Method for treating coating waste gas by manganese-loaded expanded graphite adsorption coupled catalytic ozonation

A technology of expanded graphite and ozone oxidation, applied in chemical instruments and methods, gas treatment, separation methods, etc., can solve problems such as incomplete degradation of VOCs, improve oxidation reaction efficiency and ozone utilization, improve degradation efficiency, and improve adsorption. effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

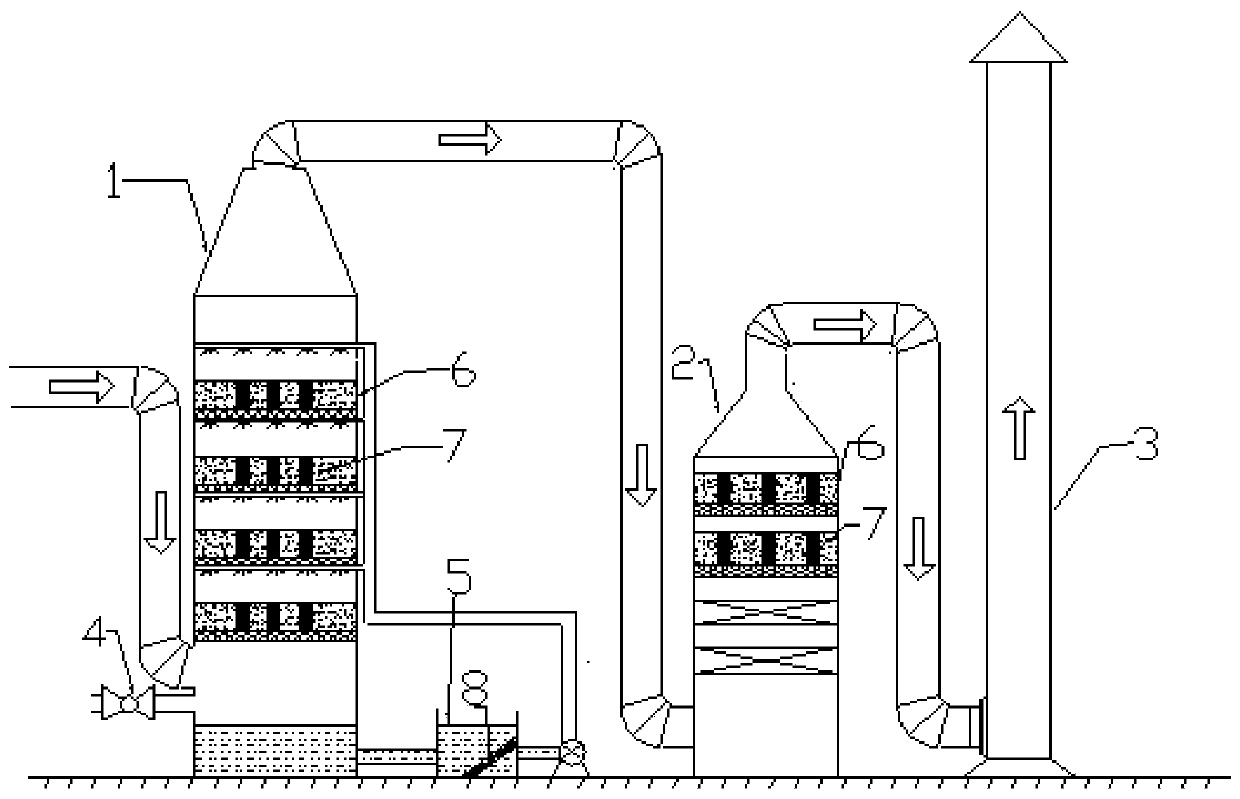

Image

Examples

Embodiment 1

[0028] Example 1: Purification treatment of exhaust gas in automobile steel plate coating workshop

[0029] Purify the exhaust gas produced in the automobile steel plate coating workshop. The raw materials used for coating are solvent-based coatings, water-based coatings and UV coatings. The main components of VOCs in the exhaust gas are benzene, toluene, xylene; butynol, butanol, Isobutanol; acetone, methyl ethyl ketone, the concentration of VOCs is 350mg / L, and the air volume is 800m 3 / h.

[0030] The preparation method of manganese-loaded expanded graphite adsorbent and catalyst is carried out according to the following steps: at room temperature, perchloric acid and concentrated phosphoric acid are mixed with a mass ratio of 4:1, and then natural Lumpy graphite (composition by mass percentage is C: 88%, O: 5%, S: 2%, and the rest 5%) and potassium permanganate (massive graphite is mixed with perchloric acid, concentrated phosphoric acid and permanganese respectively Pot...

Embodiment 2

[0032] Example 2: Purification treatment of exhaust gas produced in aluminum plate coating workshop

[0033] Purify the waste gas produced in the aluminum plate painting workshop. The paints used for painting are polyurethane paint, acrylic paint and water-based epoxy paint. The main components of VOCs in the waste gas are xylene, cyclohexanone, styrene, acetone, Butanone, glycol ether and its esters and dipropylene glycol diacrylate, etc., the concentration of VOCs is 400mg / L, and the air volume is 1000m 3 / h.

[0034] The preparation method of manganese-loaded expanded graphite adsorbent and catalyst is carried out according to the following steps: at room temperature, perchloric acid and concentrated phosphoric acid are mixed with a mass ratio of 4:1, and then natural Flake graphite (composition by mass percentage is C: 90%, O: 4%, N and S: 2%, Si: 1%, and the rest 3%) and potassium permanganate (natural flake graphite is mixed with perchloric acid respectively , concentrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com