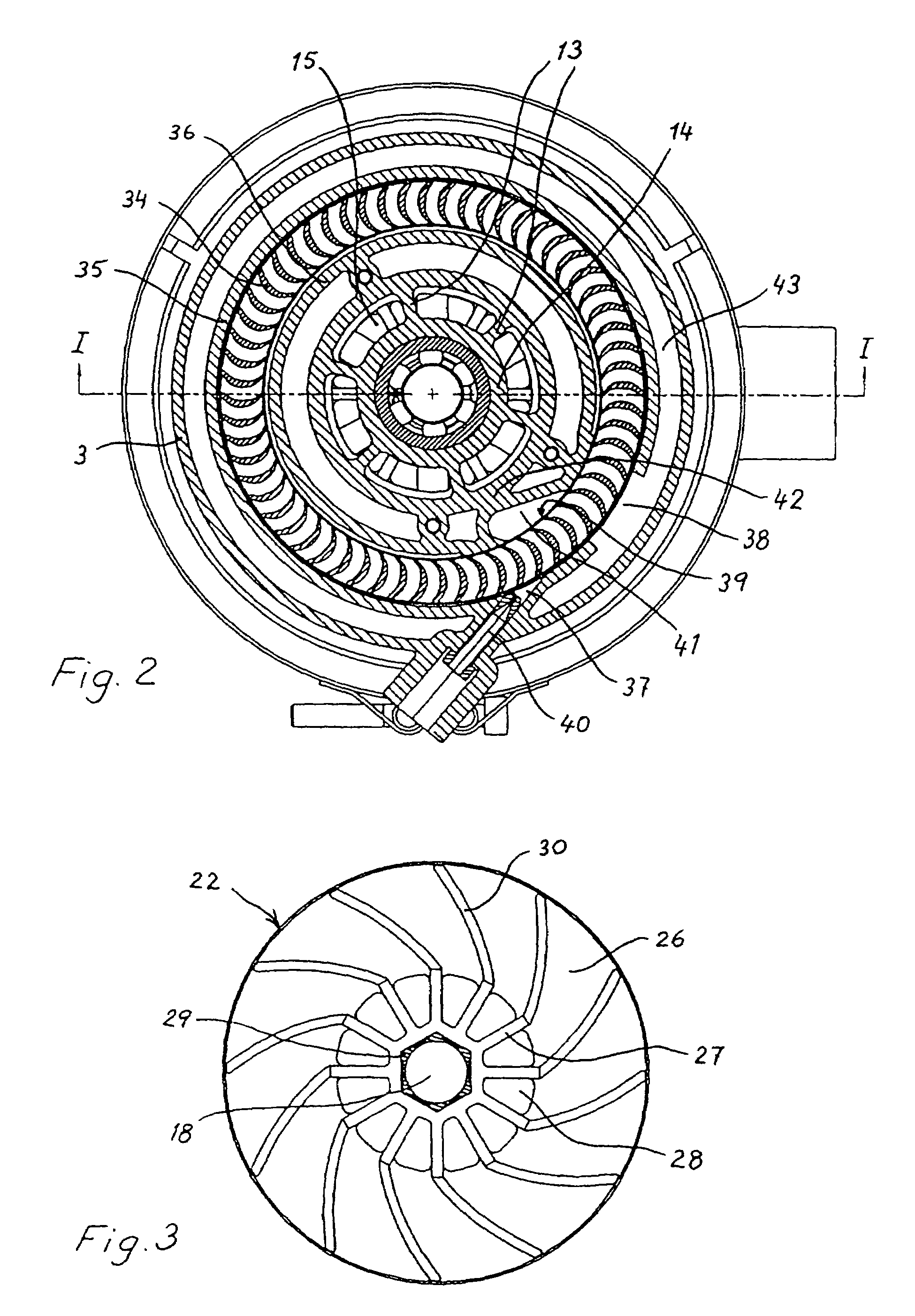

Centrifugal separator having a rotor and driving means thereof

InactiveUS7022150B2Available spaceEfficient use ofCombination devicesAuxillary pretreatmentRotational axisTurbine blade

In a centrifugal separator, the rotor of which is adapted to be driven by means of a gaseous driving fluid, the rotor itself supports a ring of turbine blades extending around the rotational axis of the rotor. A stationary nozzle is adapted to direct a flow of the driving fluid towards the ring of turbine members. After the driving fluid has passed between the turbine blades and has influenced them for driving of the centrifugal rotor, it enters a reversing chamber formed by a stationary reversing member. In the reversing chamber the driving fluid is caused to change its direction and is then conducted again towards the ring of turbine members in order to be utilized a second time for driving of the centrifugal rotor.

Owner:ALFA LAVAL CORP AB

Nitride semiconductor device

InactiveUS20050098789A1Improve emission efficiencyIncrease electron concentrationOptical wave guidanceLaser detailsQuantum wellActive layer

A nitride semiconductor device includes an n-type semiconductor layer, p-type semiconductor layer and an active layer of a quantum well structure that is sandwiched between said p-type and n-type nitride semiconductor layer, wherein the active layer has a first barrier layer, a second barrier layer and a third barrier layer. The first barrier layer is nearest to the p-type nitride semiconductor layer among the first, second and third barrier layers. The second barrier layer is nearest to the n-type nitride semiconductor layer among the first, second and third barrier layers. The third barrier layer is between the first and second barrier layers, and includes an upper barrier layer that contacts with a p-side surface of the well layer and a lower barrier layer that contacts with an n-side surface of said well layer. The upper and lower barrier layers having different composition or impurity concentrations.

Owner:NICHIA CORP

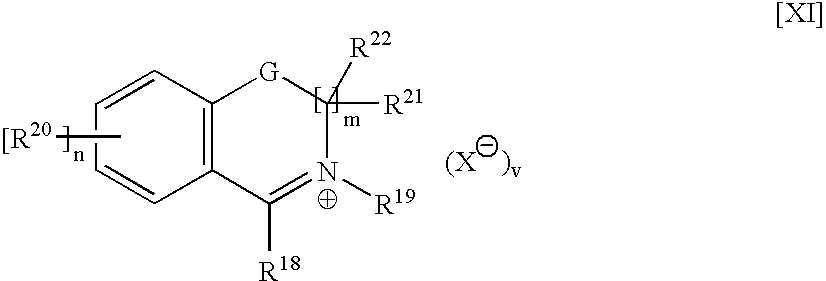

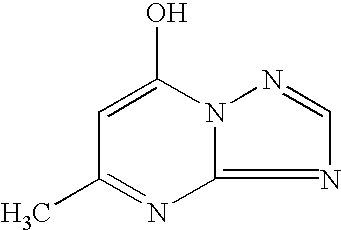

Stable formulation components, compositions and laundry methods employing same

InactiveUS6903060B1Improve stabilitySuperior emission lifetimeIsocyanic acid derivatives preparationNon-ionic surface-active compoundsBleachOrganocatalysis

The present invention relates to formulation components, such as organic catalyst compounds having increased stability, compositions and laundry methods employing such organic catalyst compounds. More particularly, this invention relates to organic catalysts compounds such as quaternary imine bleach boosting compounds, quaternary oxaziridinium bleaching species, modified amines and amine oxides, compositions and laundry methods employing such organic catalyst compounds.

Owner:THE PROCTER & GAMBLE COMPANY

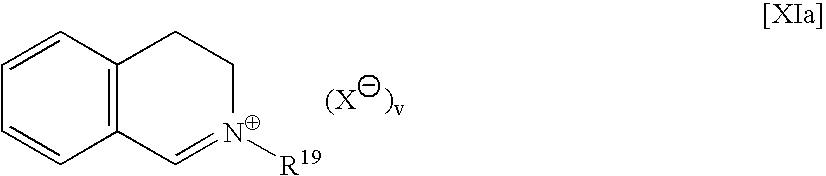

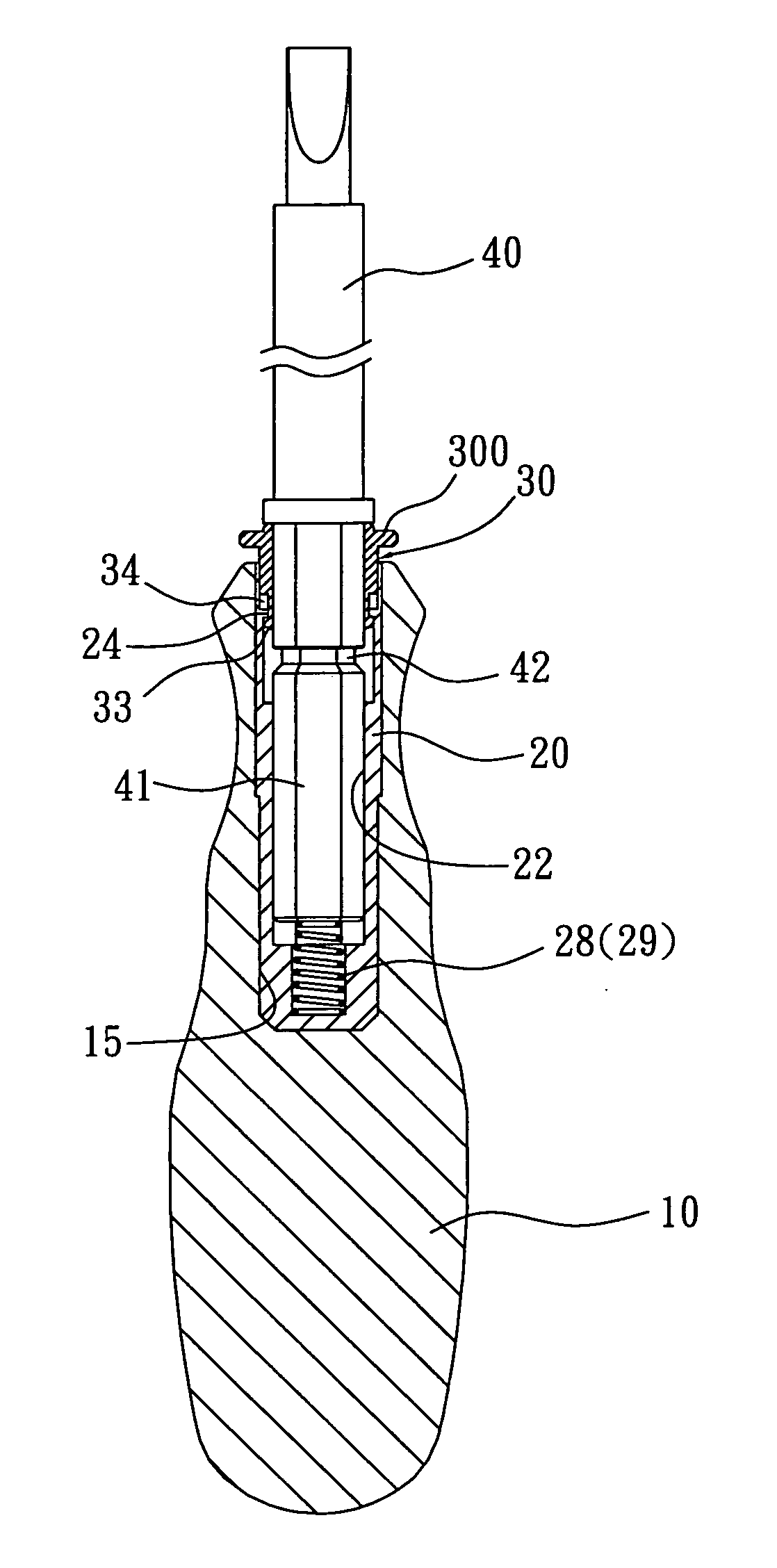

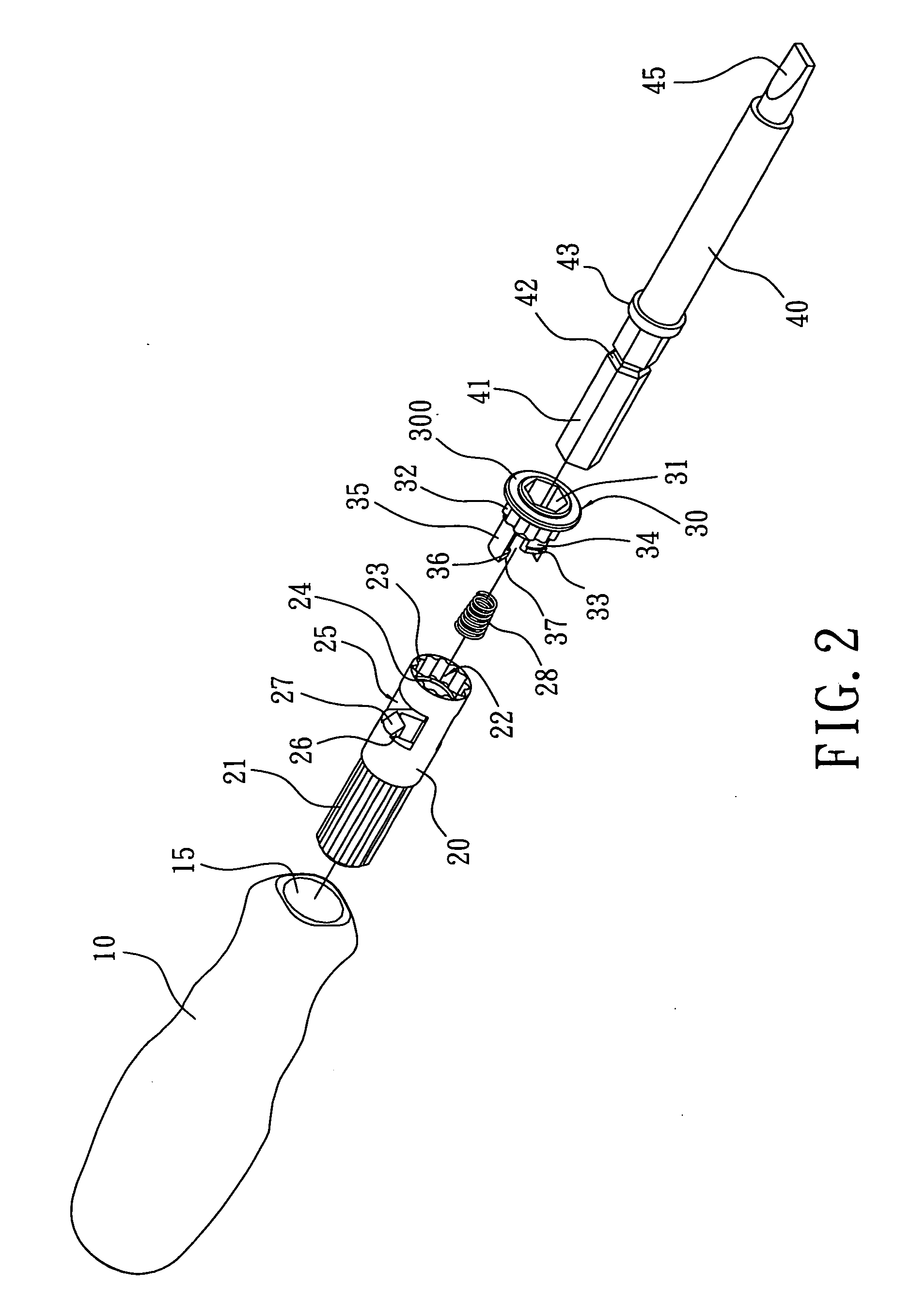

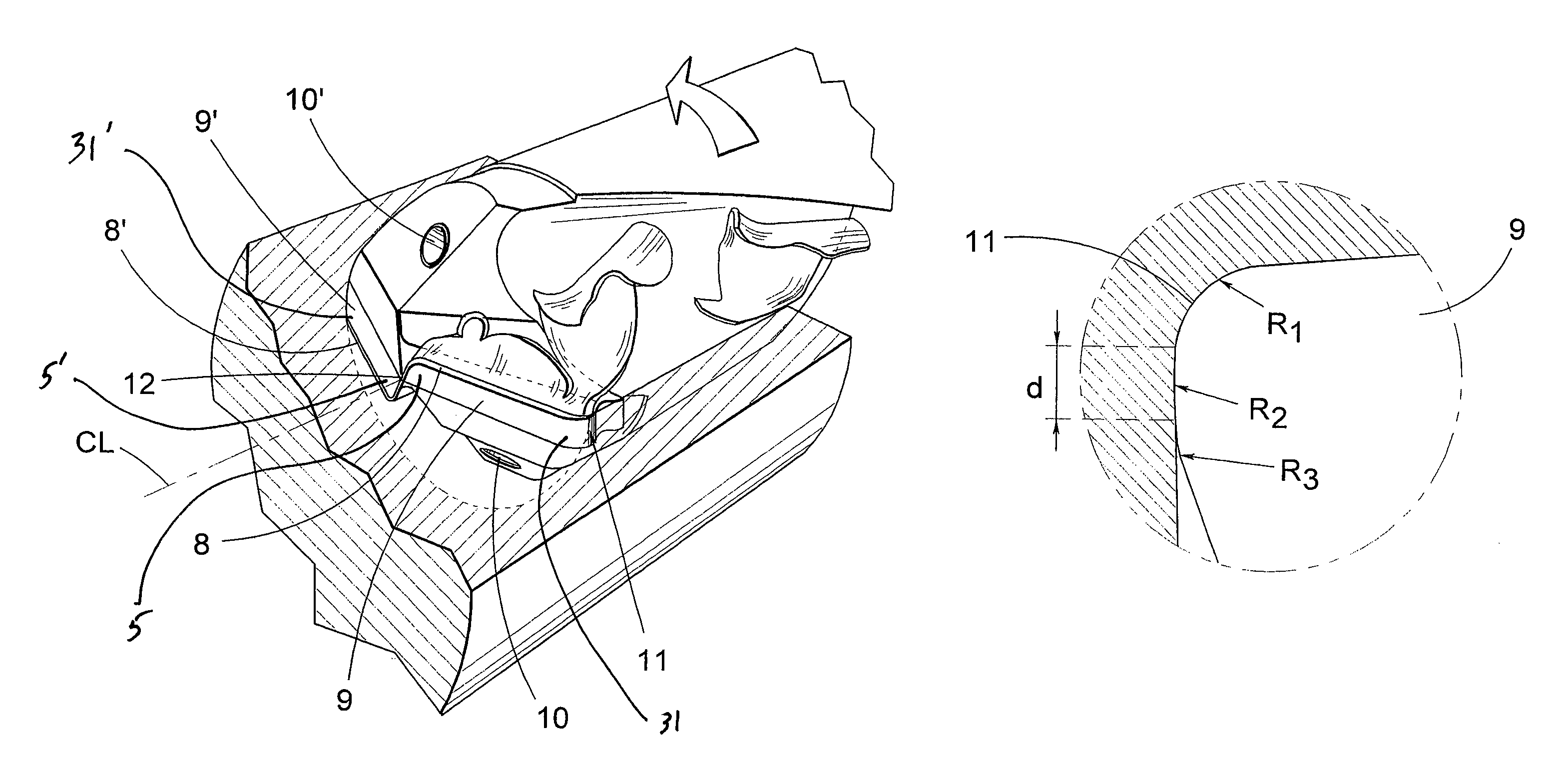

Screwdriver having quick release tool shank background of the invention

InactiveUS20080087142A1Mitigate and obviate disadvantageHigh strengthSpannersWrenchesEngineeringMechanical engineering

A screwdriver includes a handle, a fixing member mounted in the handle, a release member slidably mounted on and axially movable relative to the fixing member, and a tool shank locked on the release member and detachable from the release member by movement of the release member relative to the fixing member. Thus, the tool shank is supported by the fixing member and the release member which are supported by the handle to enhance the strength of the screwdriver so that the screwdriver is not easily broken or worn out, thereby enhancing the lifetime of the screwdriver. In addition, the tool shank is mounted on and detached from the fixing member and the handle by pressing the release member, thereby facilitating the user mounting and replacing the tool shank.

Owner:YIH CHENG FACTORY

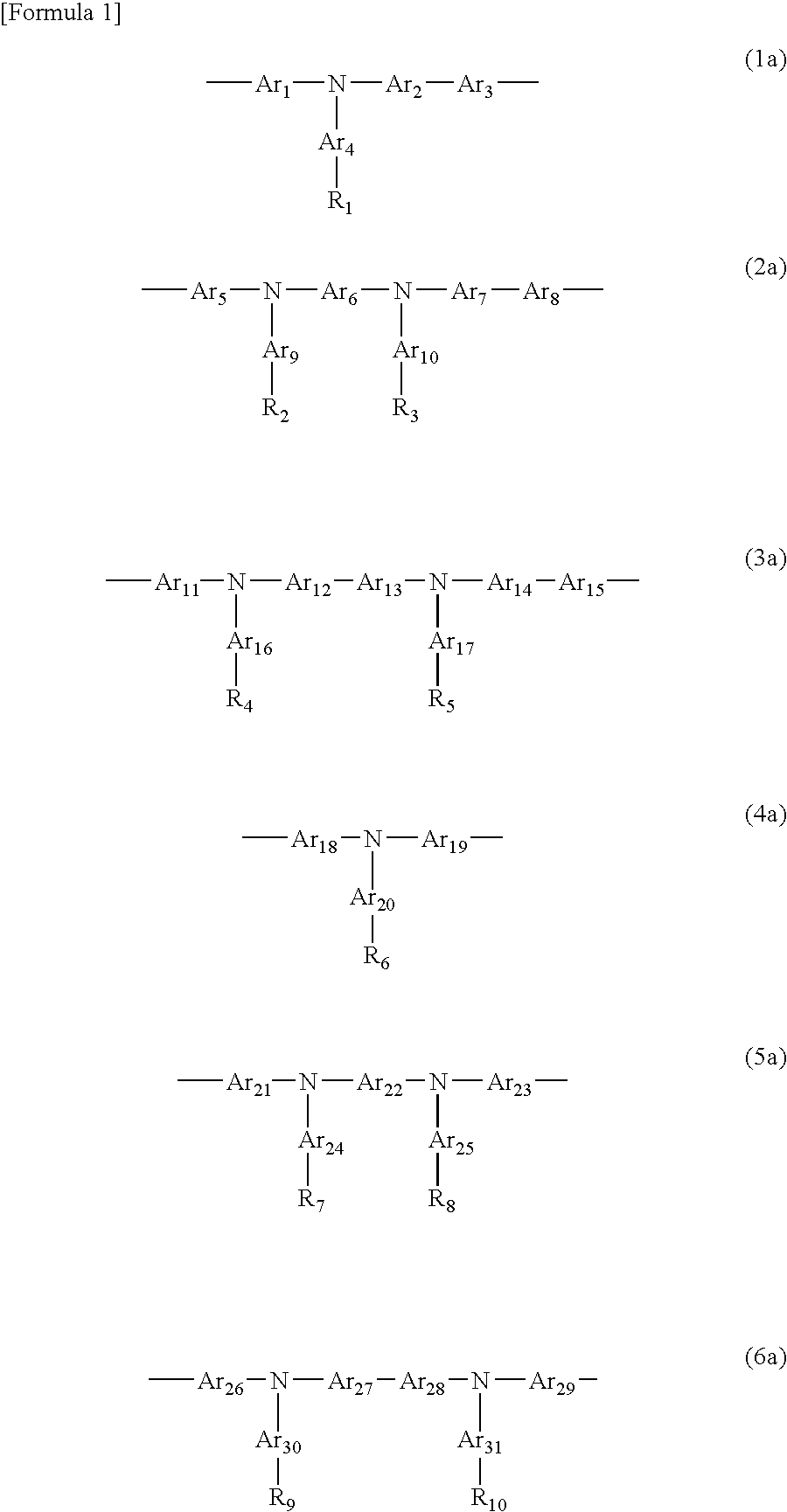

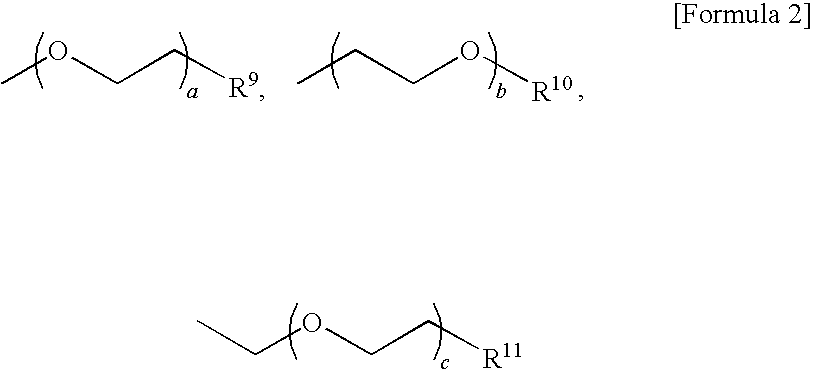

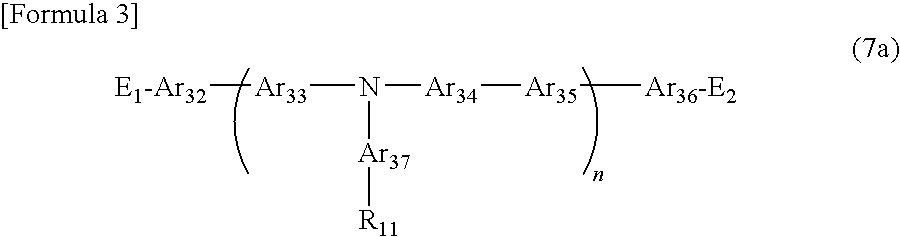

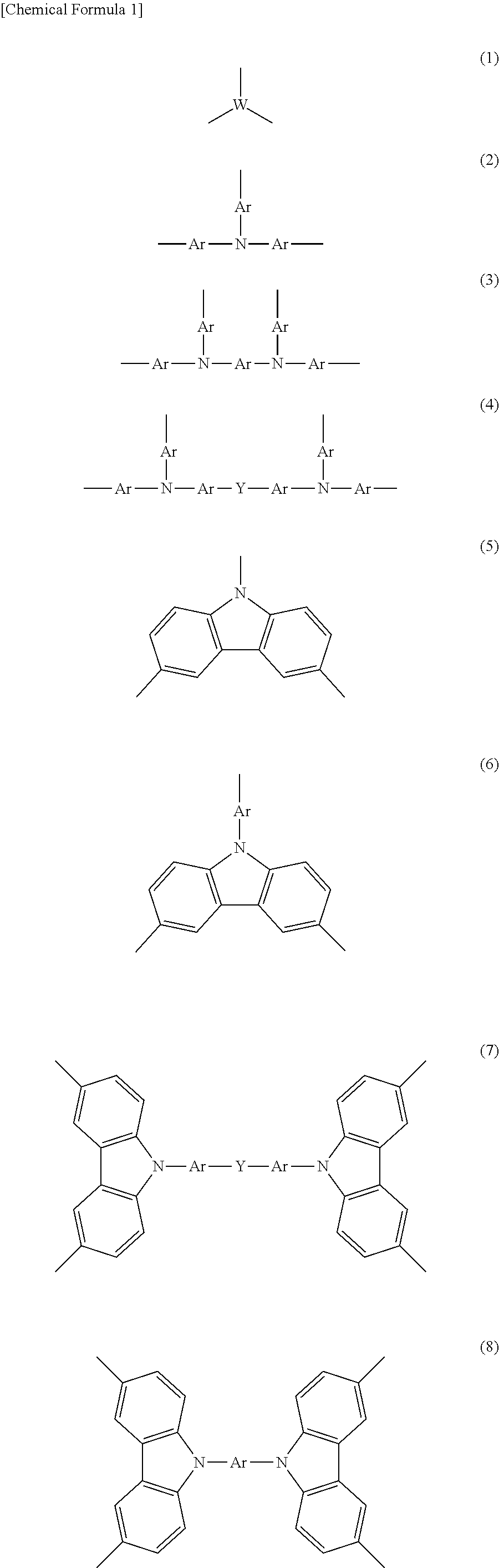

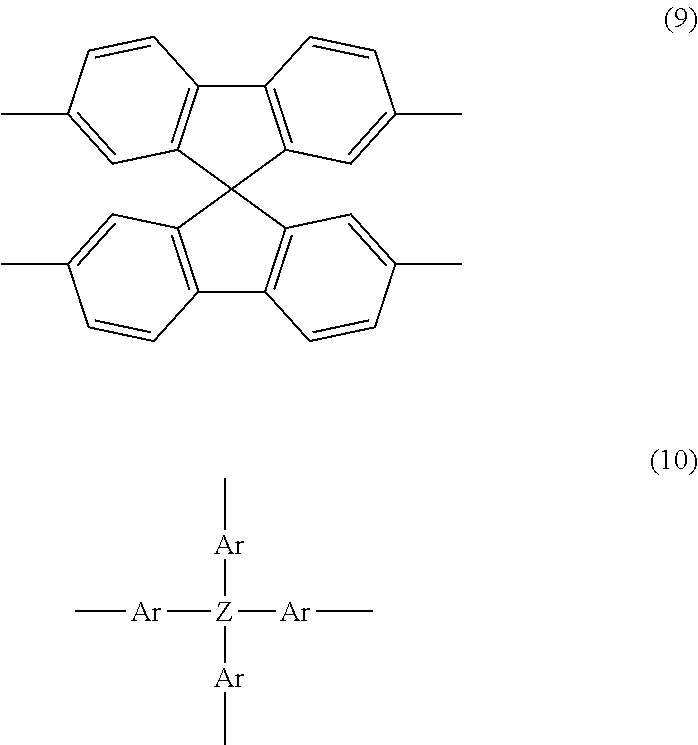

Organic electronic material, organic electronic device, and organic electroluminescent device

InactiveUS20090321723A1Improve efficiencyProlong lifeOrganic chemistryElectroluminescent light sourcesOligomerOrganic electroluminescence

An object of the present invention is to provide an organic electronic material that can be easily formed into a multilayer structure. A further object of the present invention is to provide an organic electronic device and an organic EL device that exhibit a better emission efficiency and a better emission lifetime than heretofore achieved. In order to achieve these objects, an organic electronic material is provided, the material includes a polymer or oligomer that has at least one polymerizable substituent and a hole-transporting repeat unit.

Owner:HITACHI CHEM CO LTD

Organic Electronic Material, Ink Composition Containing Same, and Organic Thin Film, Organic Electronic Element, Organic Electroluminescent Element, Lighting Device, and Display Device Formed Therewith

InactiveUS20120074360A1Well formedLight emission efficiencyConductive materialSolid-state devicesOligomerDisplay device

Provided are: an organic electronic material which can be easily multilayered and that can be used in substrates, such as resin, that cannot be processed at high temperatures; an ink composition containing the same; an organic thin film formed using said organic electronic material or said ink composition; and an organic electronic element and an organic EL element that are formed using said organic thin film and that have a superior luminous efficacy and emission lifespan than conventional elements. Specifically, provided are: an organic electronic material that is characterized by containing an oligomer or a polymer having a structure that branches into three or more directions and has at least one polymerizable substituent; an ink composition containing said organic electronic material; and an organic thin film prepared using the aforementioned organic electronic material. Further, provided are an organic electronic element and an organic electroluminescent element containing said organic thin film.

Owner:HITACHI CHEM CO LTD

Particular type of a thin layer inorganic light emitting device

InactiveUS6724141B2Easy to manufactureSmall particle sizeDischarge tube luminescnet screensElectroluminescent light sourcesNanoparticleThin layer

Owner:AGFA GEVAERT AG

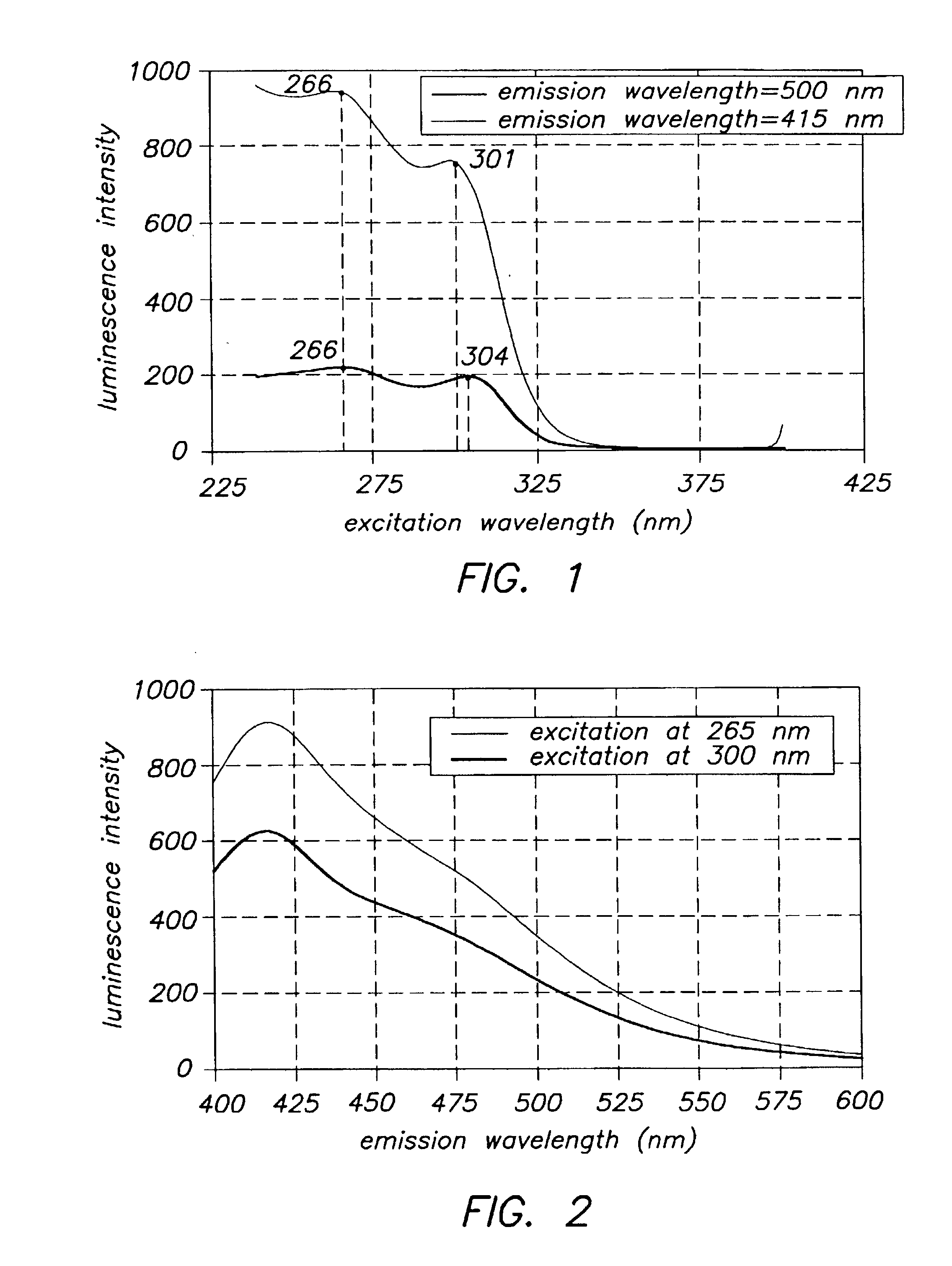

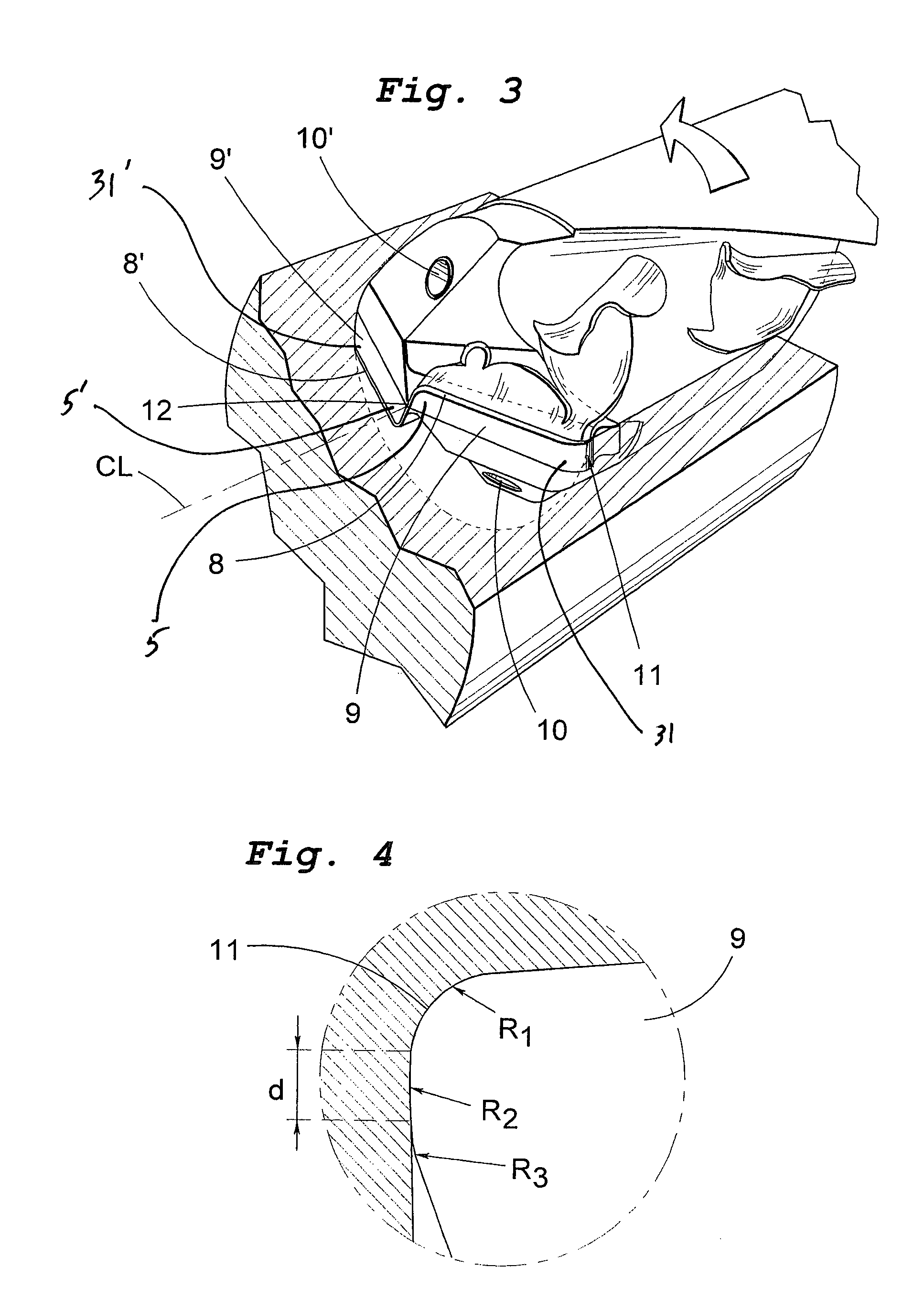

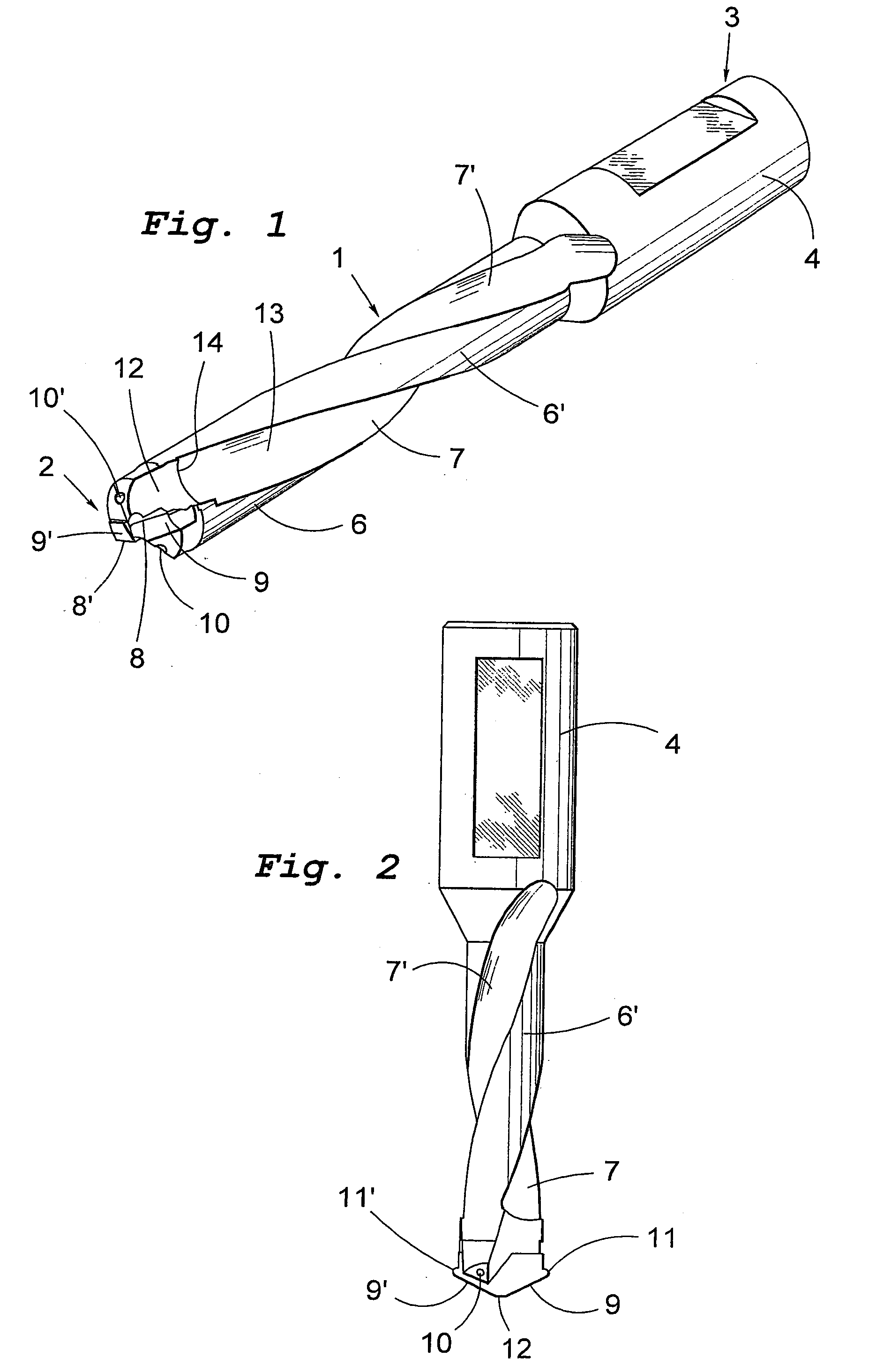

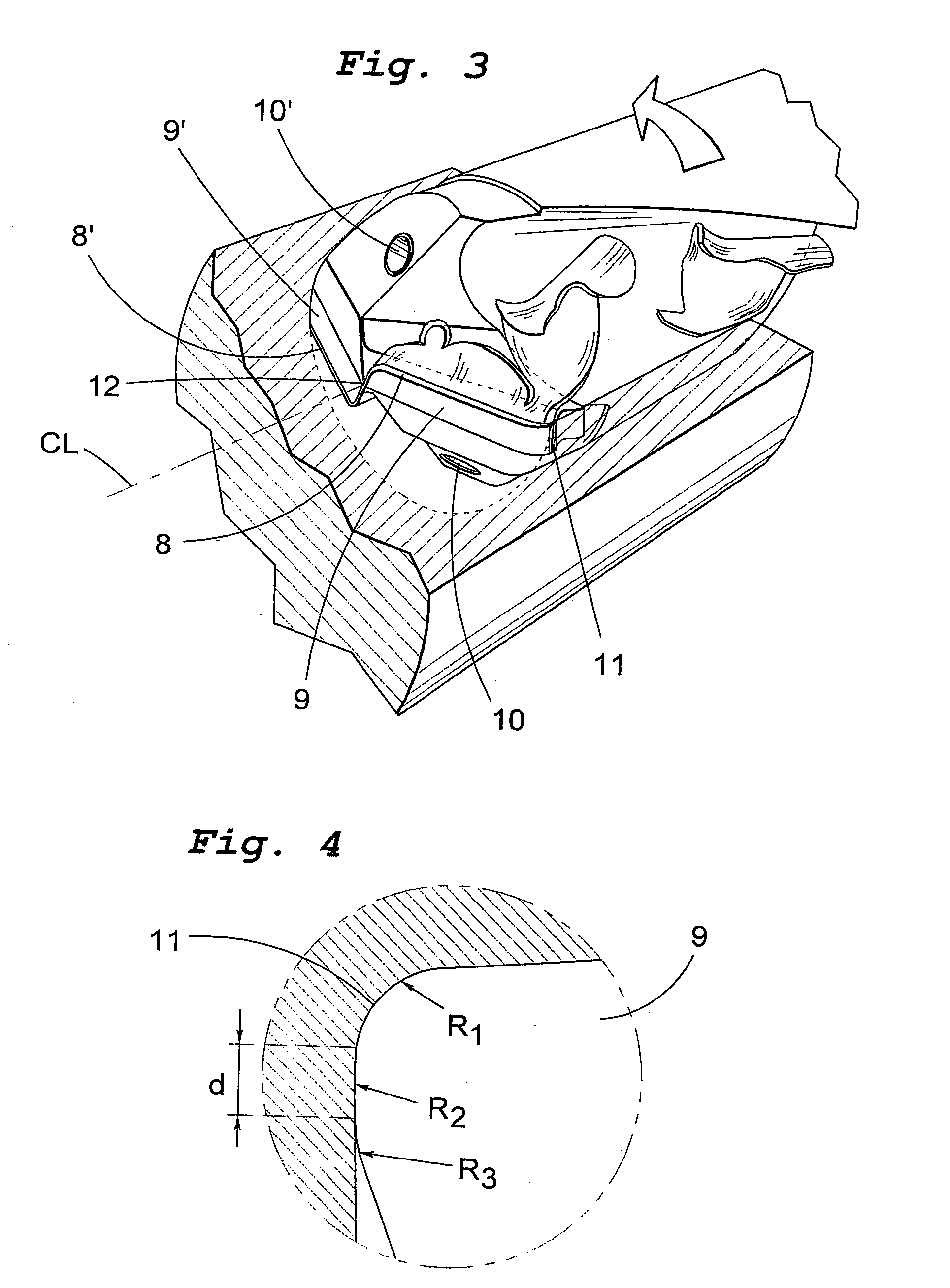

Drill with improved cutting insert formation

InactiveUS7393163B2Fast cutting speedSuperior emission lifetimeWood turning toolsTransportation and packagingFluteEngineering

A drill includes a tip-forming front end having at least two straight cutting edges and at least two chip flutes extending from the tip end towards a rear end. Each cutting edge includes an inner portion disposed near a center line of the drill, and an outer portion disposed farther from the center line. The peripheral end of each cutting edge is in the form of a smoothly curved nose portion protruding radially with respect to the center line. The nose portion is formed by several circular segments having mutually different radii (R1, R2, R3). Adjacent ones of the radii are of different size.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Nitride semiconductor device

InactiveUS20060131604A1Improve emission efficiencyIncrease electron concentrationOptical wave guidanceLaser detailsActive layerImpurity

Owner:NICHIA CORP

Nitride semiconductor laser device and method of manufacturing the nitride semiconductor laser device

ActiveUS7397834B2Superior emission lifetimeImprove reliabilityOptical wave guidanceLaser detailsWaveguideContact resistance

The nitride semiconductor laser device has a counter electrode structure where contact resistance is reduced and manufacturing methods thereof are provided. The nitride semiconductor laser device comprises a nitride semiconductor substrate having a first main surface and a second main surface. A nitride semiconductor layer is stacked on the first main surface of the nitride semiconductor substrate. A ridge-shaped stripe is formed in the nitride semiconductor layer, and a resonance surface forms an optical waveguide in the direction perpendicular to the length of the ridge-shaped stripe. A first region having a crystal growth facet in the (0001) plane and a second region on the first main surface or the second main surface are provided. Further, a recess is formed in the second region of the first main surface and / or the second main surface. A ridge-shape stripe is formed over the first main surface of the nitride semiconductor substrate.

Owner:NICHIA CORP

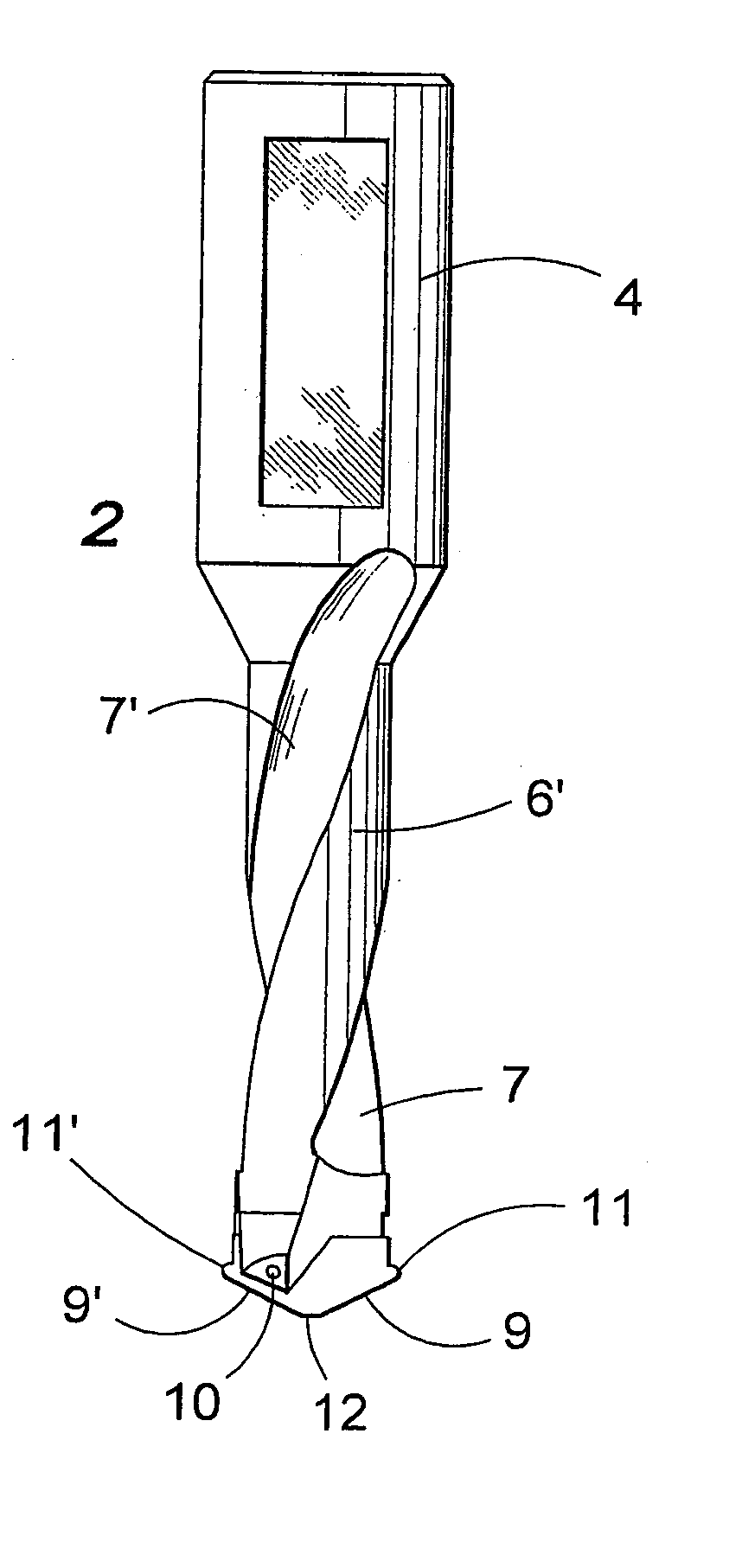

Flexible display with display support

ActiveUS9086850B2Promote sportsSuperior emission lifetimeDigital data processing detailsTraffic signalsDisplay deviceEngineering

A display system includes a continuous flexible display, two main display supports each structurally configured to support a respective portion of the flexible display, a segment of the flexible display being located between the said respective display portions. The two main display supports are hingeable between a closed configuration for fixing the flexible display in a storage position and an open configuration for fixing the flexible display in an open position. In the storage position between the main display supports there is a free space enabling a partial curvature of said display segment without conflicting with the respective main display support. At least one additional display support is configured to support said segment of the flexible display in the storage position and facilitates the curvature of the display segment with a predefined radius which is larger than the critical radius Rcrit for the flexible display.

Owner:SAMSUNG ELECTRONICS CO LTD

System and method for portable information handling system parallel-wall thermal shield

ActiveUS8553409B2Reduce disadvantagesReduce problemsEnergy efficient ICTDigital data processing detailsThermal energyInformation processing

An information handling system's thermal management is selectively altered by coupling a thermal barrier to the bottom surface of the information handling system chassis so that an air channel insulates against the passage of thermal energy from the bottom surface. A vent opening in a side of the thermal barrier allows airflow through the air channel to a vent opening of the information handling system. The airflow through the air channel cools the base of the thermal barrier so that an end user will experience reduced thermal energy if the information handling system rests on the end user, such as in the end user's lap.

Owner:DELL PROD LP

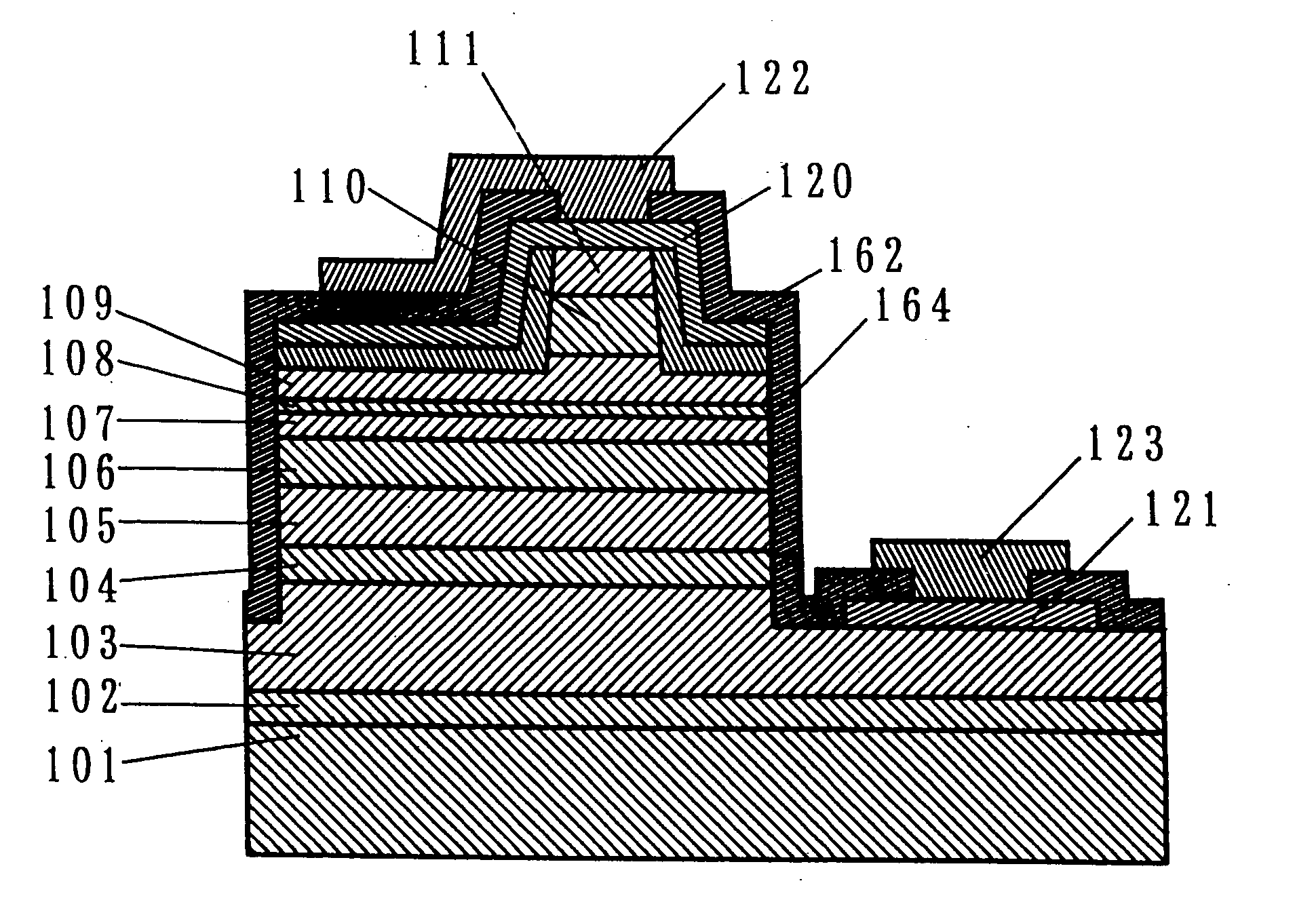

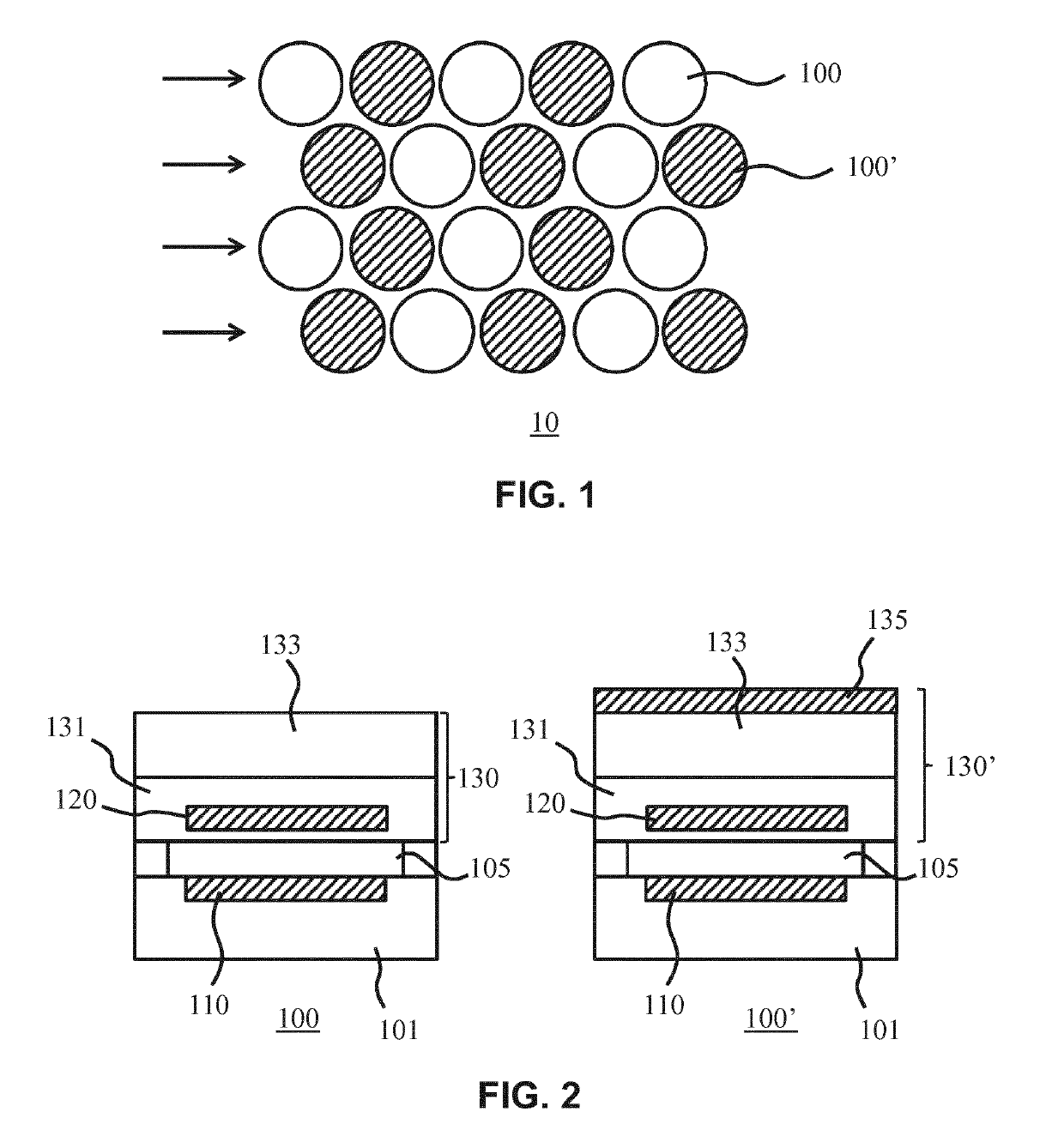

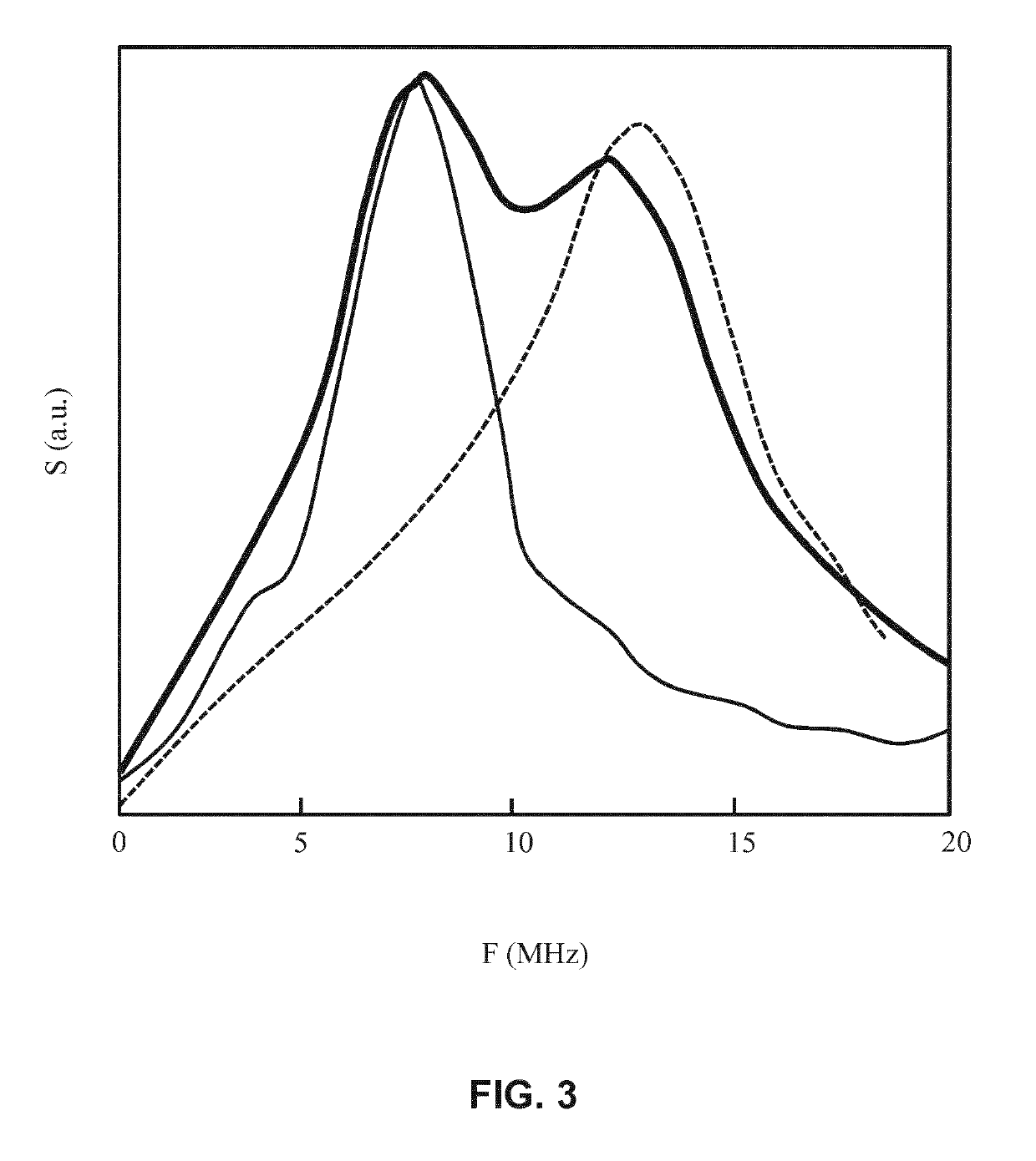

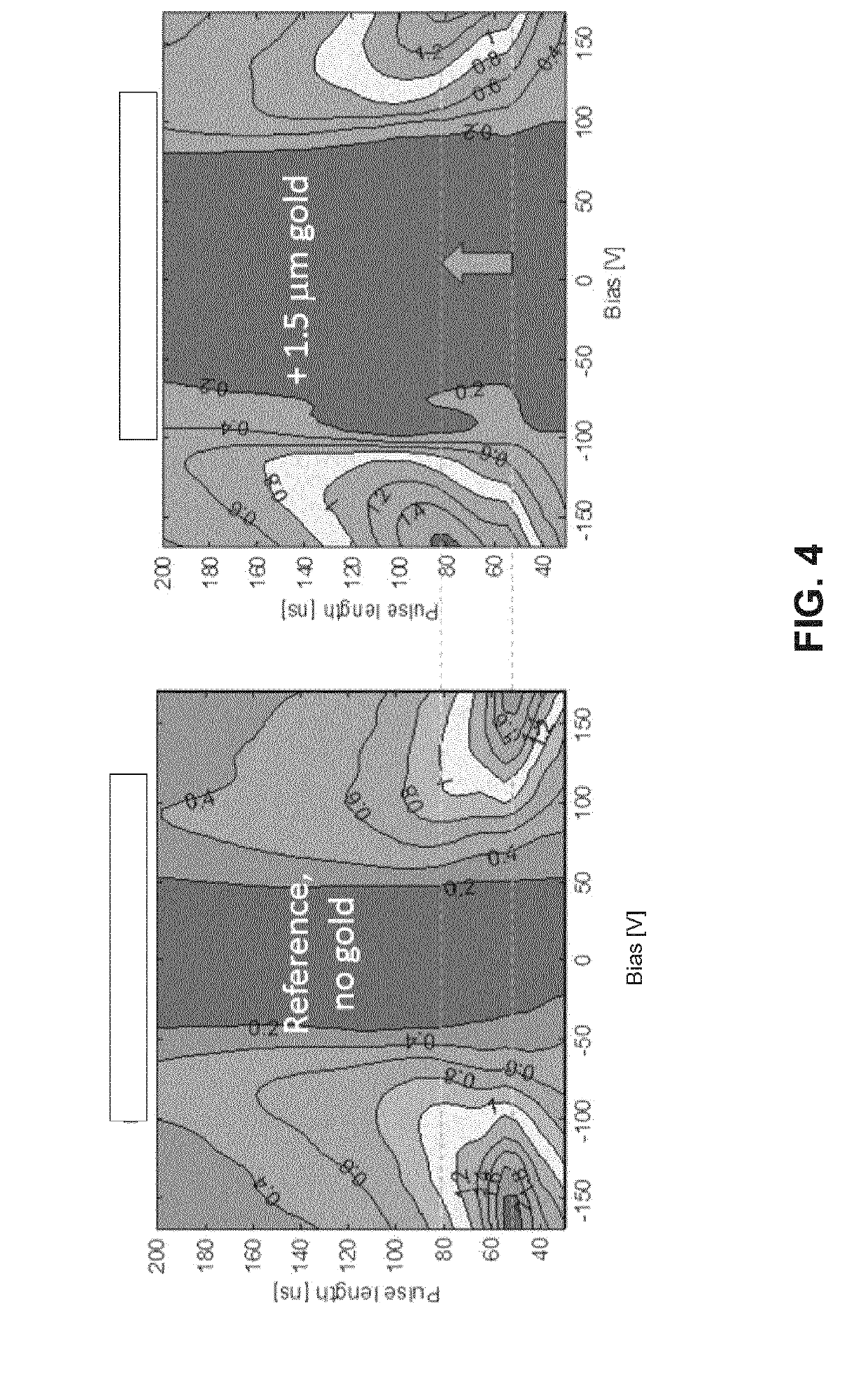

Broadband ultrasound transducer

ActiveUS20190176193A1Superior emission lifetimeUltrasonic/sonic/infrasonic diagnosticsMaterial analysis using sonic/ultrasonic/infrasonic wavesUltrasound imagingHigh density

A transducer array (10) is disclosed comprising a plurality of CMUT cells (100, 100, 100″), each CMUT cell comprising a first electrode (110) supported by a substrate (101) and a second electrode (120) supported by a membrane suspended over a cavity (105) between the first electrode and the second electrode, the plurality of CMUT cells comprising a first group of CMUT cells (100) each having a membrane comprising a first layer stack (130); and a second group of CMUT cells (100′) each having membrane comprising a second layer stack (130′), the second layer stack including a layer (135) of a material having a higher density than any of the layers in the first layer stack. Also disclosed is a device comprising such a transducer array, an ultrasound imaging system including such a transducer array and a method of operating such an ultrasound imaging system.

Owner:KONINKLJIJKE PHILIPS NV

Drill with improved cutting insert formation

InactiveUS20040042859A1Fast cutting speedSuperior emission lifetimeWood turning toolsTransportation and packagingFluteBiomedical engineering

A drill comprising a tip-forming end including at least two cutting edges (8, 8') and at least two chip flutes (7, 7') extending from the tip end (2) towards the second end (3), having the purpose of forming and removing chips from the corresponding cutting edge. In accordance with the invention the drill tip is composed of cutting edges on mutual sides of the axial centre line having a straight unbroken contour, the central portions of which extend axially beyond the peripheral portions whilst the nose radiused surface on each cutting edge at the periphery is provided with a smoothly curved radius comprising one or several circular segments with mutually different radii (R1, R2, R3) where adjacent radii always appear with different size.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

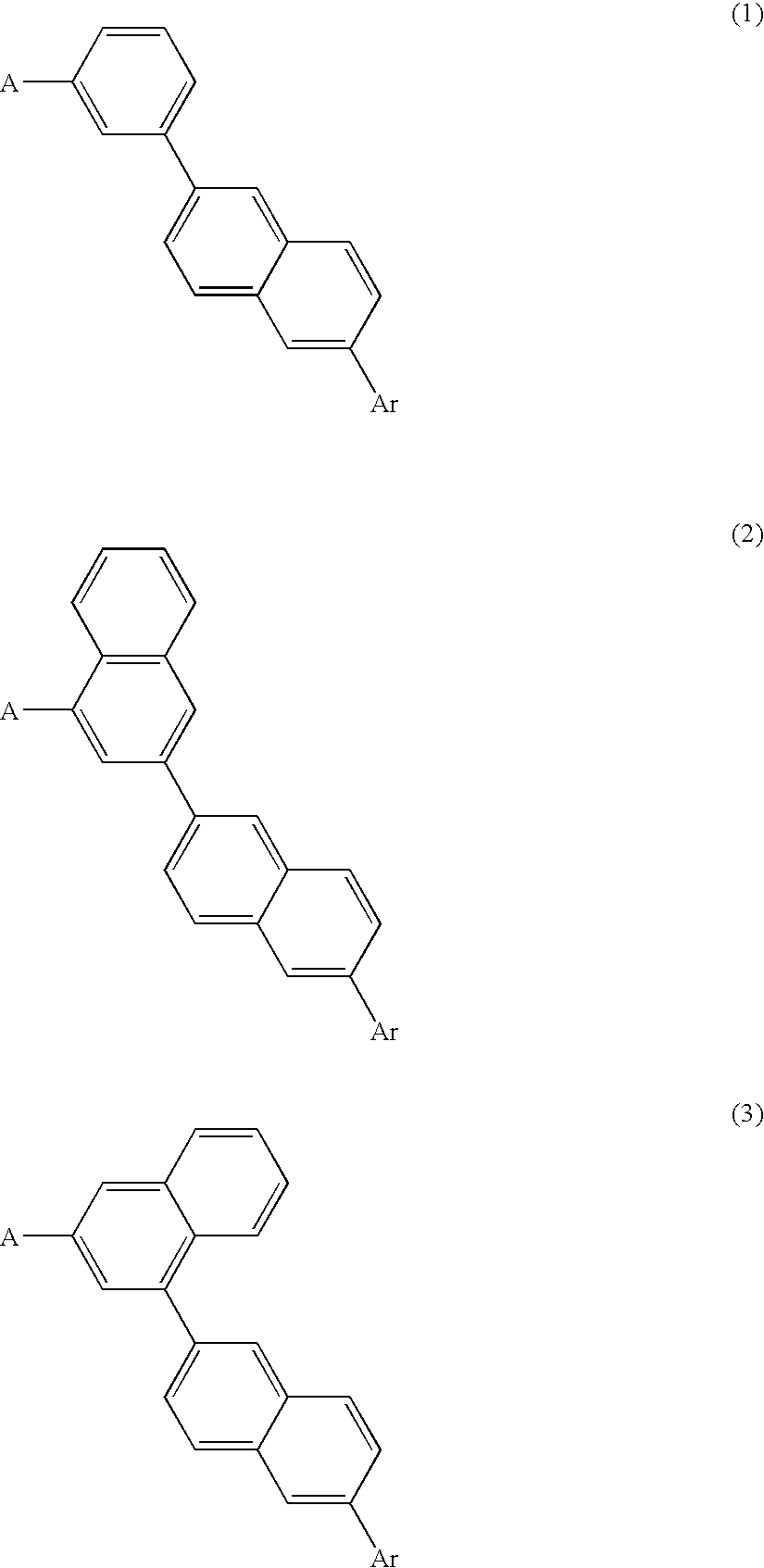

Organic electroluminescence device and material for organic electroluminescence device

ActiveUS8039127B2Reduce the driving voltageImprove efficiencyOrganic chemistryDischarge tube luminescnet screensOrganic filmBenzo(c)phenanthrene

An organic electroluminescence device includes: a cathode; an anode; and a single-layered or multilayered organic thin-film layer provided between the cathode and the anode. In the organic electroluminescence device, at least one layer of the organic thin-film layer includes: an organic-electroluminescence-device material represented by a general formula selected from the following formulae (1), (2) and (3); and at least one phosphorescent material. In the formula: A represents a group selected from a 3-fluoranthenyl group, 5-benzo[c]phenanthrenyl group, 6-benzo[c]phenanthrenyl group and 10-benzo[g]chrysenyl group; Ar represents a fused aromatic ring having 10 to 30 carbon atoms and having triplet energy of 2.10 eV or more; and A or Ar is allowed to be substituted by a phenyl group or a naphthyl group.

Owner:IDEMITSU KOSAN CO LTD

System and method for portable information handling system thermal shield

ActiveUS8705233B2Reduce disadvantagesReduce problemsEnergy efficient ICTPower supply for data processingThermal energyEngineering

An information handling system's thermal management is selectively altered by coupling a thermal barrier to the bottom surface of the information handling system chassis so that an air channel insulates against the passage of thermal energy from the bottom surface. A vent opening in a side of the thermal barrier allows airflow through the air channel to a vent opening of the information handling system. The airflow through the air channel cools the base of the thermal barrier so that an end user will experience reduced thermal energy if the information handling system rests on the end user, such as in the end user's lap.

Owner:DELL PROD LP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com