Graphite carbon nitride nanotube array photoelectrode, preparation method of array photoelectrode and application

A graphite-type carbon nitride and nanotube array technology, which is applied in the direction of electrodes, nanotechnology, nanotechnology, etc., can solve the problems of photoelectrodes without nanostructures, low photoelectric performance, and small specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

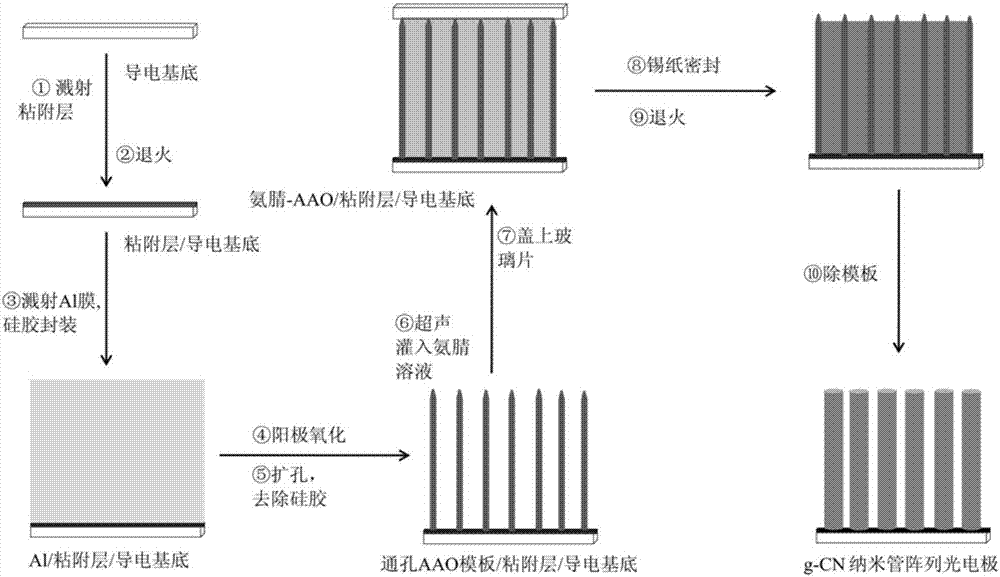

Method used

Image

Examples

Embodiment 1

[0104] (1) Cut the FTO into 2cm*2.5cm size, sonicate in isopropanol, acetone and ethanol for 15min each, and then blow dry with nitrogen.

[0105] (2) Glue one end of the clean FTO with high-temperature tape, and then sputter 30nm thick TiO on the FTO 2 , after sputtering, tear off the high-temperature tape, place it in a muffle furnace, anneal at 500°C for 2h, and heat up at a rate of 16°C / min.

[0106] (3) Unsputtered TiO 2 The FTO part is glued with high temperature tape and then sputtered with TiO 2 The part continues to sputter 1600nm aluminum, after taking it out, tear off the tape, marked as Al / TiO 2 / FTO.

[0107] (4) Encapsulate Al / TiO with silica gel 2 / FTO electrode, then let it stand for 2-5 days to allow the silicone to fully cure.

[0108] (5) Place the electrode prepared in step (4) in 0.3M H 2 C 2 o 4 solution, carry out anodic oxidation, the oxidation voltage is 40V, when the anodic oxidation is until the electrode is transparent, end the oxidation, an...

Embodiment 2

[0113] (1) Cut the FTO into 2cm*2.5cm size, sonicate in isopropanol, acetone and ethanol for 15min each, and then blow dry with nitrogen.

[0114] (2) Glue one end of the clean FTO with high-temperature tape, and then sputter 30nm thick TiO on the FTO 2 As an adhesive layer, after sputtering, tear off the high-temperature tape, place it in a muffle furnace, anneal at 500°C for 2h, and heat up at a rate of 16°C / min.

[0115] (3) Unsputtered TiO 2 The FTO part is glued with high temperature tape and then sputtered with TiO 2 The part continues to sputter 800nm aluminum, after taking it out, tear off the tape, marked as Al / TiO 2 / FTO.

[0116] (4) Encapsulate Al / TiO with silica gel 2 / FTO electrode, then let it stand for 2-5 days to allow the silicone to fully cure.

[0117] (5) Place the electrode prepared in step (4) in 5wt%H 3 PO 4 In the solution, the oxidation voltage is 86V. When the anodic oxidation is until the electrode is transparent, the oxidation is ended, an...

Embodiment 3

[0123] (1) Cut the FTO into 2cm*2.5cm size, sonicate in isopropanol, acetone and ethanol for 15min each, and then blow dry with nitrogen.

[0124] (2) Glue one end of the clean FTO with high-temperature tape, and then sputter 30nm thick TiO on the FTO 2 , after sputtering, tear off the high-temperature tape, place it in a muffle furnace, anneal at 500°C for 2h, and heat up at a rate of 16°C / min.

[0125] (3) Unsputtered TiO 2 The FTO part is glued with high temperature tape and then sputtered with TiO 2 The part continues to sputter 1600nm aluminum, after taking it out, tear off the tape, marked as Al / TiO 2 / FTO.

[0126] (4) Encapsulate Al / TiO with silica gel 2 / FTO electrode, then let it stand for 2-5 days to allow the silicone to fully cure.

[0127](5) Place the electrode prepared in step (4) in 5wt%H 3 PO 4 In the solution, the oxidation voltage is 86V. When the anodic oxidation is until the electrode is transparent, the oxidation is ended, and then it is immersed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com